-

Posts

1,578 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by redneckrigger

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

GMC Astro

redneckrigger replied to Old Buckaroo's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

When I was painting the trucks in the fleet of the company I worked for, the spyders got painted white and the rims were gray. Looked clean and sharp and matched the red color of all of the trucks. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Interior done, shift linkage installed, trailer air and electric done, glass installed, engine piping underway, pieces and parts, pieces and LOTS of parts..................more to come. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Improved Lighting & Magnification Options?

redneckrigger replied to nitrojunkie's topic in Tips, Tricks, and Tutorials

Those headband lights are VERY good. I use them for building, walking into the woods before sunup when hunting, and working on my car. Sure beats holding a flashlight in one hand! -

I use regular automotive paint, (enamels and base coats), purchased right from a paint supplier to the 1:1 industry. I buy it in half pints, and the cost is cheaper per ounce than anywhere else. Yeah, at 8 ounces it is a larger quantity, but I use my colors for lots of different projects, so it gets used. Then, I also use regular reducers, primers and clears. I HAVE used Mr. Surfacer, which is awesome, but hard to find except online.

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

3d Printed Hooks and Shackles

redneckrigger replied to mdlbldrmatt135's topic in Truck Aftermarket / Resin / 3D Printed

How about shackle type tie downs for trailers and flatbeds, the type that gets the clip welded to the body? Would love a few dozen of them! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

New Brush Truck Started

redneckrigger replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Amazing......................looks like a real M52 being built! -

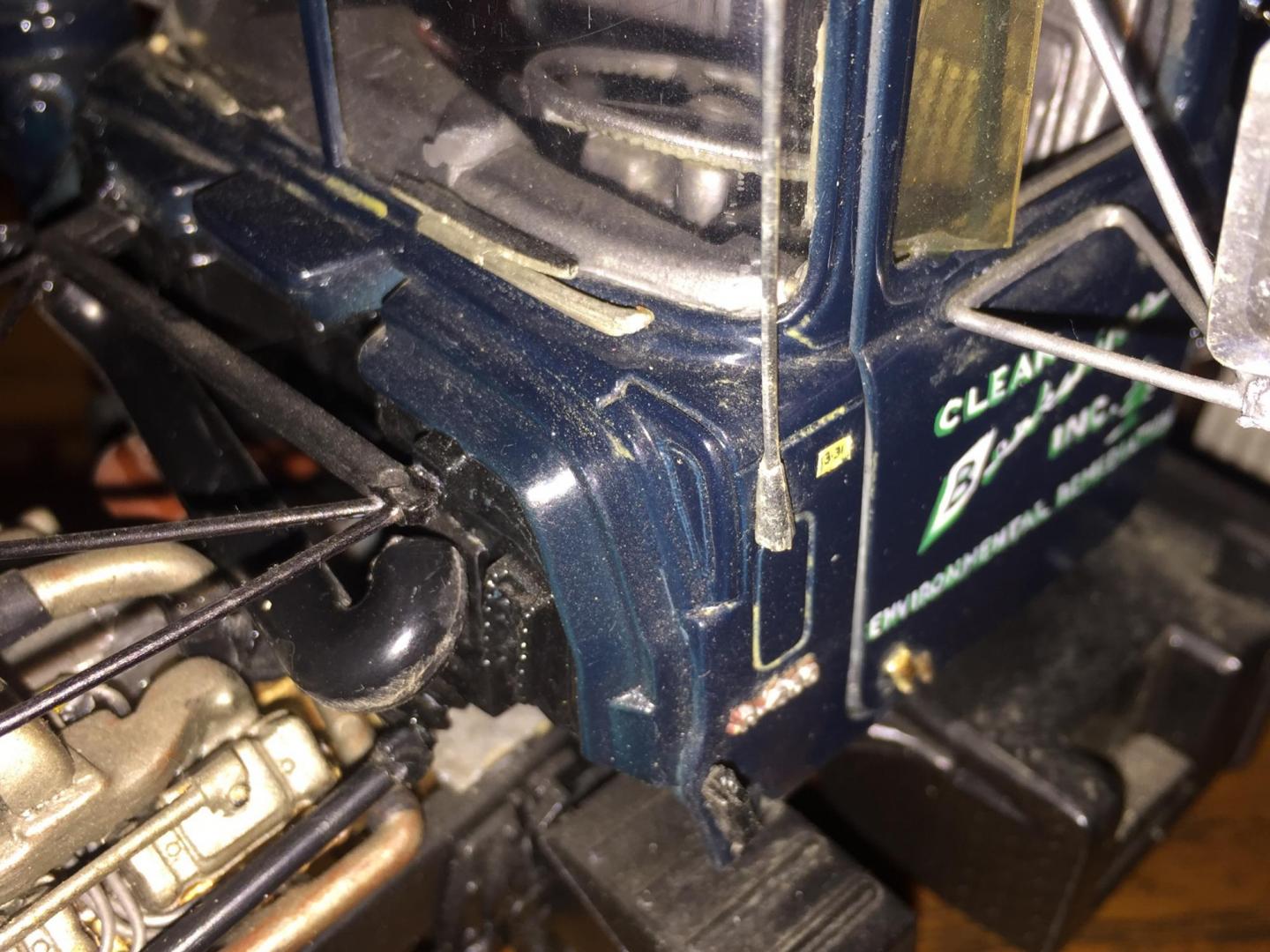

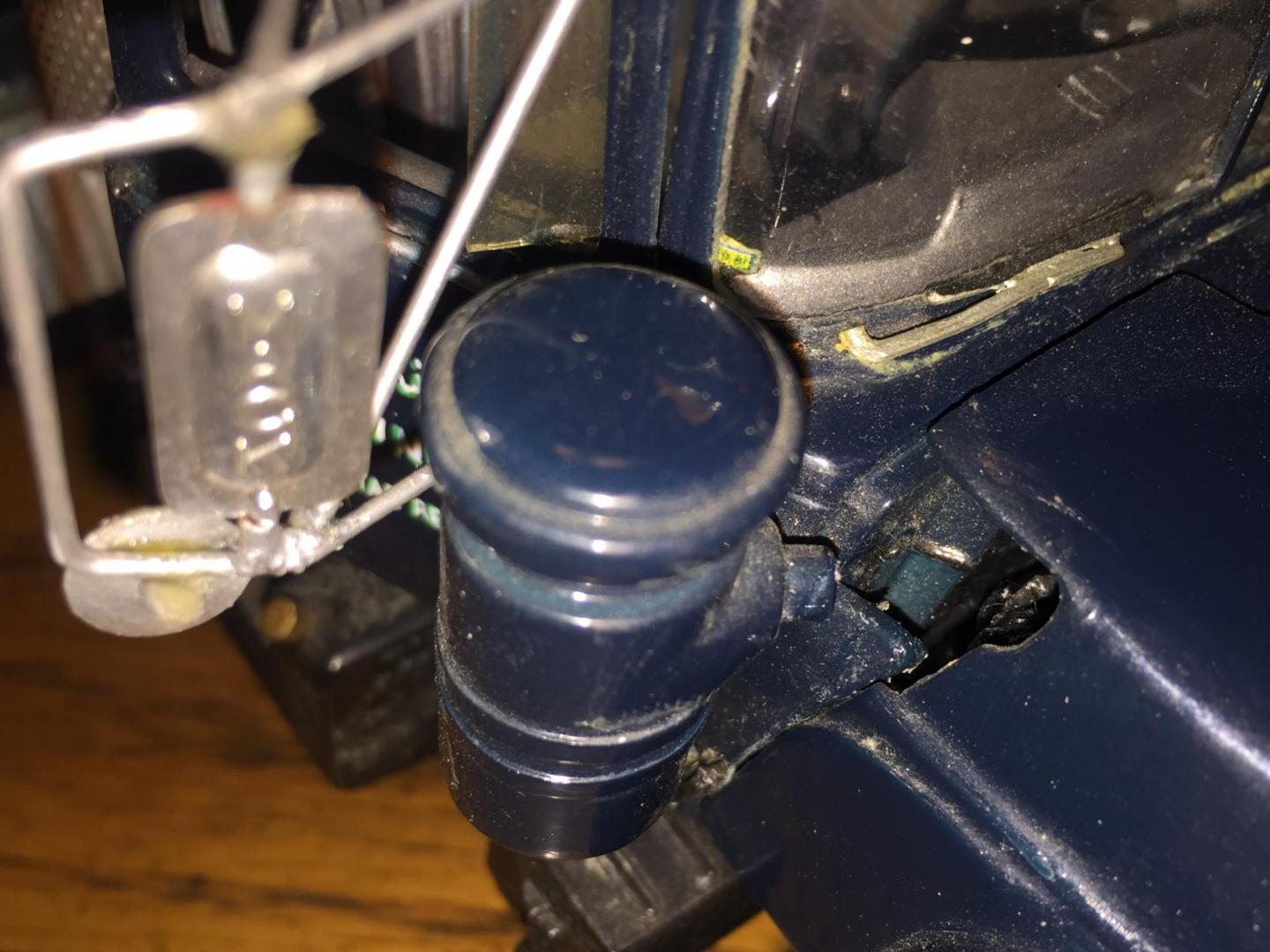

Something not often seen in models is the prototypical panel joints as found on their 1:1 counterparts. I saw a very informative thread here about proper details on the Ford C cabs and it reminded me about this Mack R model. Having been very familiar with the R, U, DM, and RD cabs as well as the Superliners, I included these in this old R700 that I built many years back. I worked for a construction company and ran the weld shop and body shop in the winter. We would do repairs on and paint about 100 to 150 pieces every winter, from trucks to cranes to loaders and dozers and anything in between. We had a few dozen Macks, R models, DM models, U models , and Superliners and RD models as well. We would completely revamp their cabs to repair rust as well as other damage. We actually rebuilt a few R models from the floor and firewall up, with all new panels, roof, rockers, doors, hoods and everything. I therefore was VERY familiar with how the cabs go together. The pics I posted here show an R700 and show the panel joints at the cab side in front of the doors, at the cowl, the rocker panels and all trim lines in between. The R kit does not reflect these joints nor does the DM kit. The panel just in front of the drivers door is known as the Texas panel due to its vague similarity to the shape of the state of Texas. Call a Mack dealer and ask for an R model Texas panel, and they will know exactly what you mean! There are rocker panel joints, and cowl joints as well. There is also what looks like a vent , that isn't, just in front of the driver to the left of the edge of the hood. I just figured I'd share this with my fellow builders to show some of the details that are sometimes not included for those looking for the super detailed build. Cheers! Tom

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

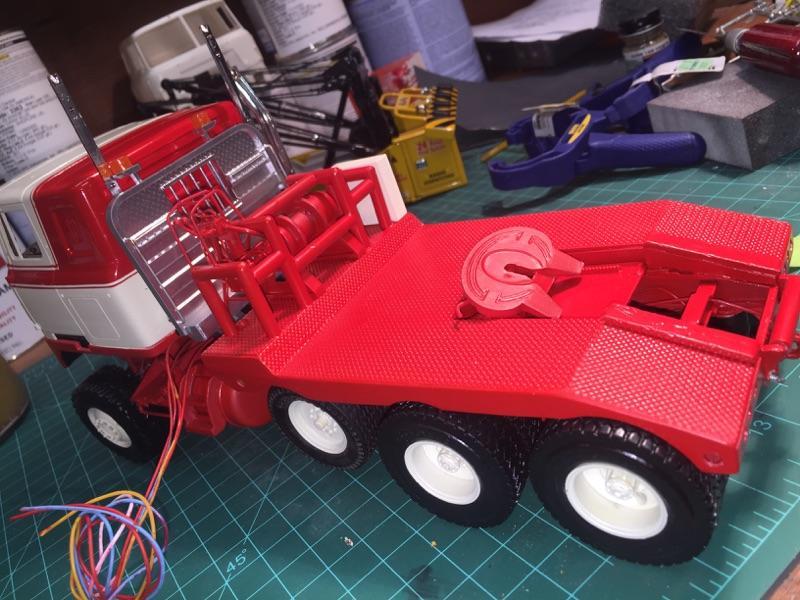

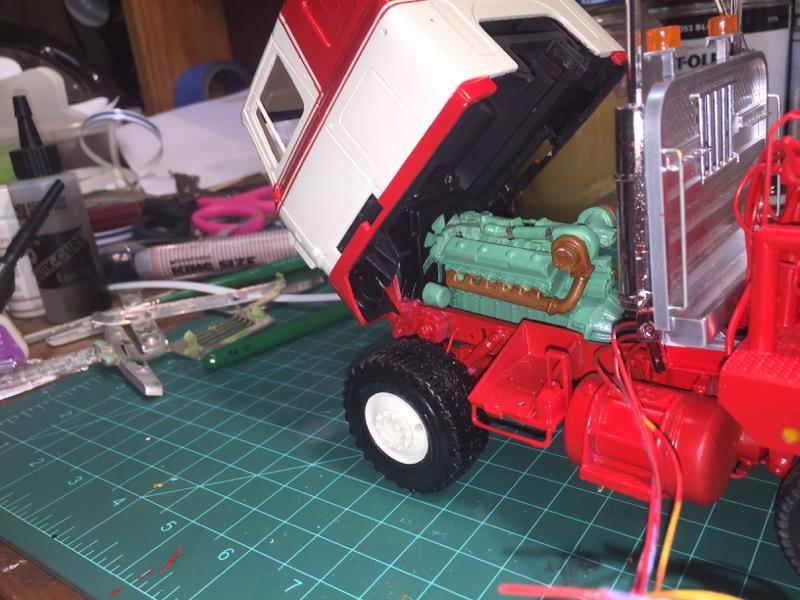

Well, I saw a truck similar to this years ago in upstate Vermont, used for heavy hauling, house moving, lowboy duty etc. I had never seen an oilfield truck before and didn't recognize it as one. But upon reflection and talking to others, it seems that the one I saw, on a KW conventional, was most likely a recycled oil field truck. So.............I figure on a fictitious heavy hauling company. Am working on a logo and name, but it will based right here in Vermont, as a refugee from an oil field moving equipment and such. I SOMEDAY intend to build a detachable neck lowboy for it, but until then I will pair it up with the folding neck lowboy from First Gear. Back to the bench! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well, here are the latest pics. Have the painted cab mounted with the interior in place and painted, medium tan. The tires and wheels are installed, all marker lights on the body are in place and the upper grille is tacked in place for photos only. The glass and visor will be next and then permanent installation of the interior. The exhaust and intake air is next to be done. Have to add the trailer hoses and wiring as well. Am using aluminum curved tip exhaust, straight with no mufflers. Haven't figured a bumper to use yet, a stock 4070 one or a shop built version. Lots of little details to go yet, but happy with it so far. Still have to do under-cab details such as all the wiring and hoses, cab jacks, and other details. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

GMC Astro

redneckrigger replied to Old Buckaroo's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I have found great luck using 3M pinstriping tape. I use their 2 line, 5/16 tape which has a 1/16" stripe and a 1/8" stripe, separated by 1/8". I use the 1/8" part to be my paint edge as it is VERY flexible but adheres very well. I use the 1/16" part for making edge stripes either as is or sliced down to 1/32" for thinner stripes. I also use 3M green tape as it is low tack and leaves no residue on the paint. I paint using PPG Shopline enamels with medium reducer and no hardener. It works well and has no reaction between the tape and paint. I let the first color dry about three days before masking for the next color. Check my WIP post, the CO 4090A, for what it comes out like. Not the best I've ever done, but for OLD shaky hands, not bad at all. Cheers, Tom -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you! Getting more done now..............it's like a logjam has been broken. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well, I certainly HOPE so, but it still has a lot to be done. One piece at a time! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

New Brush Truck Started

redneckrigger replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I think you have NAILED it so far! The engine actually looks spot on. And while I do have a soft spot for the OD paint jobs on these trucks when original, I am glad it's going to be red. Firetrucks HAVE to be red................! (Says the guy whose FD has glow-in-the-dark yellow firetrucks!!! -

Nice vintage truck! Whose cab is it? That WILL be a great build.

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I used 3M green tape and pin striping tape to mask it. The green tape is low tack so it does not leave a residue or marks on the paint. The pin stripe tape is the two line variety with one being 1/8 wide and the other is 1/16 wide. I use the 1/8 for the paint edge and the 1/16 sliced down to 1/32 for the pin stripe. Very flexible so it conforms to contours and seals perfectly. Let it dry for about an hour and unmask before the paint gets too hard so it won't chip. Did it that way when I was doing 1:1 jobs and it worked great. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Here is a loose mockup, using a Transtar II cab while the paint dries on the 4090, with tires and wheels in place though not pushed all the way into the axles. Cab sits bit high here as I didn't want to force it into place yet but gives an idea of the total package. -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Finally decided to try it again and masked it off and sprayed the second color tonite. An hour later it was unmasked and I think it came out pretty well. Gotta figure out where to get some custom decals, do a bunch of other work and start pulling it all together. So far so good! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

IHC Transtar CO-4090A WIP

redneckrigger replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Just did a mask for the next color on Monday. Sprayed the second color, also Torch red, unmasked it last night and OOOPS! One little spot under the windshield decided to lift the paint off down to the primer. The masking was over the wiper mount hole and perhaps the prep wasn't as good as it could have been around the hole? No idea, but it is not an uncommon problem, having been dealt with many times in the 1:1 world as well as on these scale builds. Oh well, just got done with a REdo of the base white. Gonna work on other parts while this dries a LONG time. Am only using PPG Shopline enamels with medium reducer, no hardener. So, I think I will just be a bit more patient! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

'nother heavy haul

redneckrigger replied to landman's topic in General Automotive Talk (Trucks and Cars)

Wow! That is a big move! Nice pics! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

How to get 6 colors from one bottle

redneckrigger replied to Kit Basher's topic in Tips, Tricks, and Tutorials

Very interesting. With any translucency at all in a color, this type of offset to the color is to be expected. Thanks for sharing!