-

Posts

38,203 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Good rattlecan (or any) paint jobs depend on two major factors: 1) Meticulous surface preparation and primer work, and 2) Developing good, consistent spray technique. Enamels can be difficult to get repeatable results from when shot right out of the can, which is why a large number of modelers prefer either automotive lacquers intended for real cars (like Duplicolor) or hobby-specific lacquers such as Testors and Tamiya. This hood is Duplicolor rattlecan... This is Testors... Airbrushing is another ballgame entirely. Unfortunately, there are many really GOOD methods that are used to get excellent paint finishes, and they could fill a thick book. Here's one thread on this forum. There are many more. Read as much as you can, do some experimenting, and try to develop more specific questions.

-

Real cars: set pinion angle/finding "true horizontal".

Ace-Garageguy replied to LDO's topic in The Off-Topic Lounge

A car doesn't need to be sitting level to determine these angles, as it's the crankshaft centerline that everything else is based on. While setting this up, it IS good to start with the car at as close to the finished ride height and stance as is practical with the tools at hand...particularly if it's carbureted. We usually use dummy coil-overs or something similar to achieve this when building a car from the ground-up, or if it's some kind of heavy mod / engine swap, the car can be ballasted to operational weight on its actual suspension (and the actual wheels / tires that will be used). Measure the angle the chassis makes with the ground, and when you jack it up on a lift, or put it on stands to work on, maintain this angle. The tops of the valve covers are almost always dead parallel with the crank centerline, so they can be used for placing an angle finder to determine final configurations on engine and trans mounts to get the desired angle of the crank centerline (which will naturally be the same as the trans output shaft) relative to the ground. You'll note that carbureted V8 engines usually have an obvious angle milled into the top of the intake manifold that's not parallel with the tops of the valve covers. This is to allow the carb to sit relatively level most of the time (when the tail of the crank is lower than the front to achieve the proper angle) so the float can do its job correctly. Usually, when building a V8 powered car, using an old carb-style manifold with a level on the carb mounting flange will get you very close. NOTE: DISREGARD THE MEASUREMENTS BELOW. THE ILLUSTRATION IS ONLY TO DEMONSTRATE THE ANGLE MILLED INTO THE TOP OF THE MANIFOLD FOR THE CARB BASE. It's particularly important that the angles of the crank / trans output shaft and the driveshaft pinion shaft match when the vehicle is in its normal driving-down-the-road stance. Some suspension systems will allow the rear axle to rotate somewhat during acceleration / braking and bump / rebound (changing the pinion angle slightly) but you need to start as close as you can. -

Beautiful. I really enjoy walking / hiking in weather like that too, particularly close to the ocean, or in the desert.

-

X2. Great to see kids taking an interest in physical reality, and adults who take the time and make the effort to show it to them.

-

Electric wench... Then of course, there's the eclectic wench...

-

'57-'60 Ford T 950 Super Duty

Ace-Garageguy replied to leafsprings's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Fine looking progress. I love old heavy trucks (though I know very little about them), so this is a real treat for me to see come together. -

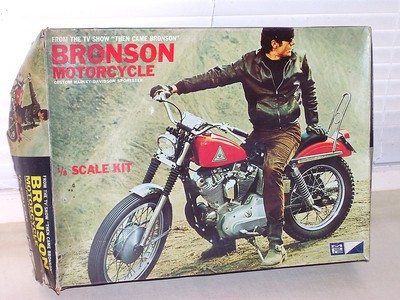

Thanks to all for your interest and comments. PART 2 There are a lot of relatively minor things to fix on this old model, so I'll be taking them one at a time as she goes back together. The handlebars were broken (and a previous repair at a different point seems to be strong enough to leave alone), so I drilled .025" holes in the broken ends to insert a length of steel pin for a reinforcement. The tires had both shrunk (badly warping the rear rim) and dissolved parts of the rims where the chrome had been scraped away for glue by the original builder. I was able to get the tires off the rims (with no additional damage) with the aid of a small, sharpened and bent screwdriver blade used like a tire-iron. The tires close to the rims are from this model. The ones on the left are repops from the same tooling, sourced from a fairly recent reissue of the old MPC Honda 750 race bike. Look closely, and you can see how badly the old ones have shrunk. The OD is almost 3/16" smaller on the originals. With some VERY careful sawing using a PE blade from MCG, I was able to split the heavily glued rims, again with very little additional damage. You have to work SLOWLY, with lotsa patience. The rims had also been assembled out-of-register, so the spokes didn't line up correctly. The new tire, a 19", fits the old front rim perfectly (but more on that later). The joining faces of the previously split jugs and engine cases were "milled" flat on a piece of 180 grit paper stuck to the bench. One jug, engine cases, and handlebars, glued back in correct register. Again, files and sandpaper will be used to address the seams after overnight drying. The engine cases are supposed to have a seam where the two halves are bolted together, and this will be re-scribed after the register problems are corrected.

-

-

What non-auto model did you get today?

Ace-Garageguy replied to chunkypeanutbutter's topic in The Off-Topic Lounge

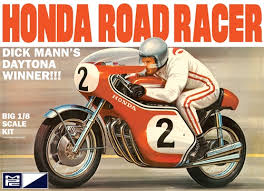

Speaking of which...I just picked up a couple of much older reissues... ...and a semi-ripoff of the Monogram halftrack... -

Great to see stuff like this.

-

An exercise in fabrication - 426 Hemi DONE

Ace-Garageguy replied to landman's topic in WIP: Model Cars

Nice going, and great encouragement for people to stretch themselves a little when they don't have the part they want on hand. -

Where Belly Tankers Come From

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

The Baby Albatross sailplane used a similar but not as cool laminating procedure to make its fuselage. If I remember correctly, the forms for this little guy were made from concrete. That's a Staggerwing wing hanging on the wall, by the way. The hangar is in Tehachapi, Ca. -

Where Belly Tankers Come From

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

You never know. That's a lot of effort to put into making something for one use. The spiral wrapping of the lamination plies particularly looks like overkill for a one-use unit. Great photos though, and now you have me going off on another search... -

Where Belly Tankers Come From

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

Very interesting link and photos, but those are all laminated wooden tanks. The "molds / forms" would have been large steel press tools. The 315 gallon P-38 tanks that are the most often seen lakester bodies are made from aluminum pressings, with riveted in ribs / bulkheads, and the two halves are bolted together. -

Stay safe, Carl.

-

COE Hummer

Ace-Garageguy replied to Grzegorz's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

X2. -

Anybody remember the one-season TV series Then Came Bronson ? The bike in the show was a modified 1968 XLCH Sportster. MPC made a kit of it, released in 1970 and '71, and never again (as far as I'm currently aware). Most of the survivors are partial kits with missing and broken bits, or gluebombs...and usually pretty expensive. "Bout a year ago, I picked up a semi-complete but poorly built and broken one. After a lot of research, collecting photos, info, and more parts, I'm ready to start the deconstruction and rebuilding process. First thing is to split some of the glued parts that are out of register (due to incorrect pin locations and sloppy building). I've found that an X-Acto chisel tip blade and a small hammer work very well for this sometimes. In the photo above, the shock unit on the right has been split apart, the halves surfaced, and then re-glued with the parts in correct alignment. After drying overnight, files and sandpaper are used to clean up the seams.

-

Model A Headlight Mounts

Ace-Garageguy replied to gwolf's topic in Model Building Questions and Answers

It just occurred to me that an easier way might be to find two symmetrical pieces of sprue that resemble the shape you want. Most sprue is round, but it's easy to flatten the sides neatly by gluing a piece of sandpaper (100-180 grit) to a very flat surface, and working the side of the sprue down. Turn over and repeat. This will also leave you with nicely rounded sides where you didn't flatten them. A lot of modelers try to scratch-build roll cages from sprue, but it's usually way too heavy looking in 1/24-1/25 scale. For this application, it might be perfect. -

Slant 6 cross ram

Ace-Garageguy replied to oldnslow's topic in General Automotive Talk (Trucks and Cars)

Put me on your list. I have a couple of "resting" projects that need those engines. -

Agreed 100%. A knockout build.