-

Posts

4,781 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

Tamiya McLaren MP4/6 build

absmiami replied to Josie's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Very nice and thank you for not clear coating .... by the way. Any thoughts on brake-ductgate ?? -

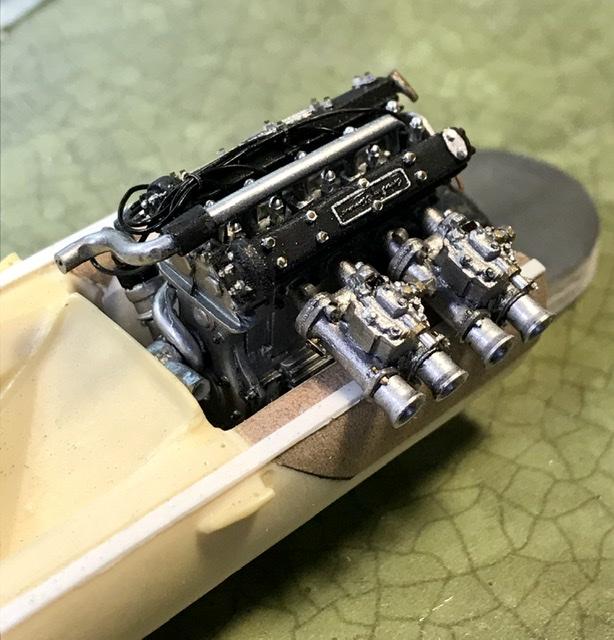

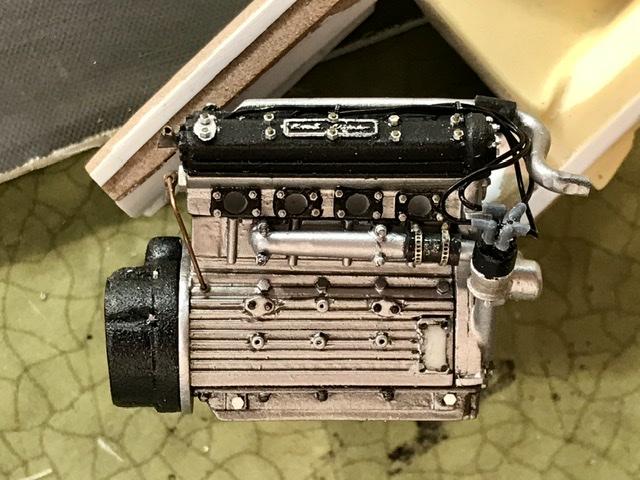

I’ll post pix of the castings later ... the Climax FPF was mounted straight up/down on the Lotus 32B. I’ll have to make the exhausts and the “swirl pot” That sits at the front of the engine. The transmission will be “borrowed” from one your Ford GT 40 printings ...the Lotus 33 used the 8 cyl climax engine - so the Engine casting in the Joker kit is now just spare resin stock ...

-

The delage was designed by someone who has spent too much time on a play station ... [oldguyrant]

-

The delage is kinda out there. But I’m really digging the Murray T50. Love that Cosworth V12... since the delage project is bank-rolled by a Miami guy. I’m thinking that the Delage mite be shown at Amelia ... that would be cool ...

-

Wonderful feature this morning on the GP 70 Silverstone pre-race show. 3 of Stirling’s GP cars demoed on the circuit - including the Rob Walker Monaco winner - which is creeping up to the top of my project list ... same engine that’s in the 32B ... why hasn’t anyone asked me about the engine yet ?? ...

-

White walls really make the look don’t they ? have you seen the new Delage ??

-

The casting comes with a great looking shift plate. - but I dont think the 32B has one. The restored car just has an opening in the monocoque. -and most of Clark’s cars [all?] did not have one. So off comes the shift plate. Made some more corrections in the cockpit - re-cited the right side mounting tube for the dash support ...the mounts were not perpendicular with the front bulkhead - now they are ...

-

Model factory hiro Porsche 917/30

absmiami replied to Brudda's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Nice I -

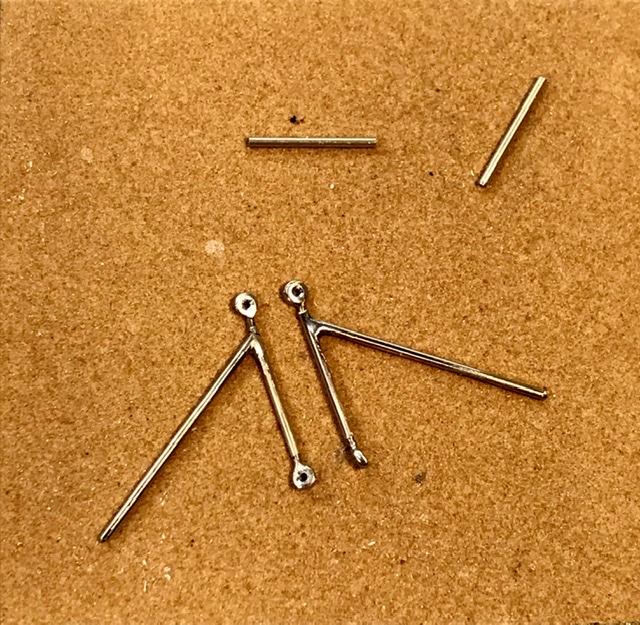

The body casting has a dimple on each side to guide the placement of the suspension arms - the kit parts are White metal - and not too good - so the replacements are placed / pinned to the body with new openings - a little closer angle - there is enough play on the parts to permit good alignment with the rocker arms once it’s time to assemble everything ...

-

Yup

-

Text from Mr Murray ... thank you so much for your patience [and 750,000 deposit]! we have just finished your T50 - painted British Racing Green - with saddle interior and red driver’s seat - per your spec. As you know - I personally deliver each T50 - and I will be in Florida next Monday for a delivery in Naples [yes - the Collier family]. So could I make your delivery on Tuesday - perhaps a blast across Alligator Alley ? How does that sound to you ?? sincerely GM oh almost forgot - balance is COD .... cheers ...

-

Has anyone else been drooling over Gordon Murray’s bonkers space ship - the T50 ?? dont think I can afford one. Wonder if he would sell me just the engine ?? In an era when engines look like ?? ??? - non-descript - things - Cosworth has designed a compact V12 that looks like the illegitimate step-child of the Gurney Weslake V12 and a Hilborn injected Ferrari Indy engine mite just have to make me one ...

-

Model factory hiro Porsche 917/30

absmiami replied to Brudda's topic in WIP: Other Racing: Road Racing, Land Speed Racers

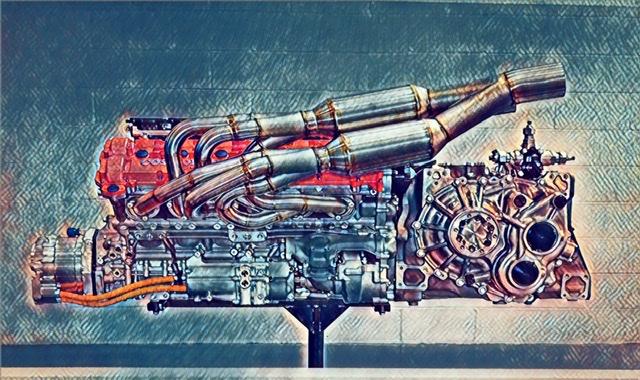

This is the car - and this the engine - that swallowed CanAm whole ... I began to go to race at Watkins Glen in the Fall of ‘73. One of my great regrets is not going to a CanAm race - drat. ... -

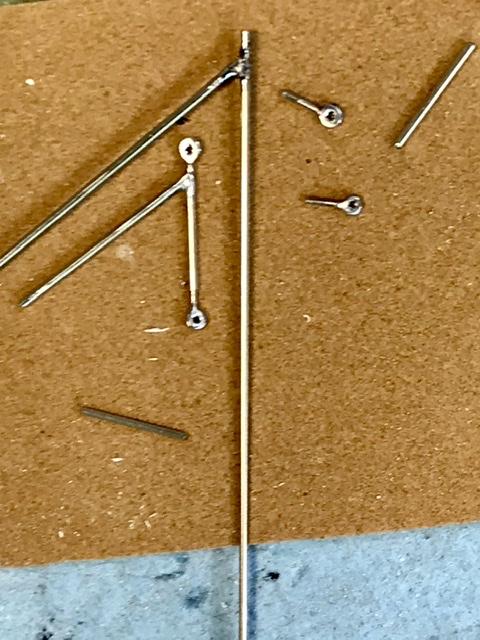

Working on the fuel filler pipes. In studying the handful of contemporary photos of the car taken during its one Tasman season - I noticed that Team Lotus used the same sort of assembly that was used on the 33. The restored car uses a different shaped assembly - either way the tubes have to clear the steering wheel column and also not interfere with the bodywork - and their is no opening for the fuel cap on either the original or the restored car .. so I’m using .047 nickel rod - heated to ease the shaping - that cleans up easily with a sanding stick - and i ground away Some resin in the body to clear the tubes as they curve out of the chassis ... it’s a tight fit - just have to add the fuel cap neck ...

-

Revell 1/24th scale Jaguar E-Type FHC: Test Shots

absmiami replied to Justin Porter's topic in Car Kit News & Reviews

The jag E lightweight is one of my favorites. It occurs to me that if the convertible is issued - assume it will be - that it would be a good base for a lightweight ... -

Did you reprint the wheels with a different material - or did you change the design ? And are you using Mr Bill’s tires - or what ??? Very nice - btw ...