-

Posts

2,503 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

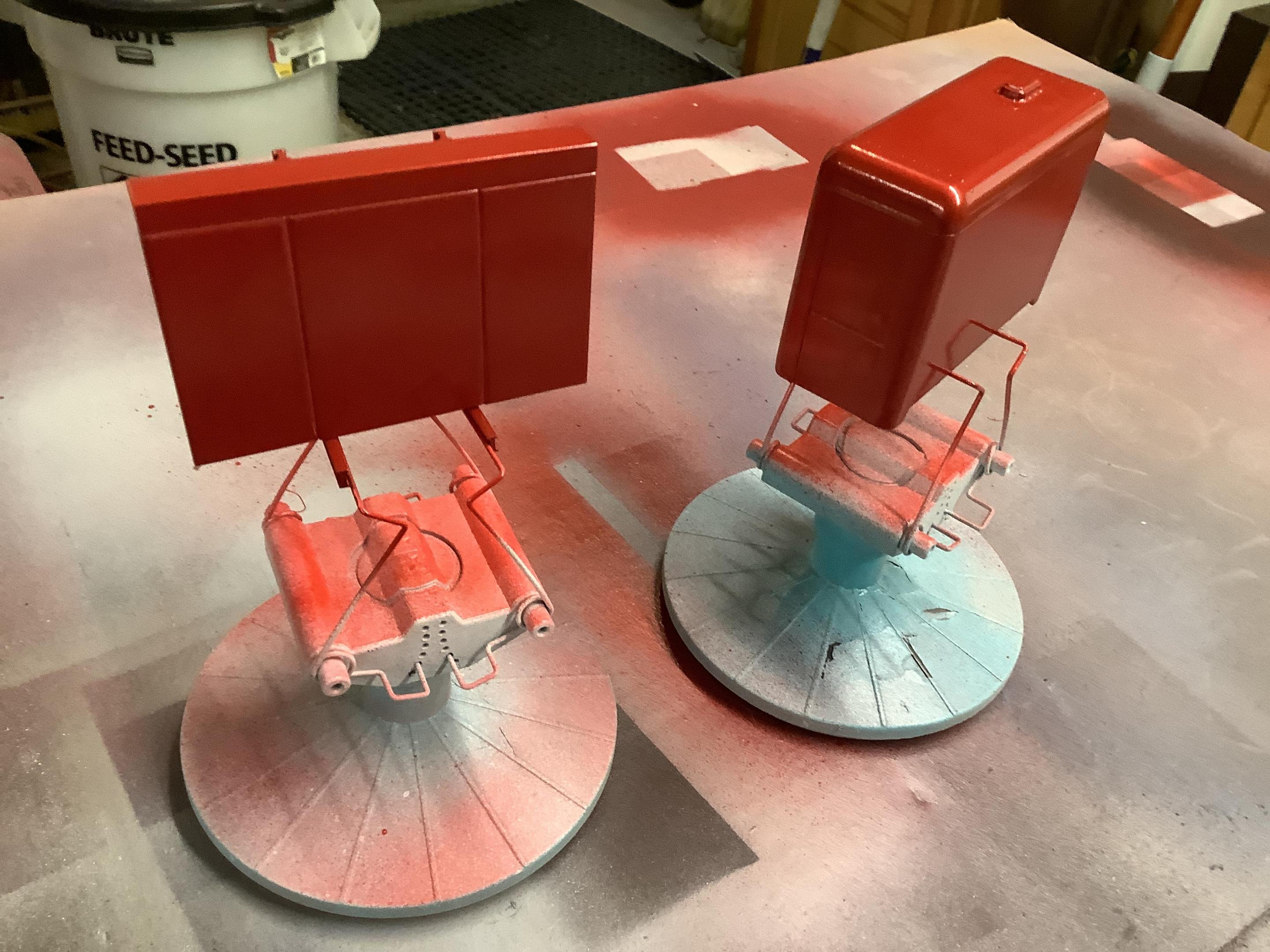

Progress today, sleeper and headache rack paint complete, next add row of lights to the top of headache rack and slam locks, add slam locks to sleeper. Finished trimming front fenders and fitting bumper and are now in primer, maybe paint tomorrow. Installed driving lights and turn signals in bumper. -

Caboverdose

Gary Chastain replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Raising that bar again🏆🏆 -

Western Star Classic heavy haul

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

TS-45 Pearl White, little bit of sparkle, is my vote -

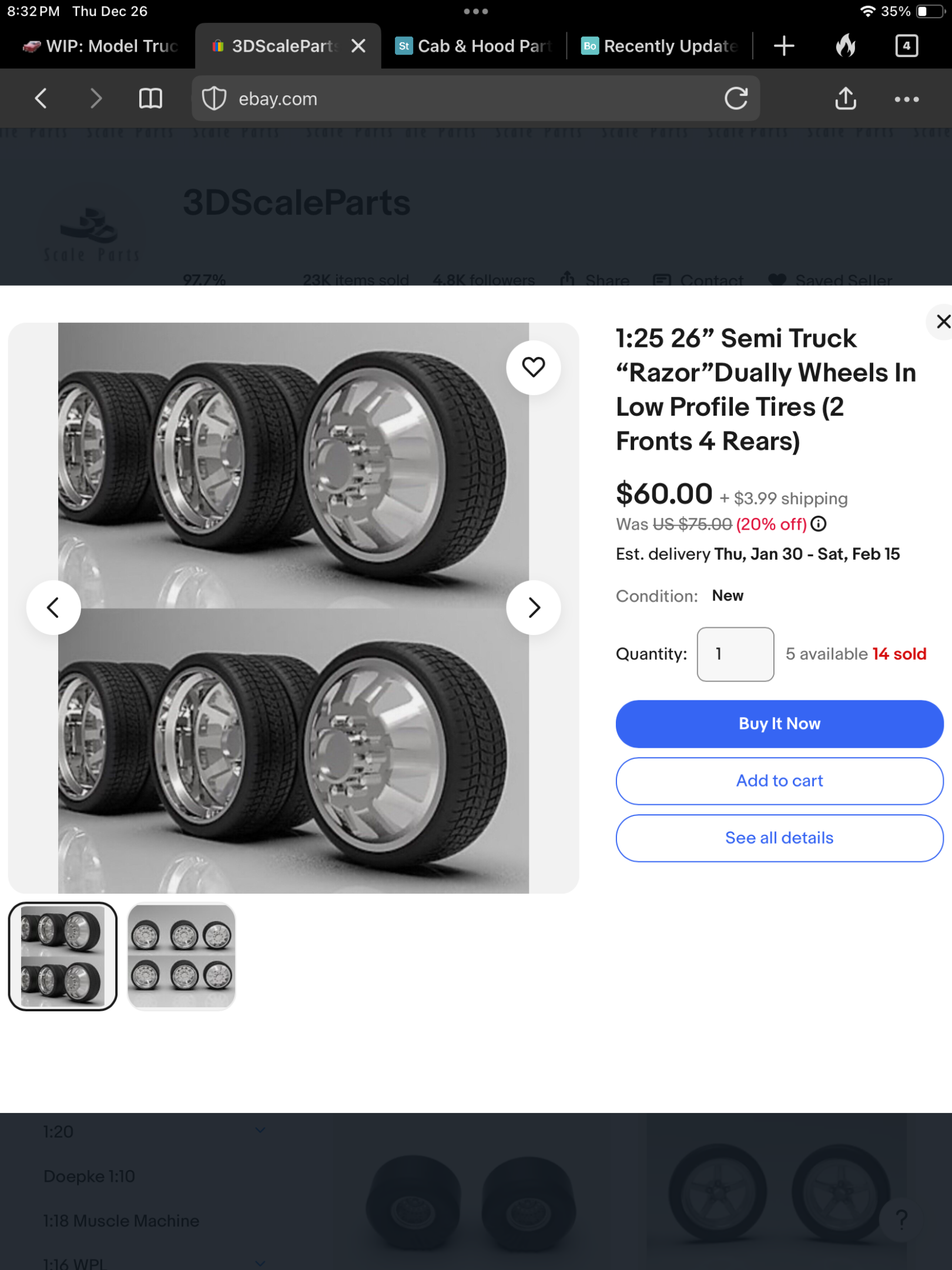

You guys been asking, so here it is, another full custom where I break all the rules again. I have full custom front and rear fenders ordered, two different sets of custom wheels, lowered rear suspension, will build the lowered air front suspension and most importantly Chopped Top cab. I have been collecting parts for a while but was unsure of what truck to build, when I found the cab in my stash, decision made. It will be a little time before I start it as I wait for parts.

-

R.O.G Peterbilt 359 Custom

Gary Chastain replied to BOZ's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Clears the oil pan nicely -

Western Star Classic heavy haul

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

We all be a watchin 😉😂😃🤣😁 no pressure 🏆🏆🏆🏆🏆you got this -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This has been an interesting build for me but in a different way. This build has allowed me to just be creative, not follow any traditional rules of following a cover build or traditional build, it’s allowed me to mix and match all kinds of parts. Normally when I build a kit, I reach a dead spot or need a break or develop a mental block. I can’t wait to get to the bench everyday, staying highly motivated and looking forward to changing something else. This is a really fun build and yes, already thinking of a couple other builds where I can break all the rules again…….. Maybe a slammed old KW or Diamond REO with custom wheels, smooth out everything, cool color and….and……and. -

Western Star Classic heavy haul

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Ok, I got front row in the center, popcorn, couple candy bars and a big drink. Now I’m watching😉😁😃 -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

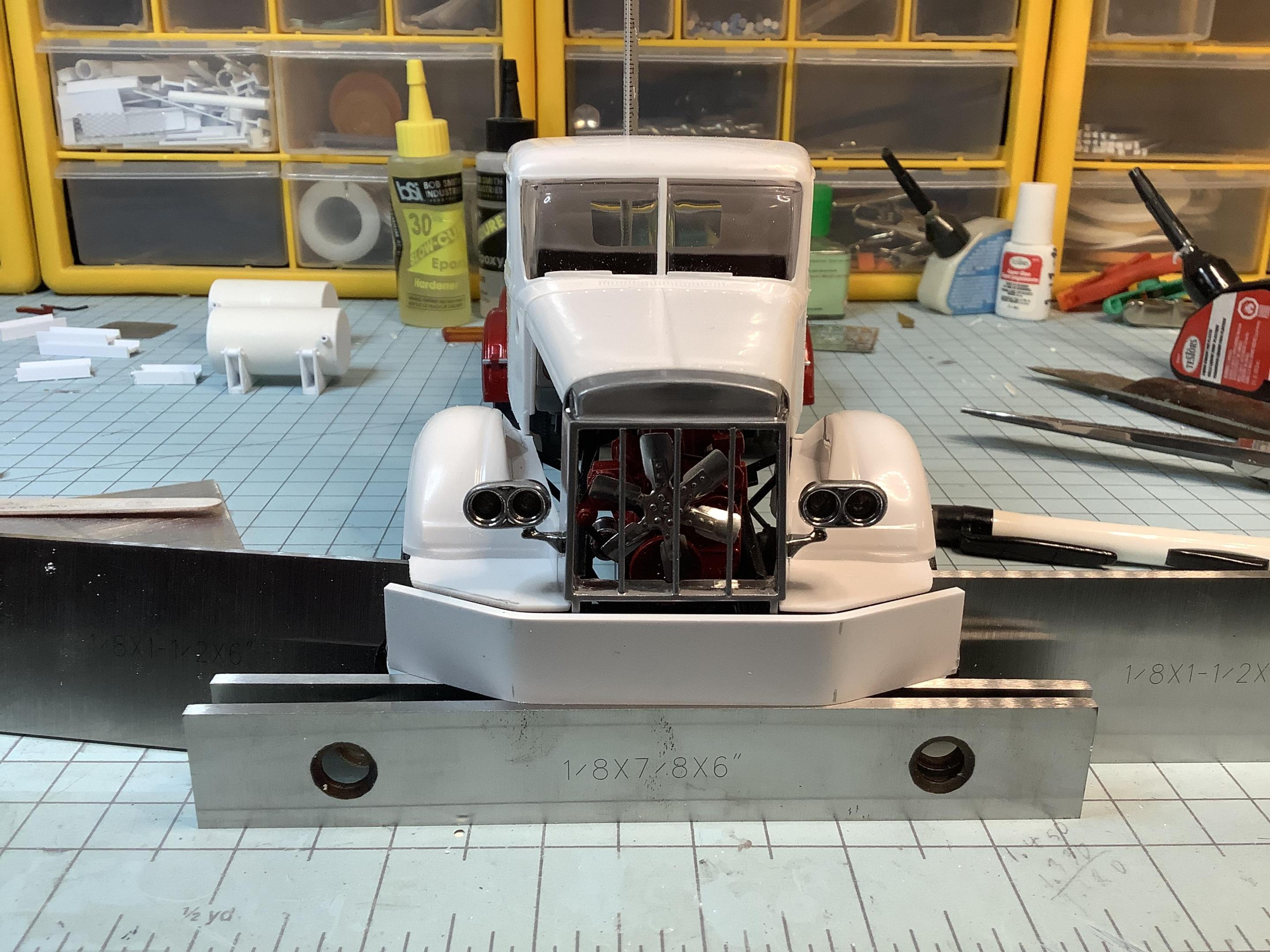

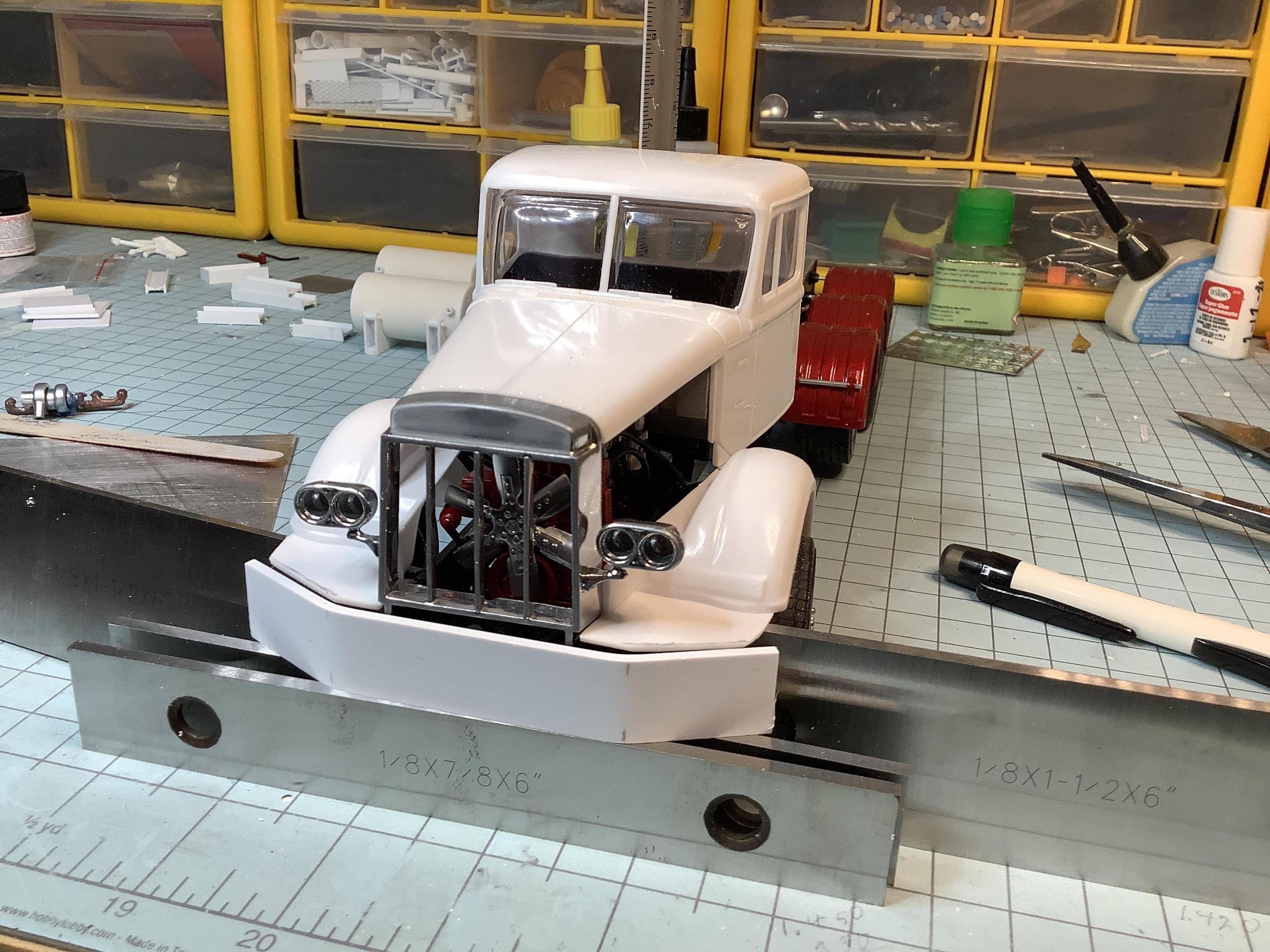

Front fenders reshaped to match bumper, gives the truck a cleaner look. Few more adjustments, then finish work begins. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Getting paint on headache rack and sleeper today. Also mocking-up front custom front bumper to trim fenders and build frame mount for bumper. Checking that cab is square to frame and hood alignment and grill are good. -

Mack r685st

Gary Chastain replied to 53gmc's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looking really good -

Kenworth aerodyne cabover

Gary Chastain replied to Bronzekeg's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Like the direction this is going, looking good -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Scott, kinda getting the look I wanted, old school truck full updated. -

FDNY Wrecker

Gary Chastain replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good progress, it really looks the business -

1/25 AMT Mack R600

Gary Chastain replied to titino's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This will be fun to watch. I see more builders rebuilding old kits. I have never given this much thought, but maybe I need to give it a try. So be stealing some tips from you. -

Ford LS Rescue truck

Gary Chastain replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This is gonna be fun to watch, darn squirrels 🤣😂 -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

little progress on this holiday. Got the sleeper modified and assembled, removed fake handles, will be using some PE handles. Need to find some cool cab marker lights. Had to make another bumper, broke the first one, will be mounting driving lights and turn signals in the bumper. -

Caboverdose

Gary Chastain replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

More clever fabrication work, well done -

Kenworth aerodyne cabover

Gary Chastain replied to Bronzekeg's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great start and thanks for the info on the hinge -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Kenworth 925 Narrow Nose 1/25

Gary Chastain replied to truckabilly's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Never seen this kit before, interested in the build.