Warren D

-

Posts

1,839 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Warren D

-

Hi Charles,

I noticed in your current military trailer build you resin cast your wheels. I find myself in a bit of a jam, I need at least a dozen of the AITM Brockway fuel tanks and battery boxes. I have a couple of each left. I've asked Mark Natale and his father didn't have any in his personal collection. I've asked a few resin casters if they would copy the ones I have but no one has gotten back to me. I would prefer not to work with the resin (I have enough health issues and I'm not sure it's safe to use). I only want them for my own use, no intentions of selling them.

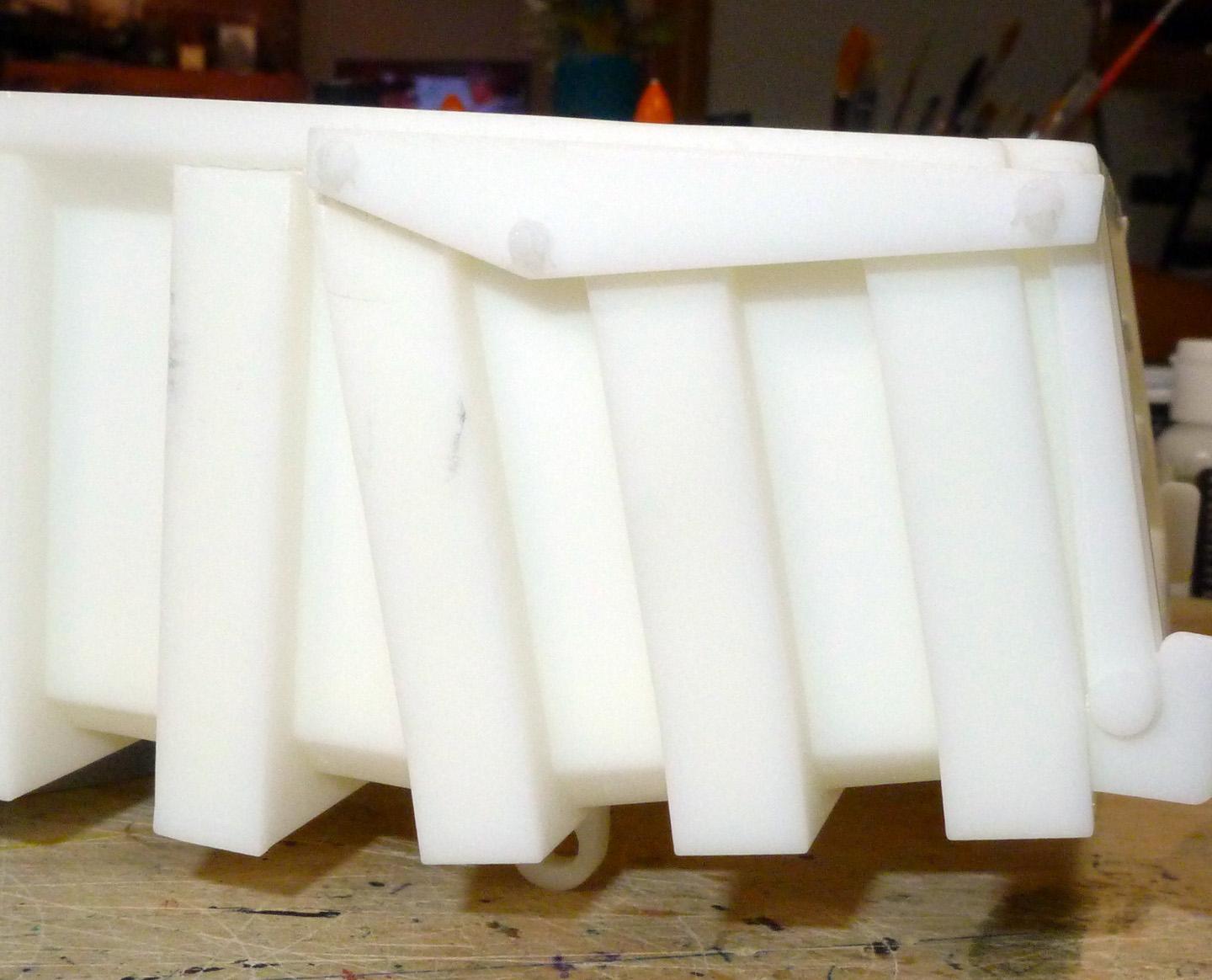

Just curious if you have any ideas. I guess I could try copying them myself but don't know the first thing about it nor where to get supplies etc. It looks like you are using a high quality white resin (looks like the stuff Dave Carey uses).

I would appreciate your thoughts.

Thanks,

Warren Disbrow