-

Posts

1,574 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by 64SS350

-

Resin to Plastic glue options???

64SS350 replied to WillyBilly's topic in Model Building Questions and Answers

I would say yes to CA (super glue) being the best option. That should make a nice ride. -

Some items over the last two days. Charcoal filter for paint booth(for now), UV curing resin, and a black Friday airbrush with a free bottle of paint to try.

- 39,223 replies

-

- 2

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

I may have a '66, I'll check after work today.

-

68-72 Suburban scratch build

64SS350 replied to 64SS350's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

-

I also don't understand the shipped by Autoworld with a Hobby Lobby sticker. But when ordering from Amazon, you do have the choice for items to be shipped in... manufacturer's package...or packaged by shipper in additional packaging. FYI for later...

- 39,223 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

-

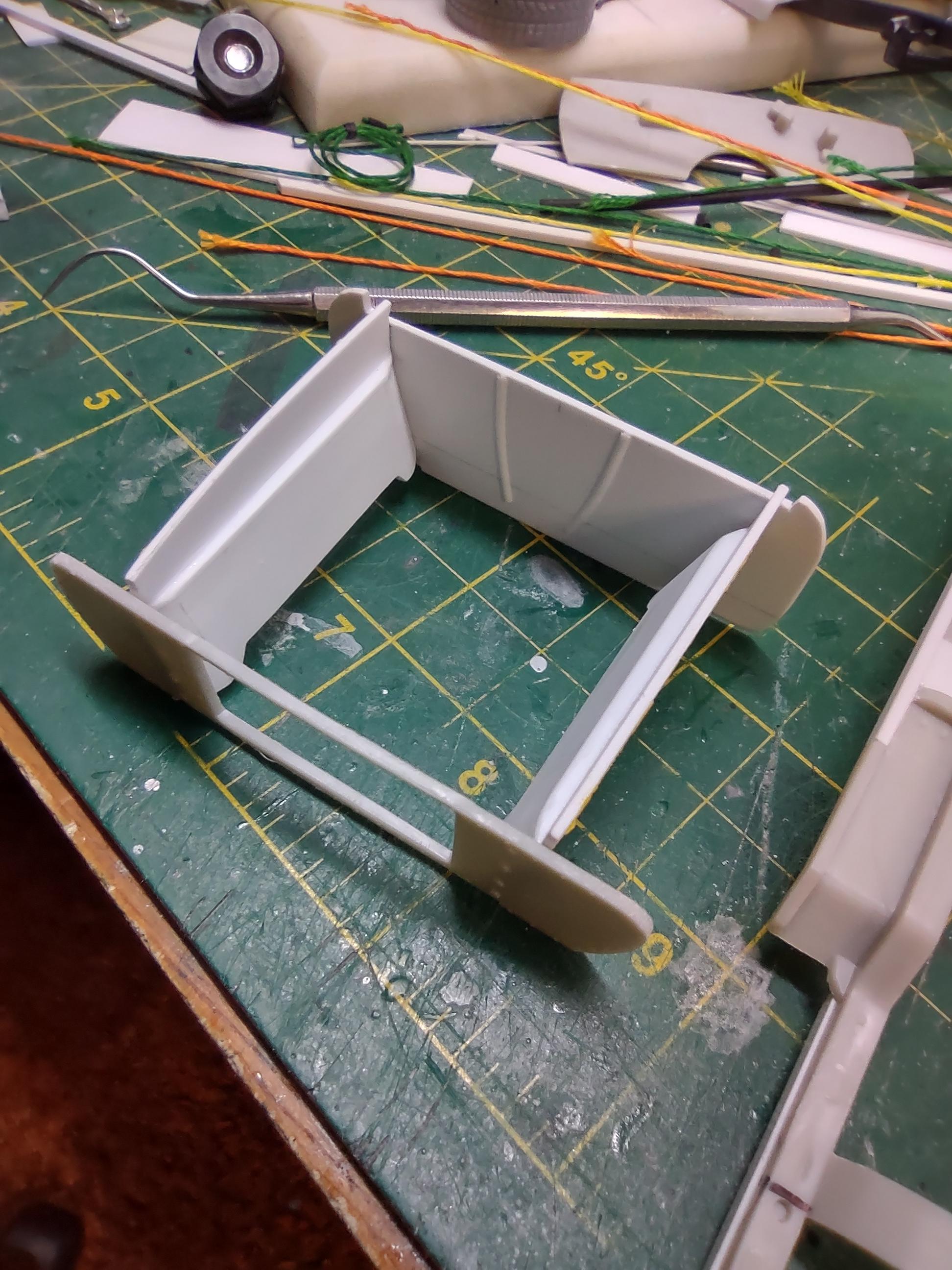

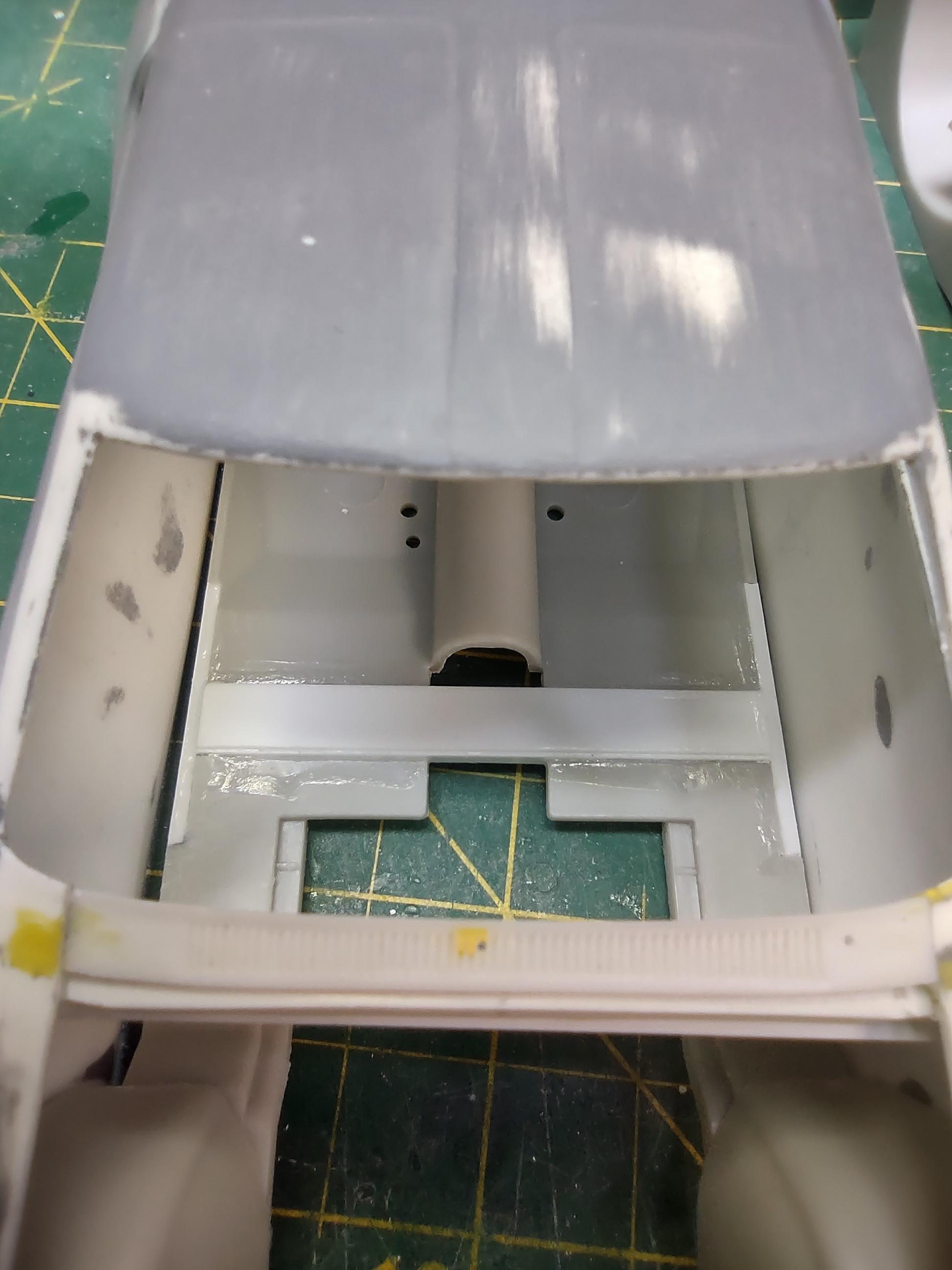

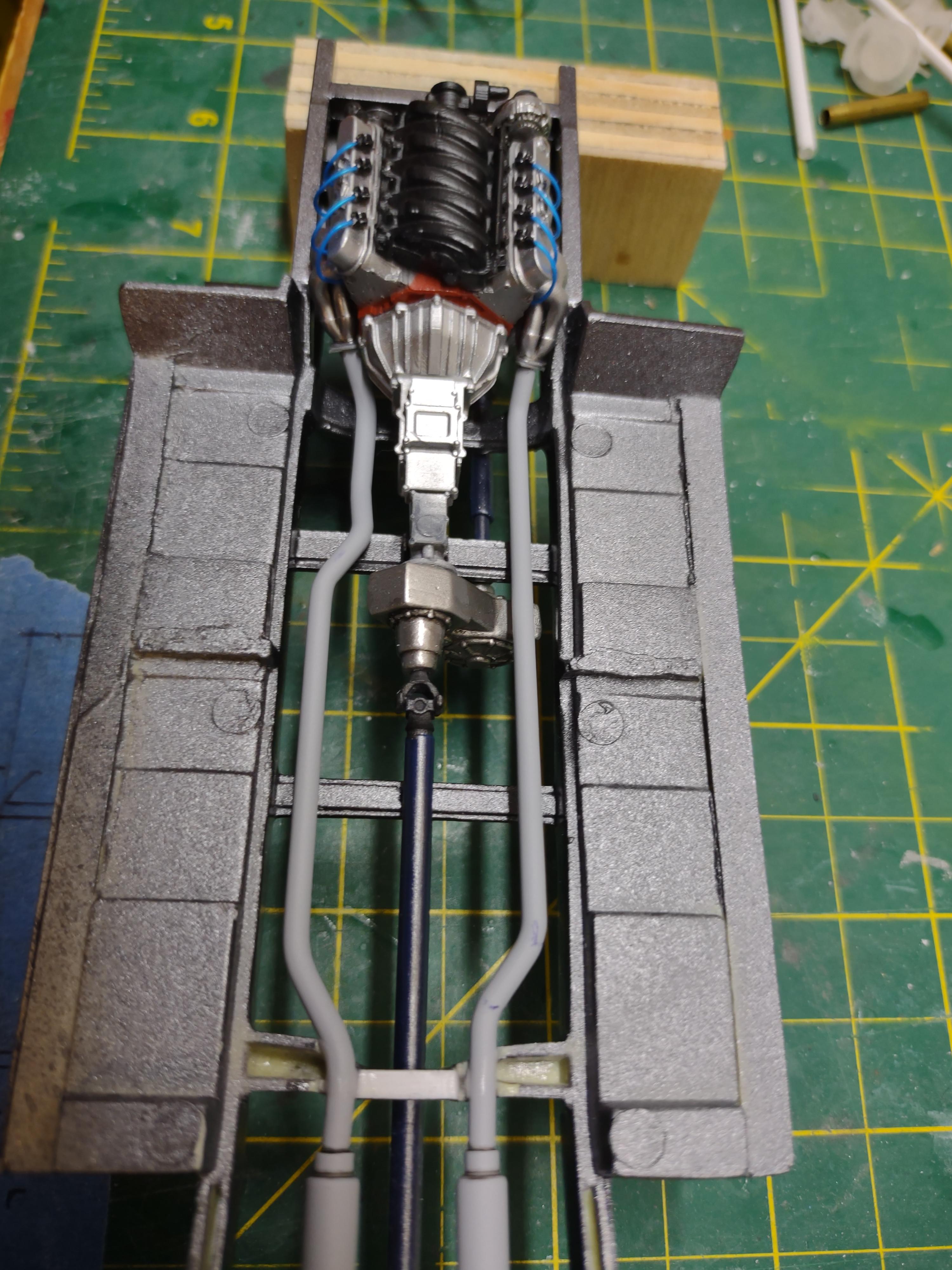

Some fabrication of the engine bay so far. Currently smoothing and blending things together. Also going to upgrade the rad support....the Nova one leaves something to be desired. Front suspension is next.

-

I know long beds have been made if you choose not to splice two together (but that's half the fun). RMR makes one, there may be a 3D version out there also. I will say RMR's has a separate bed floor..if that helps

-

Well ...you gotta have something to do when glue and paint are drying!! Right?!

-

These came Saturday. Some new super thin CA and the LED UV light. I wanted to try a different brand of CA, cheaper and a "non clogging tip". The UV light I purchased because I've received multiple orders of 3D parts that are not 100% cured.

- 39,223 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

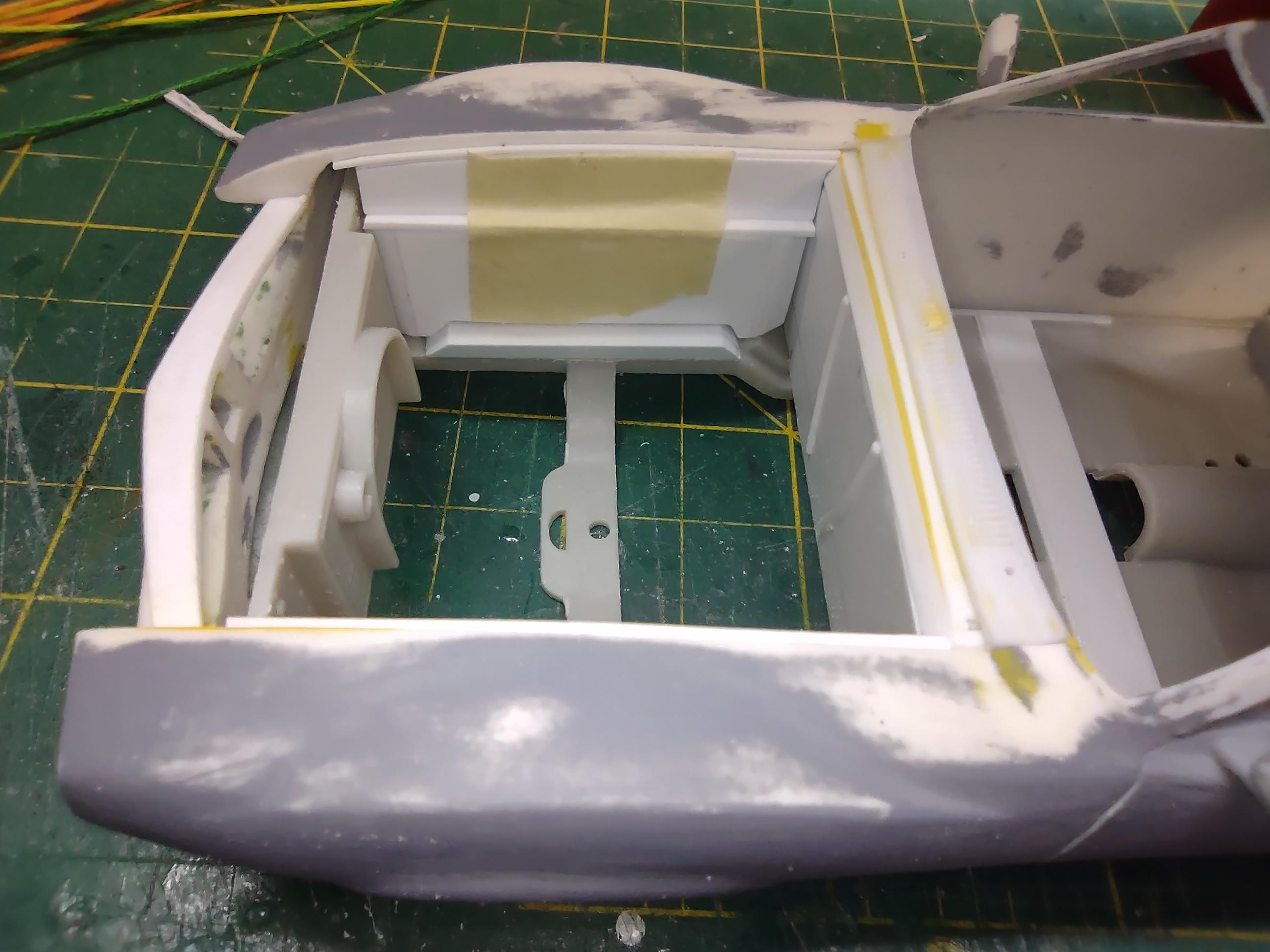

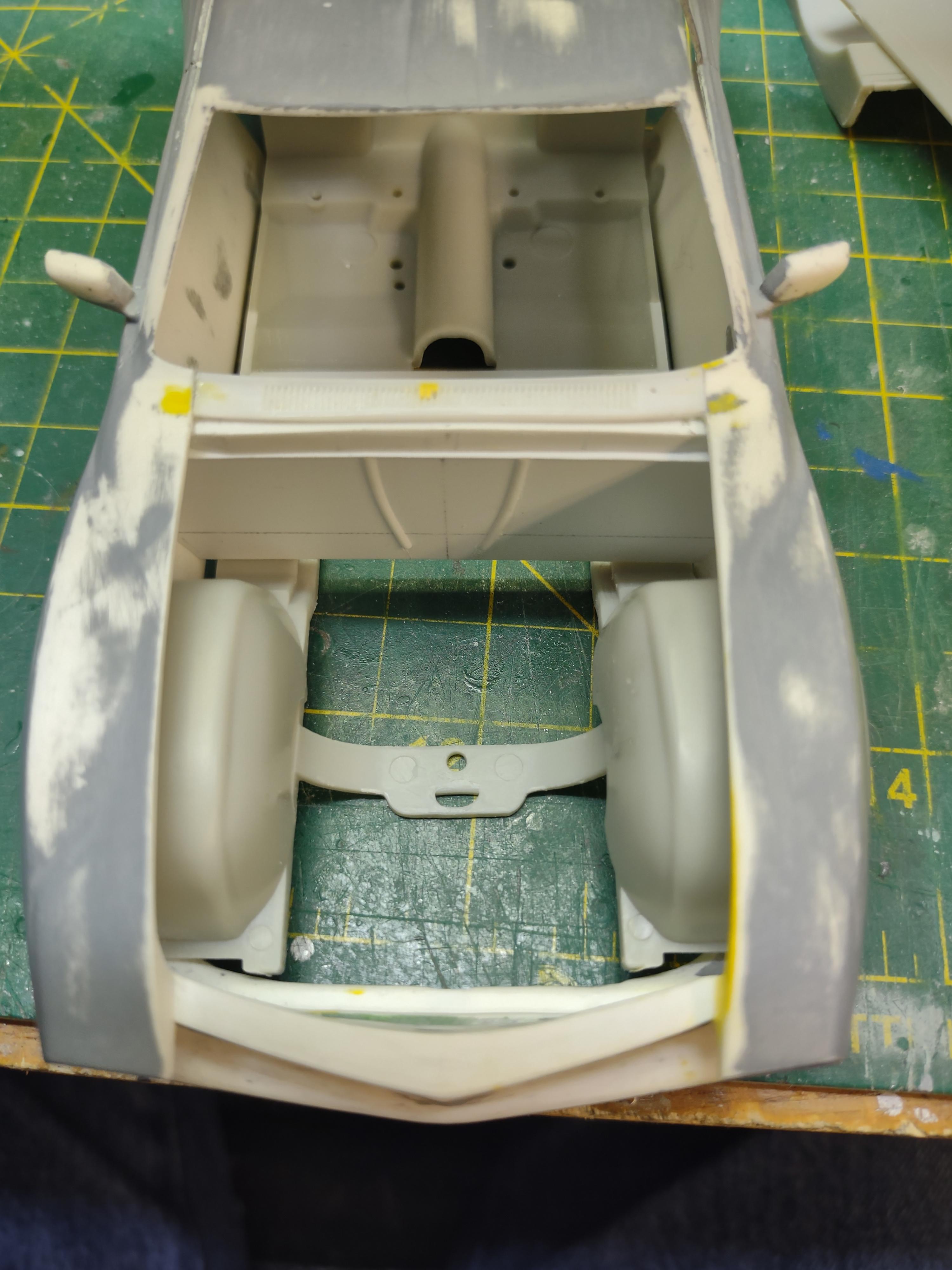

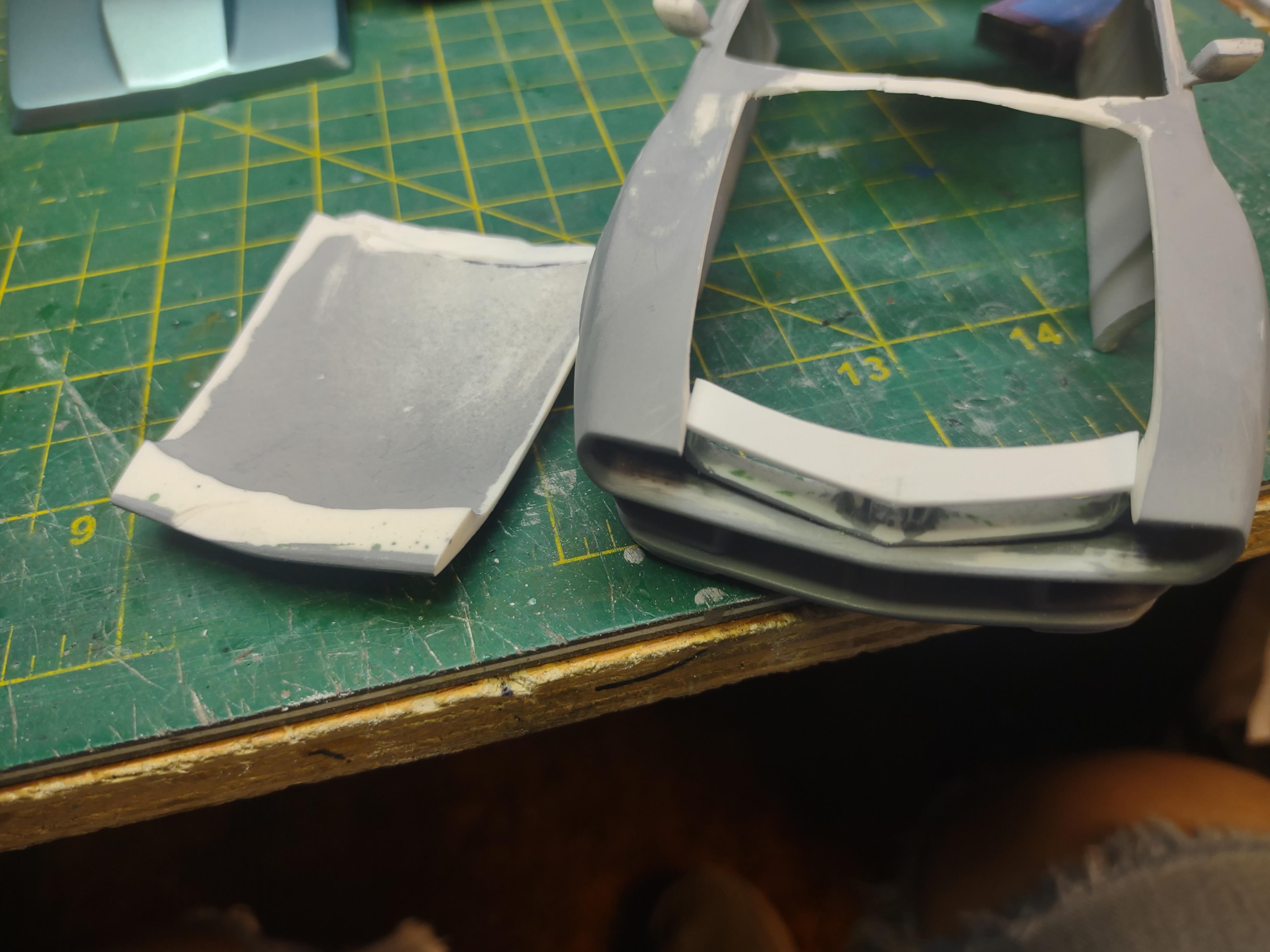

Recent progress. I have opened the hood ( because this has to show it's motor ) and the panel lines weren't great. The trunk will also be opened for similar reasons. The chassis is from the '76 or '79 Nova, lengthened so far, the suspension will be changed also. Inner fender wells won't stay from the Nova kit.

-

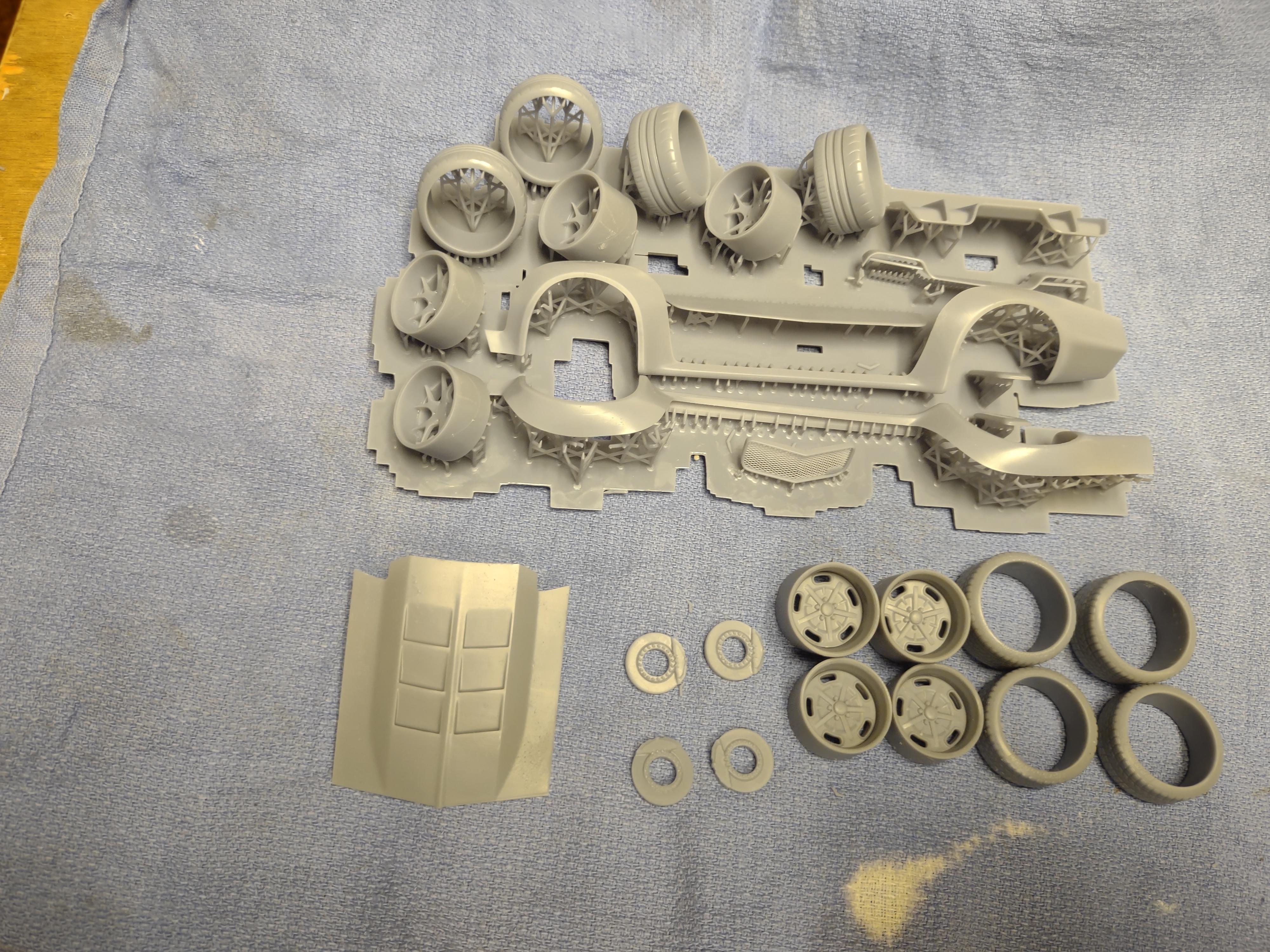

I know many of us have multiple projects going or sitting in queue, and I am no different. While trying to figure custom ideas and such, I shift to others to help move them along and hopefully....clear some space on the bench or as I call it ..'the staging shelf'. I have had this body since mid 2021, and after purchasing realized it was a slush molded body. The outside is nice, but had a ton of pinholes and some details needed enhanced. I recently decided it was time to move forward with it and after showing it to a friend, we have plans for it when it is closer to being done. Here is my current progress starting of course with the raw body.

-

Making my paint booth from galv. sheet metal

64SS350 replied to 64SS350's topic in Tips, Tricks, and Tutorials

I'll try to add some pics, I haven't done a lot on this. Got the speed control mounted and drilled the whole for one switch. I've been debating on it's final location, which changes how I vent it. Ultimately I want to vent it outside, but now it's getting cold to be able to install a glass block dryer vent. Also new outlets may need to be added. -

Resin 64 Chevy Crew Cab Pickup

64SS350 replied to 64SS350's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

The more I look at this on the staging shelf, the more I dislike the look from the front. I think the Axel tubes were fine, I didn't account for the huge backspacer on the rim. You can't see it in these pics, but I think I'm going to remanufacture the axels again. Better now than when completely finished! Updates when I tackle this adjustment. -

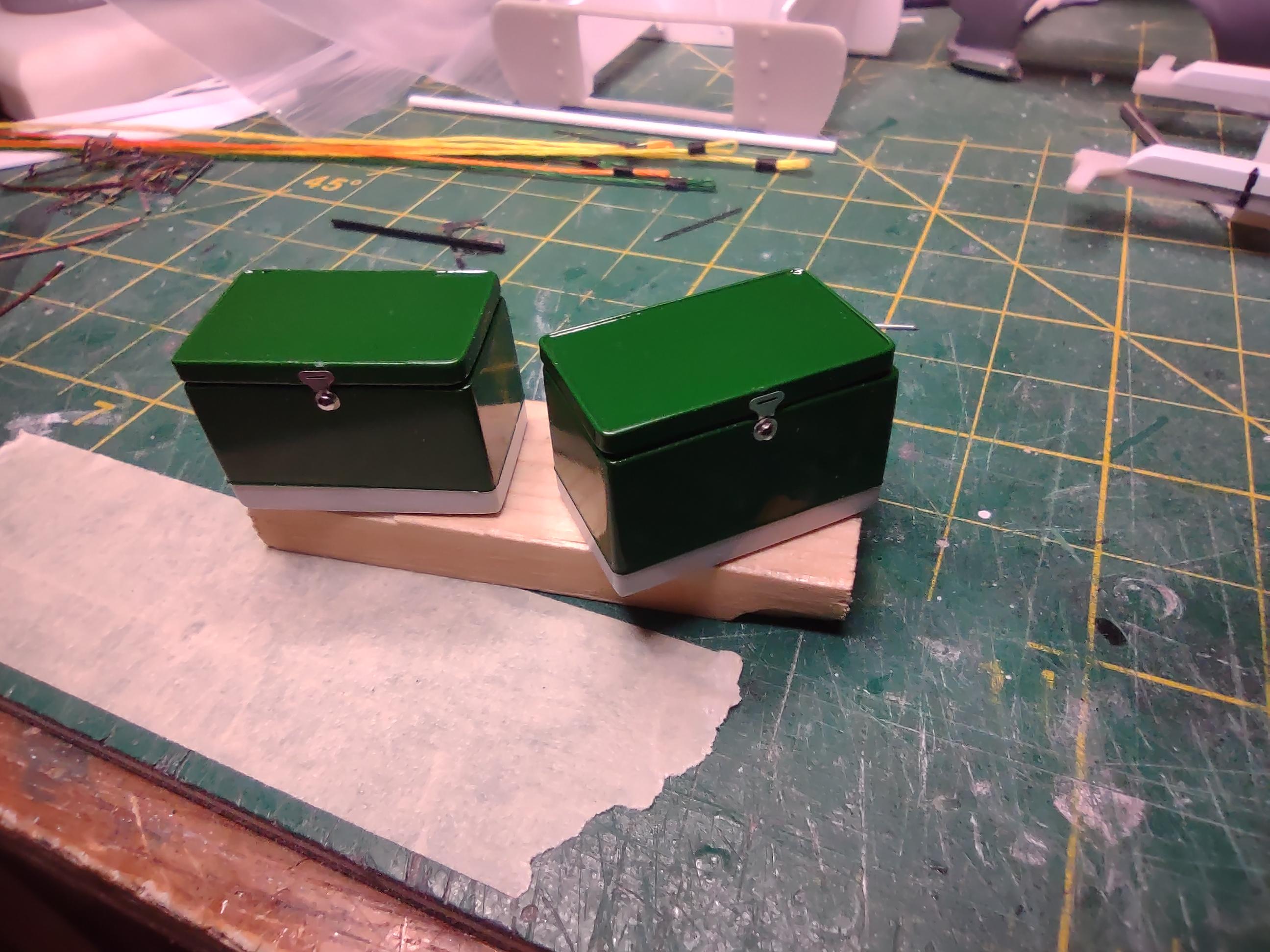

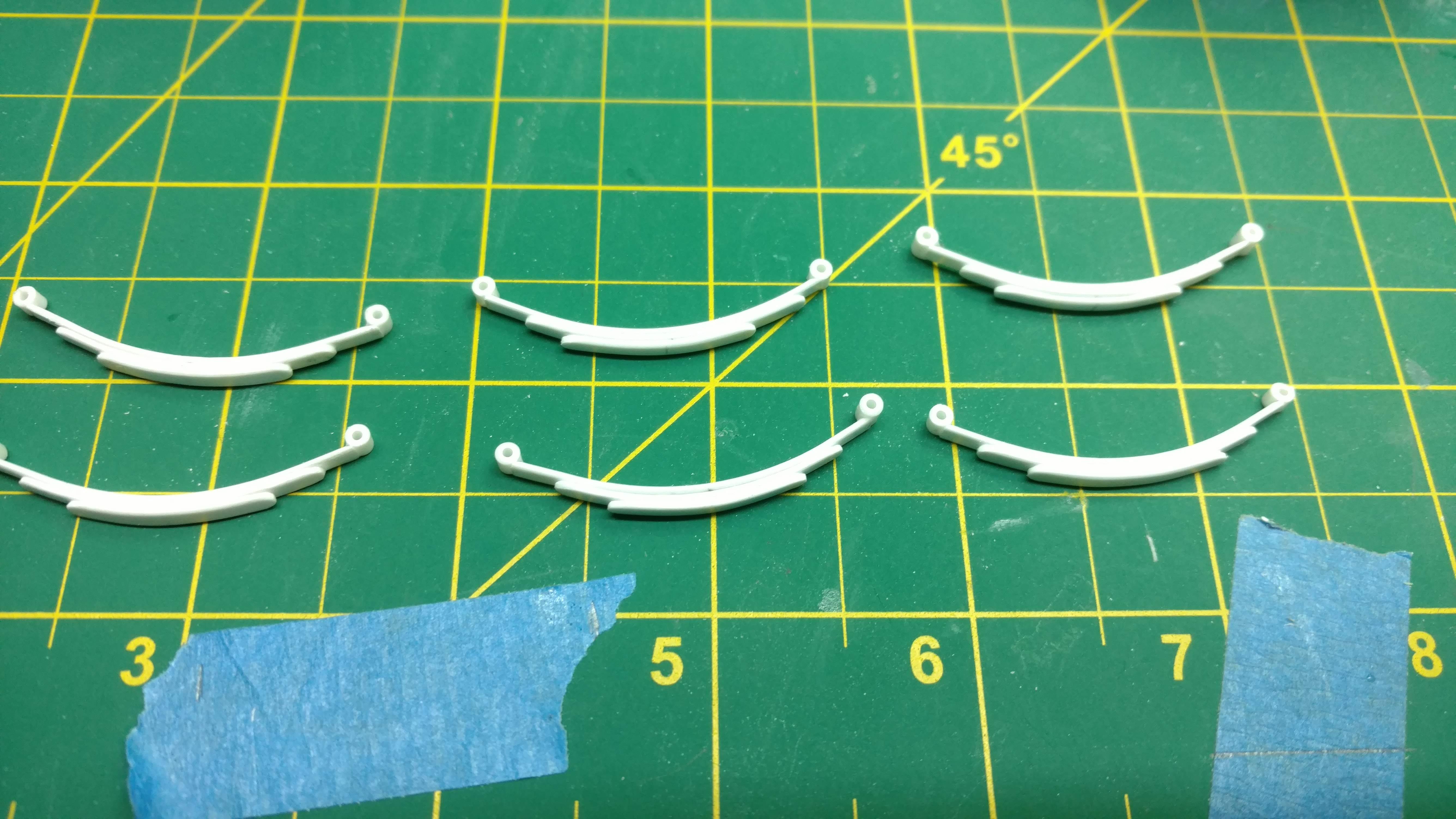

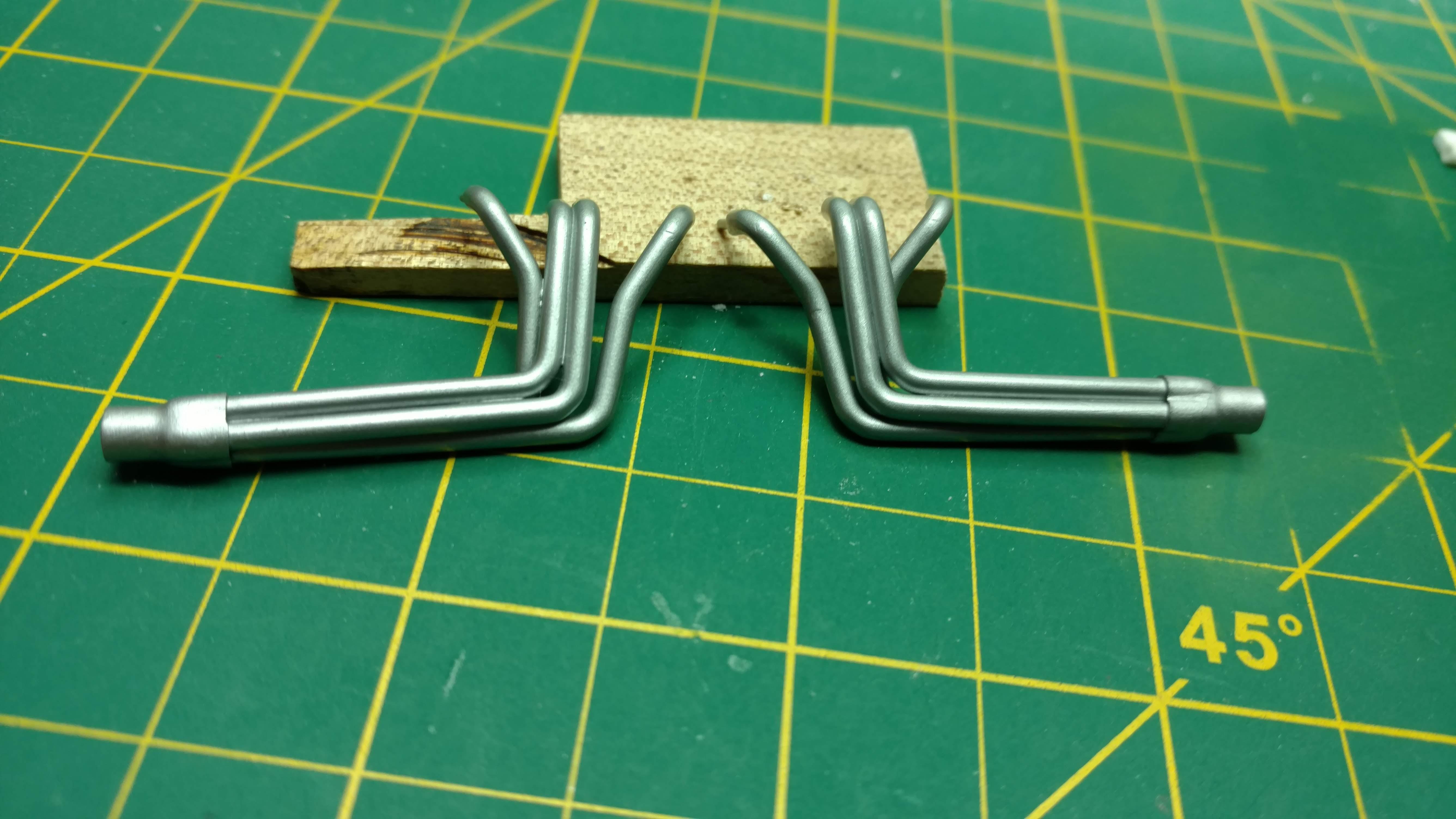

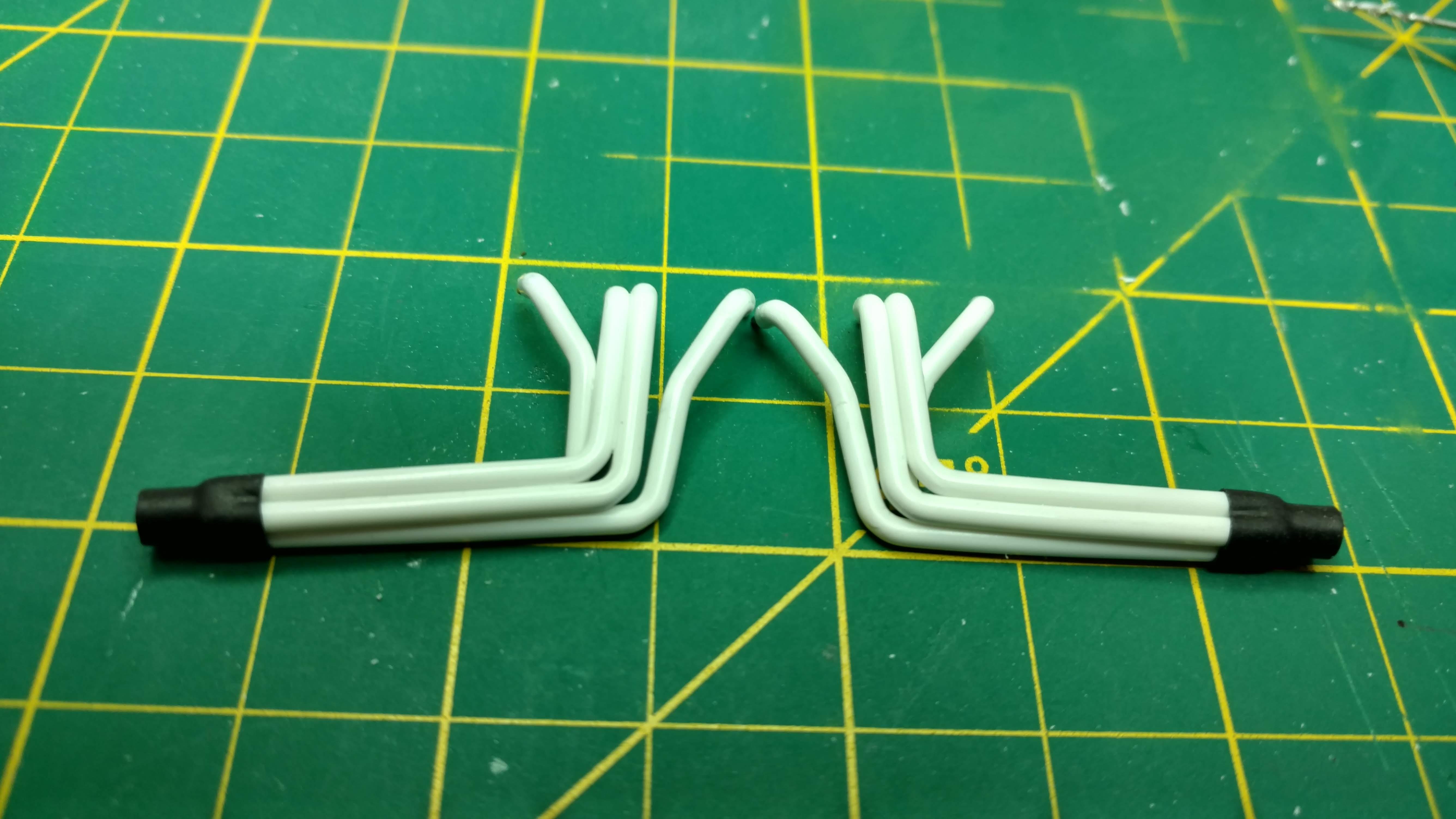

If you don't find what you are looking for, fabricating your own isn't too difficult. You will have some fabrication even if you get premade parts. Here's some pics of a style I learned from someone's tutorial , which I adapted for some builds I did to replicate my friends car.

-

68-72 Suburban scratch build

64SS350 replied to 64SS350's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

A little update, I repainted and cleared the hood awhile back with Tamiya Gloss, which is not very glossy. Decided to fix a couple issues with that and polished with Meguiar's Ultimate....and I am SOLD on it! I've had it for awhile, just tried it tonight... I'm done with Novus! I am still going to add a few detail items on the roof rack, but mostly done. -

https://ebay.us/m/e7i93Y Hooligan scale model parts, he is very reasonable and high quality!

- 39,223 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

- 39,223 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

aluminum rod inside styrene tube

64SS350 replied to fiatboy's topic in Model Building Questions and Answers

It's a heat shrink tube I picked up from a supply guy at some of our shows. I used auto primer first, so..... -

aluminum rod inside styrene tube

64SS350 replied to fiatboy's topic in Model Building Questions and Answers

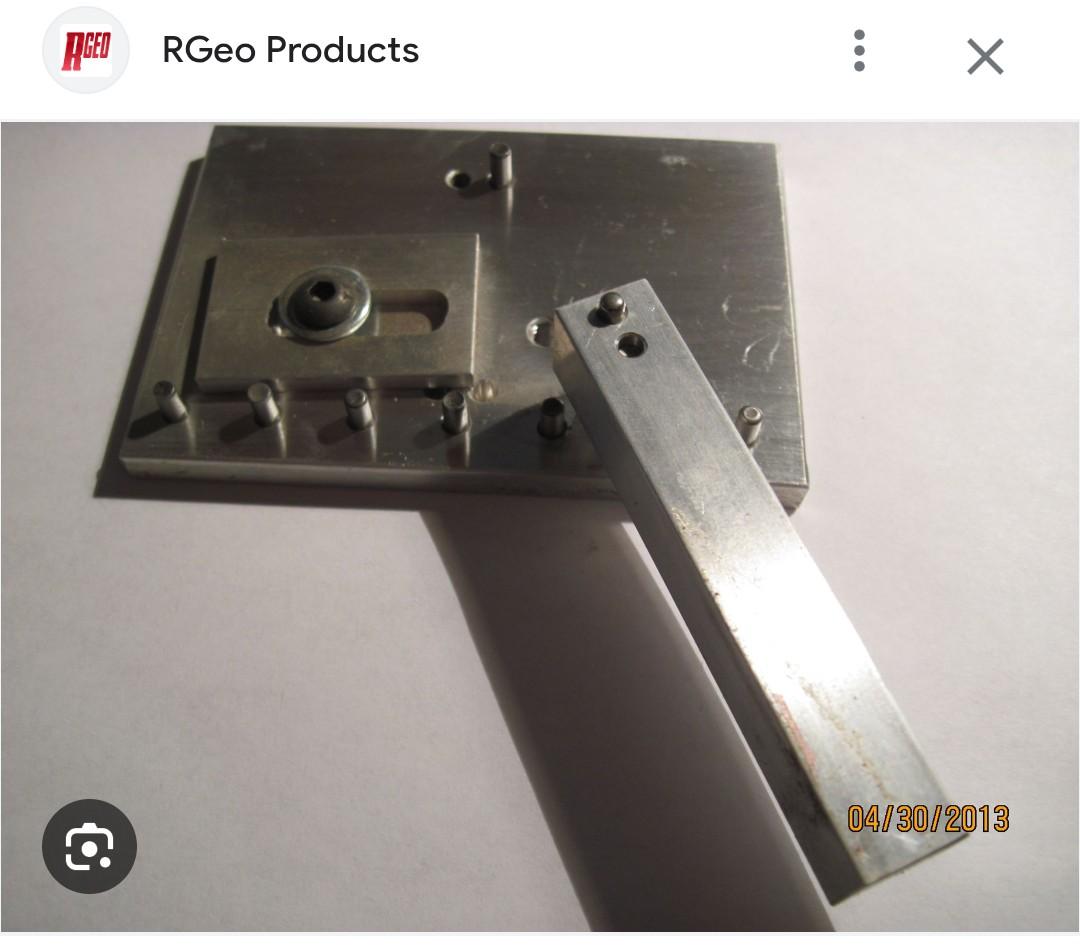

This the same one I have, made by R-Geo. I think he was/is from PA. The pins along this side with the stop are setup for a couple sizes of wire, I use the two pins on the other side mostly.( Well apparently this guy is missing a pin, but ..) -

aluminum rod inside styrene tube

64SS350 replied to fiatboy's topic in Model Building Questions and Answers

As an alternative....I use solid styrene rod from a guy on eBay that sells it in lots. I have about a 97-98% positive outcome with his materials. I use a wire bender from my slot car days to do most of the work. -

68-72 Suburban scratch build

64SS350 replied to 64SS350's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

So I borrowed a tire from a set I had, now I have a spare! Also made a kinetic recovery rope for interior detail. I have a few more additions for the roof rack coming. And I finally dared to glue the rack to the roof... -

He is not making the paint, but has ..I believe teamed with partners to make paint and influenced or has helped in designing an airbrush. The producers of products use his YouTube presence as advertisement. IMO

-

Looking for a 1/25th 2017 Camaro convertable

64SS350 replied to GLMFAA1's topic in Car Aftermarket / Resin / 3D Printed

Contact Ron at RMR, he does.