-

Posts

4,779 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

Tamiya McLaren MP4/6 build

absmiami replied to Josie's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Yup. ... -

Thank you for sharing. Made my day ...

-

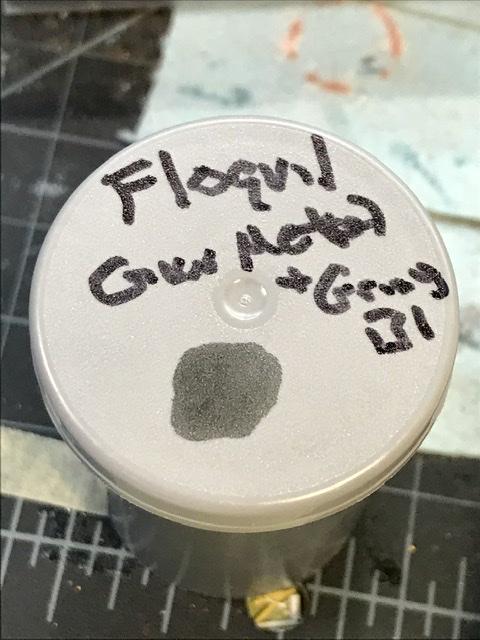

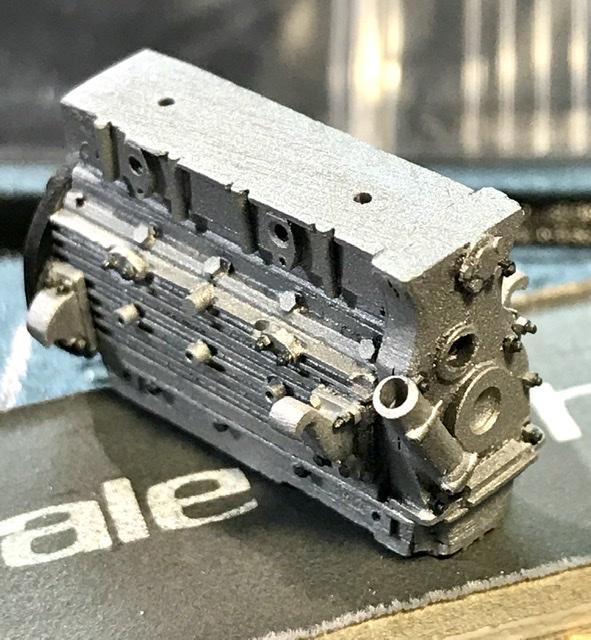

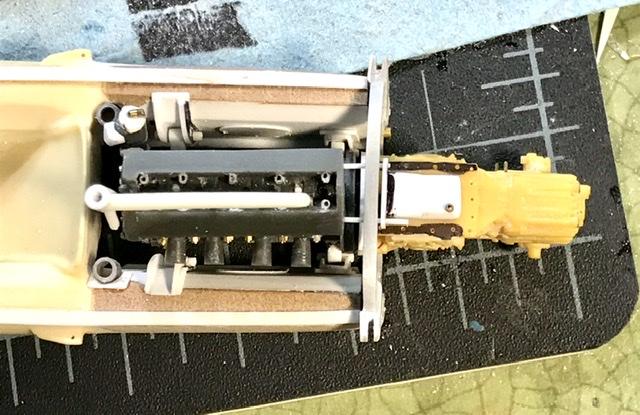

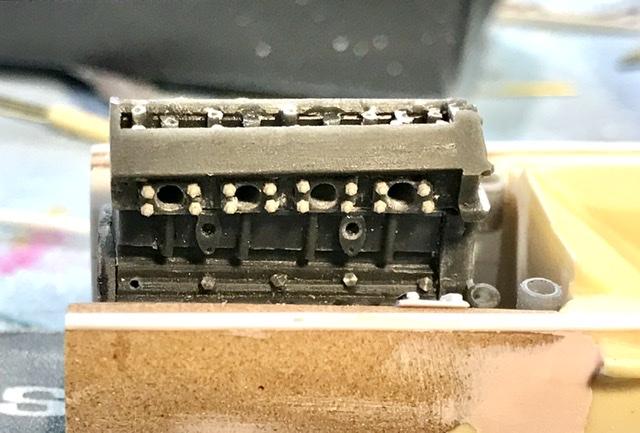

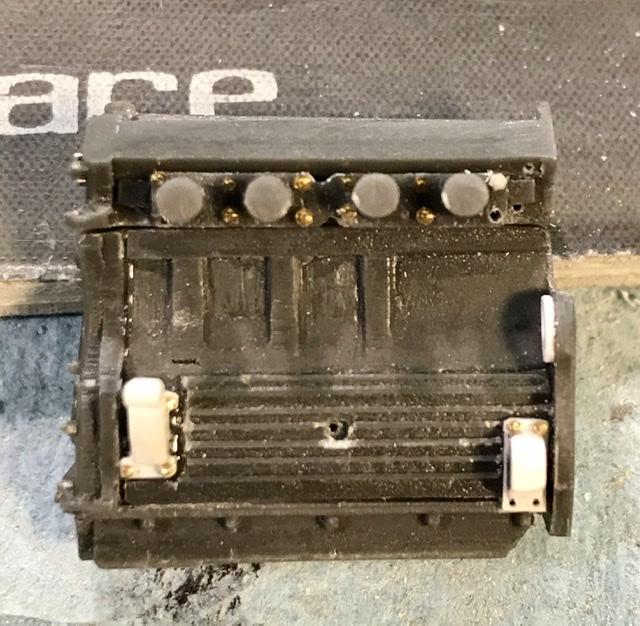

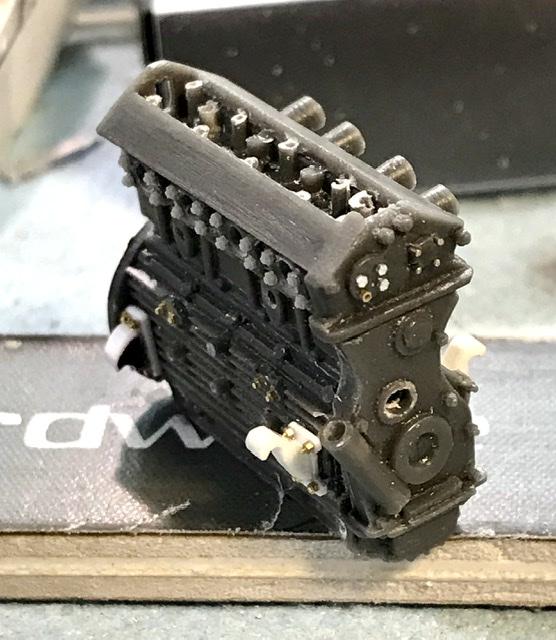

The paint finish on the block is Alcad semi-matte aluminum. Might be a little too dull - not sure - but I’ll paint the engine accessories with a brighter finish to contrast ... the valve covers are painted with hardware store flat black - again it’s impossible to know what exact shade is correct ...

-

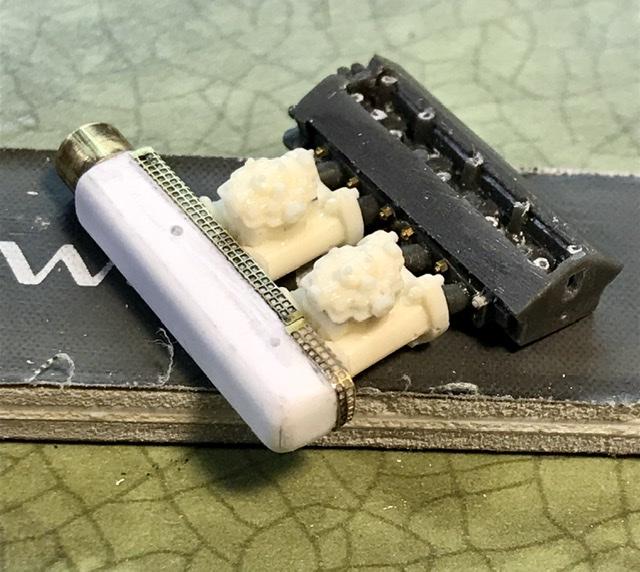

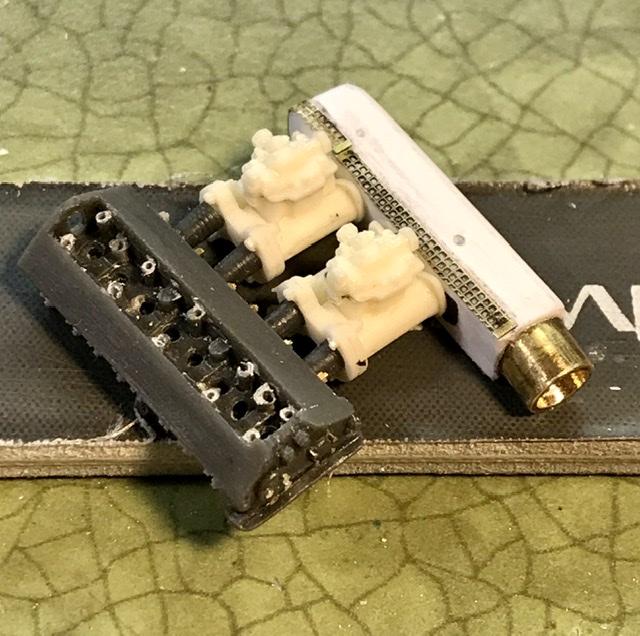

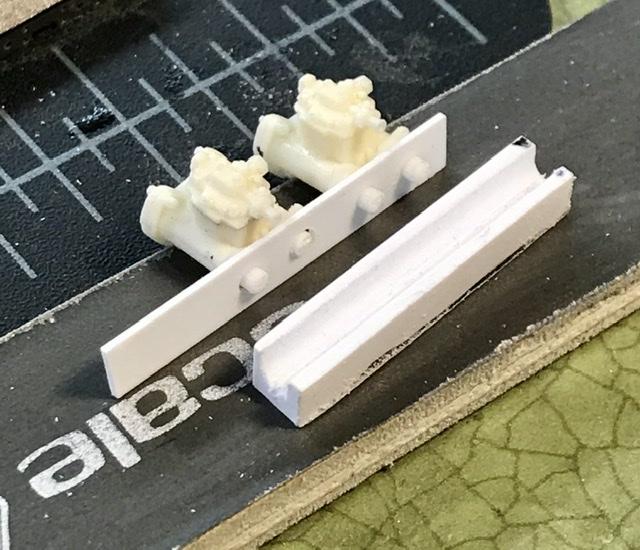

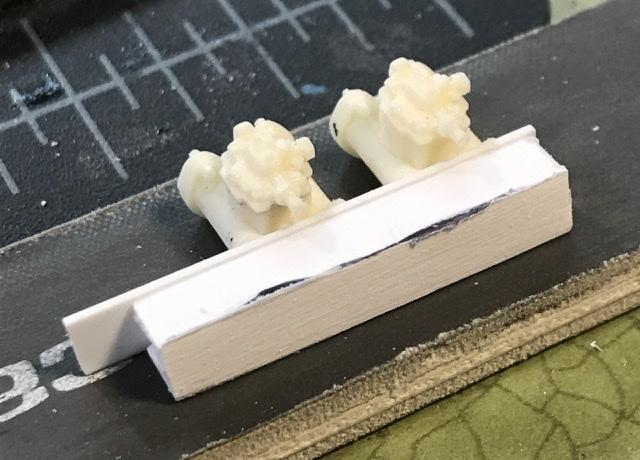

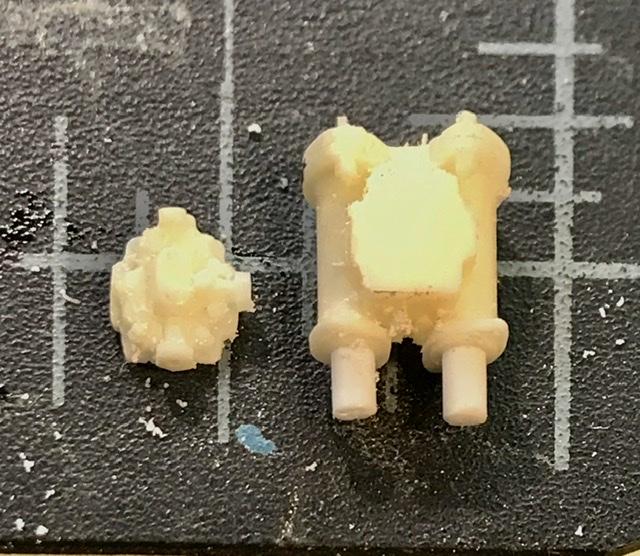

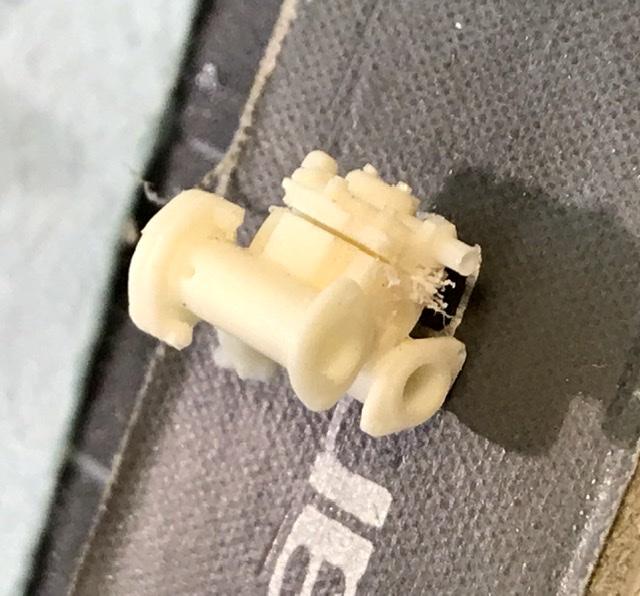

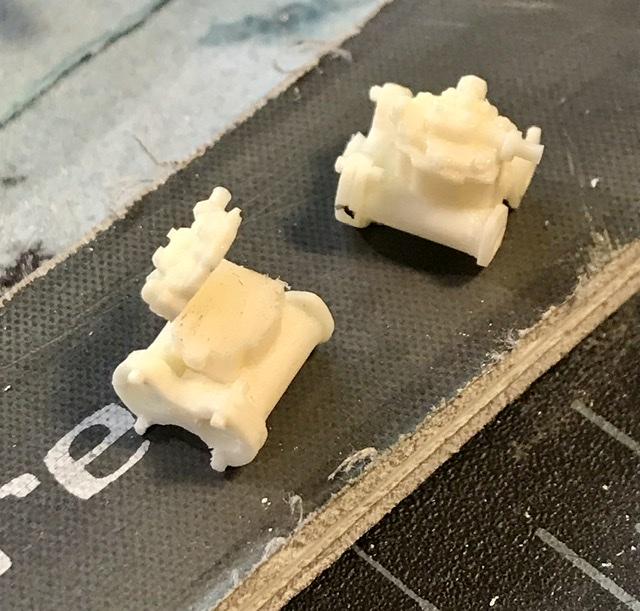

Valve covers and fuel pump... the valve covers are drilled and prepped for a bunch of bolts ... the fuel pump is made fro evergreen stock. - based on photos of a pump that I took on a different climax engine. - the restored car appears to use a slightly different pump - but it’s hard to know what the arrangement was for the Tasman season so I’m winging it ...

-

Not to mention Coconut Grove ...

-

Body Color ? I like them in gold ...

-

Gracias Now would you please dirty up your workbench some more ...??

-

The seams are very convincing what is you hand tool of choice to bend the pipes. And I assume that you anneal the metal first - have you found pliers that will bend the metal with only a limited amount of tool markings in the metal ? ? I’m about do do something like this on my Lotus ....

-

.007. ?? Holy cow. That’s scale ...

-

Looked again ... exhausts are 1/16 ?? are the pipes copper or brass and am I color blind ?

-

Yup questions - the exhausts are copper - right ? What are the dimensions ? Looks like .080? weld seams - made with nickel silver Wire ? and the fuel lines - nickel ? Dimensions - .012 ?? ??

-

Jaguar C type

absmiami replied to Miroslav Beran's topic in Other Racing: Road Racing, Salt Flat Racers

?? ??? keep going ... -

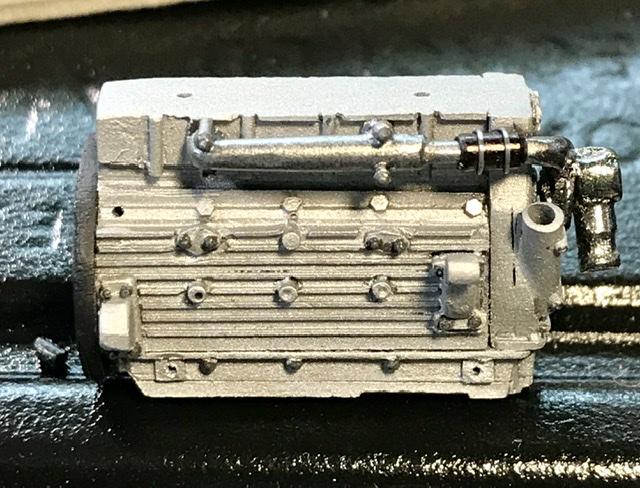

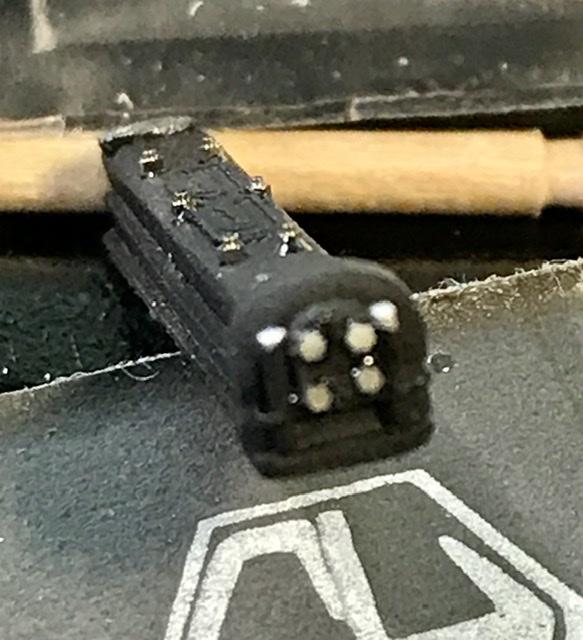

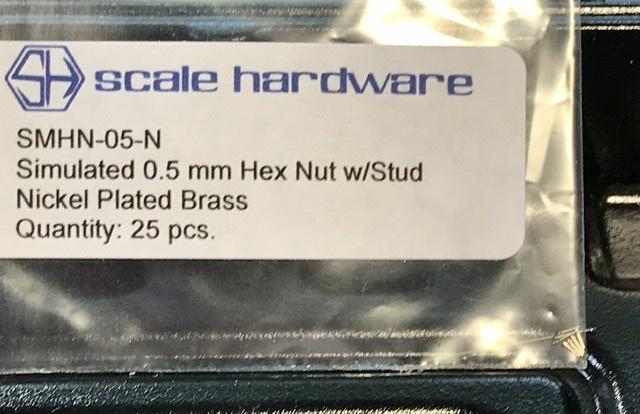

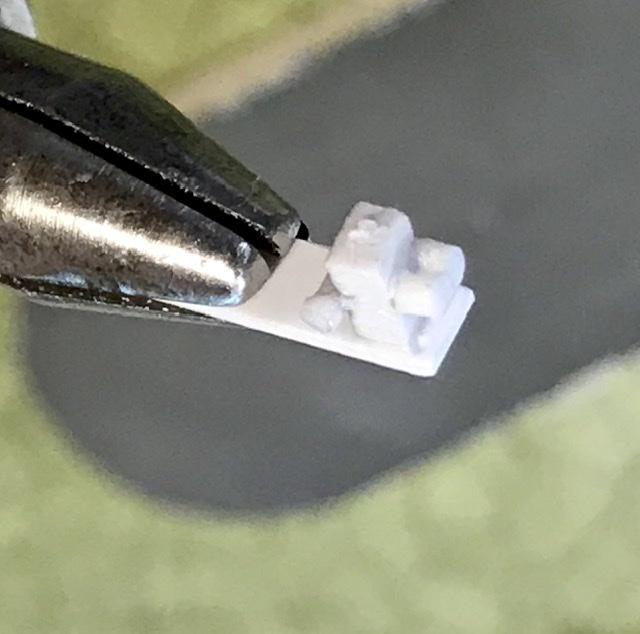

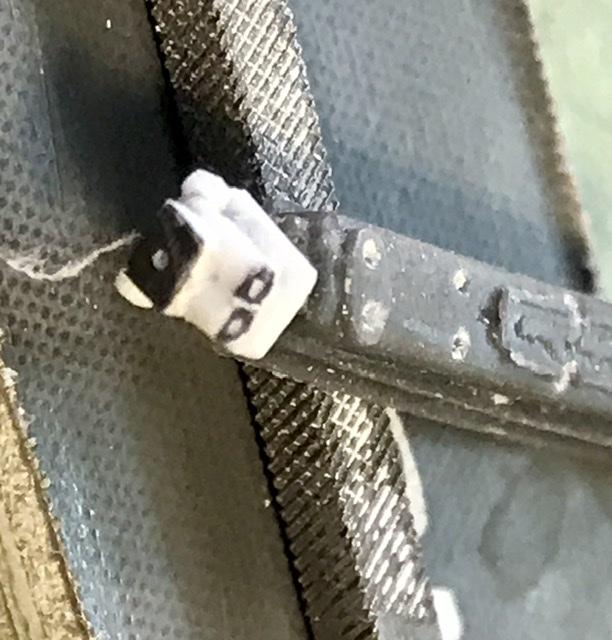

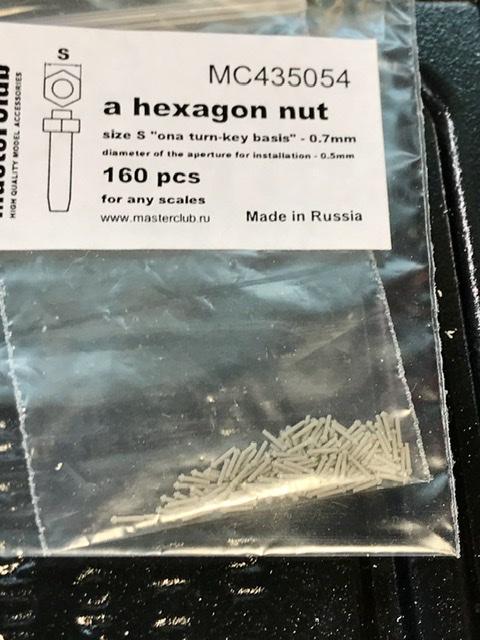

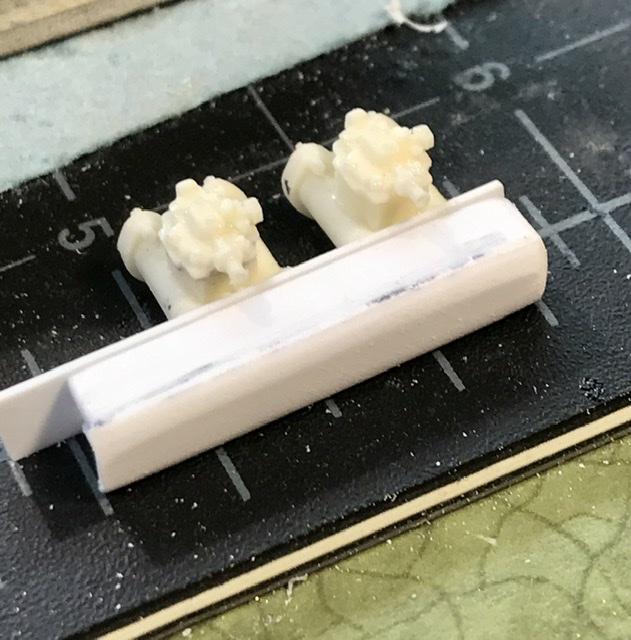

Before painting I’m adding dozens of bolts to the block and the cyl head. Doing this now so I can limit my handling of these parts once they are painted. Using .020 and .025 bolt heads and nuts from RB motion, Master Club - those are the plastic bolts on the exhaust manifold flanges. These are really very sharp castings. Some scale hardware bolts also used.

-

The air box is not used on the restored car. - and it’s a safe bet that the actual air box was binned at the end of the season - or when the 32B was sold to an Australian privateer at the end of the season. But there are a handful of photos available online - and the design was a pre-cursor of the air boxes used on the Ford DOHC Indy winner 6 months later.

-

Latest GSL posting just swam into my email box ... May 5-8 2022 and yes, it is the last and yes, Bugattifan , you’re invited too ...

-

Not to beat a dead horse ... ok. Why not the great salt lake contest will have a category for these creations ... so ....

-

Once again. Please Trailer this to the GSL21....

-

Rather nice. -is this a recent build ? ?