Ferbz

Members-

Posts

508 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ferbz

-

Show your iconic Custom Car/Hot Rod replicas

Ferbz replied to Koellefornia Kid's topic in Model Cars

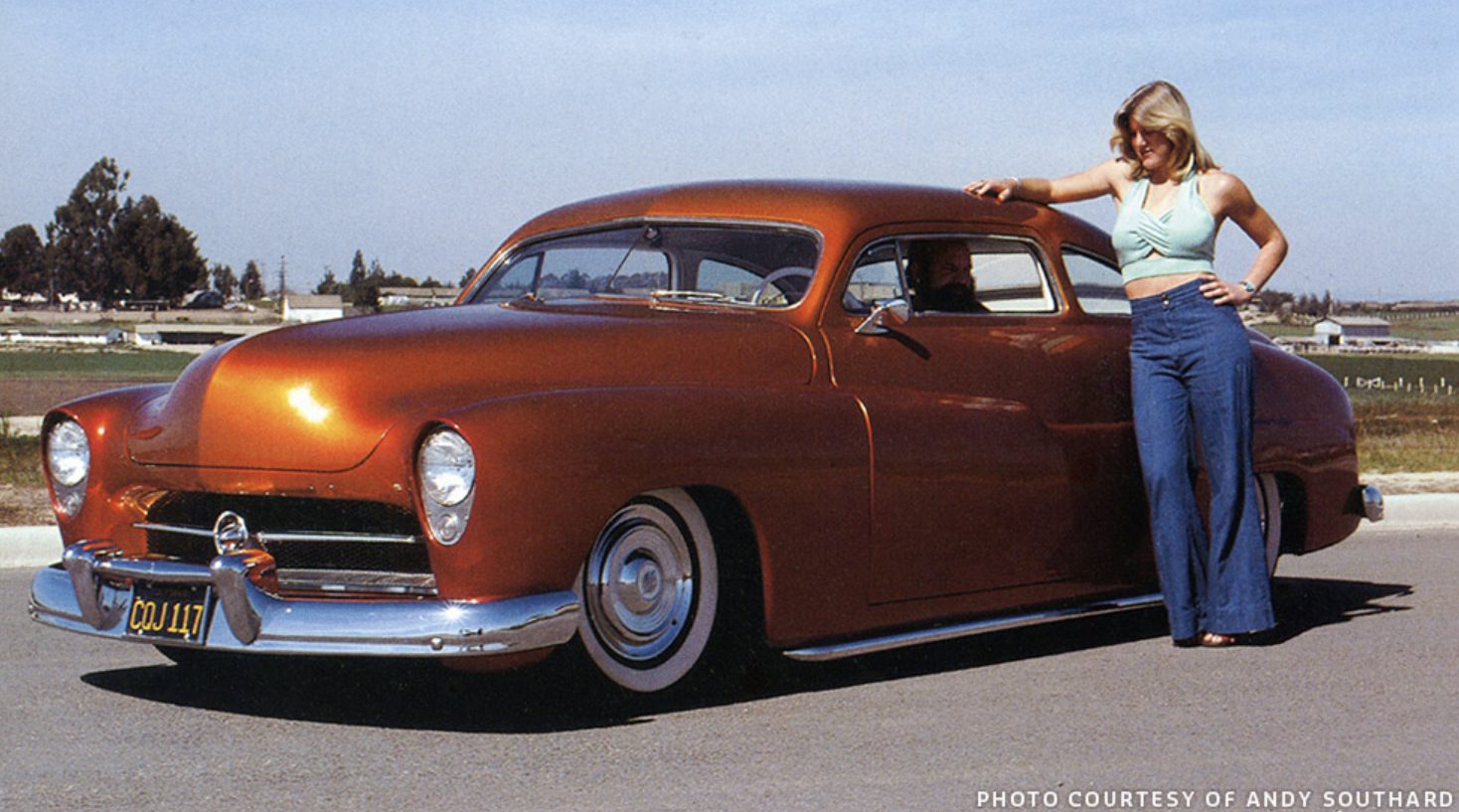

Such a great thread! I don't normally build replicas but I did model one of my favorite Mercs from an AMT 49 Merc. Curley Tremayne's 50 built by Rod Powell:- 58 replies

-

- 13

-

-

Some years ago, I briefly worked at the tee shirt company that designed/printed many of the Goodguys association graphics. When they needed a hotrod for their Suede & Chrome division logo, I designed and digitally illustrated this hotrod pickup for it. The logo was a big hit as they used it for not only tee shirts, but stickers, coffee mugs, shot glasses, hats, etc. For a long time I always wanted one of the metal signs. Thanks to eBay I finally have one now! 😎

- 1 reply

-

- 1

-

-

I was really bummed I missed this last year. Will you have another show for 2025?

-

Thanks!

-

Thanks! I'm glad you think so! That is totally my intention with this build. The 1:1 car really is an icon in drag racing history. It has a very distinct vibe; particularly wild for it's time. And when I learned about it I thought: why not try and build a shoebox ford version? 🙂 I'm actually working on a silly/fun, fictional backstory about it......stay tuned!

-

Update! A quick mockup to check overall progress of my whacky High and Mighty Ford model car idea: The headers are assembled and glued into place, factory front gravel pan was modified and also glued in place, and the hole in the hood was cut open for the intake. I'm currently fussing with gaps of the hood...what a pain! lol It's sitting just a little too high in the rear which I'll adjust, then I'm back to prepping the body for paint. Overall, I'm pleased with where it's heading:

-

Looking really bitchin!! And the ride height is dialed in nicely

-

Fantastic build so far! I'm a big fan of the Inman Chrysler car and you're well your way to making a great inspired build 😉 The GTO rear window looks right at home, and modifying the hood to be more of a Windsor style was a must. Some years ago I also did an Inman inspired build. I closed up the rear window area using the AMT 50 Ford custom half top and the front hood was changed by grafting in the front portion of the Chezoom hood:

- 128 replies

-

- 10

-

-

A small update: I managed to get the solder rods bent to shape so that they exit out of the fender much like how the 1:1 High and Mighty car does. I initially thought I should glue the header units in place first, then bend each rod to the shape I wanted, but I thought it might be best to keep them loose to ease the process of bending them. This worked out much better as I was able to manipulate each rod easier and double check the left and right sides as I went along. The next step will be to glue the headers into place and add the megaphone tips. These are mockup shots with all the engine pieces temporarily in place just to check to and see if I'm capturing the vibe of the original car 😉 On retrospect, I might've been more careful about the scale of the solder and paintbrush tips as they look a bit large scale wise (they might look better if the whole project was 1/24th scale and not 1/25th) but I'm too far along to go back now lol

-

Solder header 'tubes' are glued to their flanges. It's a fit tight between the heads and the frame but they'll work lol Next step will be to glue them in place then bend the tubes with the body in place for reference to make them look like the exhaust tubes on the real car. After cutting them to length, the paintbrush ferrule megaphone tips will get glued onto each solder end and that should wrap up the headers (whew!):

-

So I'm now focused on making the exhaust system, which is a very distinct character detail of the 1:1 High and Mighty drag car. I decided I would try and make the exhaust using cheap paintbrush ferrules and solder. First, I pulled the bristles out of the ferrules. Then using my xacto blade, I carefully cut the ferrules away from the brush handles by applying light but steady pressure while rolling it back and forth on my work bench until they're cut free. I then scratch built header flange plates from sheet styrene. Scale wise they're a bit thick, but I needed them to be a bit beefy in order to confidently anchor the solder 'exhaust tubes' in place. After staring at it awhile and scratching my head on how to approach snaking each of the 'tubes' thru the wheel opening, I decided I would keep each length of exhaust straight at first. I'll make a small tight bend at the flange end, then glue them all to the flange keeping them parallel to one another and perpendicular to the flange. I will then glue the entire unit in place to the engine so that all the 'tubes' will stick straight out of the wheel opening. Then by eyeballing, I'll gingerly bend each one matching the bend and spread of the tubes of the real car the best I can. I'll then cut each one to length, then glue the paintbrush ferrules to the ends. Should be a piece of cake, right? 🤪 LOL Wish me luck.....

-

I happily stumbled across this post. Great start! Has there been any more progress? Chopping a 49 Merc is not easy, but with some planning and patience it can be accomplished with very satisfying results. I've ruined a few Mercs before I was able to get one that I liked lol This is my most recent one:

-

Looking good so far! 39-40 ford coupe tops are not easy to chop! And opening the doors on a chopped top is an exercise not for the faint of heart 🙃 I've chopped three 40 Ford coupes so far and I still feel like I can't get the top to flow the way I want lol On my last chop, I leaned the windshield back a tiny bit, and leaned the rear window forward:

-

Thanks for posting! And I just noticed you happened to catch ME hanging out in the background in one of your pics....🤪

-

Super cool build! Reminds me of the scale 'pro sled' days in the late 80s/early 90s 😎

-

Quick update: I added spark plug wires to the motor. 'Posing' the wires by bending them in a way that makes them look natural (without any kinks or jogs) is extra work but really pays off in the end I think. Funny thing is, in this case the plug wires will sit right up against the firewall.....no one will ever see how nice they drape lol That might not be altogether bad since I think they hang a bit low, especially the really low one on the left side....🙃

-

I've chopped a handful of Mercurys and it is not easy to get the top flowing from front to back, nor is it easy to get it even from left to right. You've done a fine job! On your next one, if you like you can keep a small center section (a 1/4 to 1/2in. will suffice) of the rear window attached to the top instead of cutting the rear window completely free. This small attached section can be a hinge that can be gently bent to rotate the window to lower it into place as the top moves forward and down to realign the A pillars. I also like how you angled the B pillars farther forward than where they normally line up after a chop! Looks way better in my eyes. Famed norcal customizer John Aiello did a similar thing on my 1:1 shoebox ford. He told me it was the same amount of work so why not! 😉

-

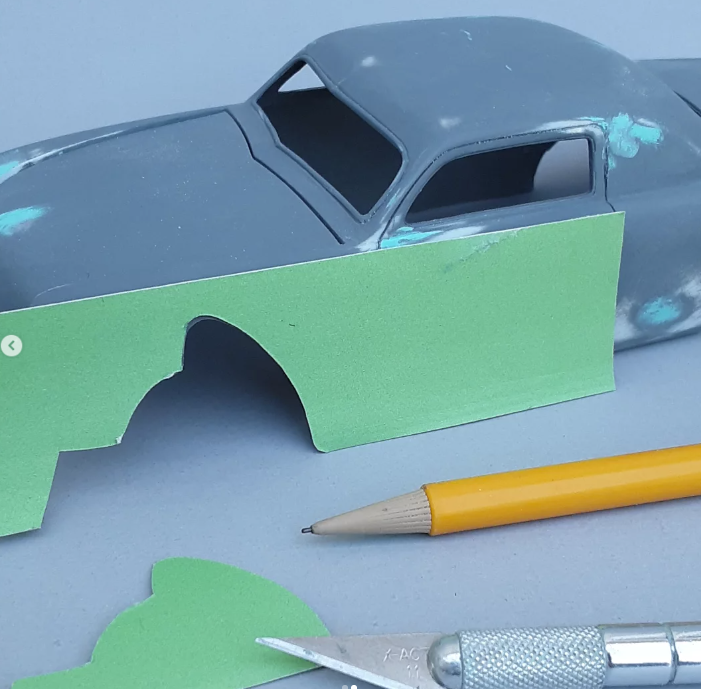

Progress on this has been slow but sure. Since my last update, I've painted/assembled the wheels, and have been tinkering with the motor and wanted to show a quick mockup. @Steamboat shared the fact that he used Evergreen angled rod to make the intake plenum supports for his model so I made those and glued them into place. I added a vertex magneto and drilled holes in it for the plug wires. Installing plug wires is next. Admittedly, I'm not really an 'engine guy' as my modeling interest is mainly in bodywork and exterior custom styling, but this project has been quite a bit of fun 😉 As I mentioned in a previous post, this model is not meant to be an accurate representation of a real car, but a build that just captures the spirit of that crazy High and Mighty drag car. Having said that, I wont be plumbing/wiring much else other than the mentioned plug wires. I also cut open the front wheel wells to accommodate the wild exhaust tubes. I plan to use solder and tin ferrules from cheap hobby brushes to make those. I have no idea how they will turn out....hopefully they'll be some kinda decent lol After cutting and shaping the opening on one fender, I used file folder paper to make a template for the shape of the wheel opening. I traced the shape from behind and cut the shape out of the paper with my exacto. I lined up the template on the opposite fender in the proper place using the bottom rocker panel and rear door line as a placement guide. It was then taped in place, then I traced the shape with a pencil onto the fender. After that, it was a matter of cutting and sanding the wheel opening so that it matches the other fender. It's not exact, but it's close enough lol

-

Thanks! I think the corvette side coves will work on your project just fine. Altho I did extend and 'massage' the overall shape of the rear fenders to kind of teardrop them a bit, which probably helps a little. You can see what I mean slightly better in these shots. Keep going....you're onto something!

-

Great section job! Are you familiar with the Polynesian custom car? It was built by Valley Custom in the early 50s:

-

I just thought of a somewhat related question: If/when you have a build that was assembled with epoxy and you want to disassemble it, what's the best way to do that? I've never disassembled an old glue bomb or torn apart a previous build (once I build something, I'll leave it as is, problems and all! 🤪) I have heard of various techniques of soaking builds in water, then freezing it. Does that work on epoxied parts?

-

Thanks!

-

Indeed 👍 I did neglect to mention that it arrived in a bubble wrap envelope 🤪 The seller might have benefitted from sending it in a small cardboard box to protect it better during shipping maybe....

-

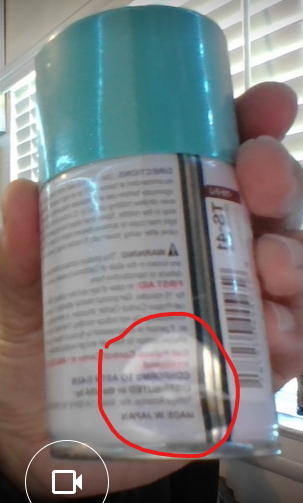

Bursting was one of the things mentioned online about damaged cans. I would think something like that would be the worst case scenario, but also not out of the realm of possibility. Yeah, there's no sign of leaking at all which is a good thing 👍 I was also considering decanting it by spraying it into a jar then using my airbrush to apply it. I still might do that. Thanks for the advice!

-

I recently ordered a can of 100ml Tamiya spray lacquer online and it arrived with a dent in it a little larger than the size of a dime. I looked up safety concerns online about using dented aerosol spray cans and the info I discovered was enough for me to not risk using it. The dent is near the bottom seam as well as near the side seam (both of which apparently are high risk areas for potential problems). The seller has kindly refunded my payment for it and told me not to bother returning it but to dispose of the dented spray can. I will likely do what he suggested but I'm curious: Have any of you had any problems with using dented spray cans, particularly with dents in these areas? I've used spray cans of various and paint types for many, many years but I don't have any experience using dented cans since I almost always buy my spray cans in person at a store and have never come across a dented can on the shelf: