Warren D

Members-

Posts

1,839 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Warren D

-

Looks good! I find weathering is tough and very subjective.....what looks great to one person is over or under done to someone else.

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks for the kind words, I was wonder how long it would take for someone to get the Bunyan reference. Had to put something on the front guard and it seemed to fit. -

Diamond Reo flat bed

Warren D replied to Bronzekeg's topic in Model Trucks: Big Rigs and Heavy Equipment

Nice build, I like the color! -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Calling this one done. Thanks to all for the kind words of encouragement during the build! -

Calling this one done. Cab and chassis from AITM, trailer from AMT. Crane from Italeri, front drive axle from KFS, logs from the back yard. Lots of extra parts. KFS front drive axle had to be narrowed (1/24 scale). Grapple on crane from scratch. Weathering is a variety of acrylic washes, chalks and airbrush. Rust is the salt method, tried the baking soda method for the mud but didn't like it so I created my own mix using acrylic craft paint ($0.99 per bottle!), water, acrylic gloss and fine sawdust. Probably the most involved build to date, first one with weathering. Overall, I like the result.....

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

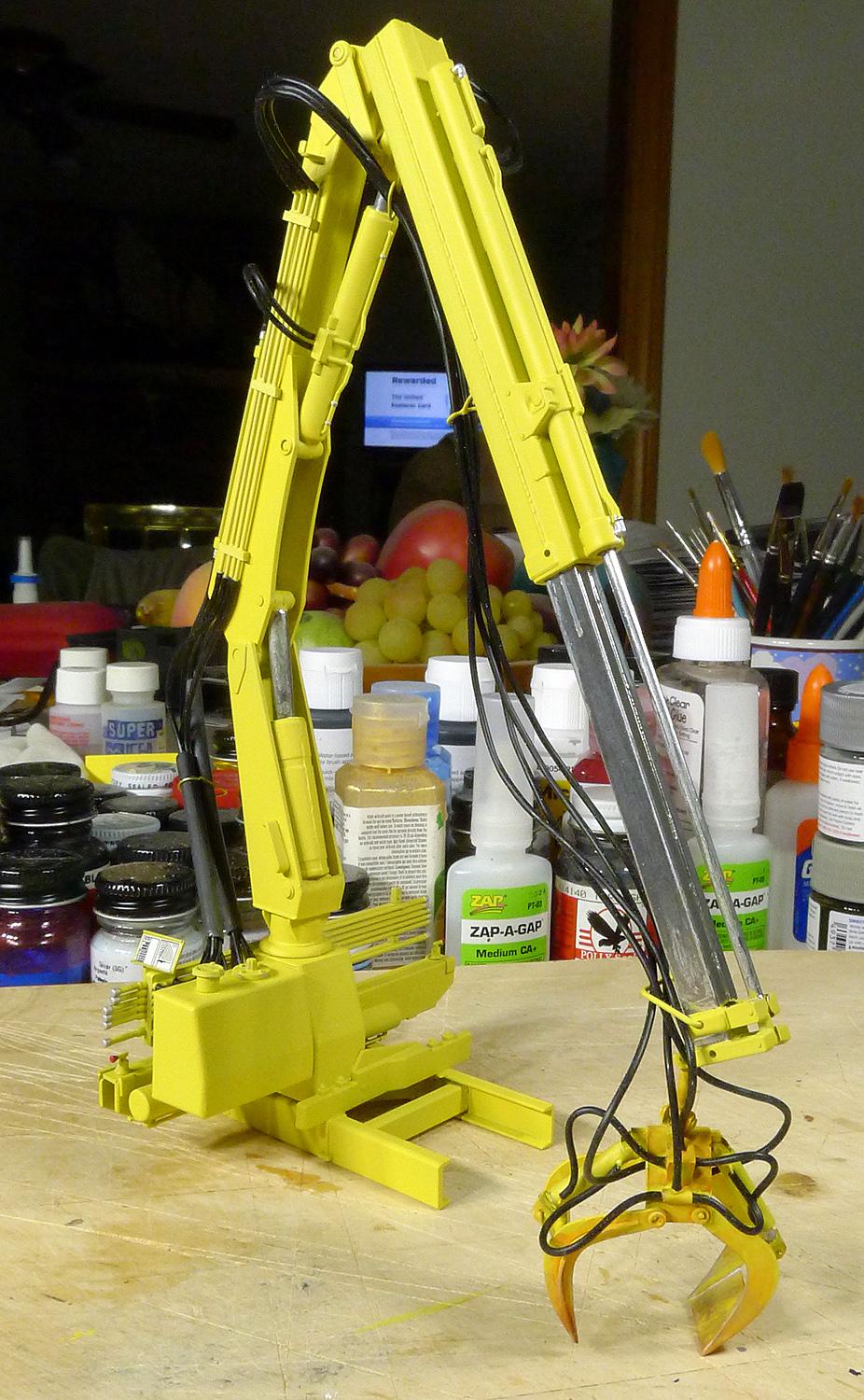

A few more pics of the grapple now mounted to the crane. It pivots, rotates, jaws work and moves like the real one. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Final update. The grapple is almost done, need to attach it to the crane, add a little weathering and mount the crane and it's done. Not sure how some of you scratch build these small devices, it was very frustrating. -

Looking good, nice progress.

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Getting close to calling this one done. Cab is done except for the crane, grapple is all that's left there. -

Oshkosh snow plow

Warren D replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looks great! -

I'd say you guessed right, I figure the round ones are aluminum and the rect ones are steel, especially with the diamond plate.

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Progress update: Cab is coming along, glass and interior are installed, also checked fit to chassis. Photos are mock ups, still some details to add before it gets mounted. I packed the front fender wells with mud, seemed to add a lot of extra weight to an already heavy resin casting. As I go, I keep finding more things to add. I really need to wrap this up soon, otherwise it might never get done! Chassis is also coming along, mud and rust added along with grease and oil. Fuel tanks and battery boxes are on and I had some room to add a step from the log trailer kit on the passenger side which still needs to get dirty. I've tried several methods for the mud. First was the well known use of baking soda as a filler/texture but by the time I got the texture I liked, there was too much baking soda and it turned the mix white requiring many coats of mud colored washes. I tried a blend of fine saw dust, acrylic paint ($.99 at the craft store) and some clear gloss as a binder. I like the results, the sawdust adds body and the fiber seems to go along with the logger theme. Next are the cab accessories, a few chassis details then the cab can get mounted. Biggest thing left after that will be the grapple for the crane. I think I see the end......until I find something else to add/change....sigh...... -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks. Well, you can add it up, B815 from AITM, Mack Chassis from AITM, AMT Logging trailer, Italeri Crane, chain material was about $50 so about $300 so far give or take. -

Tire and wheel question

Warren D replied to kenton44's topic in Model Building Questions and Answers

AITM has several choices in resin and Moluminum has resin wheels and rubber tires, also in several varieties. -

BRBO KW K123 and 40' Great Dane

Warren D replied to DRIPTROIT 71's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Like the tires also, Jamie's? -

Autocar Logger

Warren D replied to delta99's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I think it's the same frame as the A-Car tractor which attach that way. -

Autocar Logger

Warren D replied to delta99's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks, I think I have about 2 hours invested in each wheel just for the chains. Not something I plan on doing again anytime soon. -

BRBO Mack B815 Logger

Warren D replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Not sure anyone really cares how a logger rides except maybe the driver. The large sidewalls on the tires should help! With all the mud, probably smoother than a paved road in pothole season!!! LOL!