-

Posts

1,931 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Rockford

-

Service Truck Kitbash

Rockford replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very clever stuff, looks the part. -

Resto Rod Autocar

Rockford replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Excellent stuff, very tidy. -

Farm Floater Truck 1/24th scale

Rockford replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Randy the blacksmith! Great stuff. -

The Same but “ a little “ Different

Rockford replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very realistic weathering, I especially like the mud in the tyre treads, it really picks out the tread. The chassis looks brilliant too. The only time our trucks got a thorough clean of the chassis and engine was when they went for their annual Ministry Of Transport roadworthiness inspection (present a dirty truck - instant fail), or when they went to be repainted which was only once in their lifetime usually. Weekly, the drivers did their best but they were mainly interested in the cab so they didn't get dirty just working the job. In other words, what you've done is representative of a real feet truck. Well done. -

Pete 359 tanker with trailer

Rockford replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

You need to print a copy of yourself to sit at your desk in work! You'll still be working faster than many I'm sure. Nice progress on the job. -

Brockway 260 Dump

Rockford replied to Warren D's topic in Model Trucks: Big Rigs and Heavy Equipment

Very nice piece of kit that. -

M-20 and M-9 trailer are complete.

Rockford replied to Chariots of Fire's topic in Model Trucks: Big Rigs and Heavy Equipment

That's craftsmanship right there, making something of museum quality from pretty much nothing. Unbelievable! -

Lee, you're very naughty dropping bombs like that and then walking away! 😁 In all honesty I have pondered that project many a time, I'd love a Wilson. I've considered reducing an AMT kit but I'm so sentimental I wouldn't be able to face it, I'd have to build it and buy a tractor to go with it. So the only route is one of my own making. 🤔 By the way, you said not to get too stupid, I think I missed that bus a long time ago!

-

1/32 1977 Chevy Bison Steel Hauler.

Rockford replied to Pete68's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Ha! It's nice to see more snapper subjects on the site. The General was the first snapper I ever built and I was amazed at how well it went together and how good it looked. I ended up with quite a few. You're doing a great job there Lee, looking forward to seeing them parked together. -

1/32 Mack F700

Rockford replied to The Brush's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

You're one clever beggar! You think outside the box on things all the time. Great work on the door panels and windscreen, AND you're making it all repeatable by casting them! Brilliant stuff. -

Good choice. You're right, 1/32 could have been more than just snappers, look at what AMT did with 1/43 scale, sadly that only stretched to a few kits too. Both scales could have been so much more but it appears that door closed decades ago and the best we can expect is reissues of old kits at best, no new subjects. Revell reissued most of the Monogram 1/32 snap kits with lacklustre stickers instead of the original, and decent, decals so we can see their regard for 1/32 scale. It's only going one way. Enjoy your 359.

-

Farm Floater Truck 1/24th scale

Rockford replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This is just something else! Brilliant. -

International V190 Quarry Dump

Rockford replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I've never seen a tailgate setup like that. This will be interesting. -

I am odd, I do seem to have attached myself to 1/32 now. I do enjoy seeing other 1/32 builds, helps ease my scale isolation, but I would build 1/24-5 if I had the space. There's so much more detail right out of the box, chassis detail, engine, axles, brake chambers, steering. There's also a host of aftermarket parts available and the kits are generally cheaper than 1/32 kits on Extortionbay. I do have a few AMT 1/25 kits to build because they're very special to me, kits I built in my youth, but I can't afford the space to build any more than those. I'm happy for others to chip in on this page with their feelings on the matter. I would not want you to make a choice that disappoints you. I know others have.

-

1966 Peterbilt Unilite 352 COE

Rockford replied to RoninUtah's topic in Model Trucks: Big Rigs and Heavy Equipment

With the trailer attached it's a real time capsule of a truck. The paint job looks perfect for the era too, well done. It took a lot of work making the little adjustments to backdate the cab. You've got me thinking about a 1/32 scale Unilite 352 now. -

Pete 359 tanker with trailer

Rockford replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great stuff! Another unique build. Well done. -

Mid 60s Peterbilt Unilite COE

Rockford replied to RoninUtah's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

You've done a brilliant job on this mate, it's a Peterbilt but not as we know it. You've educated us with this build, I only thought of Unilite referring to the conventional, the cabover was just a 352 or a 352H. Well done, it looks great, a build to be proud of. I noticed the three centre clearance lights are green, I've never seen that before. -

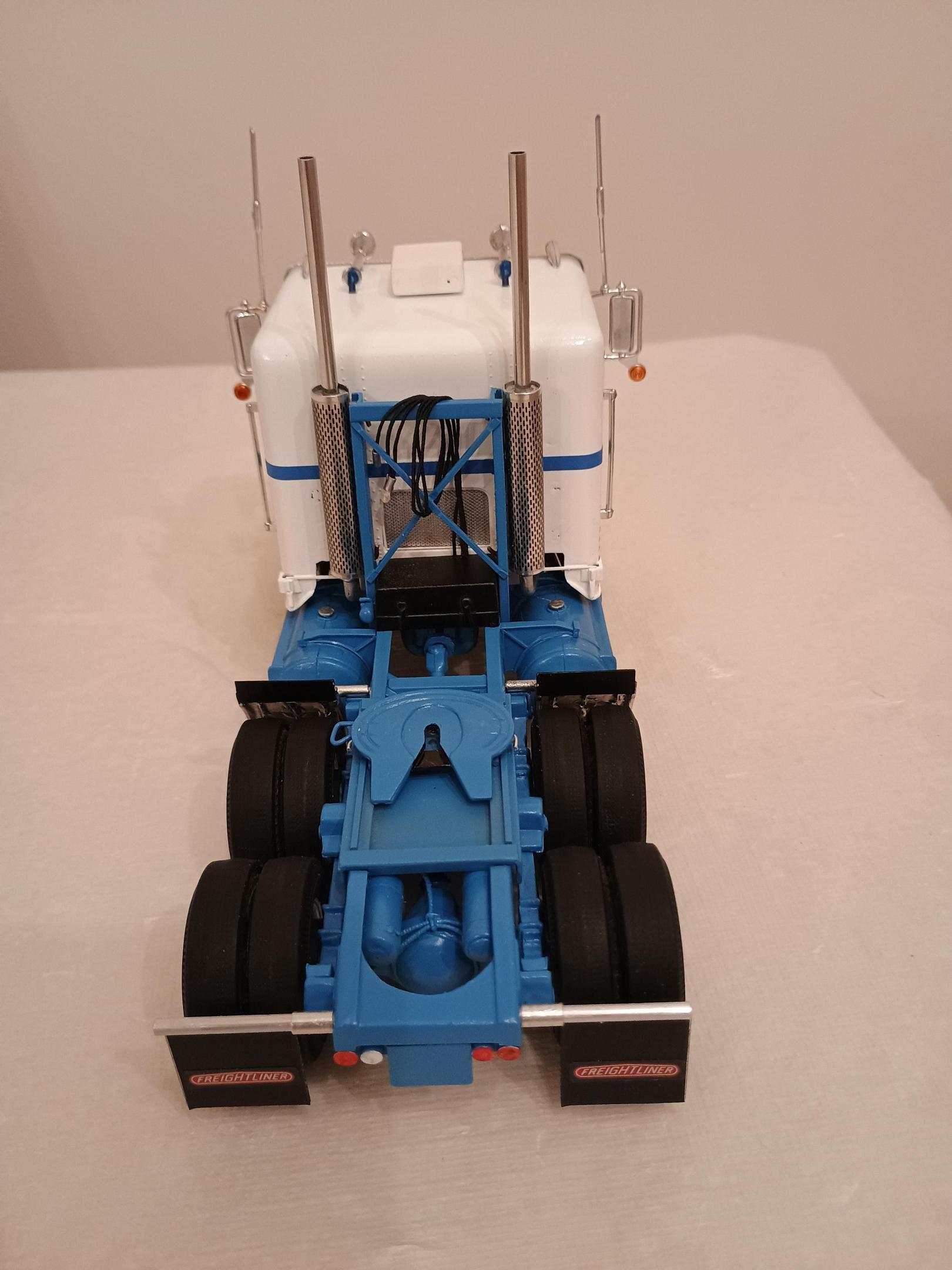

1/32 Freightliner cabover

Rockford replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I don't know what buying and selling houses is like in other countries but in UK it's such an archaic process. I'm sorry I started but it's got to be done. -

1984 GMC General “Autumn Almond”

Rockford replied to Pete68's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Those colours really blend well together, especially with the stripe. I'm salivating. -

1/32 Freightliner cabover

Rockford replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks lads, I'm really happy with it and the workaday appearance of it. Brian, my trucks chop and change trailers because where we live is so small that there's no room to display more than one truck at a time, the rest are stored away 99% of the time. I also come from a haulage fleet background where drivers regularly swapped trailers from day to day from flatbed to tipper to powder tank depending on the demand. Some days I'll get some out and dot them around the place but they have to go away after a while as the place looks so cluttered. We're in the proces of buying a two bedroomed house at the moment as we're both pretty much retired and our little apartment is proving somewhat claustrophobic with both of us here all the time. In the new place we have a garage with windows and power but we're not there yet and the amount of garbage you accrue living somewhere for 25 years is just staggering! We have a lot of sorting to do but hopefully I'll have somewhere to display my trucks and a dedicated space for building. -

Yes another Freightliner but a 1/32 Snaptite job. Chassis shortened, batteries relocated, cablocks scratch built, sliding fifth wheel scratch built, quarter fenders scratch built, steps opened up on the cab, bumper cut down, drive wheels deepened, scratch built exhaust stacks and framework, steering mechanism fabricated, tank brackets scratch built and air tanks added, homemade decals, and a few other things I can't recall. This could be the last thing I work on for a while because we're selling our little apartment and moving to somewhere a little bigger. I've had to hide all my trucks and tools to make the place more appealing to prospective buyers. I've had to pack my garage and the Chevy with kits. I can't work indoors anymore and it's too cold to work in the garage. I'm a spectator for a while.

-

1/32 Freightliner cabover

Rockford replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Pulled the final pieces together this afternoon. Added the bracing struts for the cab steps (almost invisible), popped the bling back onto the cab and glued the Aircon unit onto the roof. Glued the cab on and that's it. I'll post it in Under Glass. -

GMC Astro double bunk

Rockford replied to The Brush's topic in Model Trucks: Big Rigs and Heavy Equipment

What a fantastic piece of work. Excellent paint scheme. Any Astro is a sight for sore eyes but this is a stunner.