Warren D

Members-

Posts

1,840 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Warren D

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Not sure anyone really cares how a logger rides except maybe the driver. The large sidewalls on the tires should help! With all the mud, probably smoother than a paved road in pothole season!!! LOL! -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I think it was worth the effort, I'm sure I'll like more as time goes by and I forget what apain it was to do. I think it's the scale difference but could also be that KFS is geared to Euro trucks (like AITM is geared to American trucks) and there may be some differences due to that. I had to narrow both sides, if I just did the long side, the diff would have landed in the center and it really needs to be offset to one side. Only one I've seen with a centered front drive axle is a center cab cement mixer. Not saying there aren't others, but that's the only one I've seen. I did notice the scale difference between 1/24 and 1/25 years ago when I tried taking 2 1/24 scale Chevy p/u beds and making a long bed. The cab I was using was 1/25 and that bed was ugly wide. Ended up taking a good chunk of width out of it to match the cab width. Some things don't matter as much, ie, the crane for this build is 1/24 but looks fine on a 1/25 scale truck and I don't recall having to make any changes to the crane's mounting channels for frame width. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Change of direction......well, a small one. A few weeks ago, I saw a post of an Autocar mixer with a front drive axle. I had really wanted to do a front drive axle when I built my mixer a few years ago, but I was just getting back into the hobby and didn't know of the parts resources available. Knowledge can be a bad thing. After seeing that post, it re-kindled a desire to put a front drive axle in something.....so I decided to take some steps back and convert the B815 to all wheel drive. Ordered up parts from KFS and waited for them to fly across the pond. Then the fun started, the track was way too wide (maybe 1/24 scale difference?) so I had to narrow the track by removing a little from both sides. The real fun was to come, trying to remove the "kit" front axle. I was able to get it off the chassis without damaging the springs but the axle itself was toast. I now have all wheel drive, and there is a slight height difference, the front end sits a bit higher than the rears but that will look better once the load is added, the back will look like it's sagging under the load. I need to get this finished before I change it up again......either that or I need a dose of willpower to resist those ideas! Photos are a mock-up of progress to date, still a long way to go. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks, I'm obviously better with the chaulks....... -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

While waiting for chassis parts for the truck, I spent some time on the trailer. I may have gone a bit over on the mud, but it'll have to do. Cable was made from the bare copper lead in a mouse cable, dipped in Blacken-It then over painted with rust. I have to add some bare metal paint to areas where the logs will rub when I figure out where that will be. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

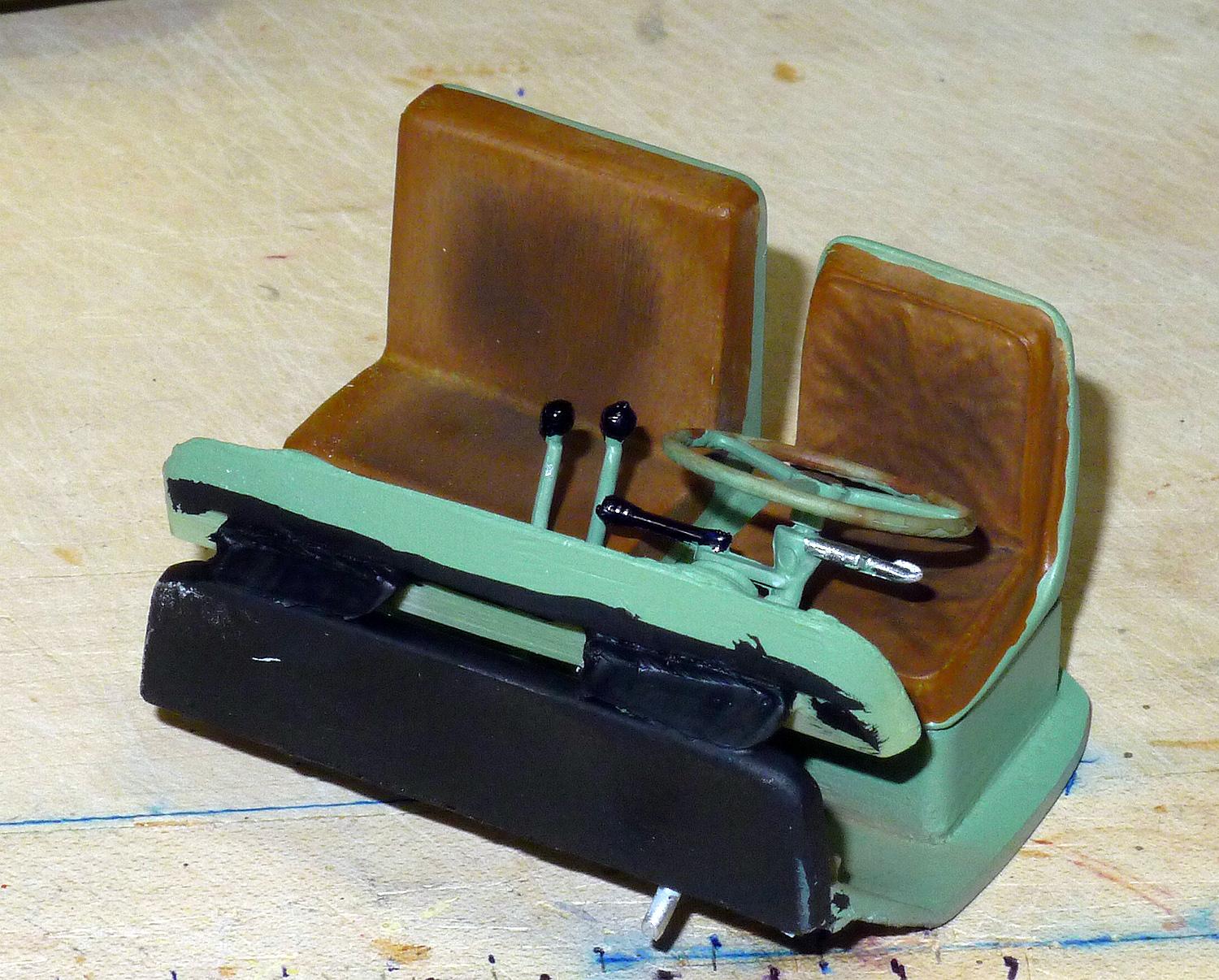

Interior almost ready for installation. Took out the old weathering chalks which did a great job on the seats. -

Revell Kenworth W900

Warren D replied to JordanFordF1's topic in Model Trucks: Big Rigs and Heavy Equipment

Looks pretty good to me. It's all a learning process. I look at the ones I built 40 years ago and usually end up rebuilding them. -

Site Can't Be Reached

Warren D replied to BigTallDad's topic in Forum News and Questions (formerly: How To Use This Board)

No issues today! -

BRBO International KB8

Warren D replied to landman's topic in Model Trucks: Big Rigs and Heavy Equipment

Came out great, the spacing between the tank and the rear wheels looks spot on! -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Site Can't Be Reached

Warren D replied to BigTallDad's topic in Forum News and Questions (formerly: How To Use This Board)

Still going on this morning. Win 10 and Firefox. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

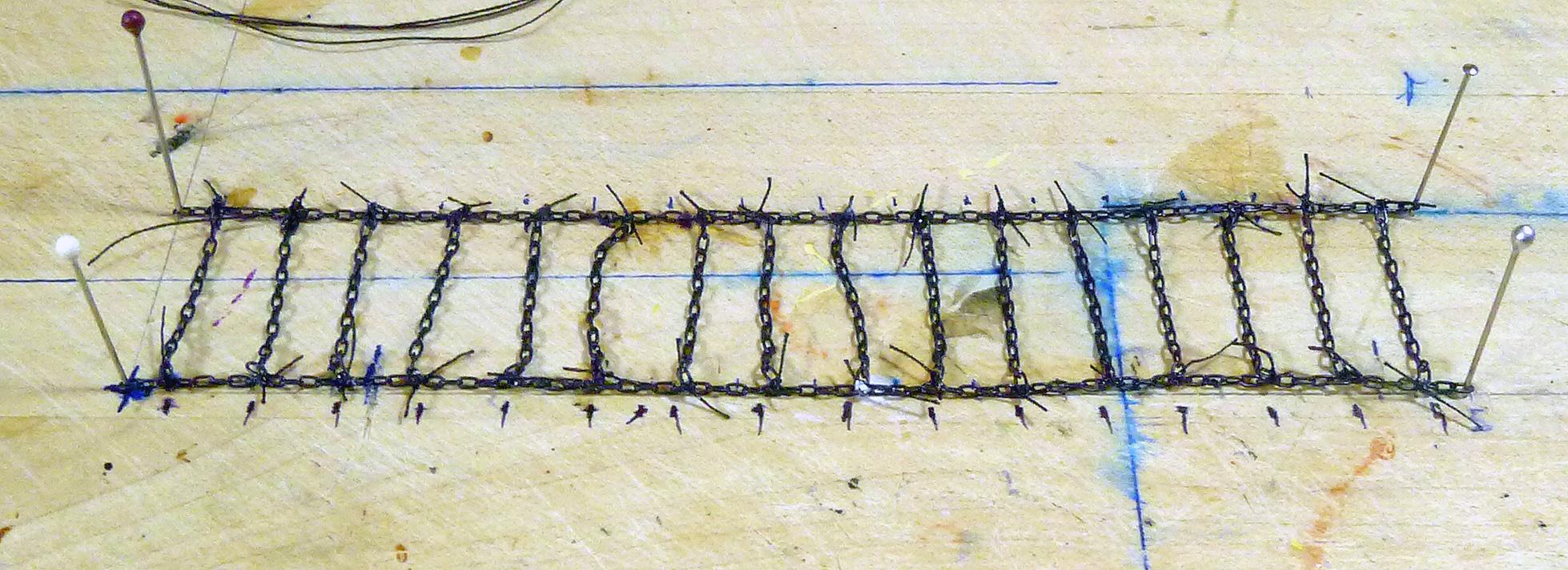

Parts from Micromark came in so I took a break from the grapple to work on the tire chains. After cutting the sections and making the jig, it seems to take about an hour to assemble one. Two down, two to go...... -

Oshkosh snow plow

Warren D replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looking very good! -

Site Can't Be Reached

Warren D replied to BigTallDad's topic in Forum News and Questions (formerly: How To Use This Board)

Just happened to me again, after browse cache clear. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Spent way too many hours today on the swivel connection to the boom. In the end, I think I did 4 of each part and re-built it at least that many times. Finally got it move the way it should. Pic of the grapple I'm using as a guide: -

Shell Oil Mack

Warren D replied to Travis Waits's topic in Model Trucks: Big Rigs and Heavy Equipment

That's a great looking rig! -

New Flea-bay Trend?

Warren D replied to Warren D's topic in General Automotive Talk (Trucks and Cars)

I know what shipping costs and I have no problem with paying fair shipping fees. What I'm seeing is domestic shipping of $50-60 for a 1/25 scale truck kit. This isn't overnight, either. Seems to go along with item prices significantly lower than average for the item. -

I've been noticing lately that lots of sellers are lowering the buy it now price but their shipping "costs" are thru the roof. Maybe it has something to do with the fees? Based on selling price, shipping charges exempt from fees?

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Quick update as it's been a couple of weeks but haven't had much bench time. Valve on the furnace let go shooting parts throughout my water pipes shortly before a heat coil in the oven turned into an arc welder. Any way, I've been on a parts hold waiting for Micro Mark and after almost 3 weeks, I called them. They can't explain why in stock items didn't ship but said they will be on their way shortly. I have more parts on the way from KFS, saw a post that gave me an idea so I might make some changes before I go any farther. Started the grapple for the end of the crane but quickly found I need some parts I don't have. So I'll continue to putter along.... may have some pics after this weekend. -

Another great build, good job!

-

Started a new master...

Warren D replied to Repstock's topic in Truck Aftermarket / Resin / 3D Printed

Looks fantastic! -

Autocar A64B Concrete Truck

Warren D replied to Tankman's topic in Model Trucks: Big Rigs and Heavy Equipment

Great job, I did one similar a few years ago without the front drive axle and weathering. I have seen mixers with the front drive axle! -

Great, thanks again!

-

Thanks, just one per side?