-

Posts

1,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by BK9300

-

Resto Rod Autocar

BK9300 replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks great, Gary! -

2024 Build’s let’s See them.

BK9300 replied to Pete68's topic in Model Trucks: Big Rigs and Heavy Equipment

Great idea for a thread, Lee - lots of amazing builds in here - very creative works on display, everyone! -

I agree with others - hard to hear about having to part with anything you’ve invested so much effort in - terrific scratch building!

-

Kenworth W923 logger

BK9300 replied to Rbray47's topic in Model Trucks: Big Rigs and Heavy Equipment

The paint lines on your builds are always so crisp - great attention to detail! Another quality build. -

Super clean build - dashboard looks very detailed, too - very nice!

-

Beautifully scratch built deck, crisp paint lines, and just a quality build!

-

Very realistic detailing - a pleasure to look at, well done!

-

Link-Belt HC-218 Truck Crane

BK9300 replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very cool to see an update on this build! Lots going on - great to see the progress. -

Ladies and Gentlemen, presenting my '67 Impala street/strip racer

BK9300 replied to ismaelg's topic in Model Cars

Awesome paint and detailing - love the interior, too - very well done! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

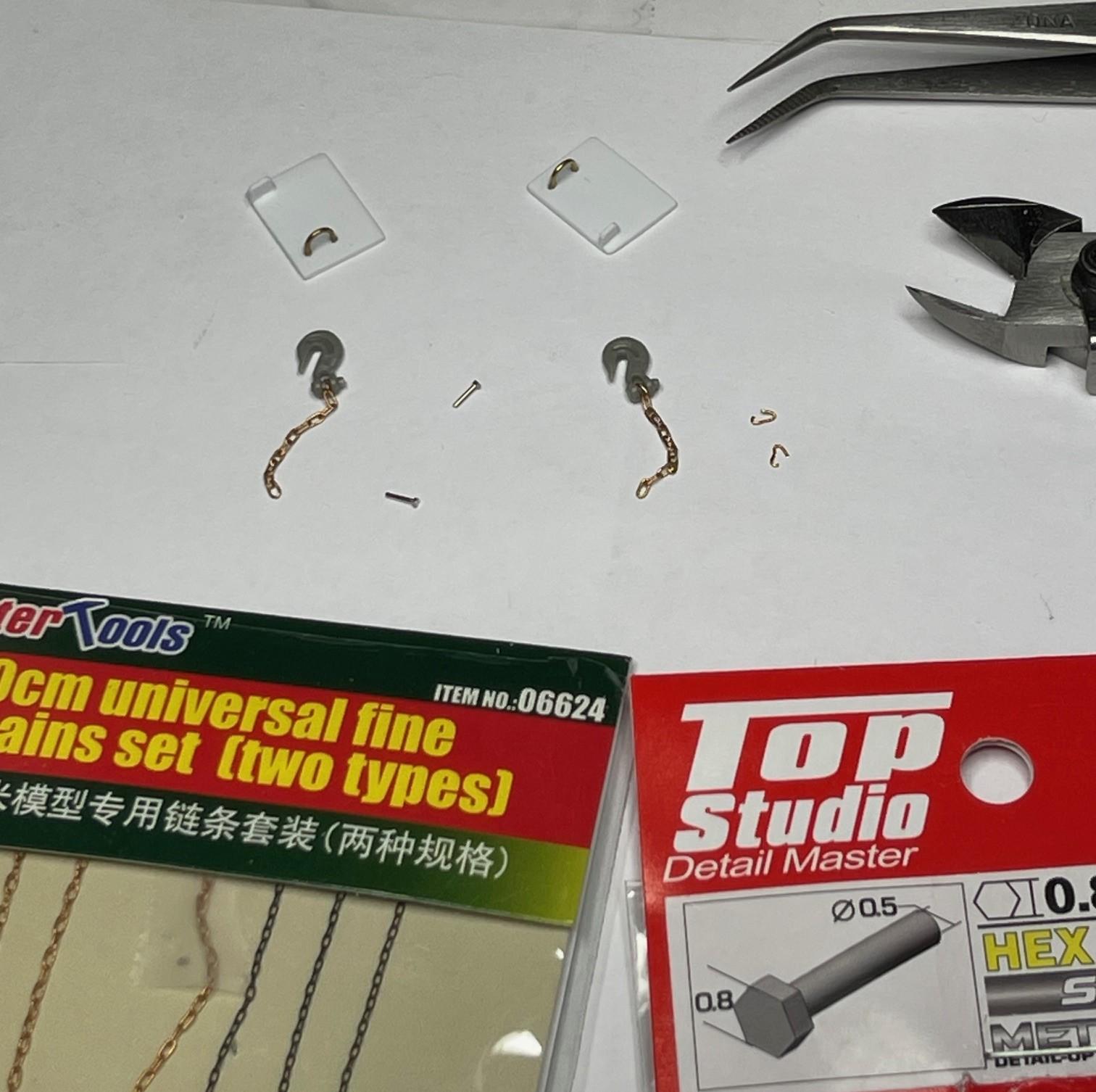

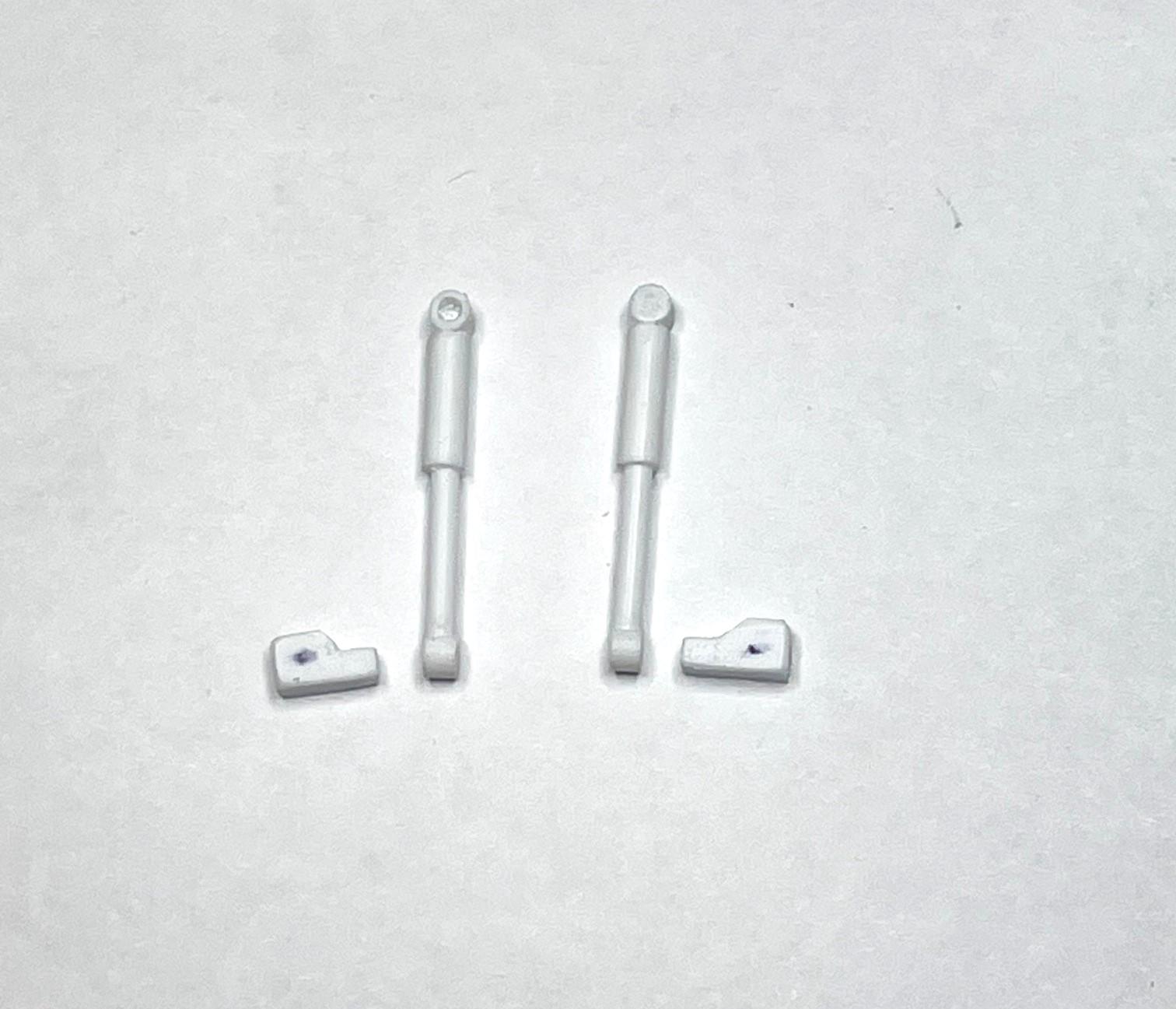

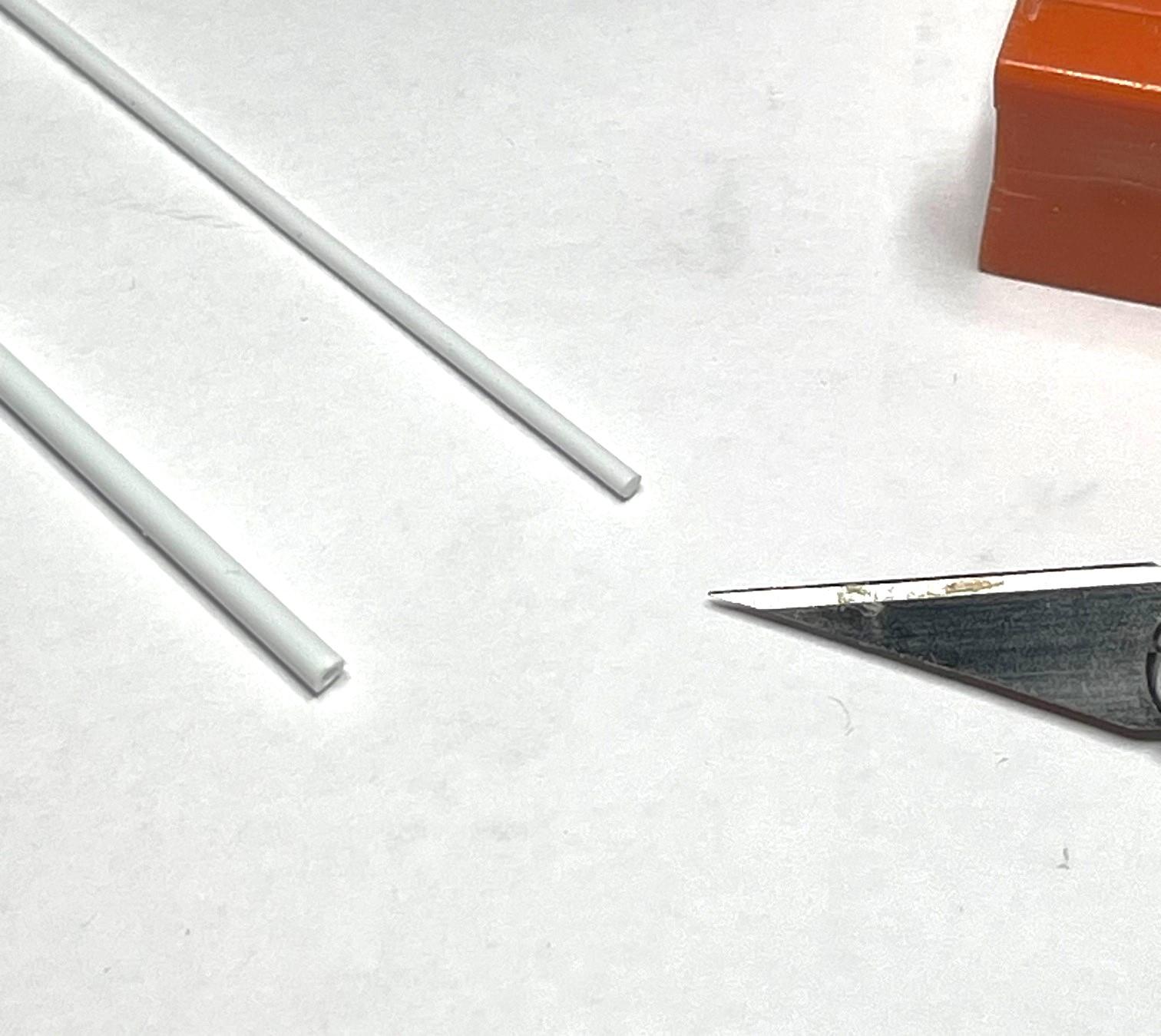

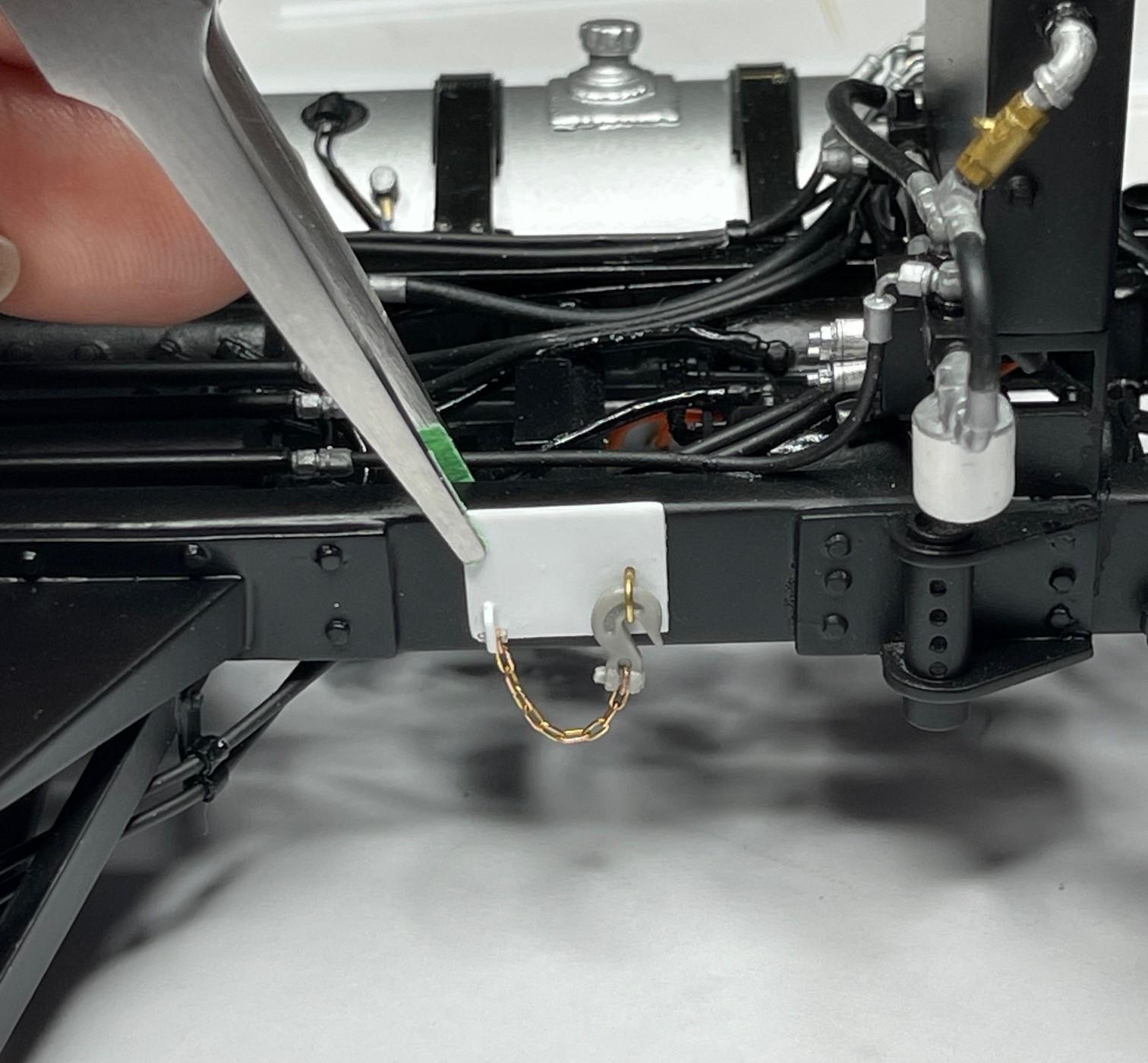

A bit of a lazy day happening here, but did do a little work. Had to repaint the front rims because they had chipped around the rim edge from too much careless handling. So, while a couple coats were drying, I made progress on something I need, that being shocks for the front. Then I worked on something I don't need but could add - support chains for the underbody plow. I made up a set, but not settled with outcome because of the size of the chains' hooks - they're a little better that half again as big as they're supposed to be. Maybe I'll get used to them in a few days. Basis styrene tubing for shocks Front shocks made, along with lower mounting bracket that should be part of the front axle, u-bolt mounting assembly; still need to make top mount that it, and the shock, will bolt to the front plow brace plate Am not sure about using these - the plates bolt to either side of frame above the underbody plow. The hooks are visibly too big but maybe, once they are painted black, they will blend into the frame less noticeably. . . They might only be a bit of extra detail overall, Just undecided at the moment - thoughts? Will give the front rims another couple days, and in the meantime will finish front shocks and mounts and get them painted and on the truck. I'll also add the extra bolt heads to the brace plate and re-do the pass through brake lines. Definitely will be a 'roller' next week! (and I'll decide about the underbody plow chain supports!) - Take care! -

Looking really good, Steve - fun watching the progress!

-

Kenworth 925 Narrow Nose 1/25

BK9300 replied to truckabilly's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Like Gary, I've never heard of this. Sounds like a very rare kit, and it sure is detailed. Very nice progress so far! -

Very cool - do you think you’ll add any doors or windows along the way?

-

Resto Rod Autocar

BK9300 replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Really like the CTM lights - what are you using for the smaller, red lights? -

Kenworth aerodyne cabover

BK9300 replied to Bronzekeg's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

There’s a lot of complexity to that rear suspension - never mind the plumbing - makes it hard to paint, too! Always liked the ‘shop’ setting in your photographs. -

Looking fabulous, Steve - I agree with Gary and Jeff - lots of great detail in those small spaces and its going to look even more awesome once you get your paint on!

-

R.O.G Peterbilt 359 Custom

BK9300 replied to BOZ's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Fine looking inspiration trucks - looking forward to seeing the modifications in your build! -

1/48 tanker progress

BK9300 replied to cdntrucking's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks really good, Lewis - wonderful detail painting at this small scale! -

Resto Rod Autocar

BK9300 replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Top drawer, Gary - that looks incredible and the colour theme throughout the truck will look great, too! -

FDNY Wrecker

BK9300 replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Making good progress, Scott - great job on the rad and CAC setup. (might be able to get a package on its way to you by end of December!) -

Resto Rod Autocar

BK9300 replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very cool pic! Hope you’re feeling better soon. -

AMT Exterior Post Doubles Vans

BK9300 replied to Bren's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very cool, Bren - like Gary said, weathering is not a skill I possess at the moment and yours looks great! Also nice to see another modeler who has about 1 square foot of space to move around in (well, 2 square feet because you have two benches!) - the rest is 'stuff' for the project(s)! -

Farmtruck Street outlaws

BK9300 replied to Gustavo Reis's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Remember first seeing Farmtruck on episodes of Street Outlaws: Memphis - also really liked Ole Heavy, too