-

Posts

4,779 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

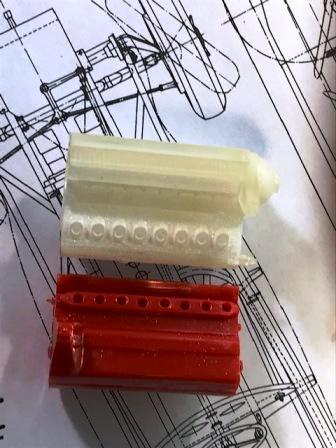

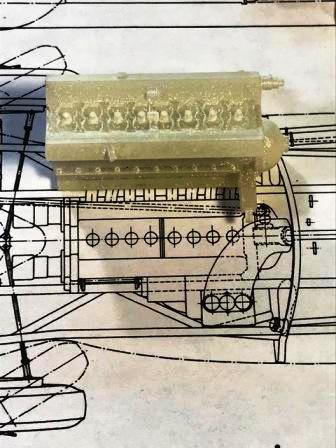

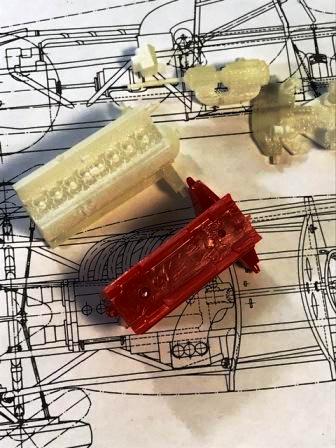

So the idea is to modify the 3D parts to something that has the correct length - which will eventually make for a better fit in the Merit kit body - once I fix the frame ...... and the 3D parts have a much more accurate shape than the Merit block - which was basically - a block ... so I started by sawing off the valve gear casing at the front then I sawed about 4 1/2 scale inches off the engine block which left me with a straight seven engine block - suppose I could build it like that but just in case some judge decides to count the spark plugs or exhaust pipes (maybe 30% chance?) I removed the spark plug and exhaust port detail - which I will replace ...

-

momentary distraction or just a break fr the Delage ... Michael Portaro - aka Indycals - has a shapeways page with his 3D printed parts including a kits of parts for the Merit Alfa 158 Michael has some issues with the new shapeways pricing policies - but we'll leave this issue aside for the moment the kit is intended to build the Merit Alfa kit without major structural change to the kit - and the 3D grill is awesome therefore: the parts look great - but the engine block was designed to fit like the kit block and use the kit exhaust pipe problem is - the engine block on the Merit kit was about four scale inches too long - why ?? - who knows this was the first attempt to produce a detailed 1/24th kit of Grand Prix car - and the design is nearly sixty years old - so I guess no one complained ..

-

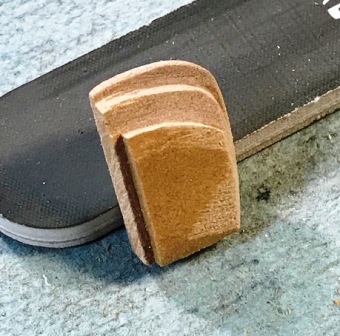

I tried shaping the part to show some creases in the seat cushion - but it wasn't working well on the mechanic seat back ... so I pulled out a bag of leather scraps and found some brown leather that matches the color on the car the grain is fine so I think it will look okay with some work to finish the leather folds at the top of the seatback and it was reasonably thin - I don't often use leather in 24th scale - but this will do ... will have to figure out the seat cushions - either cover them in leather or make "leather" cushions ...

-

the driving mechanic seat back is recessed on this car - it's a neat feature but I have to piece together the renshape parts to follow the contour of the cockpit opening once I got the part roughed out I began to think about the finish ...

-

OOPS SNOOZING AGAIN ..... the friction shocks are done so its on to the seats - just about the last parts that I need to make ... renshape again - different sizes and shapes - mostly hand tool shaped with random tooth files and sanding sticks

-

engines ... my bad thought the Mecum car used a chevy engine - but probably all of the Mecum cars used Ford engines - right? http://www.britishracecar.com/BillThumel-Lola-T70.htm this is a link to a walk a round of the Penske Lola T70 - which is Chevy powered but generally useful for the chassis and suspension photos the present day restored cars have different features - but that is more down to what was/is available at the time of the restoration ... check out the purple rivets - I was told at a vintage event that those are period correct for the Lolas rivet counters rejoice !!

-

-

2 cents ... the shape of the IMC body is much better than the AMT slot body - particularly the nose AMT box art says 1/24th but maybe not - appears to be about the same dimensions as the IMC but the wheels on the AMT kit are a bit better than the IMC the engine block in the IMC kit appears too small but that can be corrected the block is shorter than the IMC Chaparral kit engine - both used sm block chevys - which is funny - cause the body of the Chaparral is way too narrow ... are you going to make the Mecom car or what ?? I photographed the silver Skip Hudson Mark I T70 at Palm Beach motorsports park two weeks ago beautiful car !! I'll post a photo if you want to see it ...

-

each shock has an outer disc that I punched from .005 copper sheet then I made the clips - that look like mechanical spiders these are hand filed from additional machined nickel discs and then simply marked black with a sharpie the shocks are attached with some castle nut castings from that Russian aftermarket company - they make the nut/bolt assembly in different sizes - I am drilling holes in the 1.6 mm size and then cutting them from the bolt casting - probably finish these with a silver sharpie - the real things are cast and therefore have a relatively dull finish ...

-

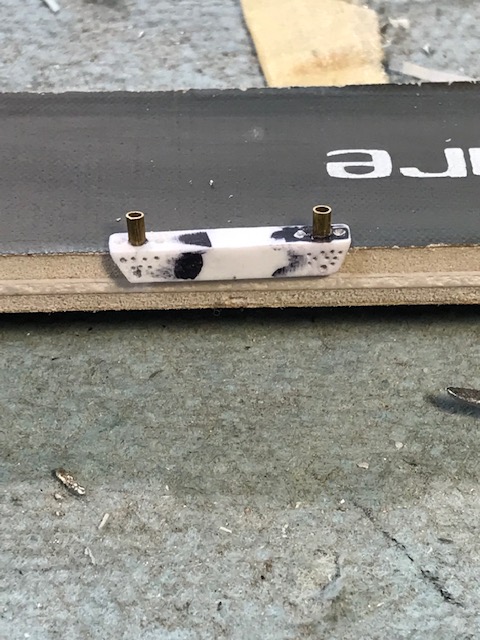

some more assembly shots not sure - but I think the disc for the middle leaf is a bit thicker - I made these about .015 thick - in contrast to the thinner outer leaves ... then made the brass posts for the chassis pickup points

-

here's how they are made the joint is tricky - used silver solder for strength and hand filed for the taper the fine cutting saws sold by UMM are helpful here ... you may have seen these made in larger scale on the excellent Voisin build on the BritModeler site ......

-

so I also need to make the friction shocks - most pre-war race cars had these the delage had opposing pairs of these shocks left and right on the rear suspension and 2 more sets of shocks under the chassis fairing up front for these I'll use model factory pico's castings the rear shocks - seen here - are made from pieces of nickel silver - discs and bars soldered and then bolted together with an .070 mm section of bolt the discs - 3 in each shock - are turned on a lathe - .010 width and about .190 width - which is just less than 5 scale inches

-

so the pickups are cut off of the L bar stock and then glued to the chassis with some pins for accuracy - they will get nuts after painting - and strength the second picture shows how the cross bar meets the pickup that will be made later - the plastic rod is in place to check height for the pick up

-

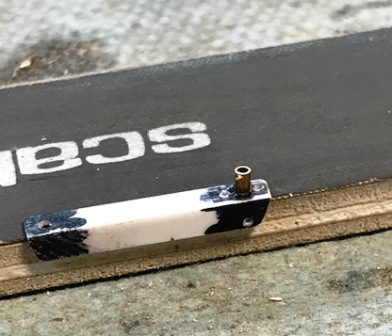

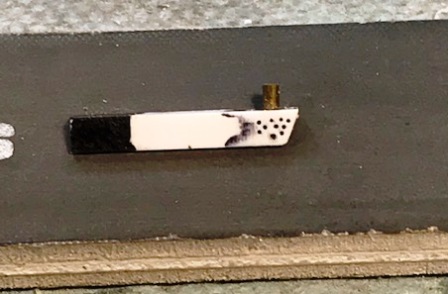

next - the brakes - front and rear - are cable operated - off of levers the front brake cable lever pivots from a cross bar running from the top of the brake drum to a pick up bolted to the chassis - probably not a great idea - but this was actually carried forward when the 1927 Delage was designed ! there are some very good pix on page 1 so I made the chassis pickups - left and right - from some evergreen L bar and a short length of br tube think the tube is .047 then drilled the perorated patterns with a number 82 drill - so just about .010

-

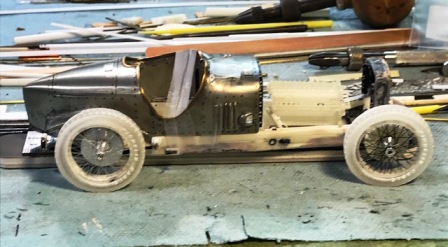

good time to stop and do a susp mockup to check ride/chassis height caliper checks on front and back - think I've got it right - looks pretty even will have to check the width - front and back - also ....

-

must've been snoozing ... finished the wheel knockoffs - each one got a little better made some solder corrections to the first one and I've got an acceptable set of four

-

yes - definitely order those carbs ...... they are great

-

wondering if you - or anyone else - recalls the photos of Manuel Sans' 12th scale birdcage model ?? It was featured at least twenty five years ago in Vintage Motorsport mag there may still be some photos of it on the net - there may still be a site for his builds ... anyhow - I always wanted to try that - or something close to it - in 24th sc and you beat me to it! and yes - your frame looks every bit as good as the 12th scale Sans frame .....

-

and the wheels may indeed be gorgeous if I paint them well ... I'll take a bow for the hubs but Pico has to take a bow for the printed wheel rims and tires scratch-building these components in 1/24th would be treacherous. in fact - these are the only proper 24th scale grand prix tires on the planet - for the 1923-1928 grand prix cars - think Alfa, Bugatti, Voisin etc. .... Profil 24 makes quite good tires - but better for the following era. .... by using properly drawn 3D printed parts - I just have to follow the dots and do the assembly - and use fishing line and not steel! Pico - are you bowing?

-

so wheel nut II came out al little better but still had to figure out how to solder the silver bar onto the turned part at a close to 90 degree angle got better on that on wheel nut III so I'll do a couple more ....

-

OK - the wheels are done - maybe not - mite try to "unwire"" the first wheel that was strung with steel and replace with fishing line the shapeways parts are made with a very tough material that I think will survive this surgery - but I'm not sure - thinking about it ... now on to the wheel nuts - again depicted in the photos on pg 1 will make these from nickel - could make them from plastic but the nickel finish will contrast nicely with the dark blue wheels - so away we go ... the first wh nut - shown here - was not so great ... tried a slightly different approach for wh nut II have to file a well defined slot onto the top of the "nut" and solder a bar across that when finished - is integral to the nut surface - then place the part back on to the lathe to drill the opening for the end of the axle - 1/16 hole ...