-

Posts

4,779 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

absmiami replied to CrazyCrank's topic in WIP: Model Cars

bravo- 113 replies

-

- 1

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

Probably just grow each kit part with some bits of Evergreen plastic - and I’ve got some 25th scale Webers in my parts box - the keys are to maintain the correct height and location of the rear axles and to make sire that the exhausts are clear of the suspension trailing arms - also deepen the crank case and open the chassis base plate for the bottom of the engine - see Mr. Ditton’s GT40 build ..

-

Magnifier 1/12 Ford GT 40

absmiami replied to cobraman's topic in WIP: Other Racing: Road Racing, Land Speed Racers

MFH wiill some day do a series of GT40’s - and they will be killer .. -

Magnifier 1/12 Ford GT 40

absmiami replied to cobraman's topic in WIP: Other Racing: Road Racing, Land Speed Racers

My theory is that the expense of tooling is such that design errors simply are not corrected due to the initial investment in the first tools …. Which is why the MFH large scale kits are expensive but maybe worth it - and their use of wh metal panels allows body assembly with the ability of the builder to tweek the fit and nail the gaps … -

Here’s an interesting thought - Ford’s factory entries were often campaigned by competing teams - including Shelby - so IF the Sebring entries had made the race - it is quite possible that they would have carried contrasting liveries - maybe the white / flat blue nose on 101 - but maybe 102 in different livery ???

-

Both GT40 prototypes were written off in crashes before the end of the race yr - but there are a handful of color pix and 2 dozen fantastic Bl whites of chassis 101 on The Ford Motor Company’s on line research site … so we know exactly what the Sebring cars would have looked like … and there is a re-creation of 101 - i think a collector in Europe did it …

-

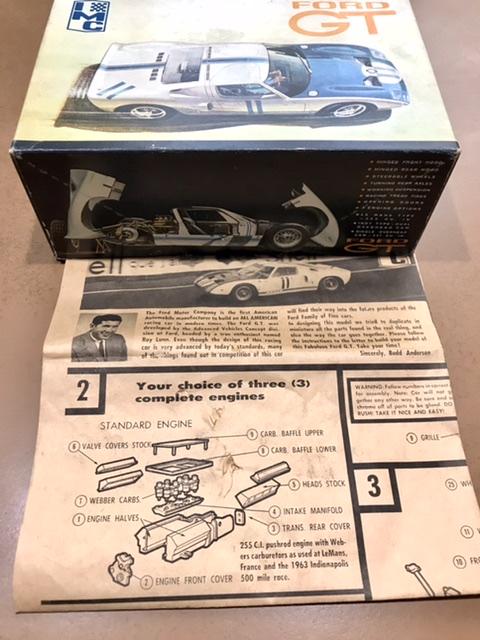

gather round , youngsters… this is the 1/25th scale Ford GT prototype kit - designed by the great Budd Anderson. with wire wheels - correct for 1964 - this is the car that graced the race program cover - and two were entered for the ‘64 race - they just weren’t quite ready - so I’m going to build the Number 9 program cover car - and i think Mr Chernosky will post one he’s built - but there’s a second entry to build - who’s in ??!

-

Magnifier 1/12 Ford GT 40

absmiami replied to cobraman's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Those wheels do look nice … -

Magnifier 1/12 Ford GT 40

absmiami replied to cobraman's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Hate to say it Cman - i think the 50 year old 25th sc IMC GT40 kit i just got is better engineered … -

Mecom Lola Mk VI GT

absmiami replied to Dave B's topic in Other Racing: Road Racing, Salt Flat Racers

Dave B - this car ran the 1964 Sebring race as the #20 entry - have a look at the workbench thread that i threw up on the 64 Sebring 12 hours - start on pg 1 - could you be convinced to join the group build ? About a dozen entries have been chosen to date - whuch means that there are over 60 entries left to choose - maybe one of the Ferrari P cars ? Is Hobart where I think it is ? -

Gracias

-

As the rows or lines or swirls are applied - the wooden tool - made fr a tooth pick - wears down and has to be replaced - so in picture 4 - the second to top row was made with the worn tool - and the top row was applied with the new one …. You can see the difference….

-

Talbot Lago t26c Silverstone 1949 1/12

absmiami replied to maysula's topic in Other Racing: Road Racing, Salt Flat Racers

Excellent engine bay finish one tiny criticism - no sidewall detail on the tires … but thats on the kit maker - not on the builder … -

Talbot Lago t26c Silverstone 1949 1/12

absmiami replied to maysula's topic in Other Racing: Road Racing, Salt Flat Racers

Oh dear my AmEx card is trembling… -

Tiger Cobra Duo

absmiami replied to Pierre Rivard's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Yup -

1/8 Scale Lotus 72c -3d Printed

absmiami replied to kenlwest's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Model factory hiro makes some fuel line for large scale and small - but its hard to source - have a look around for the next Cosworth … -

T - actually I considered your method - but decided that I wanted the rows of turned metal - although these rows are way over-scale - so I just consider it a “scale casualty”. Anyhow - Stay on board - i think you’ll like it when it comes together …

-

-