Oldmopars

Members-

Posts

2,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Oldmopars

-

Your skills and mine. While this is possible, and I may even be able to get something kind of close, there are others that have already done this and are selling this engine in resin. So, I am not sure it would be time well spent. Do you have any specs on this? I have seen plenty of pictures, but I would need dimensions. Copies/scans from a shop manual would help. I did a complete 8V71 Detroit, so this would not be too bad to do.

-

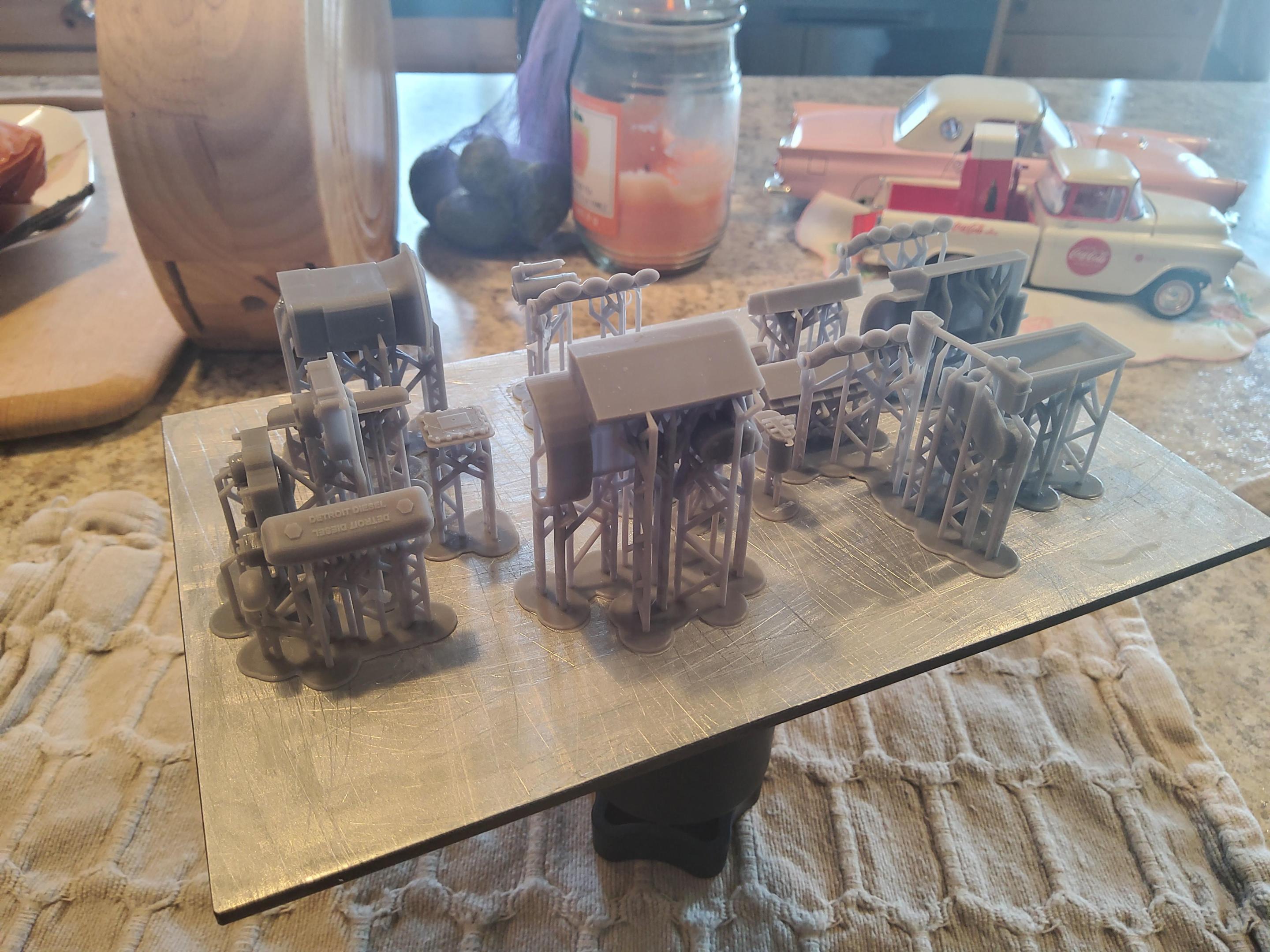

Let me start by saying that I am not looking to start a new business. I have a full time job. I am however getting into the 3D printing rather deeply and I am learning Fusion 360. I will post some pictures on stuff I have made. What would you like to see available? An engine not in kits form? Wheels that are different or not in kits? Tool boxes, fuel tanks, winches, etc? Let me know what you want to see made and send me a picture if you can. I will be working on this stuff in the evenings while I am at hotels for work, so this gives me something to do. And yes, I am in hotels every week 4 nights. If it is something that I think will be popular I will post it on Cults for a small fee, but free to the one who asks for it. Simple stuff I will just post on Cults for free. If you need it printed I can do that, but because I am only home on the weekends, you will need to be patient. So, what would you like?

-

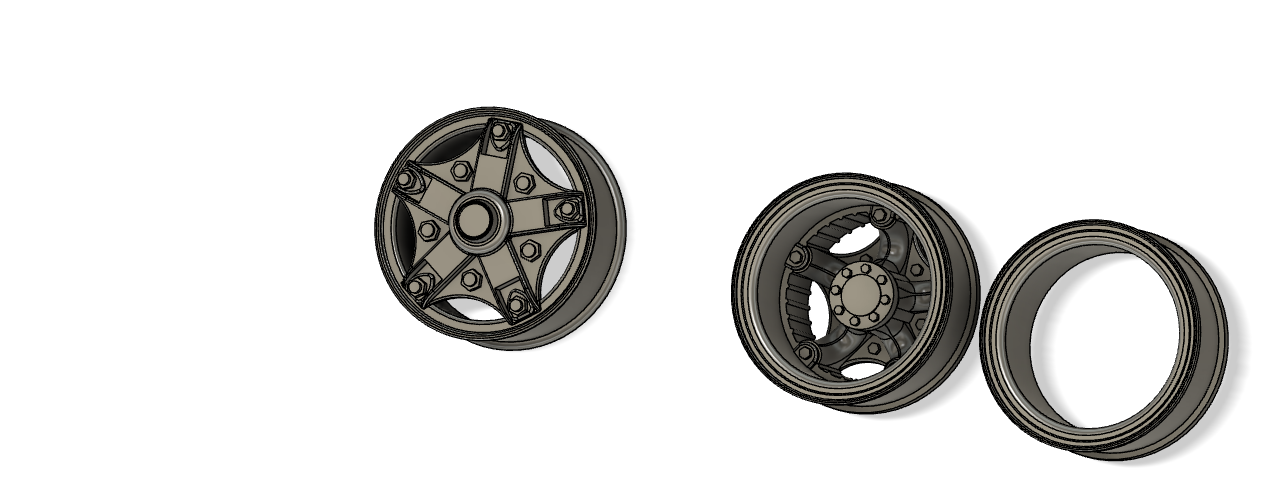

I have been spending a bit of time on Fusion 360. I started a few weeks ago and I am not to a point I feel I can make most anything or learn how. The fear is gone. I tend to build a lot of trucks, and like the work truck look. So, I have, or wanted to buy lots of 2 hole and spoke type wheels. I have made the 2 holes and they are printing now, here is where I am at with the front spokes copied from the new 4070 kit.

-

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

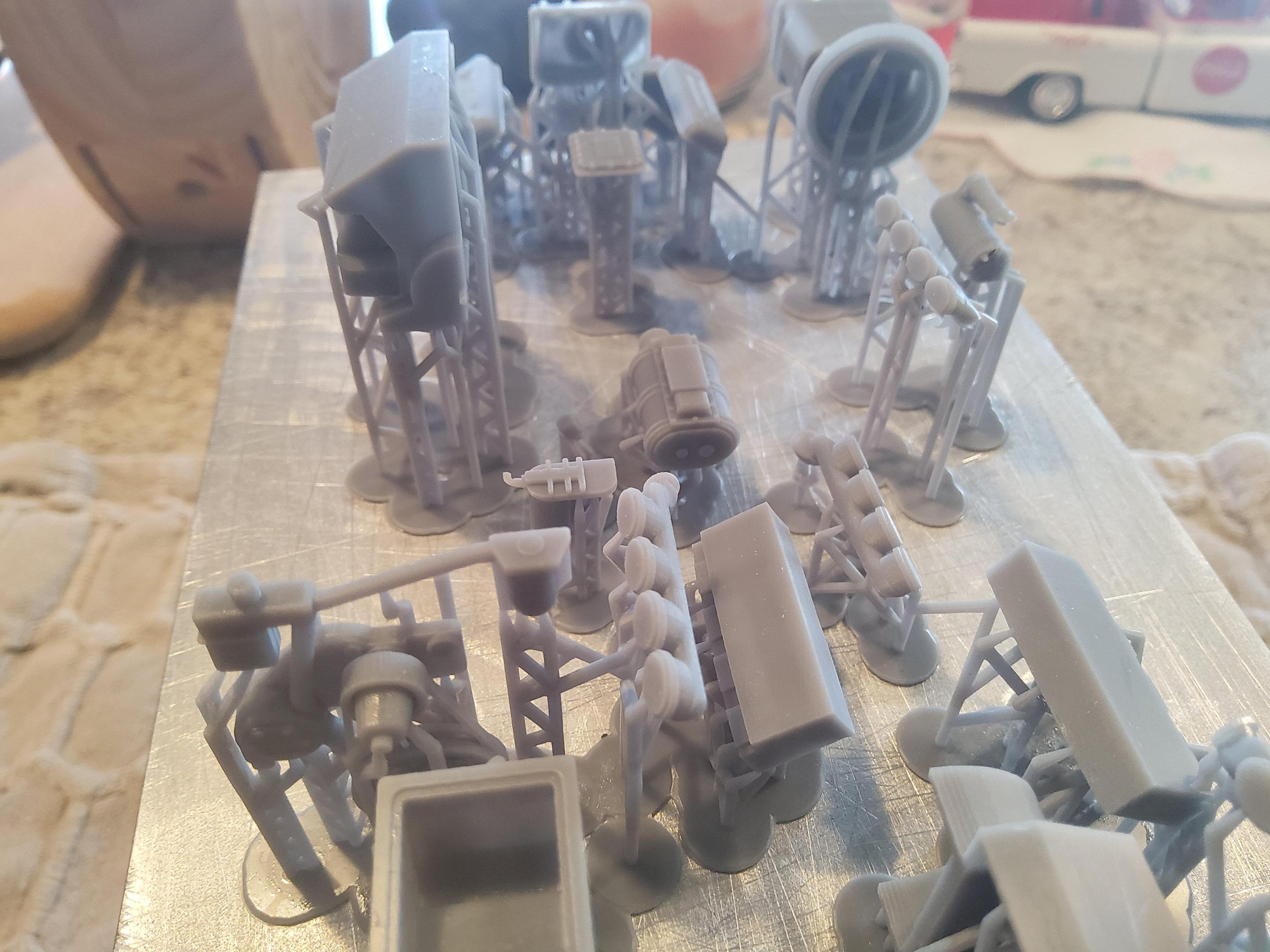

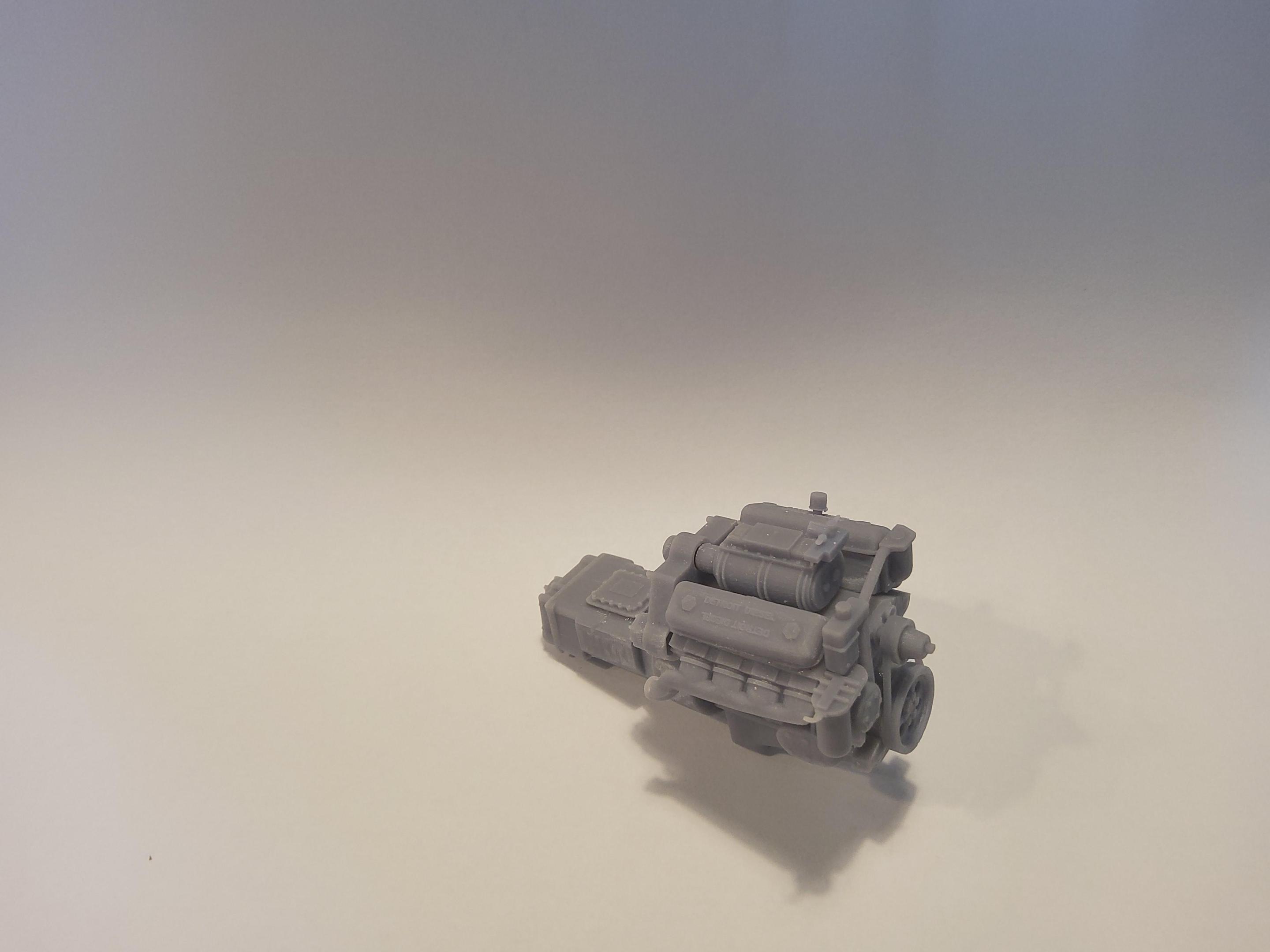

This is what it looked like right out of the printer. Not too much clean up. Took about 15 minutes. I am very excited, I feel like, I can create anything now. -

1977 Ford Motor Home

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

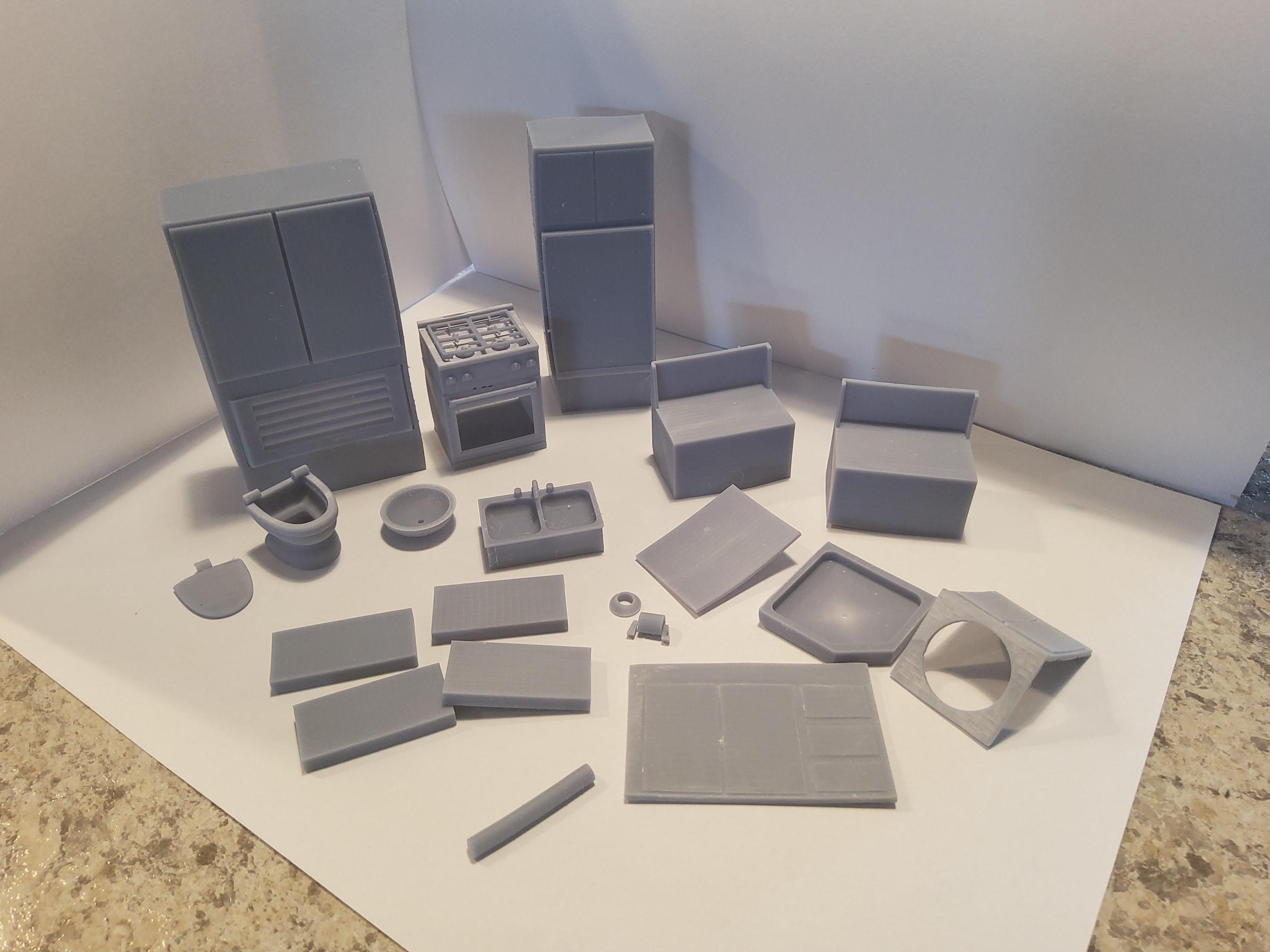

I have discovered that 3D printing is not a perfect science. There is a lot of trial and plenty of error. Strangly simple large boxes don't print well, but complex shapes do. The up side is that the large boxes are easy to fix. The complex shapes are, complex to build. So, as you may be able to see from the picture, the toilet, sink, shower pan, toilet paper roll and holder all printed fine. However the cabinets all seem to have warped sides. Changing angles may help, or some of these may best print flat with no supports. For these large box shapes, I will just cut off the face and build the rest out of styrene. The Stove turned out very good other than the small holes in the front face. I think this was just due to my hollowing it out too much. So I think in the end I am happy with the smaller parts and I will just make the larger box shapes out of sheet styrene, possibly safe the faces if they are ok. -

1941 Chevrolet tanker

Oldmopars replied to landman's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That looks fantastic, great job. A very cool truck indeed. -

I have been renting 2 of these recently. I had one for 3 weeks and swapped it for another one, not sure how long I will have it. I like these Explorers, great cars to drive. I am currently using one to drive from Yakima Wa. to Kamloops BC. 7 hours each way. I'm not sure what engine you got, the ones I have had are 4 cyl turbos and get right at 20 MPG. Better than my Suburban, but not near as good as my wifes Forester at 31+ MPG. Anyway, hope you enjoy it, they are very nice.

-

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

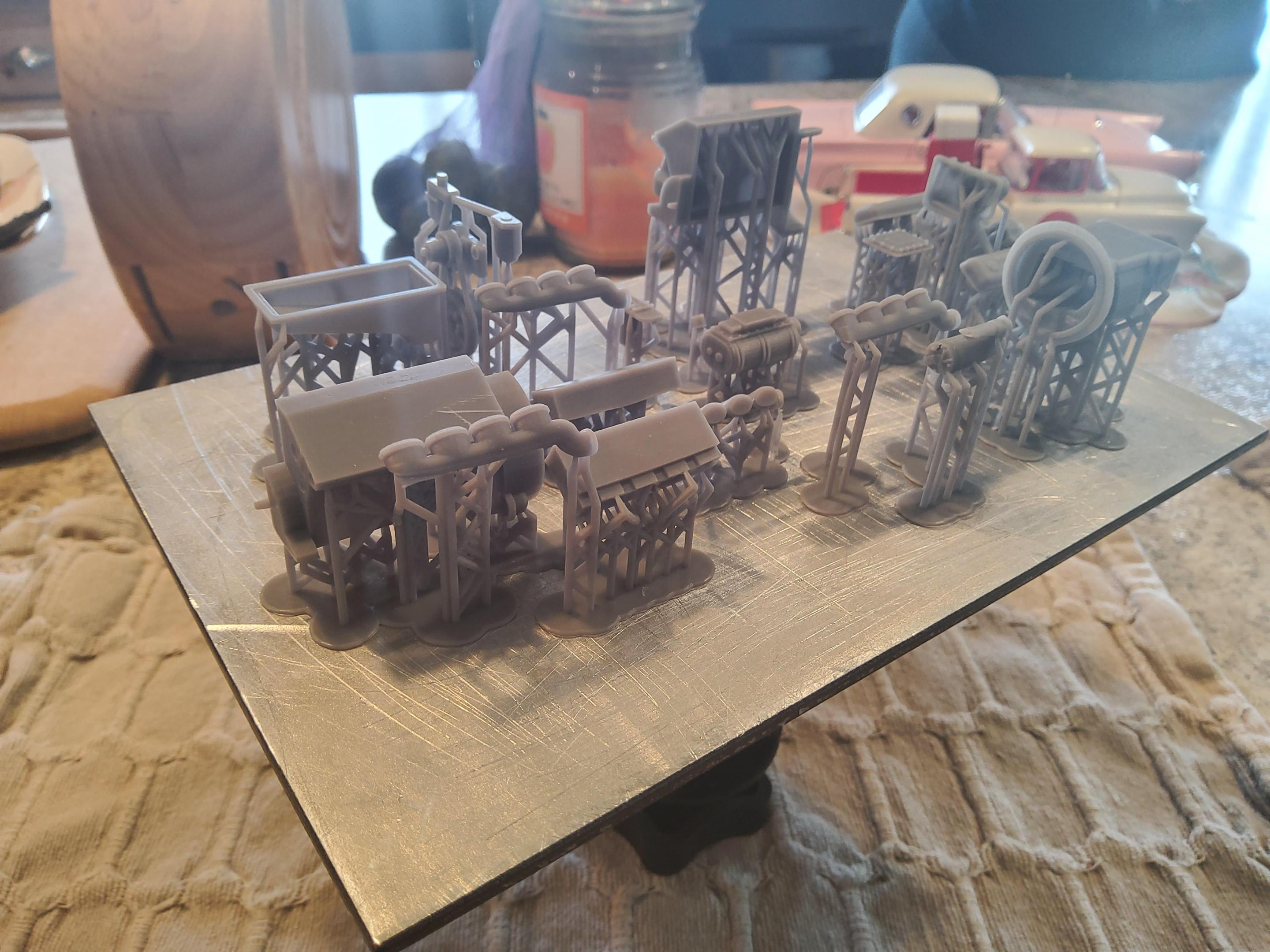

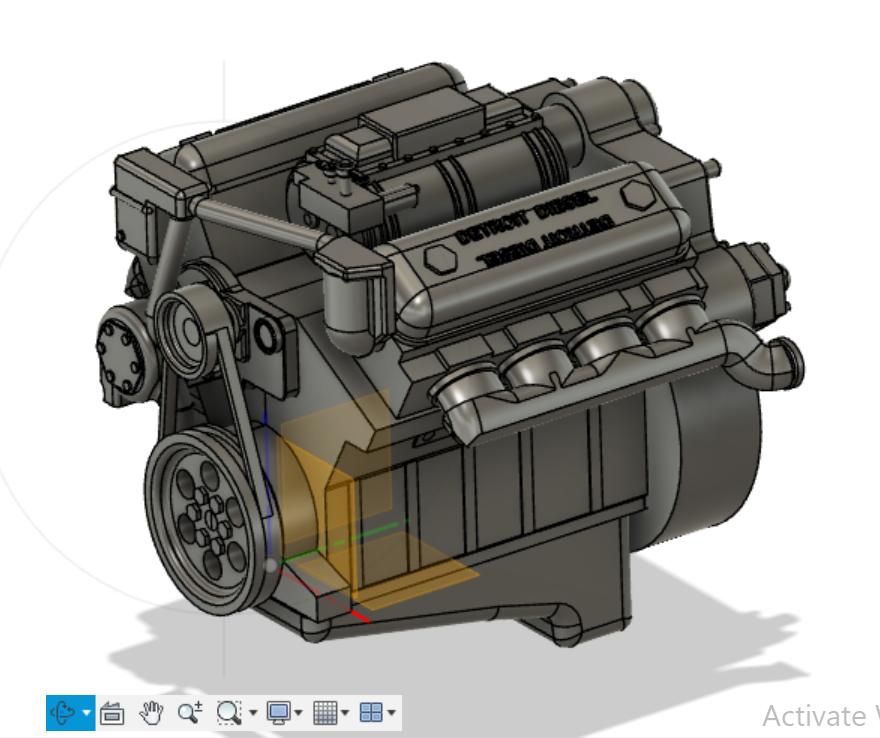

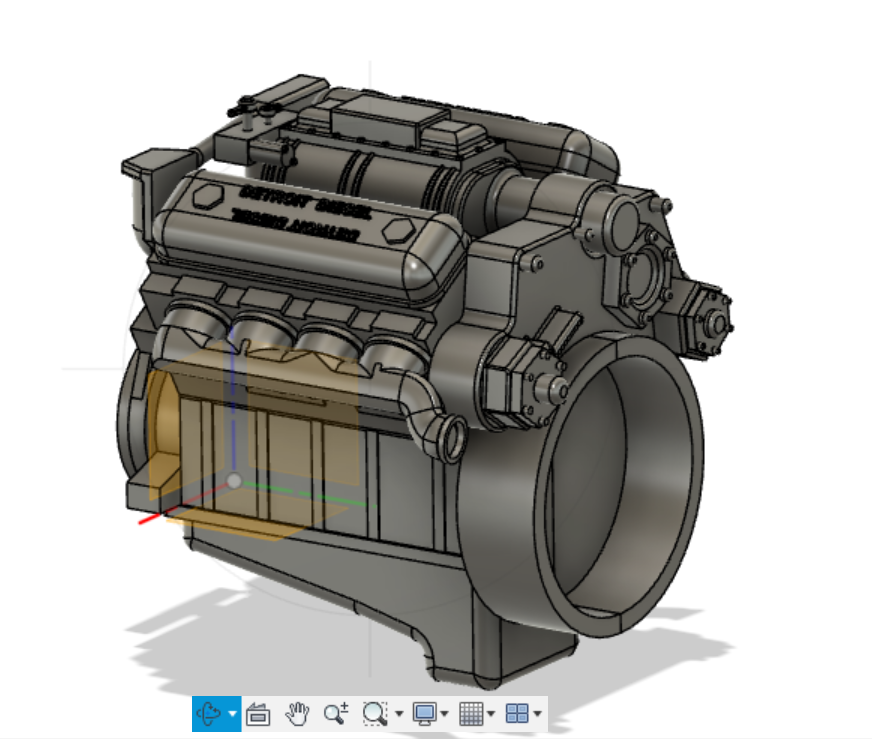

Well, I have now taken it from idea, to drawing, to reality. There were a couple of minor flawsin the first print, but overall I am happy. The starter solinoid did not come out perfect, so I just replaced it with aluminum tube. The bottom of the trans needsjust a little bit of filling, but not too bad. So, here it is, Detroit 8V71 waiting on a truck to put it in. I have the intake elbow, but I did not glue it on as I don't know what ttruck this will go in and don't know what direction it will need to face. -

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Are These for the 71 or 92 series? What would these be correct on? I know very little about Detroits, I have worked on them a little bit, but it has been 30 years. -

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

No problem, I am happy to answer the question. Cost of the engine, about $2, this is in the cost of the resin. The resin is about $25-35 per Kilo. So a large bottle. I have been running a lot of prints including a 9in tall Mandalorian figure with several extra large parts and a Grogu, extra cape, etc. and I have used 2/3 of one bottle and 3/4 of another. So, while the resin is not free, the $30 bottle lasts a long time and you get a lot of parts out of it. Printers range in price, from $200 on up. Mine is a larger format, not the biggest, but I can print a 1/24 scale body flat without cutting it. I am into mine for about $520. The software can be free or costly. TinckerCad is free, Fusion 360 is free for a "Hobbiest" version (what I use) and there are other free 3D drawing programs. However for the PRO version of any software it can be very expensive. The slicer software is again free for the basic version, that is all I use. Yes, Not only can you draw something and send it to someone else to print, there are sites that you can buy a file and it gives the option of sending it to someone to print. Or, if you have a friend with a printer they can print it for you. Shapeways is another option, you can draw something and load it to Shapeways an they will print it for you and also make it available for other to buy and you get a kick back when they do. If you buy a printer you can buy files from a large number(and growing) of places and print files others have made. This includes full car and truck kits, cool stuff too. Thingiverse is a web site that hosts free files (.STL, .OBJ) that you can download, print, modify, etc. I am just getting into this, so I do not have all the answers, but I am happy to share what I do know. I think this is the future of our hobby, but I don't see the kits going away, this will just allow us to get the most out of the kits and create things that are not practical for manufacturers to kit. Like say a Lada Niva, I doubt Revell will ever take the time to kit one, but I can buy a file off of Cults 3D and print it myself. -

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I'm getting to really like it. You really have to change the way you think. You have to be able to mentally break things down into little parts. If you try to see the whole, you get overwhelmed. -

1/8 Revell '79 Pontiac Firebird Trans Am

Oldmopars replied to Casey's topic in Car Kit News & Reviews

This is one of the few 1/8 scale I don't have. I will be getting this. Imagine, new 1/8th scale and not paying Ebay prices. Excited.- 129 replies

-

- revell 07710

- trans am

-

(and 2 more)

Tagged with:

-

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

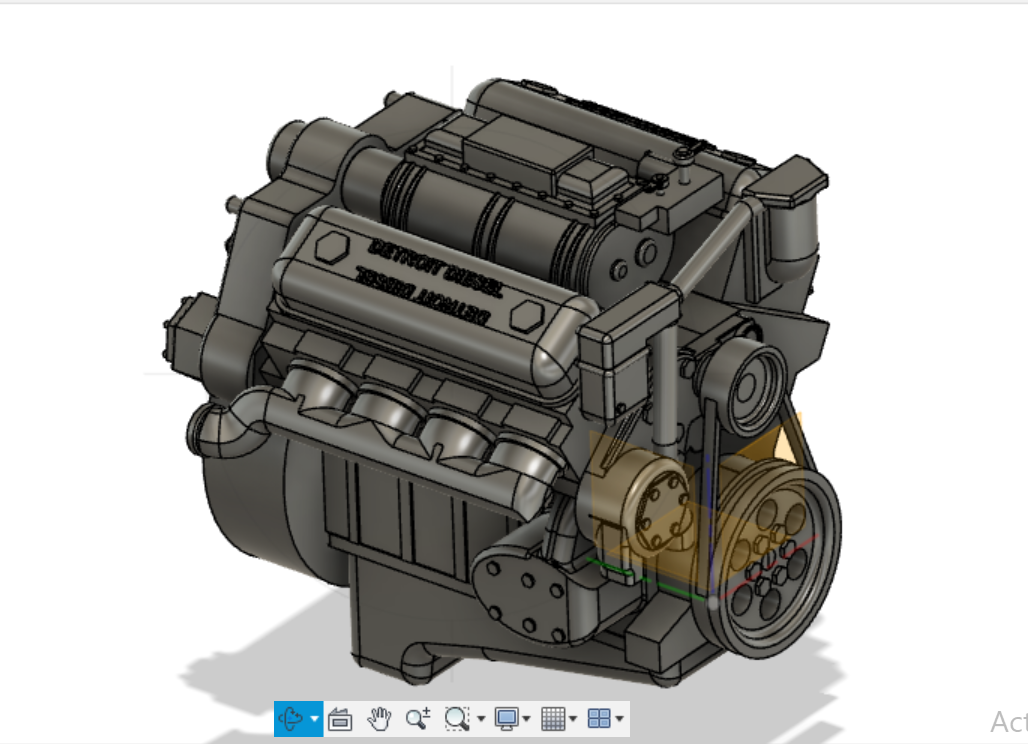

I hope to try a print this weekend, it is sliced and ready to go. I am sure there will be issues, but I wont know till I try it. -

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

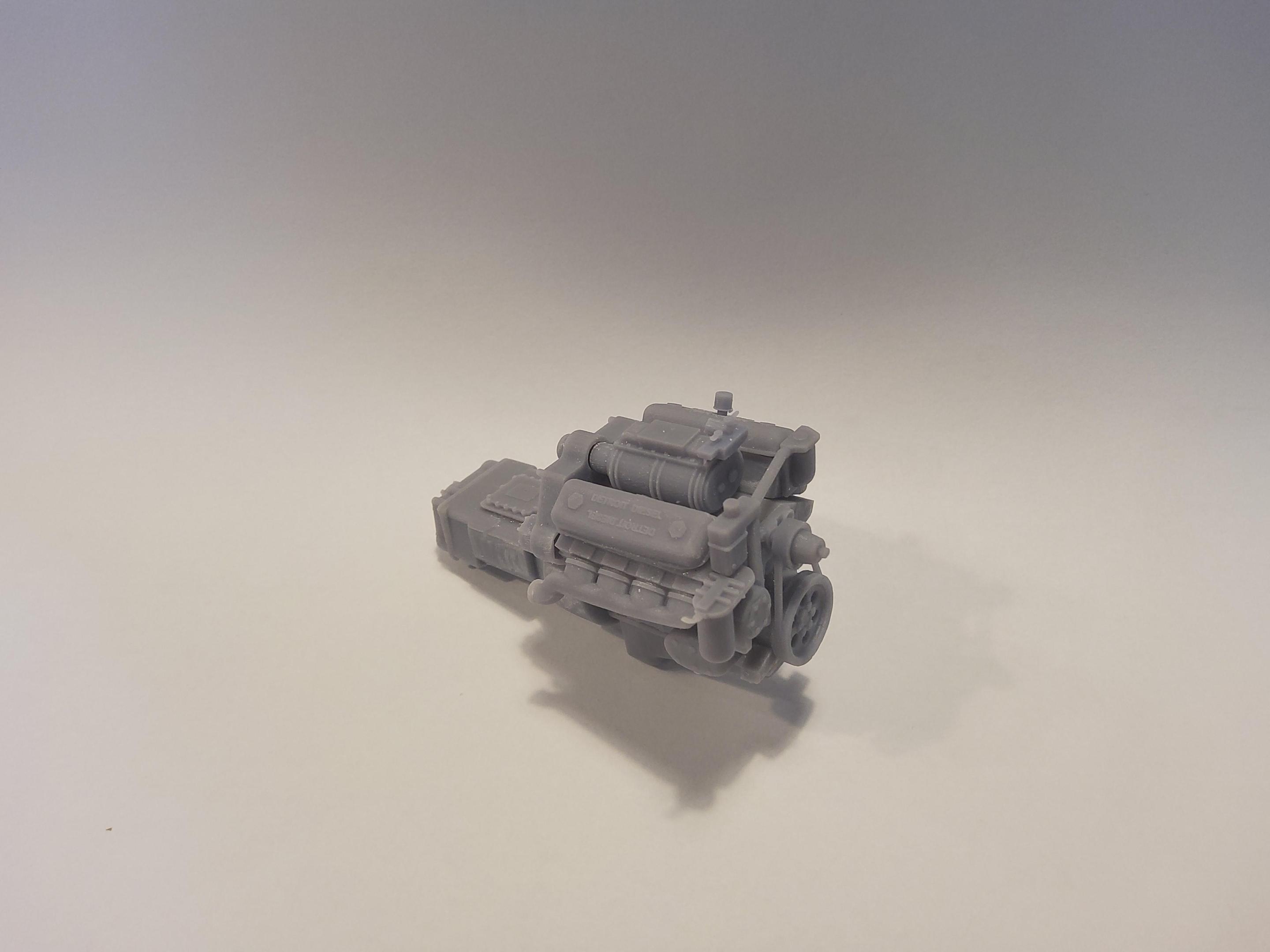

My goal was to see if I could do it, I know that the engine is available in kits, but sometimes I want the engine and don't want to have to buy a whole kit, or spend $20+ for a resin and wait for shipping. I also set it as a challenge for myself. I wanted to learn Fusion and I figured I would draw something I wanted and that was of use to me. It was also a challenging project. I used the 8V71 from the 4070 kit as my donor to copy. If I had to good pictures, or the manual I could add the turbo, DDEC or Electronic Control. The 4070 is non-turbo, so that i why it is what it is. I will also be using it for older 70's vintage trucks and so the non-turbo was more common. Someday I am going to build a 1974 Hendrickson/Ryder Paymaster and it will get the turbo. Learning Fusion 360 and owning a resin 3D printer really opens up the world of models beyond what is available in kit or aftermarket. If I can dream it and draw it, I can make it. -

Detroit Diesel engine project

Oldmopars replied to Oldmopars's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

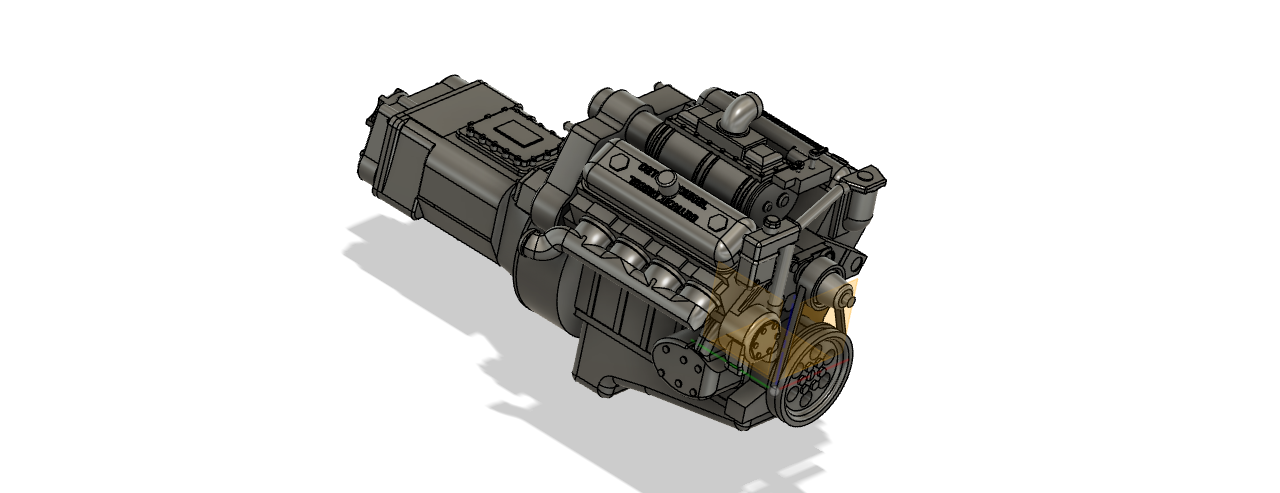

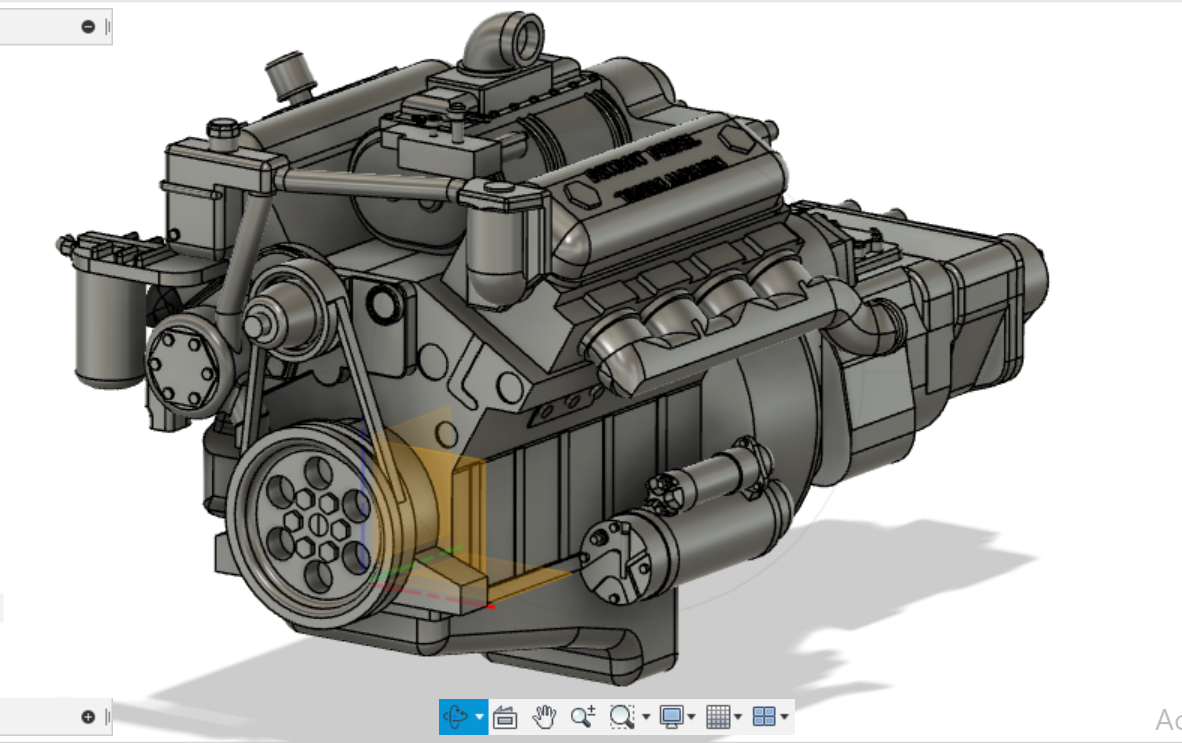

It still needed few things so I added the trans, fuel filter, air intake and starter. I hope next week I can get all the parts broke down and loaded into my slicer for printing. -

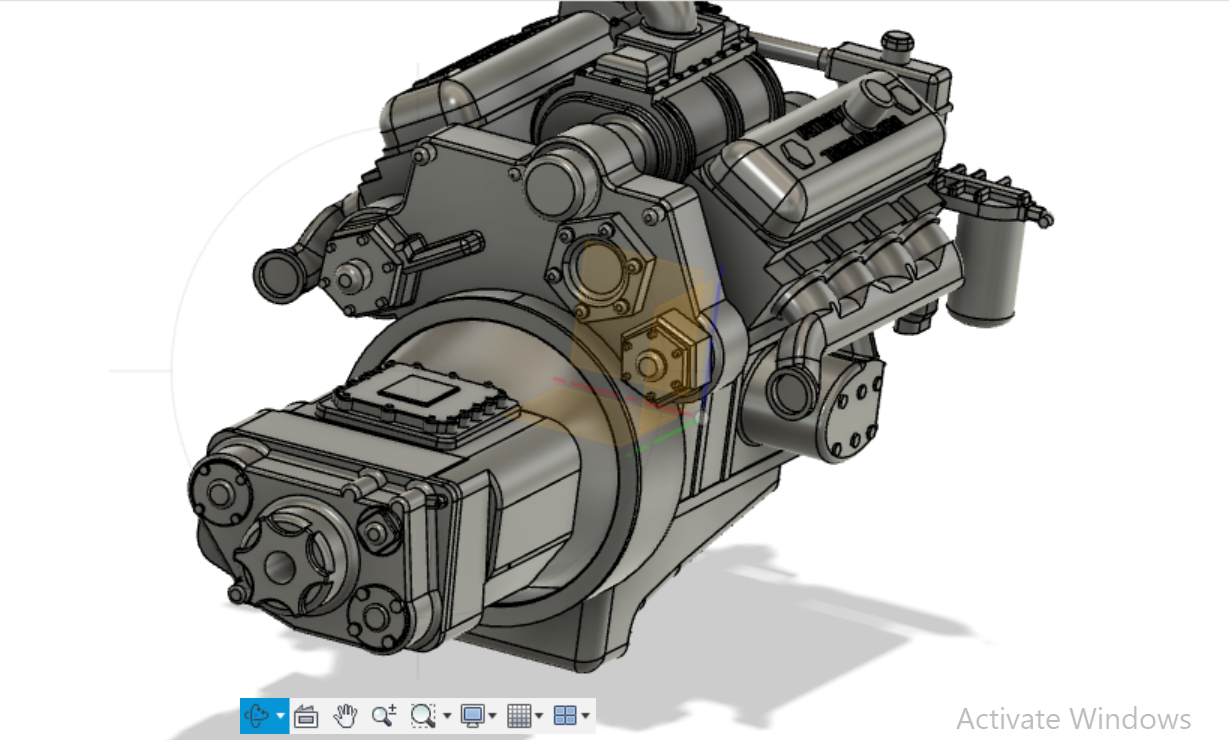

Just over a month ago I decided that I needed to jump into the world of 3D printing. My biggest issue with it was that I have absolutely no 3D software experience. I didn't want to rely on buying what I wanted from others, as this can get expensive. So a week and a half ago I decided that Fusion 360 was the best option for me and I set out to learn it. I love the Detroit engines and thought I should create one in Fusion so I can print them for future projects. I started with a plastic part from the new 4070 kit and a set of calipers. Here is where I am at right now. It is not perfect, but at 1/25 scale I think it will be close enough for me. I still have a few details to add, but I am close to done. It is in separate parts just like a kit engine, the block is 2 halves, heads, valve covers, etc. The block and heads are shelled(hollowed out). What do you think?