-

Posts

10,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

Nice upholstery work!👍

- 30 replies

-

Why doesn’t everyone go right now to their stash and grab a fresh model to start assembling?

-

Yes that color looks fabulous on it!😎

-

Rear end is looking good Jim. Heck, it’s all looking good.👍 I’m not normally a fan of fender skirts, but I don’t think they look bad here.🤔

-

Driven to the edge of insanity is how I feel while building some of these old AMT kits.

-

'64 ElCamino

NOBLNG replied to Can-Con's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

That is one beautiful looking El Camino! Well done Steve.👍😎 -

1927 Ford Model T Tank Truck

NOBLNG replied to Bobchayer's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Very nicely done Bob.👍 -

A handsome pair indeed! Outstanding work.👍😎

-

Absolutely beautiful looking Shelby!👍😎

-

'57 Vette Fuel-Injected 283 Small Block by AMT 1/6 Scale

NOBLNG replied to DougS's topic in Model Cars

Fantastic detail on this, and really nice display!😎 -

What kits have a good 56 and up 283

NOBLNG replied to junkyardjeff's topic in General Automotive Talk (Trucks and Cars)

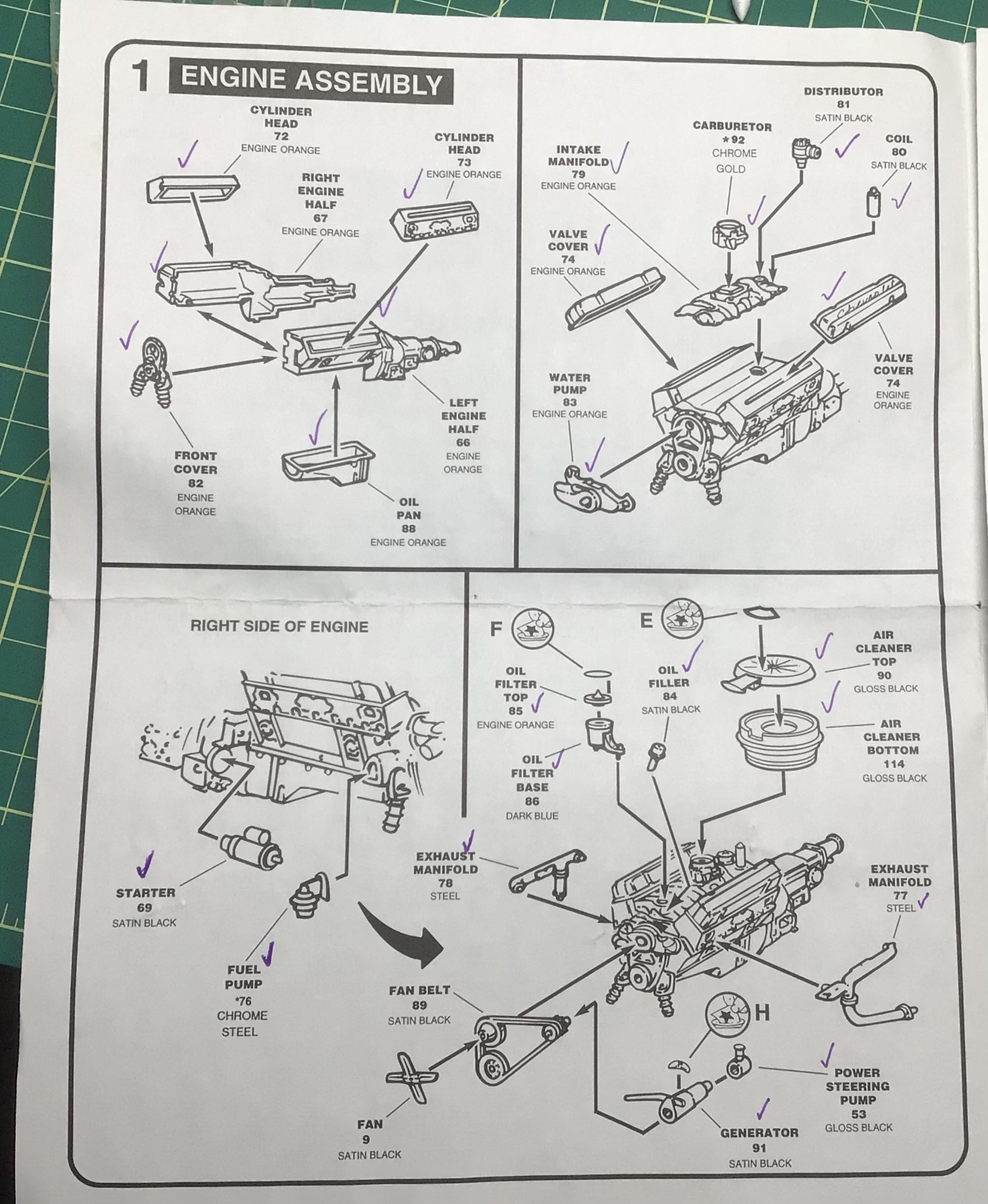

The Revell ‘56 Del Ray kit has a nice one…but no oil filter. The Monogram ‘55 Bel Air Convertible has a really nice 265. You might be better off looking for a 327 though. -

Resin to Plastic glue options???

NOBLNG replied to WillyBilly's topic in Model Building Questions and Answers

If the material is thick enough, you could drill and pin it in a few spots for added strength. -

Pets also doomed to be replaced by AI and bots...

NOBLNG replied to Ace-Garageguy's topic in The Off-Topic Lounge

-

The pictures are a bit blurry, but I think the passenger side looks more realistic.

-

-

Fun work project - old display model Vette

NOBLNG replied to OldNYJim's topic in General Automotive Talk (Trucks and Cars)

It’s not like it’s gonna rust.🙄 -

Curtain call is when the performers come out and take a bow to show appreciation for the audience.

-

Movie night with Netflix and Prime is now every night.🍿

-

-

I like the look of it Jim!😎

-

Beautifully done, and great pics!😎

-

Great work Kelly.👍 Foiling can be tedious work, but it is the absolute best treatment for trim and well worth mastering. Looks like you’ve got a pretty good handle on it.😎

-

Days will be getting longer again in less than three weeks.