-

Posts

3,653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by bobss396

-

The factory '41 to the '46-'48 post-war cars were quite similar in the 1:1 world. I would consider doing one. Now if someone would make up a 3D printed '42 grille...

-

I did a wheel alignment on a Grand Am back in my car fixing days. It was a '74 or '75 with the 455 H.O. and a 4-speed. Needless to say, the alignment required a longer-than-usual test ride before and after. It had the shaker scoop and was FAST.

-

I just made up a red sauce, 6-7 quarts worth and it came out great. I put in 4 large chicken thighs (browned first), a pound of hot sausage, 24 or so pre-made meat balls, a package of pork neck bones. Of course around 10 cloves of pressed garlic, one large onion grated, 2 peeled carrots to cut the acid, oregano and basil, bay leaves, a grated large jalapeno pepper, 4 anchovies chopped. 2 cans of tomato paste, 4 cans of crushed tomatoes. I brought some over to my girlfriend;s house for Sunday dinner, she made pasta and I picked up a loaf of bread on the way. I am freezing the bulk of it and using the rest this week. I need to pick up some mozzarella cheese, I have a Jones for shrimp parmesan. I have a set of little pyrex dishes I use for things like this.

-

VCG Resins makes a couple of nice 3D printed quick change rears that would work well on this kit.

-

Check out Iceman as well. I buy from him on eBay.

-

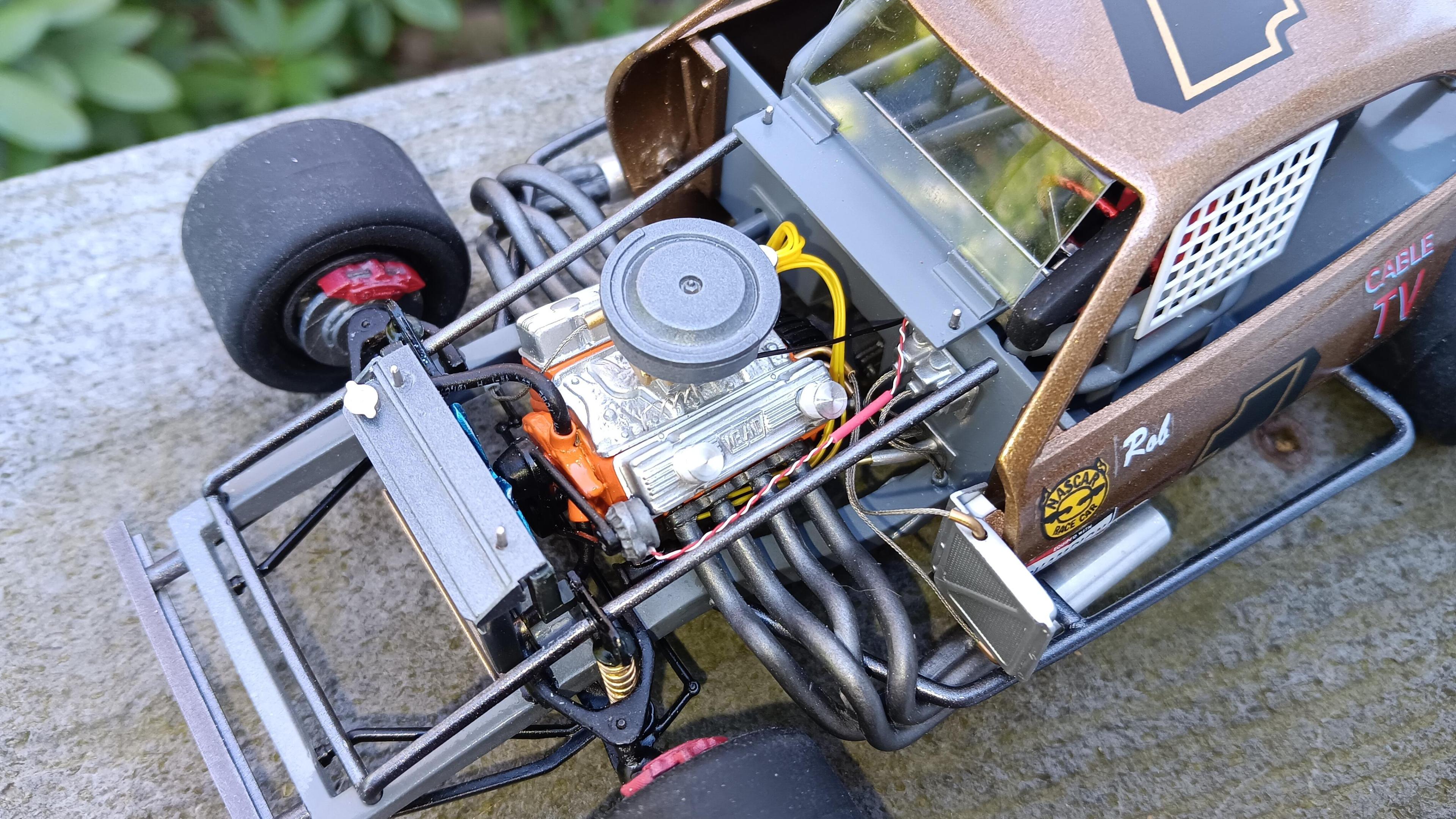

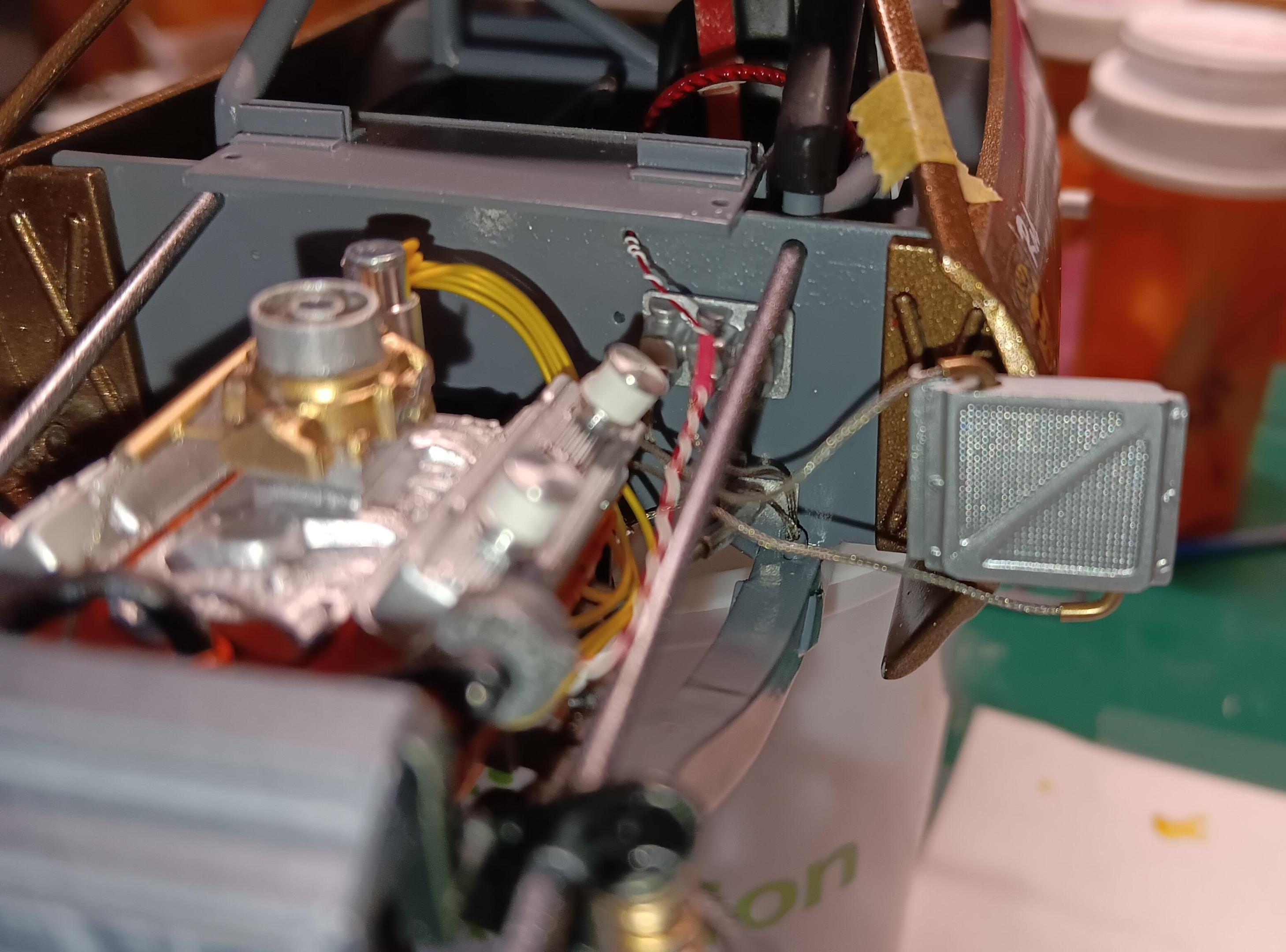

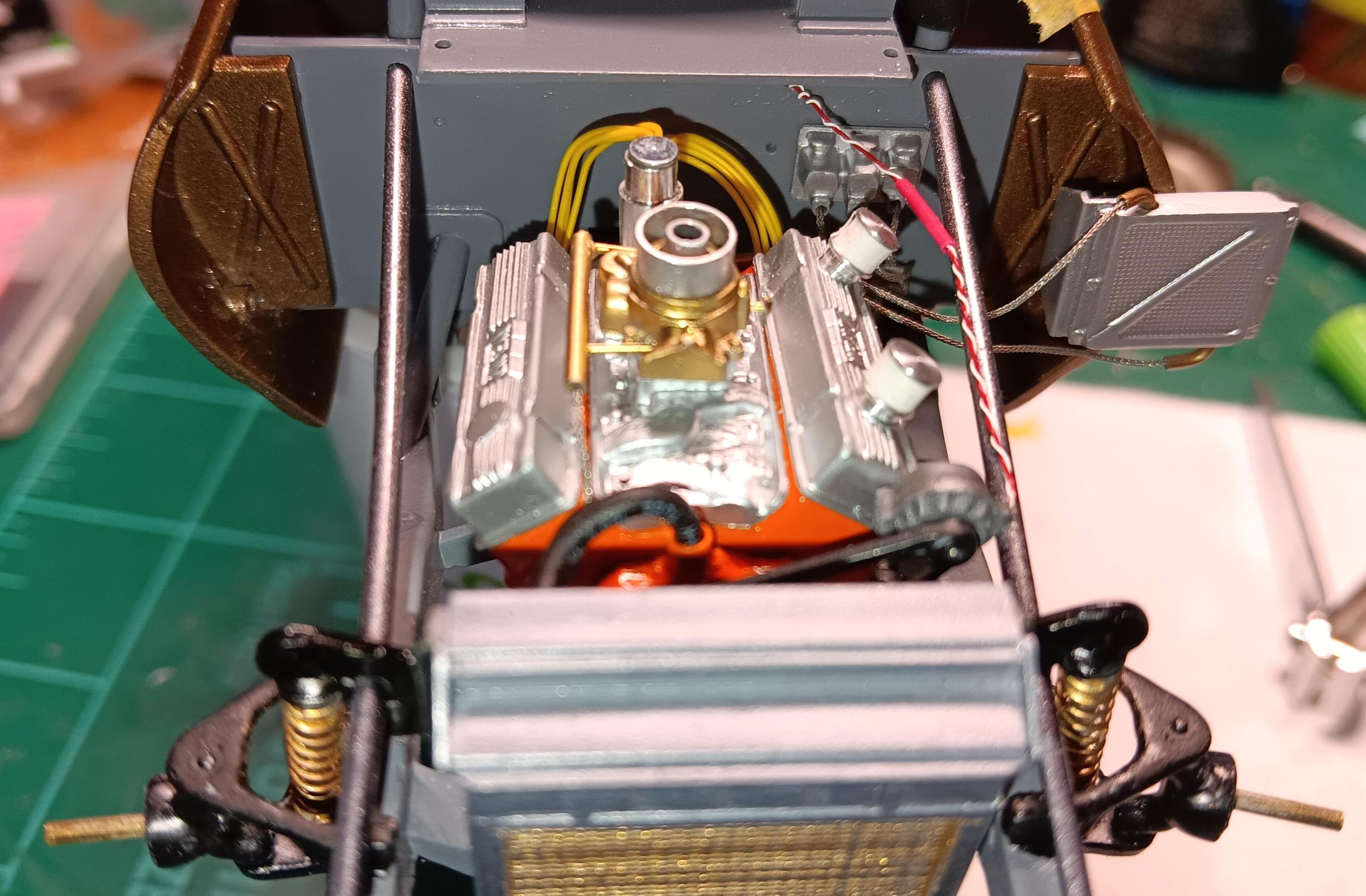

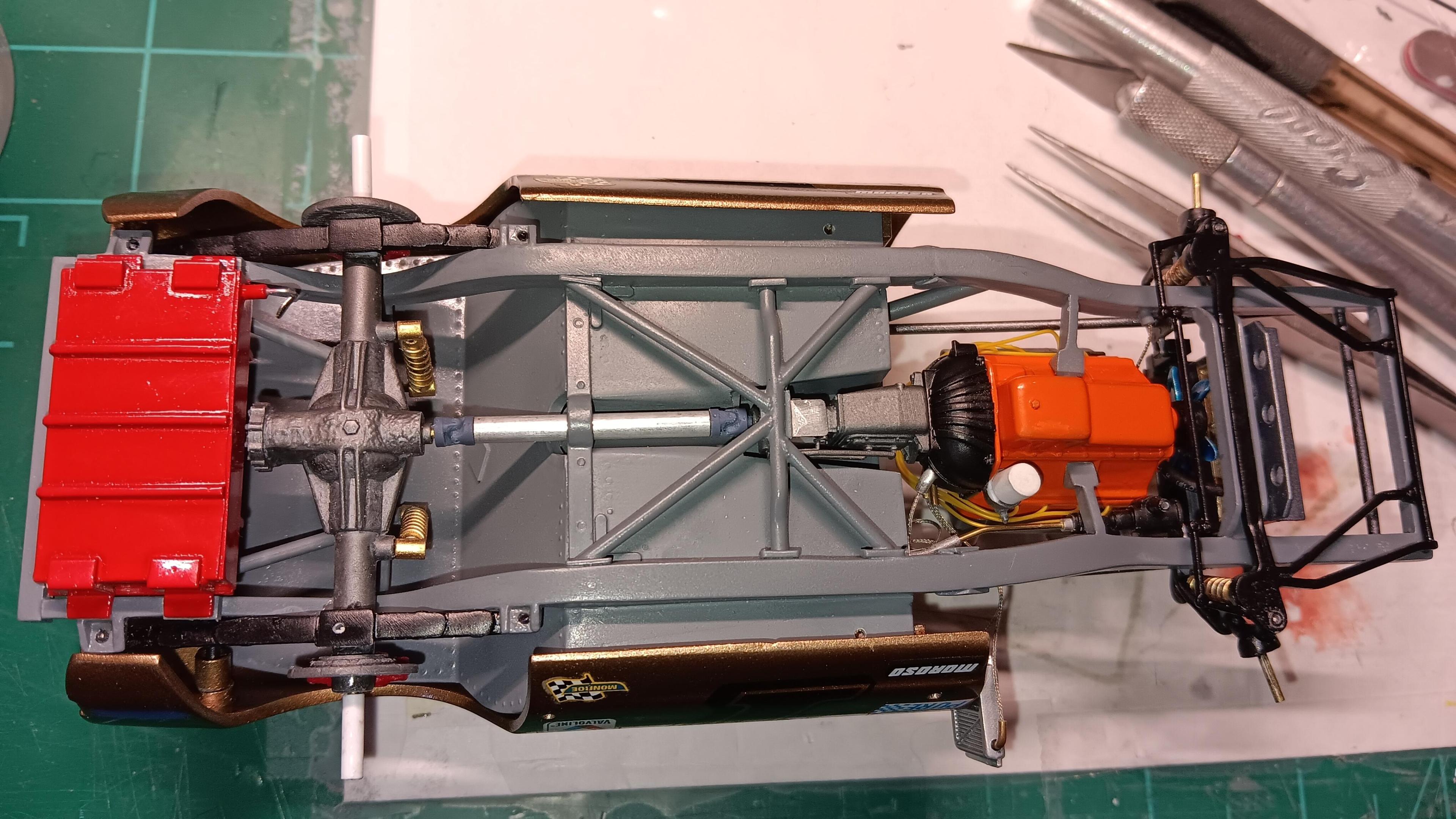

Pinto Modified .. DONE!

bobss396 replied to bobss396's topic in Stock Cars (NASCAR, Super Stock, Late Model, etc.)

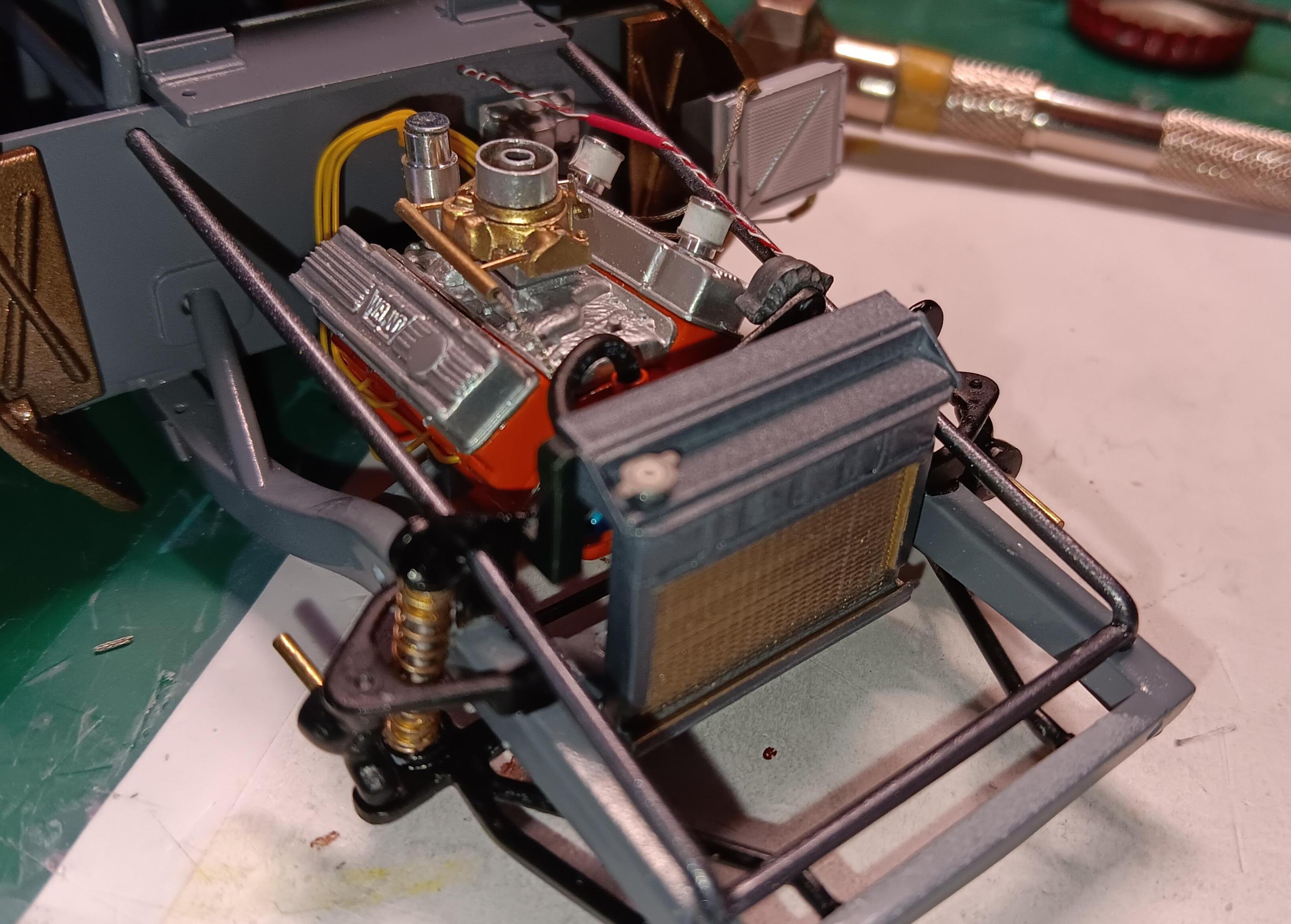

Thanks. This was my late-stage stumbling block last year. I HAD a radiator, painted up and I lost it, it will turn up. I have a box that I call "Future Modified" full of modified parts and sub assemblies. I picked out a radiator from that. I had split the radiator off from the coil-overs and needed another way to hang the radiator. I had to attach it to the "bridge" I made up between the coil-overs and the crossmember. It went together fairly easily and once painted it looked good. -

I had bought out a lot of Duplicolor paints at a parts store that had changed hands at 99¢ per can. This was close to 20 years ago and I'm still using them. This formula was very forgiving, not like their current crop of blushing paints. I did a green 1940 Ford in November, I was working out of my finished basement then. It was COLD out... I'd go out into the stairwell, paint and go back inside, put the body right into the dehydrator.

-

Very cool build. I use a lot of VCG and Iceman parts. VCG has a couple of QC rears I like. One is make for the Revell 32 kit.

-

Very good! I have a stalled one I have to get back to. On side pipes, I make up "J" hooks and attach them to the inside of the body or the chassis. I use .010" thick aluminum flashing.

-

Big time crazy... me like!

-

I paint outside all year. I step out onto the deck, spray and run back inside. As of late, Duplicolor paints blush no matter what I do. Outside, Tamiya, the old Black Gold line and the Mopar touch up cans are very drama free. In a pinch in really snotty weather. I place a cardboard box (with the front and top sides cut out) on an old snack tray in the finished part of the basement.

-

I would look at what 3D resin guys like Iceman and VCG Resins have. Also 3dscaleparts. There are others in the 3D vendor forums.

-

I finally finished up the Pinto. I ran into issues late in 2023 and parked it. I had to do the side rails, put on the headers and make up a lot of radiator parts over the weekend. I'm happy with the way it came out.

- 21 replies

-

- 12

-

-

1/24 Scale Seat Belt Buckles?

bobss396 replied to Noah H.'s topic in Model Building Questions and Answers

I grab any flat ribbon ? that I see, mostly off gifts. Curling ribbon is good too, run it across a steel scale to take a little texture off it. I fold tabs in the ribbon, put it through the hardware and secure it with CA or tacky glue. -

MPC ‘36 Modified

bobss396 replied to shoopdog's topic in Other Racing: Road Racing, Salt Flat Racers

Nice clean builds. I go overboard with mine... too much like work. They are a good starting point though. I am finishing up a Pinto right now. I did the Vega last year. -

Old school late model

bobss396 replied to Vettegasser's topic in Other Racing: Road Racing, Salt Flat Racers

I like it, nicely executed. I use a lot of Ron's stuff on my cars. How much work was the rear clip to install? I'm considering one for a late model Nova build. -

1963 Galaxie light weight

bobss396 replied to ShawnS's topic in Other Racing: Road Racing, Salt Flat Racers

I really like it, nicely done. Everything looks very accurate. They were heavy cars but they could move. Plus larger cars were harder to pass. -

Food City Lumina

bobss396 replied to James2's topic in Stock Cars (NASCAR, Super Stock, Late Model, etc.)

Very clean too... nicely done. I have a slew of these kits and similar ones. I never pass up a $3 NASCAR kit. They do build up nicely, I need a break from the Frankenstein builds I'm in the middle of right now. -

Interesting, I'm not totally in with no judging however. There is another show on the 18th in Peabody, looks like an IPMS show. I'll have to see if I can dig up some of who vendors will be at the RTS show. Thanks.

-

We have a local club that meets at a library, for at least 25 years. The time slot is only 2 hours, ours at a community center is 3.

-

1/24 Scale Seat Belt Buckles?

bobss396 replied to Noah H.'s topic in Model Building Questions and Answers

Gofers are not so bad. I have never been successful getting the thick ribbon through the hardware and getting it glued together. I use either paper from other belt kits or ribbon. -