Firebuilder

Members-

Posts

243 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Firebuilder

-

Ford LS Rescue truck

Firebuilder replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Jeff , nice work on the chevrons and lights. Overall truck looks great! -

Kenworth C500

Firebuilder replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks like this is going to be a heavy duty monster! -

AMT Aero Chief car hauler

Firebuilder replied to BIGTRUCK's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very nice build! -

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you Scott! Cool that your dad worked there. I had no idea there was a Maxim dealer in E.O. Hmmm, does anyone make a Waukesha in 1:25? -

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you Jeff! -

R Model Mack in 1/32 scale

Firebuilder replied to Chariots of Fire's topic in Model Trucks: Big Rigs and Heavy Equipment

Charlie, nice build and refit , well done! -

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Charlie, I took your advice and swapped the kit trim, for the .030 stock. It took some work to get the trim off. The Ca glue was set pretty firmly . I got it off with out gouging the cab, and did some light sanding to remove the glue marks. The thinner trim looks 100% better. Here are the before and after photos. -

Mack B-61 Dump Body

Firebuilder replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice work Scott , tarp system looks great. -

Link-Belt HC-218 Truck Crane

Firebuilder replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good to hear your doing better and recovering, being at the bench is always good therapy! -

California Special

Firebuilder replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice progress ,looks good. -

Cat D7 cable dozer

Firebuilder replied to The Brush's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice job, weathering as you go is a good idea. -

AMT GMC ASTRO 95 Rebuild from 1986

Firebuilder replied to Pete68's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice build , looks great! -

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you foe the information greg -

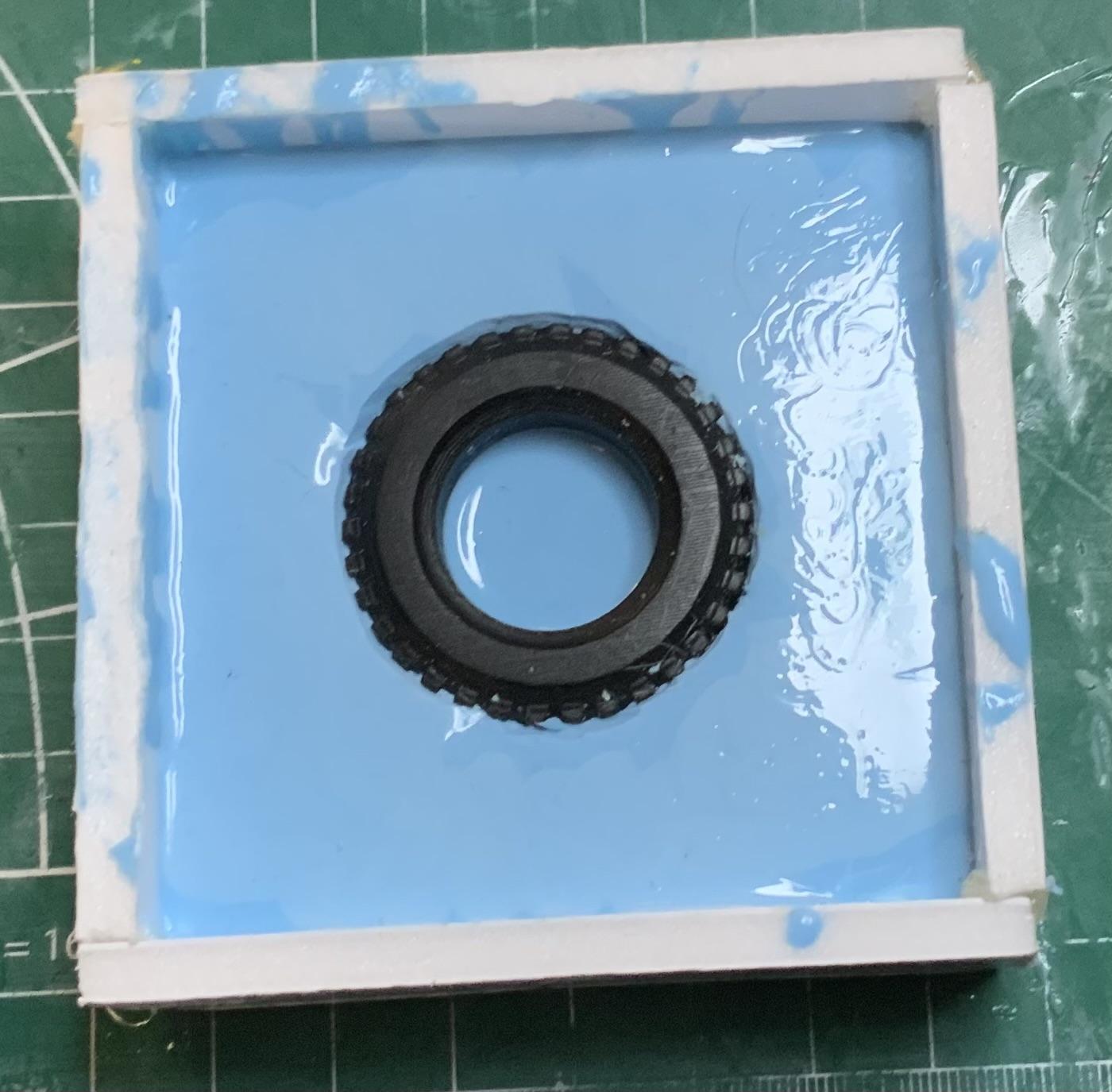

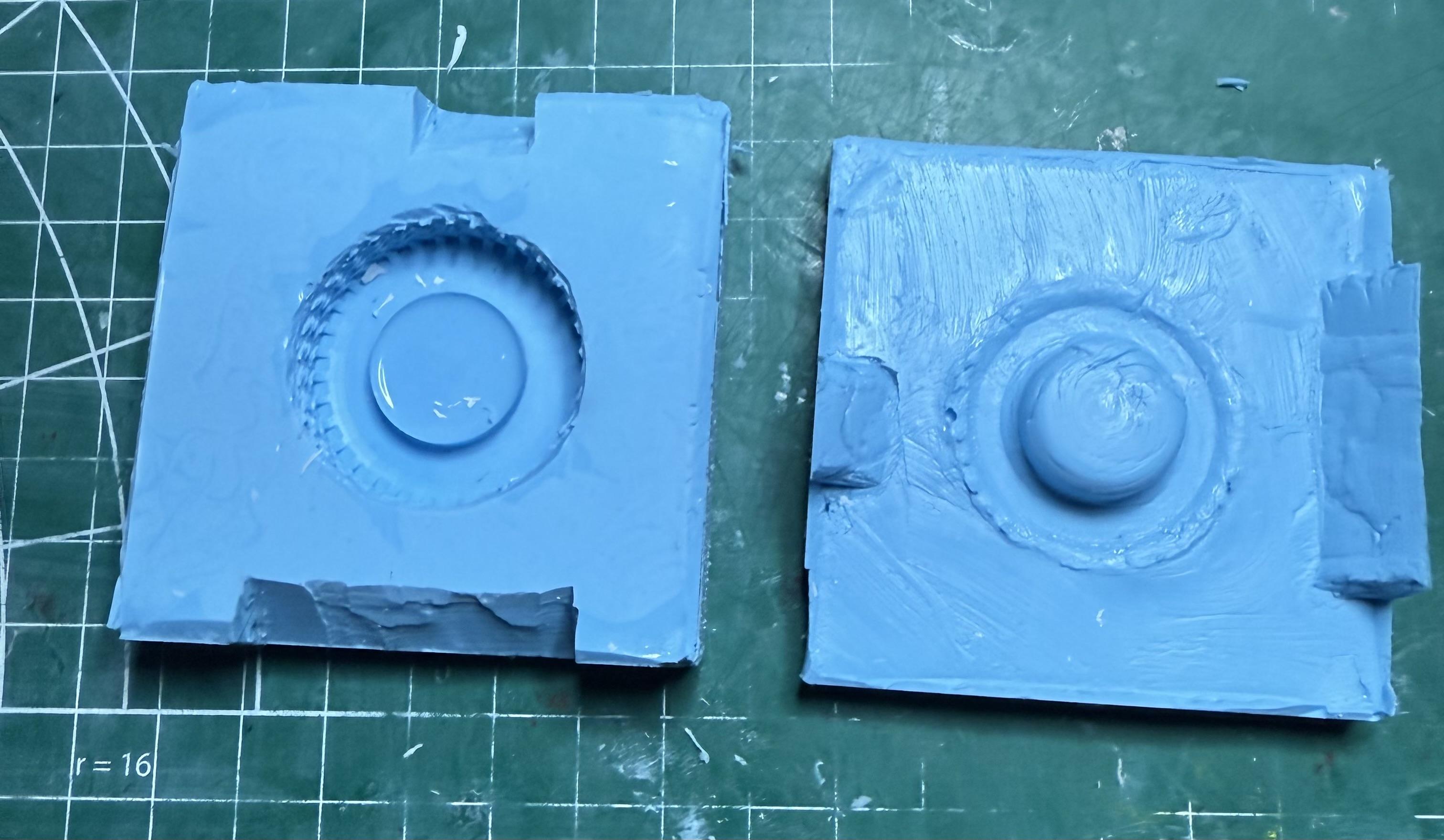

You are correct that the tire I used for the master was 3D printed. I am not a 3D printer there &ore I need to purchase or make my own items. The Tires are not always in stock and there is also the cost. So now I can cast the amount I need anytime I want to. Also by following Charlie’s instructions I learned something new and advanced my mold making skills. Just a note, while I did use someone else’s tire for the master, what I make is strictly for my own use, and if asked where I got the tire , I would recommend the vendor who produced it.

-

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you for the tip, I will pick up some evergreen at the hobby shop this week and try it out. -

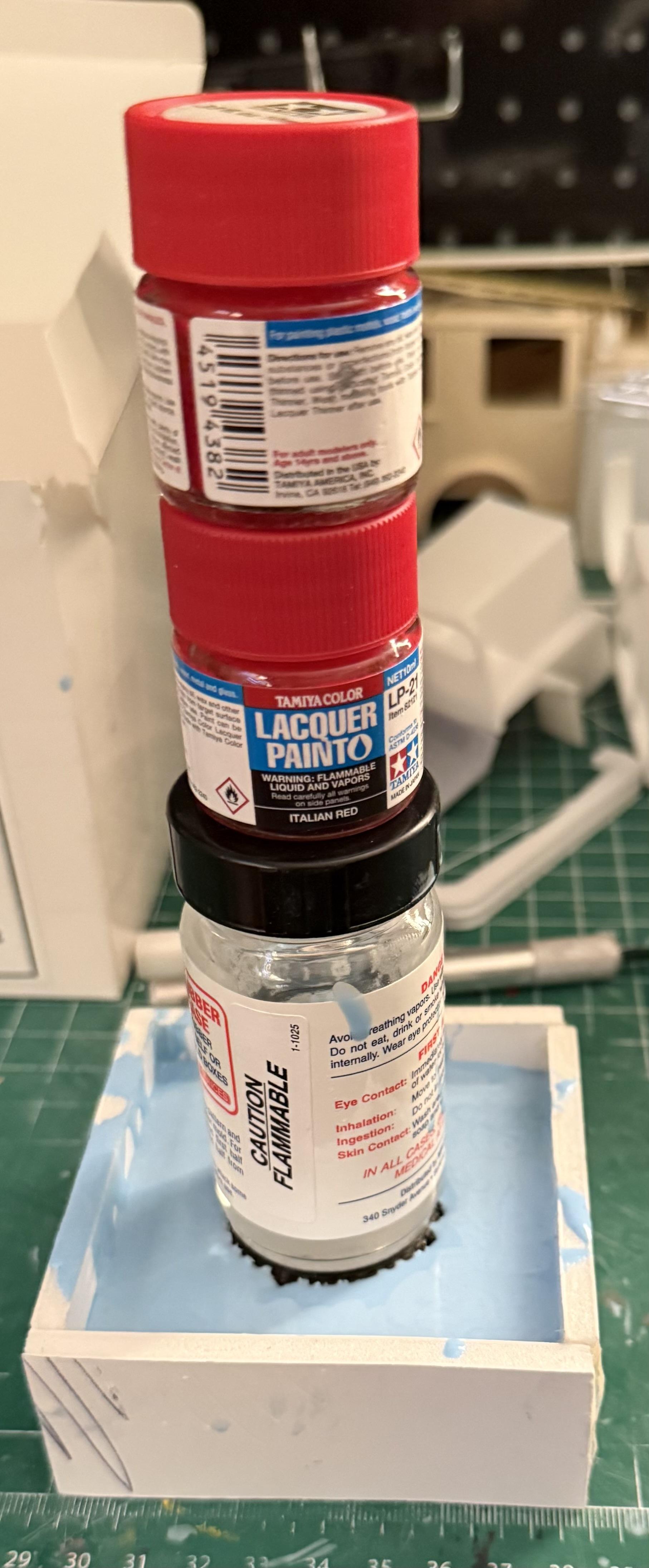

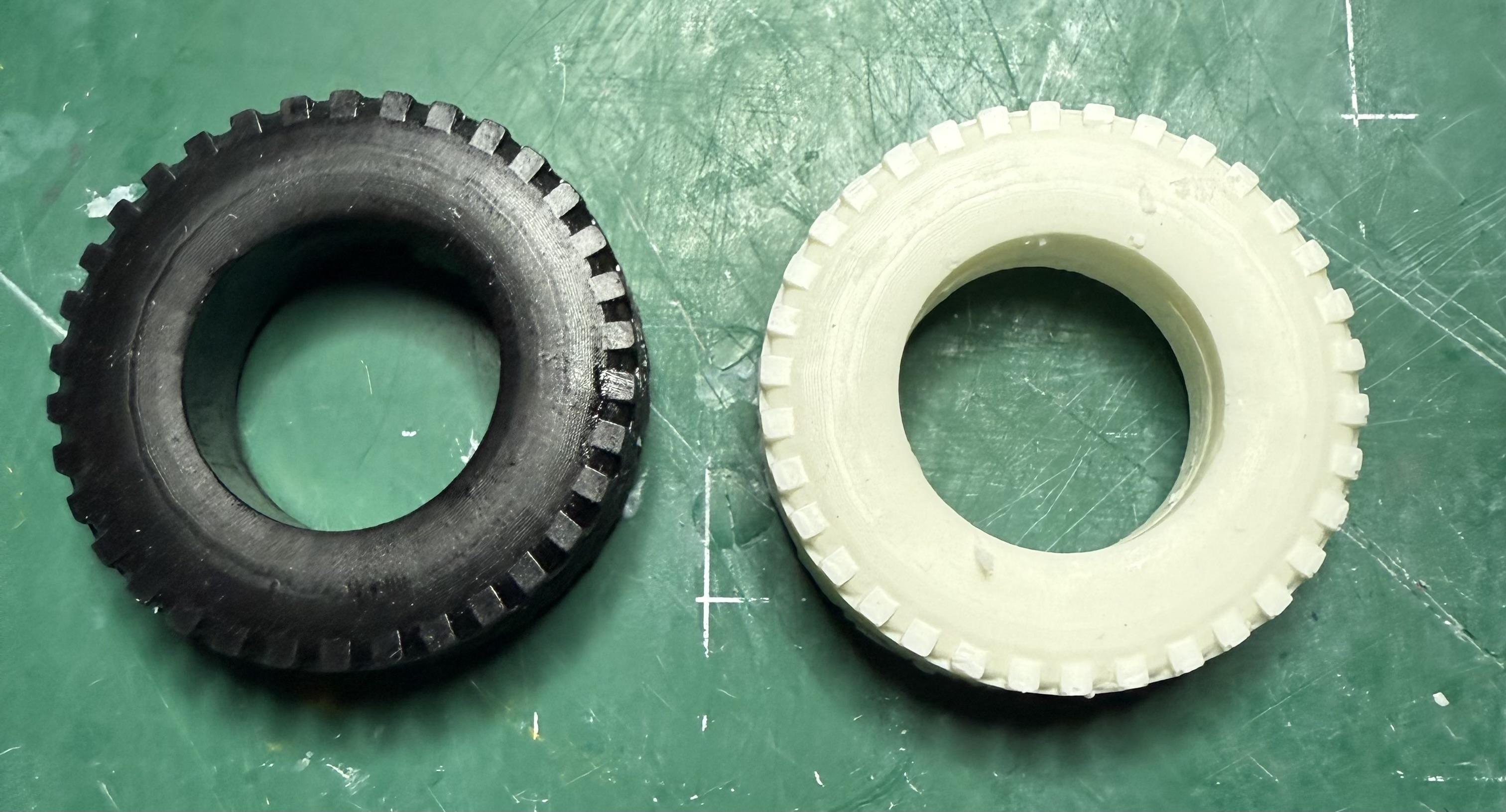

Charlie, Here are the results of the tire mold following your instructions. They came out a lot better than my first attempt. The black tire is the master . I needed a heavier tread or knobby tire for some of the older rigs I am building. They will look much better than any of the rubber kit tires I have on hand. The backs of the molded tires are not as clean and crisp as the front face, but once painted they will be ok. Thank you. For all your assistance with the instructions! Dom

-

Maxim F model

Firebuilder replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Charlie, Where I was in North Jersey there were very few if any Maxims. The only time I ever saw one in person was at a muster. So for this build I am basing the cab on internet pictures. I did notice on later F cabs they added a blinker assembly. On this cab from Ranger the front trim pieces are not molded in, they give you 3 pieces of half round stock which has to be cut to size. I didnt think to sand them down to a thinner width, but now that you pointed it out, comparing them to photos, they do look a bit to large. I also liked your idea of an airport crash rig, but have not been able to find any reference photos for a maxim ARRF. The only one I did see was one with a different Maxim cab and the tires looked like they were from a tractor. Back to the trim I may try and pry them off and redo the pieces. Any other thoughts on this project from you are appreciated! Dom -

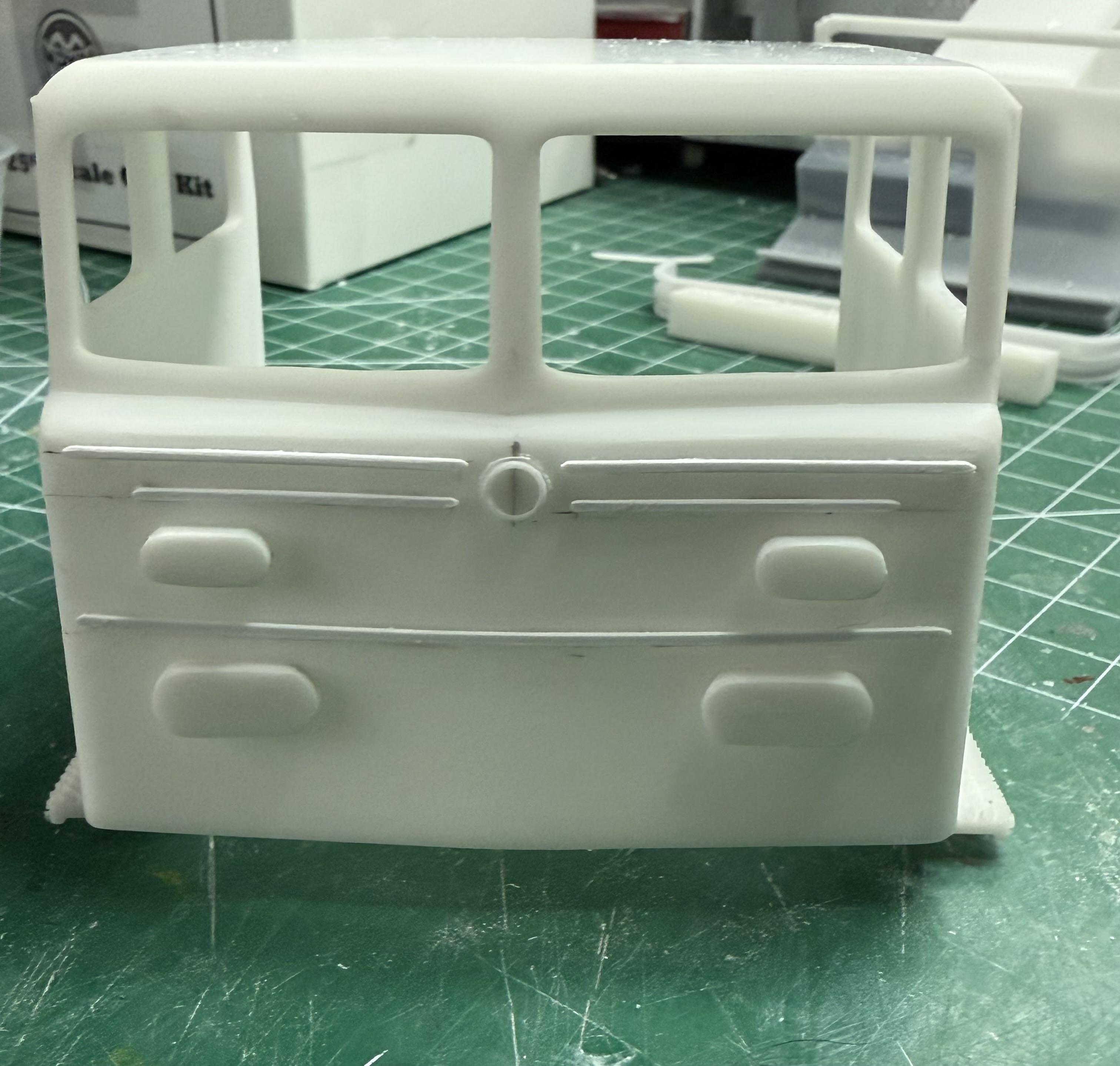

The industrial pumper is just about done. I have not been able to find decals that I need to complete it. So for now onto the next project. The cab is a Maxim F model. It is a 3D print from Ranger Detail Technologies. Almost Every thing needed for the cab comes with it, including the maxim decals. The was only minor sanding of some print lines that needed to be done. This is my first 3D print and I am happy with the quality and details of the print . I have not decided on what this build will be yet. Either a n aerial ladder , rescue or a pumper. I have started the assembly of the cab in the photos below.

-

Charles, Thank you for posting this, I see 2 steps where my attempt failed. Step 2 where you do 1/3 layer and let it cure, and also covering the face down side of the tire and sidewalls. I had just paced the tire flat on the foam board and pored around it! I plan on making a second attempt sometime this week. Again I would like to thank you for taking the time and providing the instructions you have given on rubber mold making. I have many molds for parts that I can replicate as needed now (couplings, foam cans, light bezels etc). Hopefully someday I can pass along this knowledge to someone else as you have done. Dom

-

Kenworth W-925 (mild custom)

Firebuilder replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks great Gary, nice job on the castings -

Mack B-61 Dump Body

Firebuilder replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great work once again!