-

Posts

3,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by AmericanMuscleFan

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

You prove with each update that you are gaining in competence, this can be seen in the quality of your custom-made parts. I too think that the rotary table is one of the most useful tools and it allows you to machine surprising parts with great precision. There are several talented modelers on the forum and you are certainly one of them, I always find in your post ideas to use for my own projects. Thanks for that my friend! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Yes, I am, I bought all this nice equipment in order to improve the precision of what I could do manually with the basic tools and my two hands. I often take unconventional paths but my goal is to try to improve the recipe from time to time (what we call gaining experience). These are tools that seem intimidating but I have learned that you just have to work slowly and measure twice (maybe more...) before cutting. On the other hand, you need a wide range of cutting tools because this is often what limits the realization of a part where several sizes are necessary to create the details. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Daniel! I've thought about it before and will probably buy one one of these days, but I've always been a little worried about the stiffness due to the weight of the motor assembly (head stock) when positioned at an angle. Keeping the cutting assembly (head stock) perpendicular to the bed with an angled table for the workpiece has always seemed like a more traditional way to go. I am self-taught in machining so my way of working may seem strange to experienced machinists. The goal is to get there but it's always interesting to see the approach of other modelers who make their own custom pieces. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Bob, the second part is "in the works" and I hope to have them installed next week. Francis We would still need a digital camera or a smart phone to take pictures of the good shots developed to be able to upload them to the forum... ? Francis -

The "to do list" is pretty extensive but it is good news for those who like this kind of build and I am one of them! ? By the way, the master cylinder and line lock are both superb!

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hello everyone! More progress on the doors and the huge amount of work involved in this part of the project. I could have made it simpler by using a simple brass rod and a styrene tube but I wanted something more realistic so I decided not to back down. I didn't take pictures of the whole process of thinning the door panels because it's very repetitive and I didn't want to bore you with all that, you probably know the principle. I machined the first part of the hinges, the one that will be mounted on the door pillars and I will make the other part, the one that will be mounted on the doors afterwards. I'll get back to you later with the rest. Francis Both doors side by side showing the one I slimmed down and the original. Different angle of view. Another one... Part of the side fabricated and mounted in the vice to engrave the latch opening, admire the amateur installation to hold the part in place! ? Aluminum hinges in the rotary table chuck. I made 45 degrees cuts on the shoulders for more clearance. The four amigos! I can't wait to see if they will do the job, there is a bit of an unknown in all this, I'm in unfamiliar territory... -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Luckily, digital cameras and smart phones save us from disappointing trips to the lab to get all those bad pictures... ? Francis Thanks Ian, I must admit that I surprised myself! I couldn't reproduce all the details of the car but the essence is there. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Marcos, you have the skills to do it, I'm sure, you just have to be patient and take more precautions. Anyway, nothing is lost, it will always be possible to glue the doors in closed position in case of major disaster, it will just add a hundred hours to my project. ? Thanks Daniel, anyway, as we often say, photos can't always do justice and it's with naked eyes (or with glasses...) that we can appreciate all these details that we take so much time to create. Obviously, I must be a better modeler than photographer... ? Thanks Ron! I put a lot of effort into it and I am sure that in the end I will find a different way to do it. It's part of the fun of trying to improve on what you've learned, there's more than one way to get there! Thanks again guys, Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Ray! I appreciate your great sense of humor! That being said, I remember putting together a kit or two in my early days that had the option of working doors and it was a challenge that gave me a hard time. I guess time has made me forget a lot of things as I embarked on this adventure decades later. I'll try to do better this time! ? Francis -

48 Ford Ranchero

AmericanMuscleFan replied to Butter 1's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Very nice parts you made Ron, lots of effort that is paying off! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

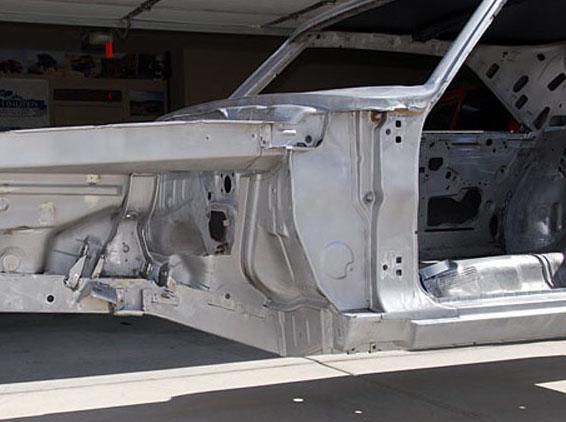

Hello everyone! I spent the time available to me at the workbench these last few days to make the door frames. As planned, I used the reinforcement I made for the rocker panel as a base to build the door sills. I tried to replicate as much as possible the details of the door jamb lock pillar and I am very pleased with the results considering all the work that went into it. I now realize that making functional doors is more than just cutting the panels, it's probably one of the hardest parts of building so far and I hope I don't regret committing to this process. However, I am sure that the visual effect on the finished product will be worth the effort. I still have the hinges and door details to make, I have a lot of work ahead of me! Comments are welcome and appreciated. Francis I started by closing the inside of the rear fender. I added the first details according to the references found on the internet. I made the door sills by connecting the front door pillars and the jamb. Another shot, I used the dime to try to have a better focus but it's a waste of time... The completed door jamb, I surprised myself -

Claude strikes again! This could be the headline of the day and those to come! I don't know where you find your inspirations and your ideas, but the designers of all these cars will eventually get tired of seeing their designs improve and say to themselves why I didn't think of it before? You're setting me up for a long day of talking next week and I don't think I'll be the only one asking for details on your fantastic offerings my friend! Great Claude at its best!!!

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Tim! It's always a pleasure to see you stop on my thread and leave your comments and appreciations on my construction methods. I can't wait to move on to machining mechanical parts, your prowess in this aspect gives me a lot of energy and I myself am greatly inspired by your own creations. Glad to see you back in the neighborhood my friend! -

Dear Tim, I am so sorry to read in your last message that you lost your mother this way, this disease is terrible and unforgiving. We always want the most peaceful departure possible for our loved ones, but we are never fully prepared for this inevitable stage of life. I am lucky to still have my 2 parents, my dad celebrated his 92nd birthday this week but I almost lost my mom last week to a sudden heart attack. One day or another I will have to go through this difficult moment like you, so I want to express my deepest condolences to you. Now take good care of yourself and your health, I hope to see your magic again soon because your work inspires me to the highest degree. Francis

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Everyone takes the hobby to their own level, the rule is that there are no rules and that's fine. I am older than you and in my case, racking my brains can only delay the relentless effects of aging and keep my brain healthy, my ideas clear and my hands precise. I think it's not bad for a simple hobby! ? Francis -

48 Ford Ranchero

AmericanMuscleFan replied to Butter 1's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

The details are beautiful Ron, this is another very well started project, you have good taste and great skills, it shows! -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Ron! The details will still be visible with the doors open and those who like this kind of details always find an angle to see them. I always display my models on mirrored bases, it helps a lot to see more subtle details. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Marcos, I plan to finish doing the majority of the door frame fabrication and then I'll get into machining the hinges. It's a time-consuming process and I understand why many modelers don't want to go down that road. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for your comment and your patience Bob! Sorry I can't go any faster, I feel like I'm putting you through a weekly TV show... ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hello everyone! I finally made the door pillars. I tried to respect as much as possible the aspect of the real parts on the car, but mine will be separated from the sides of the firewall, this way I will be able to engage 2 of the mounting bolts from the inside and the 3rd one from the outside as it is the case on the real car. I made sure to note the holes spacing and will drill at the same positions on the hinge. The base of the pillars rests on the rocker panel reinforcement I made and is glued under the cowl vent panel, this also helps to reinforce this weakened part of the fenders that I thinned during my last update. Thereafter, I will continue the fabrication of the frame of the doors starting from the base of these same pillars. It will be clearer with pictures I think... ? Comments are welcome as usual. Francis The target, the real one of course. My personal version at the beginning of the machining, yes, machined in styrene, it is less hard on the tools! The two bases of the pillars are made, they are mirrored to simplify things... ? I added some details to make them look more like the real thing. They are glued in place, this will allow me to engrave the front fender parting line without the risk of it coming off the body. There is still some work to do but I'm quite happy with this, I've been racking my brains to figure out how to start this section without separating the front fenders from the rest of the body.