-

Posts

3,653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by bobss396

-

Sort of box stock-ish. Wheels and tires are from Jay's Resin Wheels. Headers are 3D printed, possibly VCG Resins. Stacks is got on eBay. Hood scoop I made up. Paint is Tamiya Dull Red with Mr. Hobby matte clear. Decals are from the kit. I opened the rear wells up to fit the tires. I took the chrome trim off the body.

- 25 replies

-

- 12

-

-

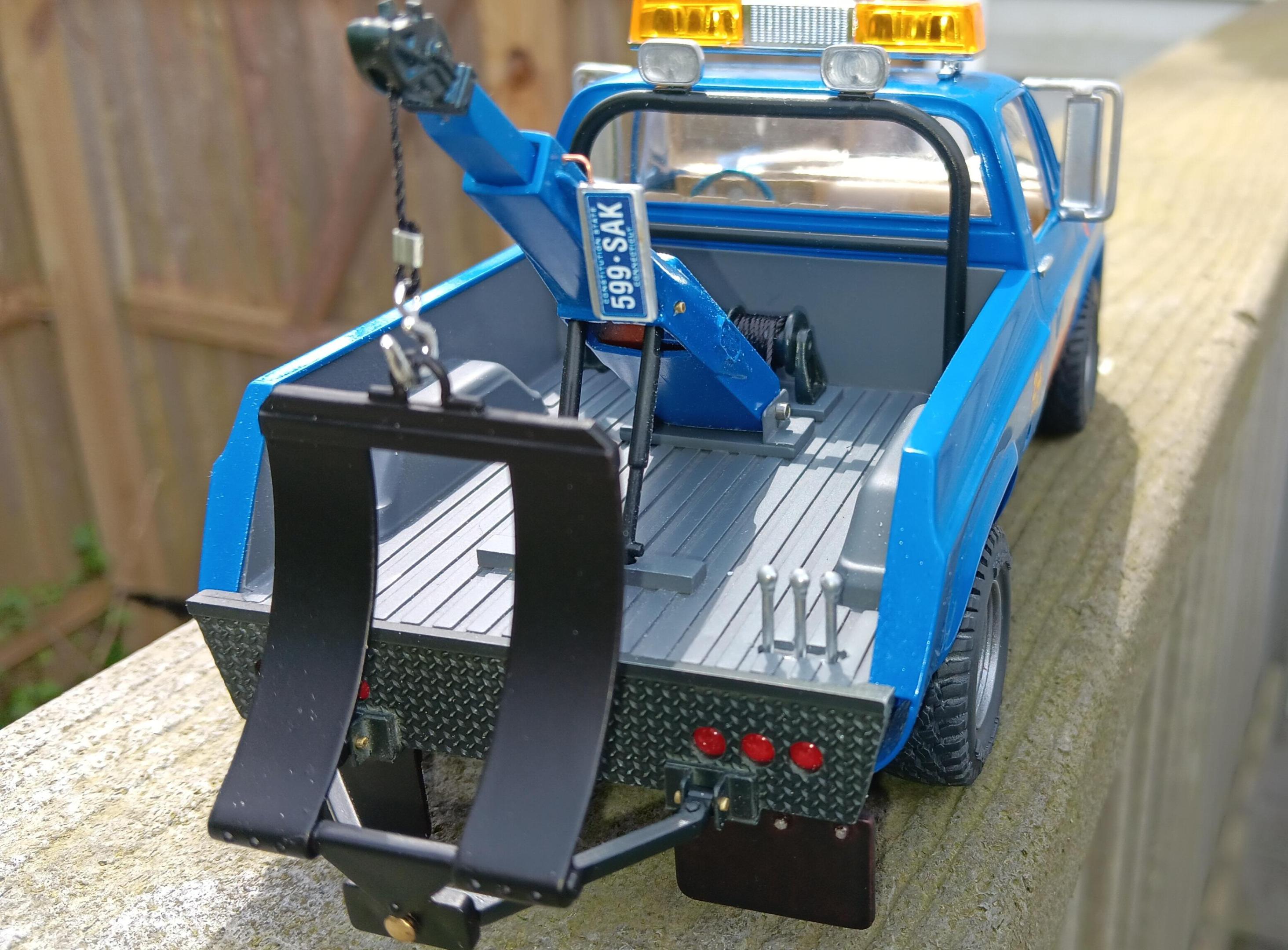

1977 GMC Wrecker DONE

bobss396 posted a topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

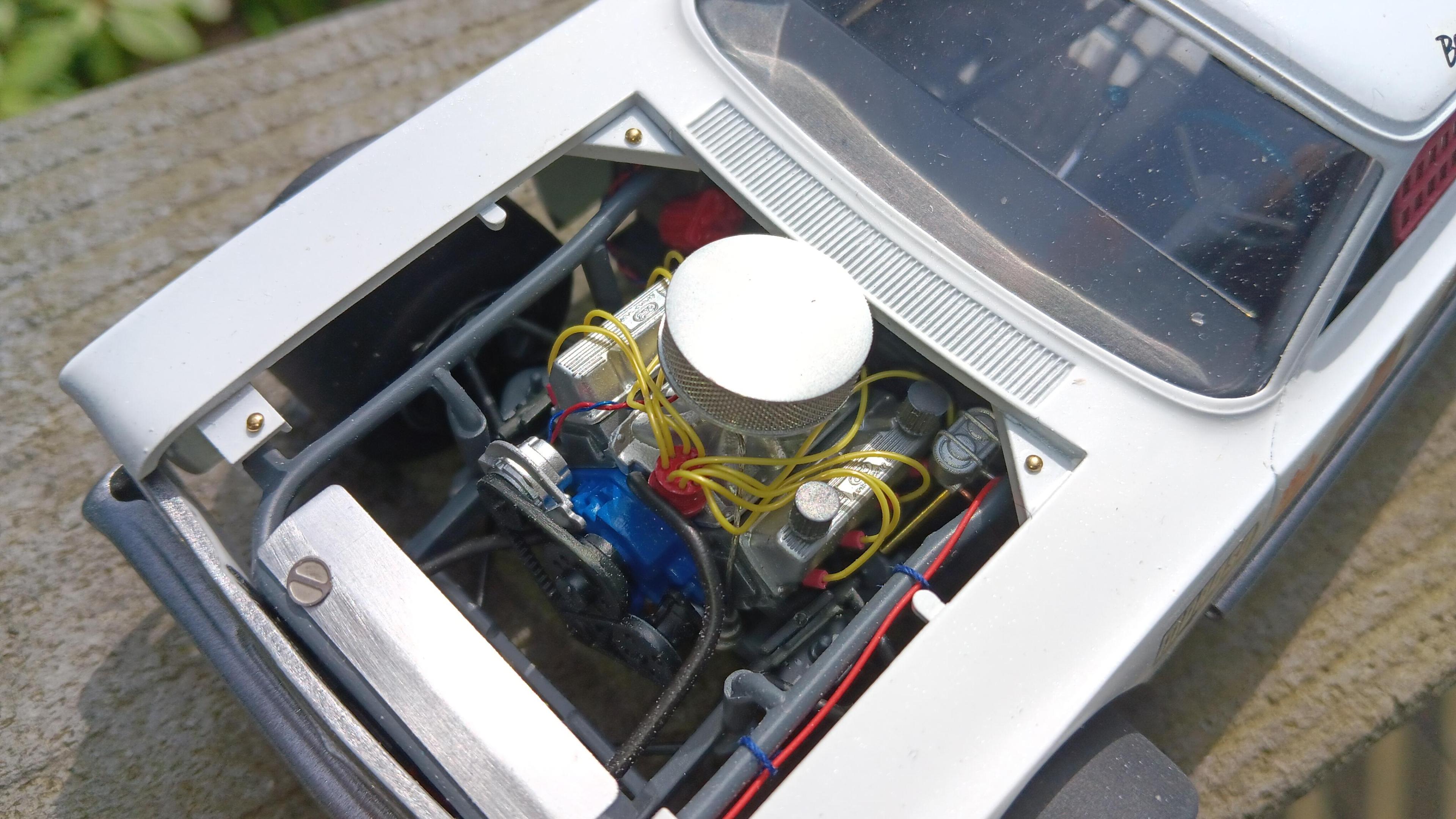

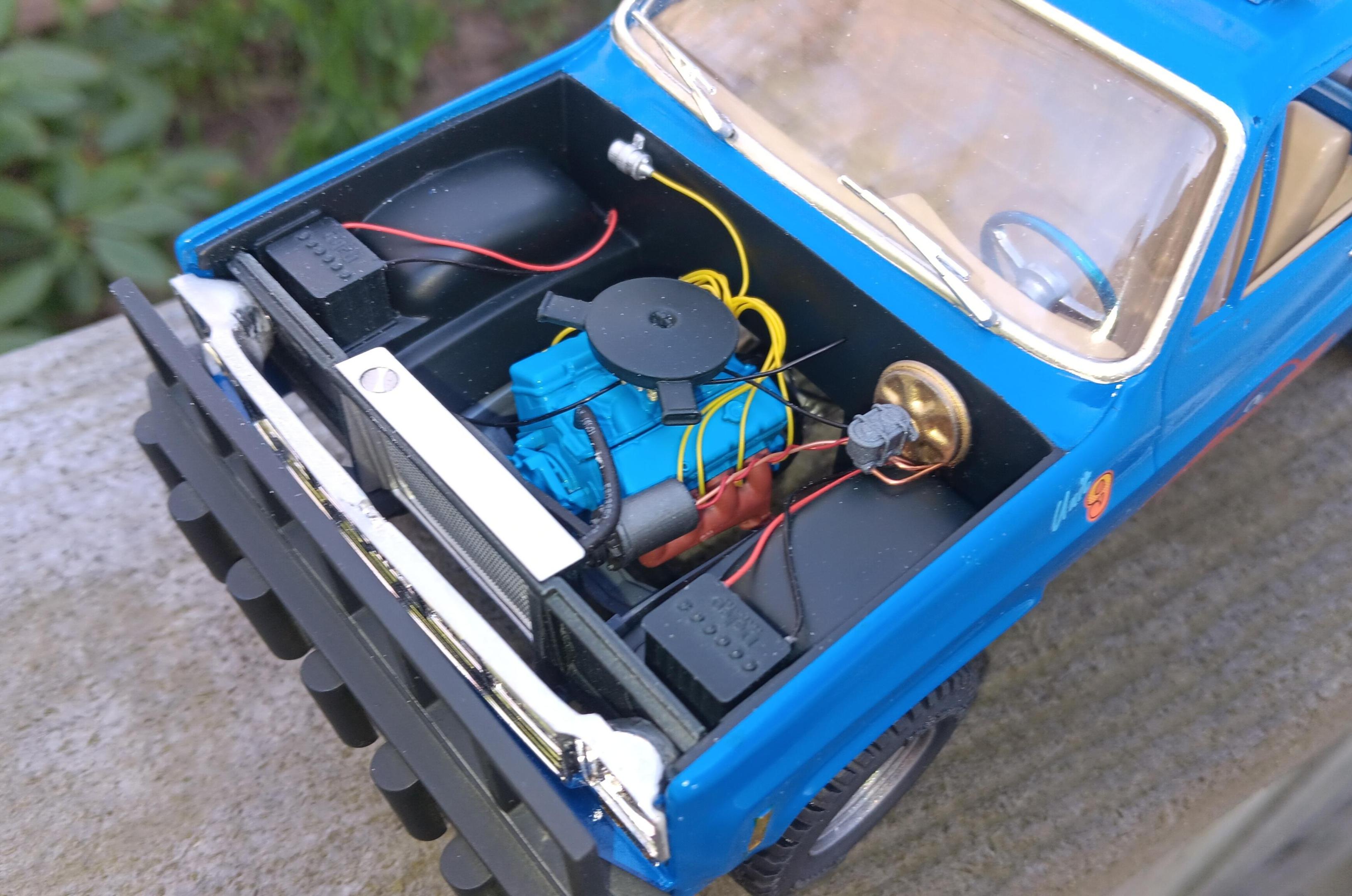

Finally finished it up. I'm also happy with it. The engine, brake booster/master and shifter are VCG Resins. Wheels and tires are Jay's Resin Wheels. Boom and tow truck parts are from a lot I picked up on eBay. Paint is Tamiya, I went with Ace Hardware gray on the chassis since it holds up to being manhandled. The grille was opened from the back. Decals are Chimneyville. The front bumper and tow plate are 100% scratch built. Light Bar is an AMT parts pack item. I have another in the works started in 1999. -

I joined the LIARS club in 1999 and we were teamed with another club (now defunct) and had a couple of shows in hotel event rooms. It was costly, but great venues (with cash bars...). Then we went to a catering hall... big mistake. I had been there for Bot Scout dinners and warned that it would be too dark, and it was quite an embarrassment for 2 years. For the past 20 or so years we have been at a recreational center. Great parking, well -lit, easy to get to. Another club has their annual show there too. We book the same date every year, so do they. Classic Plastic in NH uses an Elks Lodge and it is perfect, with a bonus of food being available. My advice is getting a similar venue, almost any fraternal organization rents out hall space. No matter where you land, venues are likely going to want to make sure you have event-insurance. Our club is IPMS based, so that is covered very easily.

-

1996 Chevrolet C-3500

bobss396 replied to av405's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I like it a lot. I'm still not sure what I'm doing with mine. I have a later wrecker bed I got on eBay, but the quality is not there. I could go ramp truck with it. The paint on yours looks amazing. -

My brother does his emblems the same way and they turn out great. The foil has to be trimmed close around the scripts/emblems so the line is minimized.

-

I see some 1979 bodies on eBay, fairly close but no cigar. These have the grille/bumpers integral, I'd prefer them to be separate.

-

I bought a box of "surgical" blades from a tool vendor, 100 for $15. They are great for BMF. Definitely brand X. I used to get real ones from work, no difference in function from what I could tell. I like the idea of the smaller holder.

-

Buddy Arrington Chassis Question

bobss396 replied to Iraceitall's topic in Model Building Questions and Answers

I see a 48 Plymouth that has a Diplomat front stub under it with a 318. -

Buddy Arrington Chassis Question

bobss396 replied to Iraceitall's topic in Model Building Questions and Answers

When I was doing alignments I recall the newer bar set ups. The Volare also had them. Probably the Diplomat cop cars too. One guy I know ran Mopars at Freeport, all the old style bars. He was quite a winner in the old Belvederes. The hot tip was to elevate the right front corner of the car when the roll cage was welded in. The dealer also had a certain part number torsion bar that was preferred. -

1/25 scale early fifties 230 Ford 6 cyl

bobss396 replied to oneoldcoot's topic in Model Building Questions and Answers

Eh not even close. A couple Mobius Ford trucks do have the later 6 in them. -

'77 GMC Wrecker

bobss396 replied to bobss396's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Getting close. Only a few items remain like the mirrors and rear license plate. And a general cleaning. -

I love Cadillacs. I worked with a guy who had the same car in black, his was garage kept and looked like new all the time. My next car will likely be a Caddy.

-

Best TZ ever... there is something on the wing....

-

I have some feelers out, nothing so far. I have the NNL East coming up, I'll ask around there. I have seen some 4-door 3D printed ones, I forget where.

-

Rahmoc Racing light blue?

bobss396 replied to Iraceitall's topic in Model Building Questions and Answers

Tamiya has a good light blue you may want to look at. -

Who sells those? I just may shrink some black sleeve over a pair to see how well it works.

-

1/25 scale early fifties 230 Ford 6 cyl

bobss396 replied to oneoldcoot's topic in Model Building Questions and Answers

That engine should be a 223, used in trucks and cars up through 1964. Then the 240, a different design was used. The 300 followed in trucks. I believe that one of the Moebius Ford trucks has a 6, if it was 1964 or earlier it should be a 223. VCG Resins has a nice 240/300, I'm using a performance one in a stock car. He may have a stock one, look at Iceman too. Edit: This is the stock 240/300 VCG Resins kit. Sold out, but close to what you want. I would just sand the valve cover smooth. https://www.vcgresins.com/shop/p/ford240300i6stockenginekit -

Buddy Arrington Chassis Question

bobss396 replied to Iraceitall's topic in Model Building Questions and Answers

Down on the page it discusses the Petty front suspension that used a modified torsion bar suspension on a 1971 car. I forget what year that the torsion bar suspension was changed to a different design. Possibly in 1978 that Petty was not happy with, hence the move to GM cars. https://www.motortrend.com/features/hrdp-0510-1971-plymouth-road-runner/ -

Buddy Arrington Chassis Question

bobss396 replied to Iraceitall's topic in Model Building Questions and Answers

Petty cars were probably similar, no? If Petty ran torsion bars, so did others. Petty cars should be easier to research. -

It did get breezy for a while around 3, I read that this may happen. The street lights did come on. I went out a few times after to look with the glasses and box viewers. I didn't see anyone else outside. Out on the road earlier, the parkways had electronic signs saying not to stop on the shoulder to view the eclipse...

-

I'm not using my glasses. I made a couple of box viewers. I gave one to a nurse where I had my infusion. Cut a 1" hole in one end of the box. Cover with foil and punch a small hole in it. On the inside wall opposite that, tape a piece of white paper, this will be the projection screen. On the side I made a flap where I'll be looking in. I figure I can close it a bit if need be. Lastly, close up the box bottom. Both worked well, I may mess around with the pin hole size.

-

The one I go to has the Model Master lacquers, some unknown to me acrylic paints. The array of models and the space given to them is pretty good.