-

Posts

10,236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

-

Neat marketing gimmick I think.

-

Beautiful! I love the colours too.?

-

I have made an impression in silly putty and cast them using Bondic. It was just an experiment and I haven’t used them on a model yet. I have also made them out of clear plastic in this thread. Maybe someone knows of another source? http://www.modelcarsmag.com/forums/topic/161380-making-headlights/?tab=comments#comment-2452651

-

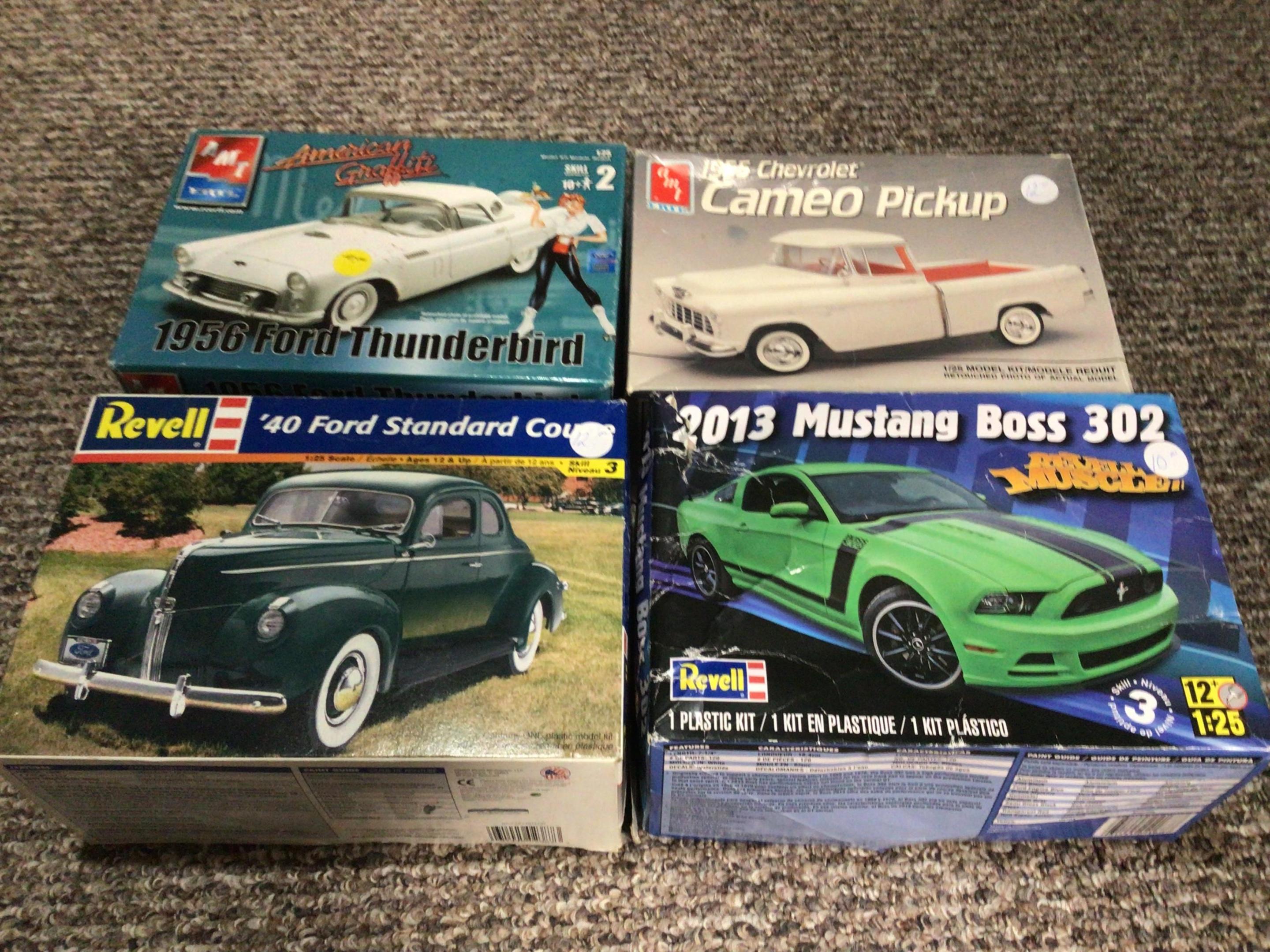

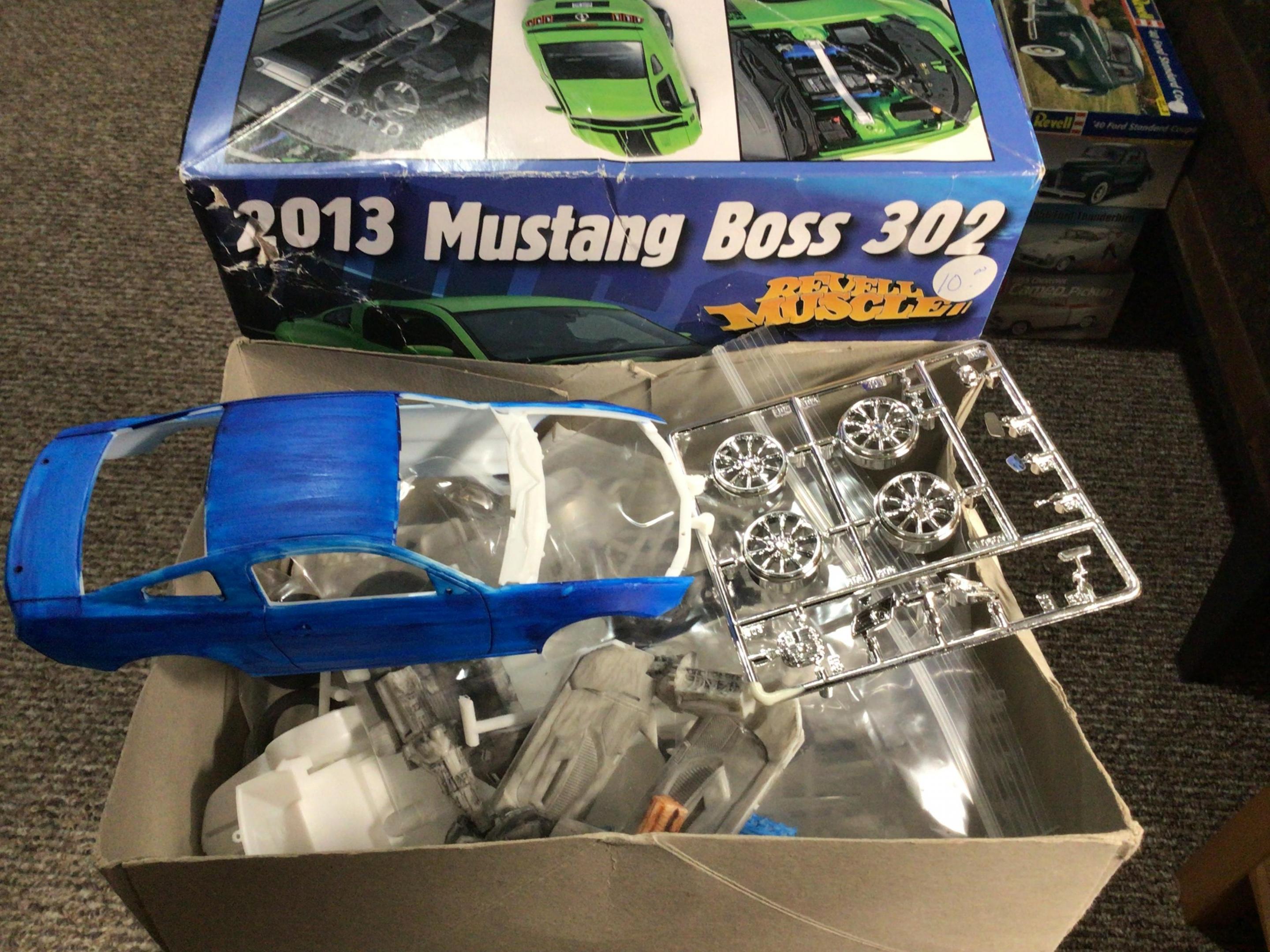

Got a good deal on these at a flea market. They have all been started so I hope they are complete. The Mustang I just got for the wheels and tires and engine.

- 39,276 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Wow! You like to keep a lot of paint in stock.?

-

1964 C10 Longbed Crewcab Dually

NOBLNG replied to sidschopshop's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

That turned out great! Really good job on the weathering!? -

I understand completely! We Ford and Chebby guys have it easy. You know, being a Mopar Guy….that the “hehe times” are very few and far between.??

-

Group 29 - the thread for everyone's '29 Ford Roadster builds

NOBLNG replied to Phildaupho's topic in Model Cars

-

I didn’t have any warpage issues with mine. I did however have the chrome peel off of the front axle and the radiator shroud…so I wound up painting it. Be careful if you mask any of the chrome. http://www.modelcarsmag.com/forums/topic/159642-‘29-model-a/?tab=comments#comment-2370560

-

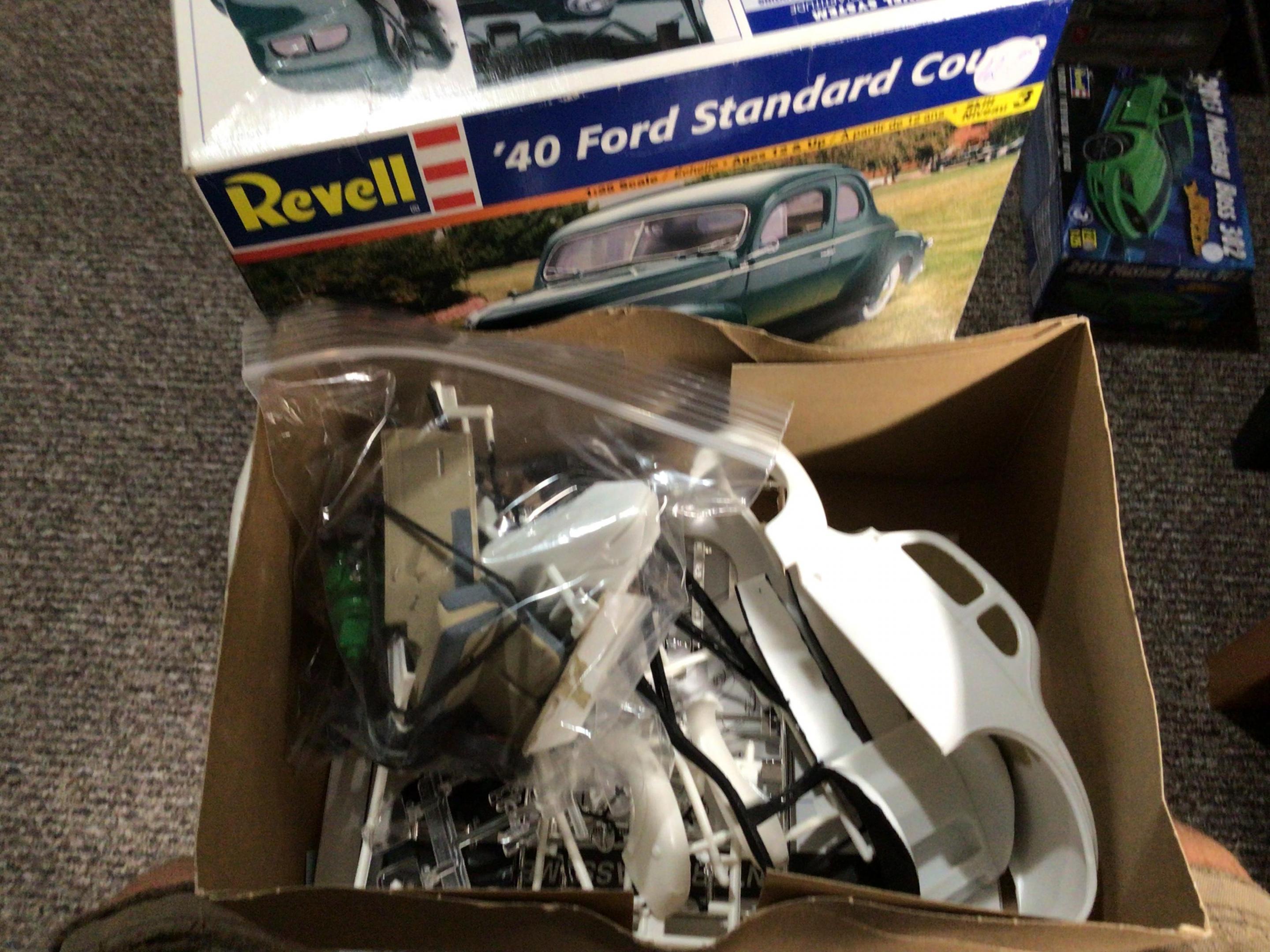

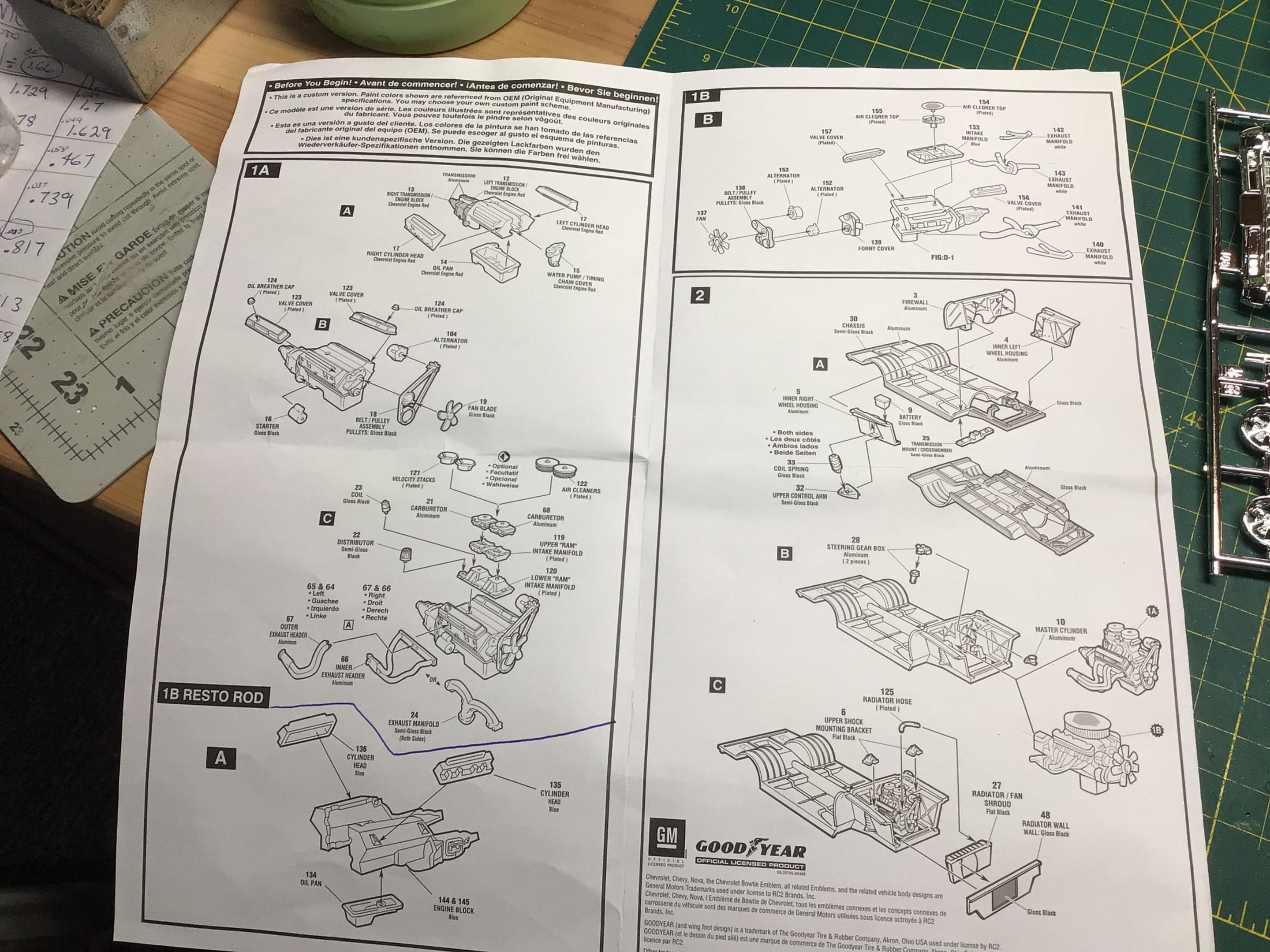

Mark, that sounds like exactly what is in my box, including the wrong instructions.? It looks like it should build up nicely though.

-

Beautiful…one of my all time favourite cars.?

-

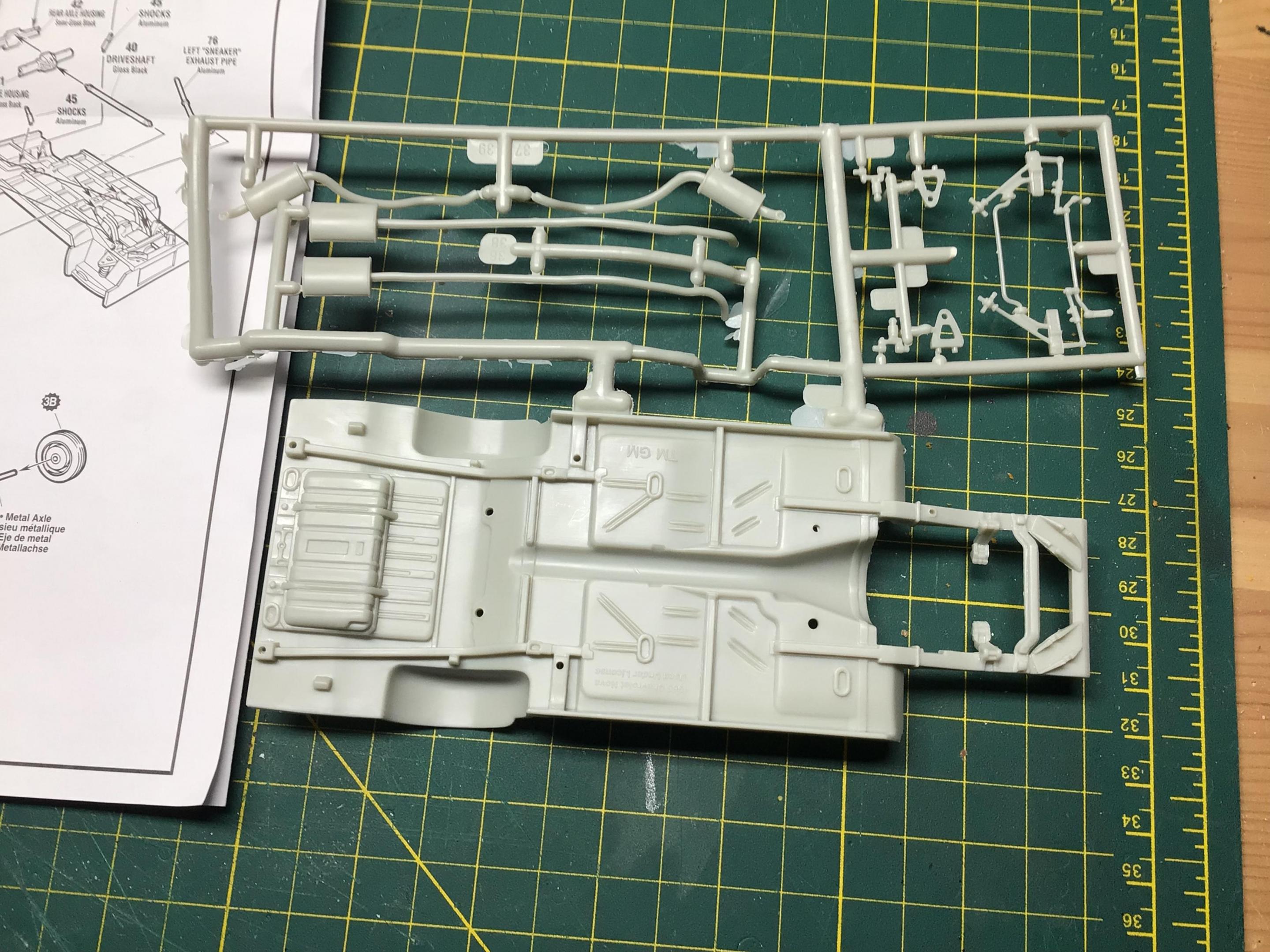

I bought it at a flea market, unsealed. All the parts inside were bagged though, and all the parts are the same shade of grey.

-

It could just be the angle of the photo, but it doesn’t look like your bulkheads are symmetrical? Fold a piece of paper and draw a half pattern, cut it out and unfold it. It will then be symmetrical. The method Charles suggested should work (think wooden barrel). I would go even thicker with the strips, like .060” maybe? More material to sand smooth. Good luck with it.

-

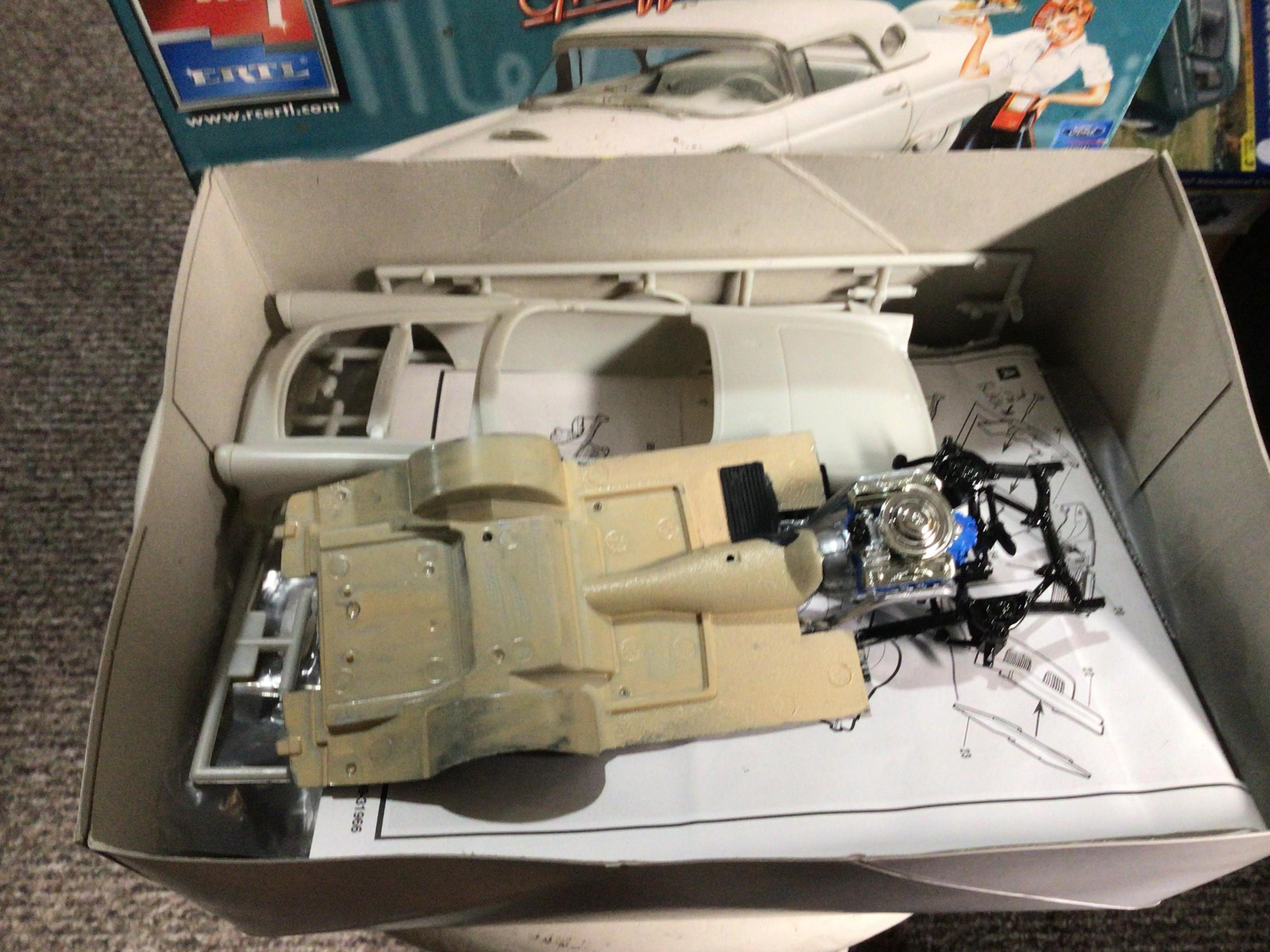

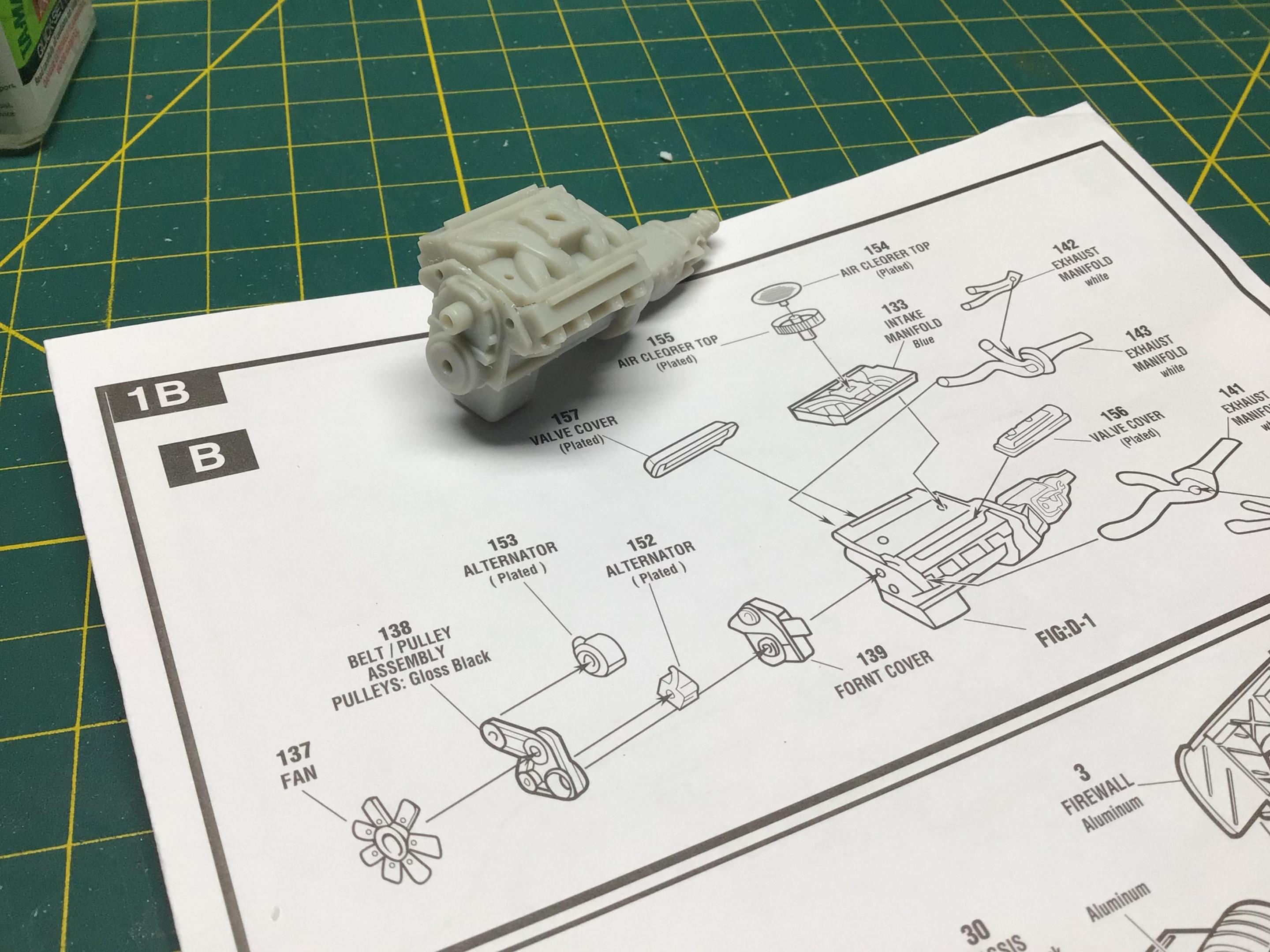

Well theres NO WAY that engine is going in the Nova! That would be sacrilegious! ? It seems like they threw all their leftovers and floor sweepings in this box? It also has this partial engine. Since the instructions don’t really match what is in the box….I guess I’ll be muddling my way through it.?

-

-

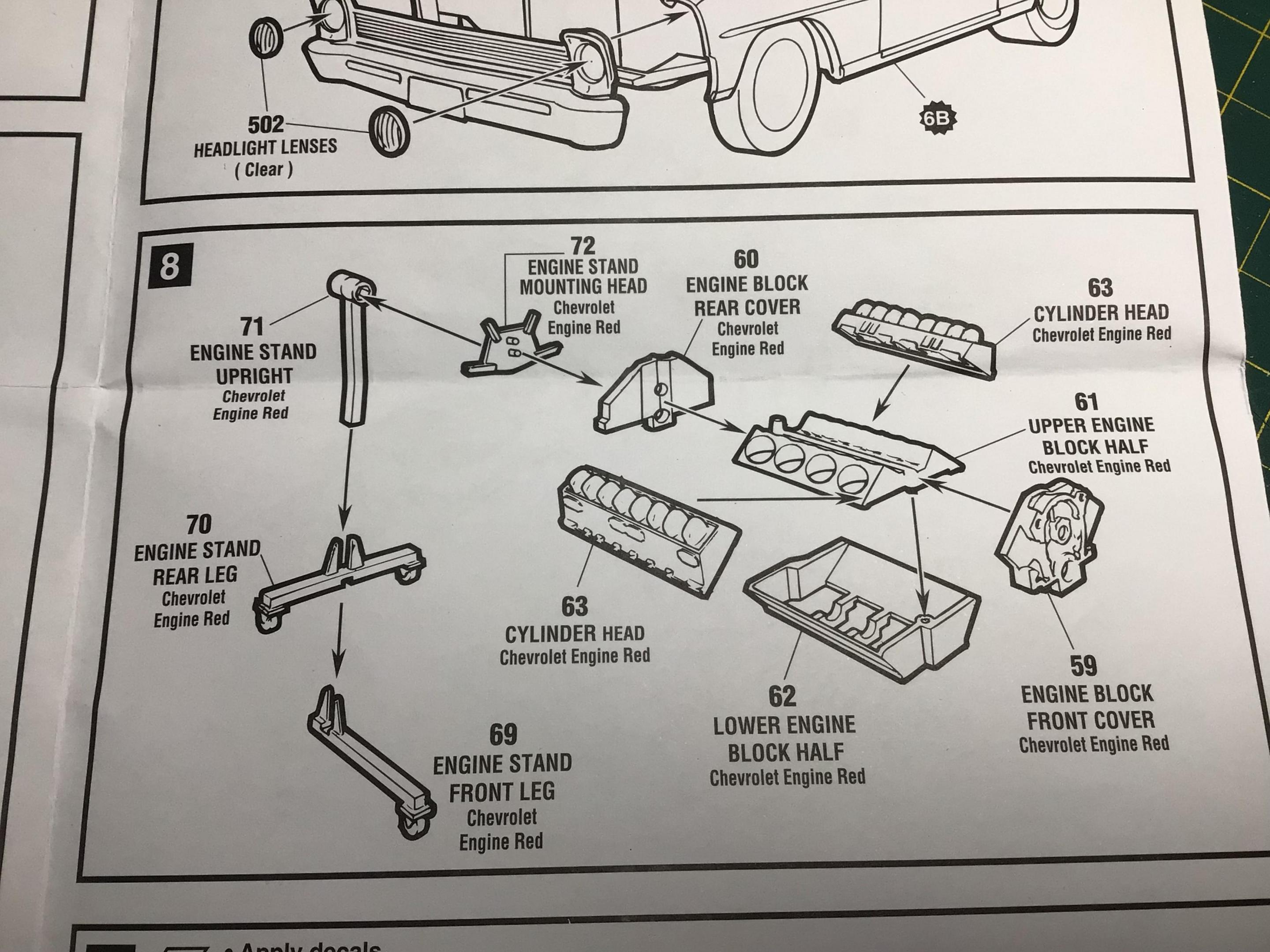

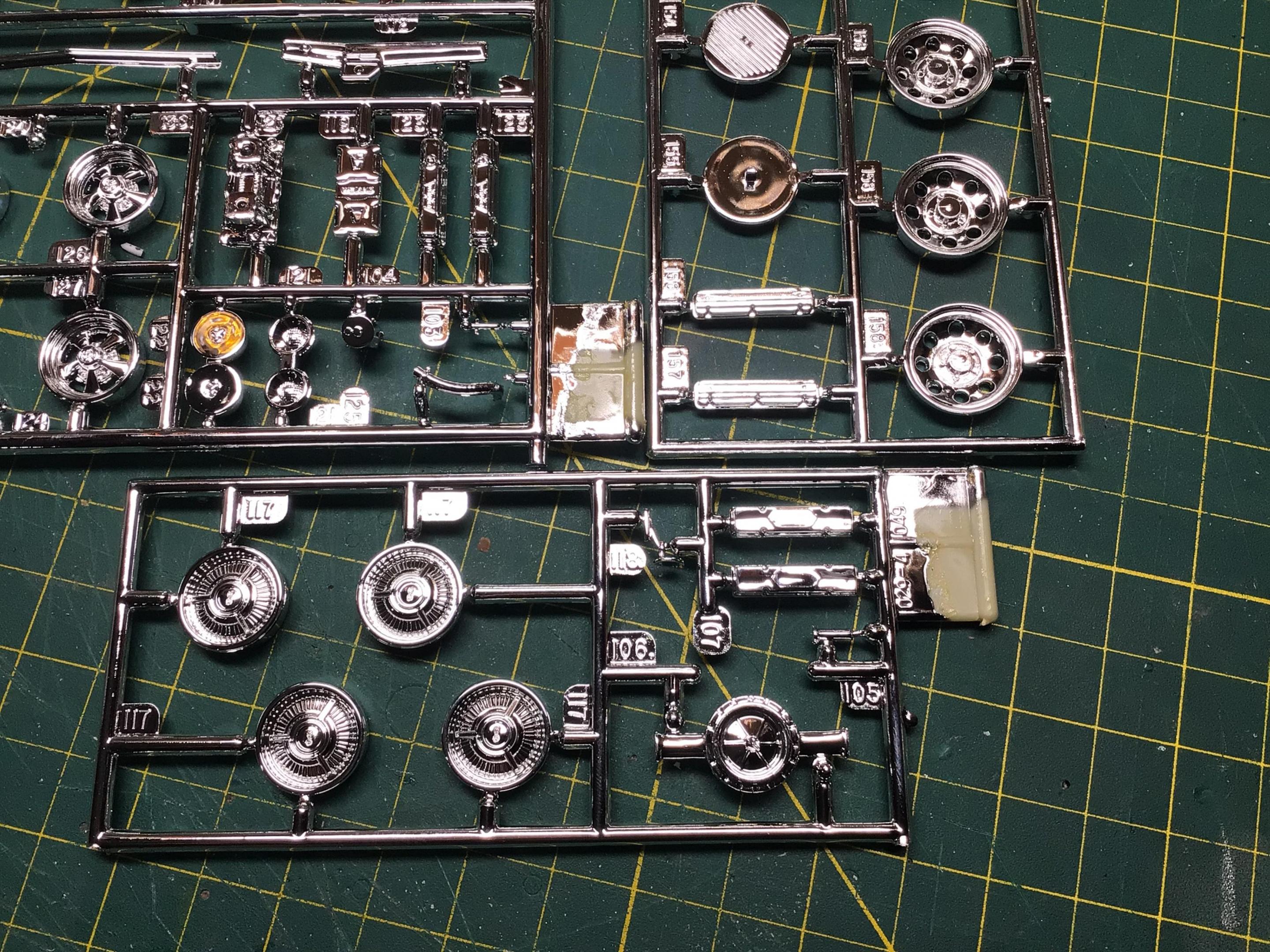

What engine is this 1B supposed to be? There is no starter, oil filter or distributor for it. The valve covers (#156&7) have three bolts on one side only. For the 1A SBC engine, there is also a single 4 barrel manifold that is not mentioned in the instructions, and what I imagine are supposed to be stock valve covers and air cleaner (also not mentioned) on the bottom chrome tree in the pic.

-

The Grape Crate - a (mostly) scratchbuilt Model A Woody

NOBLNG replied to OldNYJim's topic in WIP: Model Cars

Cool project! ? -

I like that blue too! What is it?

-

1946 Dodge Power Wagon

NOBLNG replied to Paul Payne's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I can see where that might have possibilities! ? -

I am relatively new to this forum and have never laid eyes on any of those that I can recall. Thanks for re-posting them because they are beautiful! Definitely among the finest work I’ve seen anywhere. This is indeed a great forum!?