-

Posts

3,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by AmericanMuscleFan

-

Excellent work on the paint Rich, this is not an easy task that you have embarked on but your determination deserves to be highlighted, few would dare to venture into such a complex painting job and I am one of them! ?

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Ian! I would like to be able to make certain elements even more to scale but there is a limit to what I can do and what the material can render without distorting. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Rich! Unfortunately I don't have any leftovers but they are actually quite easy to make with a good sharp Xacto blade. It's even easier to do with Styrene but you have to paint them to have the metallic effect. Francis Thanks Dwane, I had thought about it but I wanted the car to remain parallel to the ground. ? Francis Thanks Andrew! Yes, I cut them by hand from a large aluminum sheet. The stock is 0.016" thick, I wanted to make them thinner using stainless but it's too difficult to work with. Lots of sanding to make them acceptable and reduce the shine of the material though. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

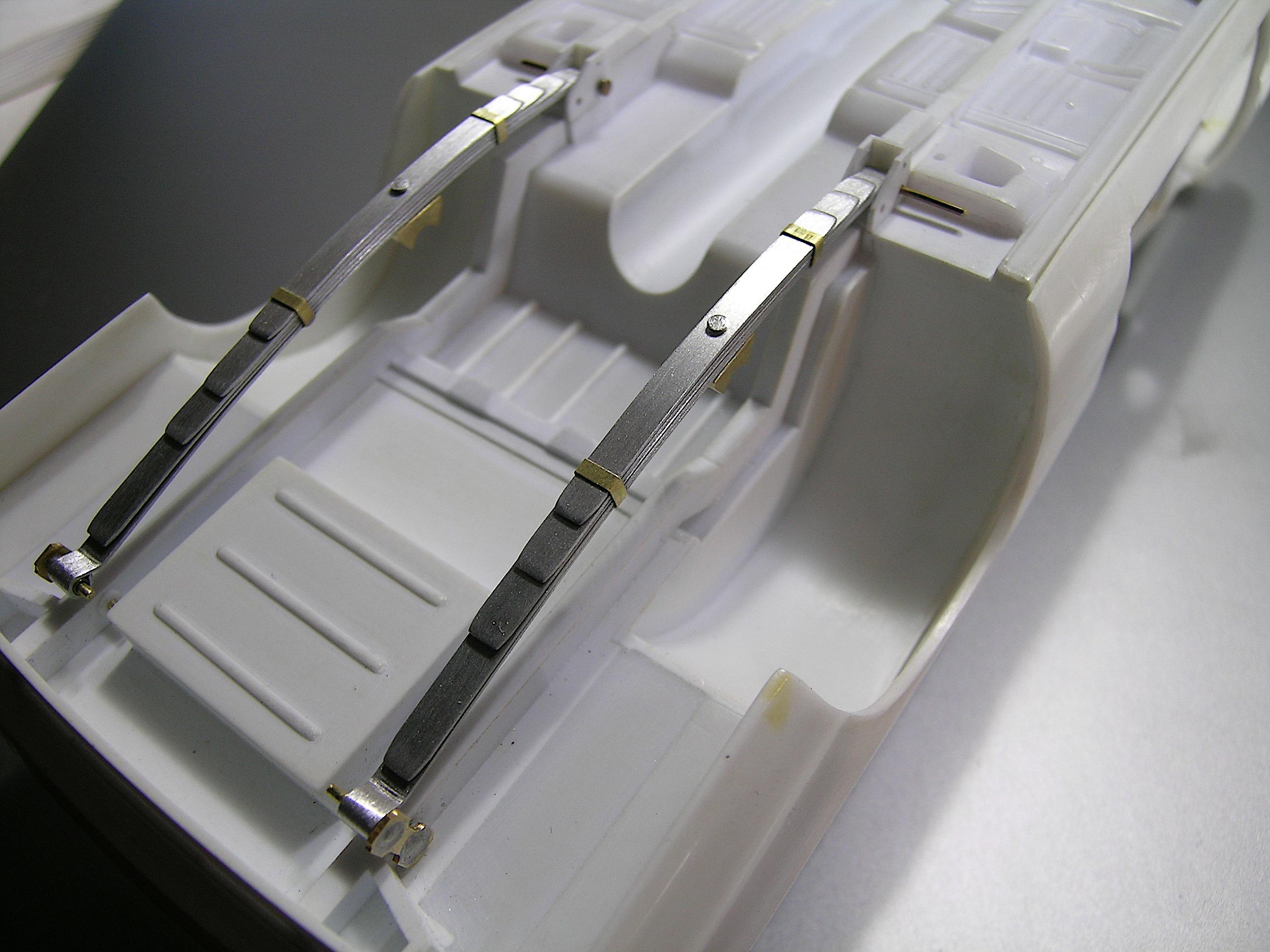

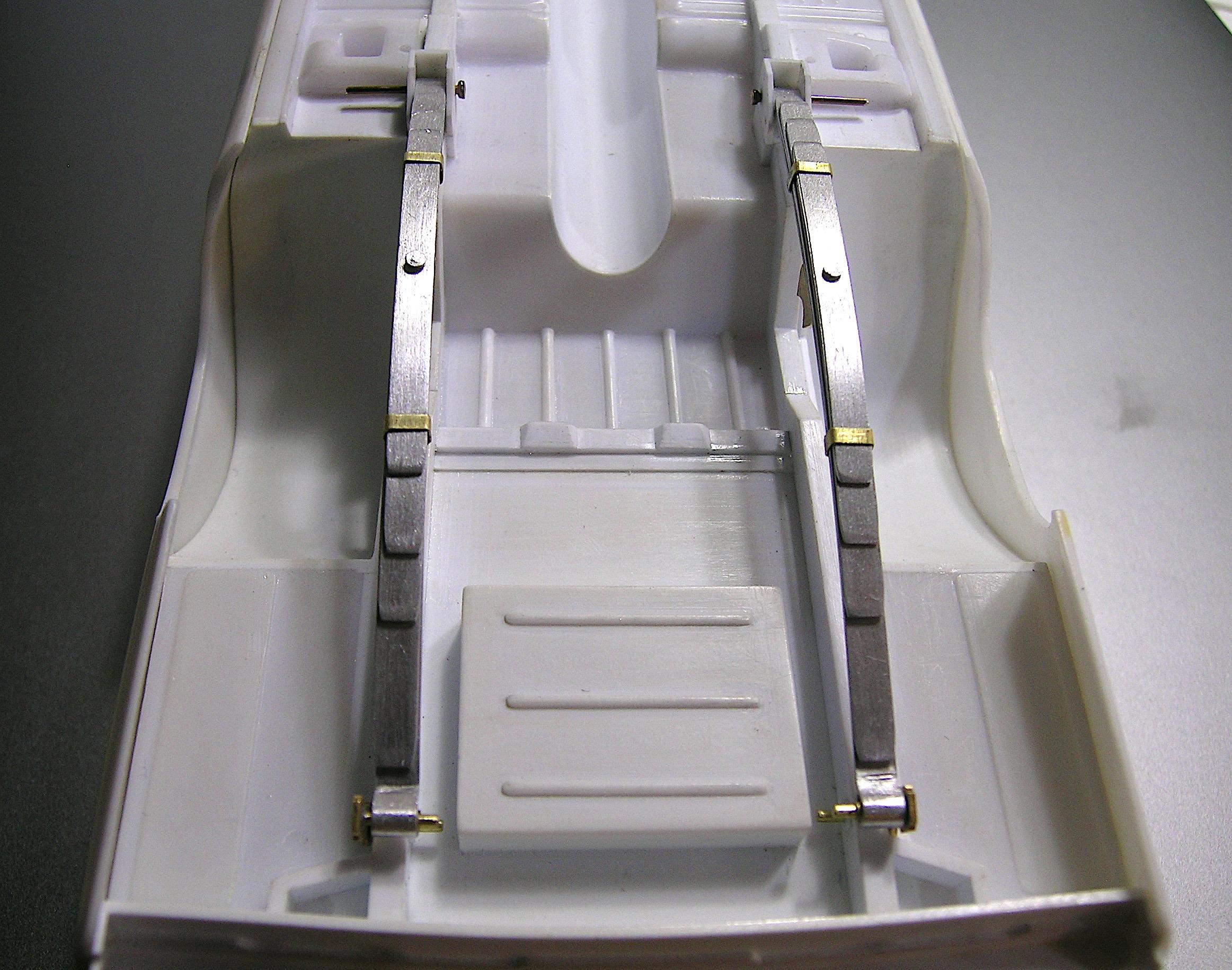

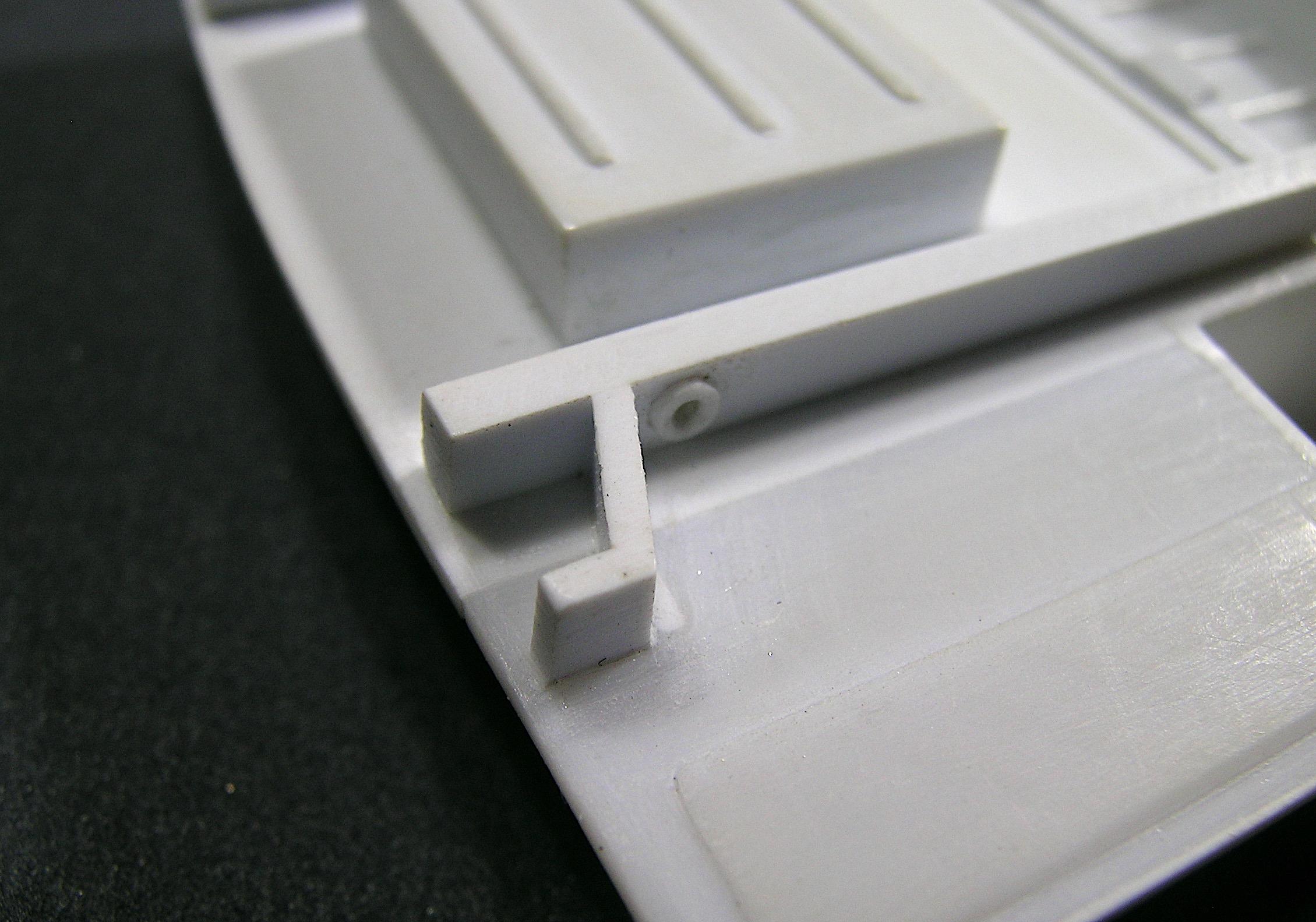

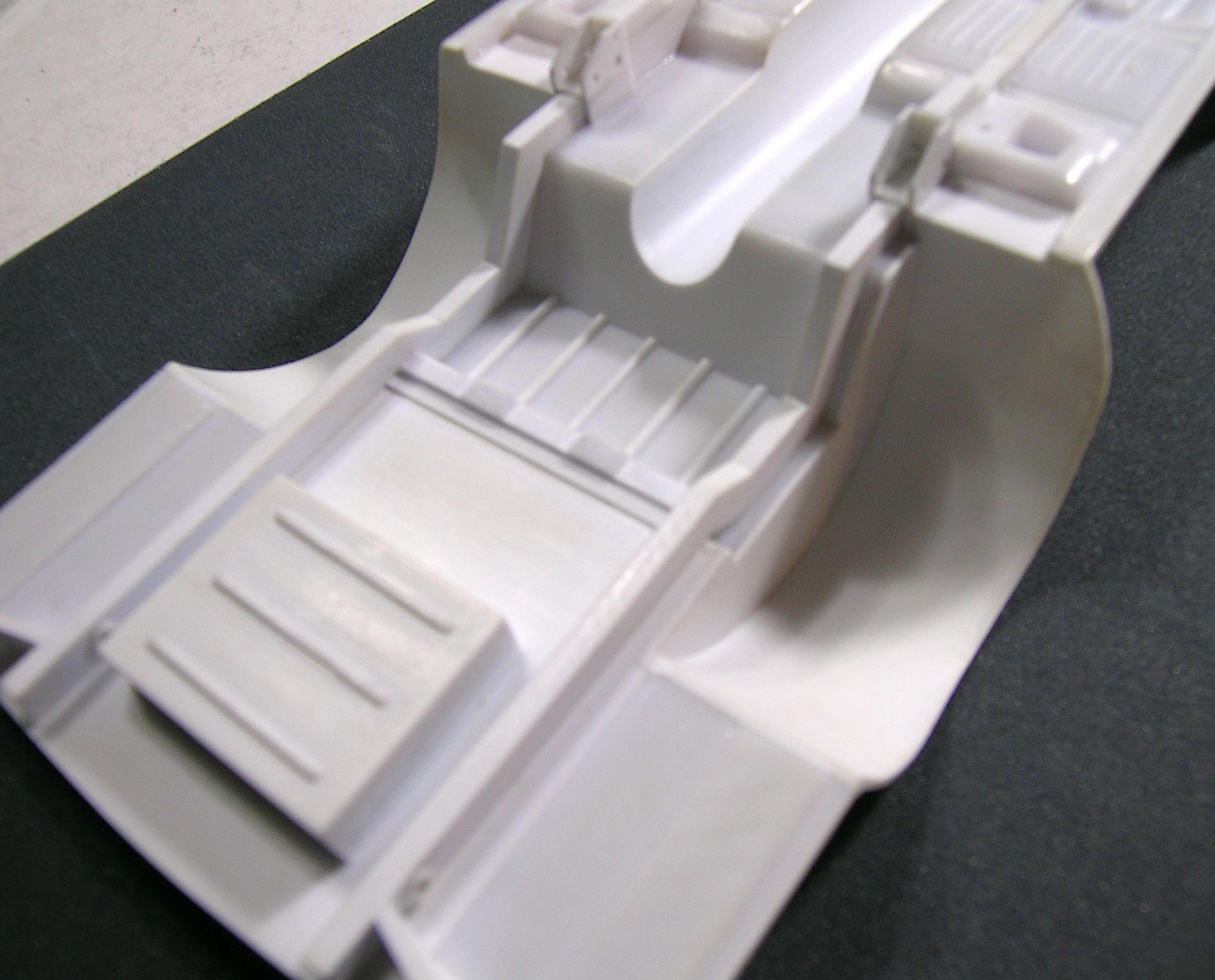

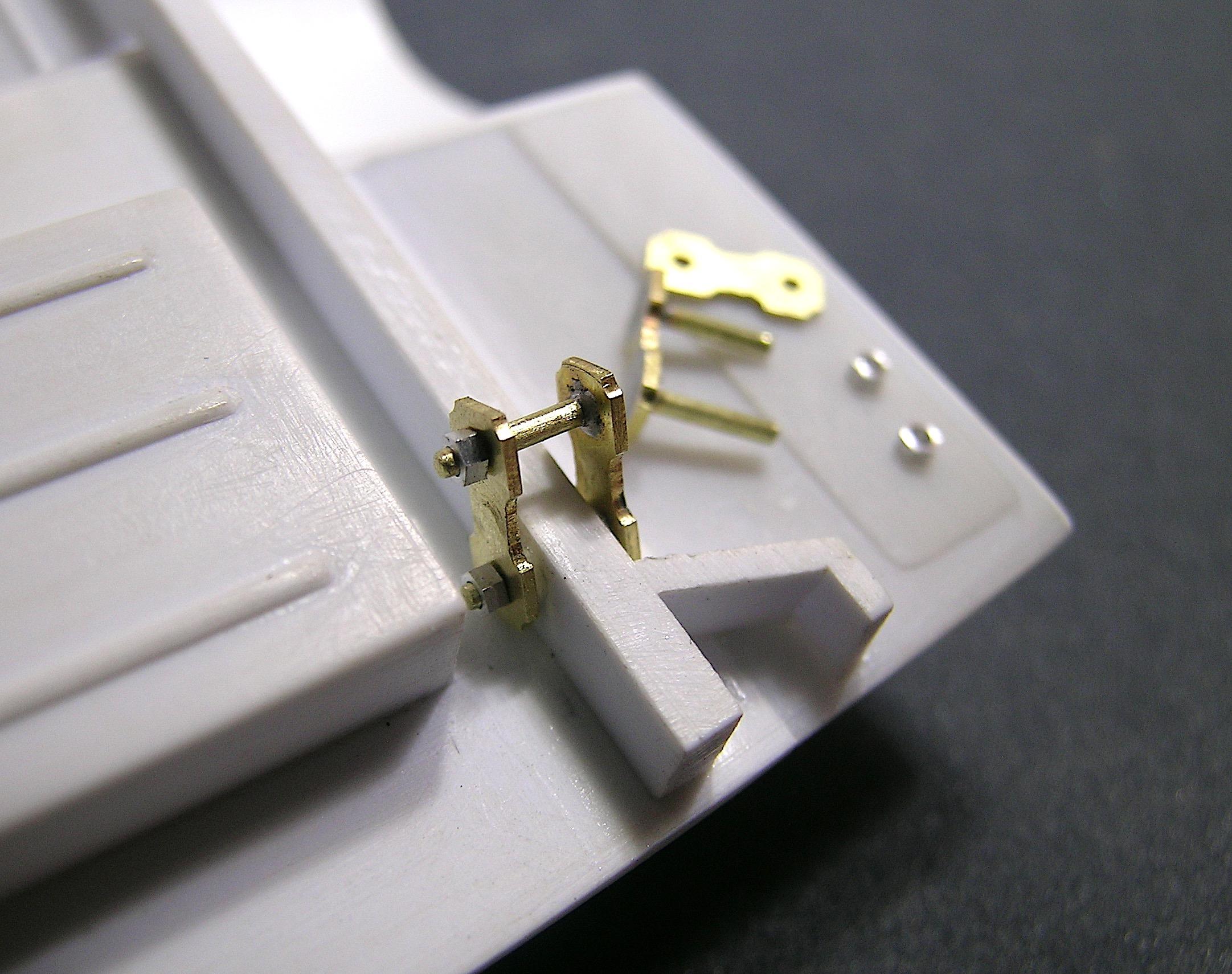

Hello everyone, I made some progress in the last few days and I had to go back to making Styrene elements, because I still had to make the attachment points for the leaf springs and the shock absorbers. I needed to have the leaf spring supports made to find the right position, it's a kind of order to follow, one thing leads to the other if I can put it that way! The leaf springs are made from strips of aluminum that I cut individually from a 4x10 sheet and sanded to remove the shine, the collars are brass and soldered using my resistance welding unit. Next, I will continue to make the elements to finish (or garnish) the rear axle (disk brake calipers and brackets) and the wheel bars. Francis Front attachment point for the leaf spring and CalTracs. Brackets for the rear shocks. I realized that the frame is 0.080" (2 inches) and the leaf spring must be 0.100" (2.5 inches). I put some sort of 0.100" sleeve centered in the frame rail to solve the problem. An overview. Sorry, the image is a little blurry because it's difficult to get a good focus in this sea of white elements. Leaf springs made with aluminum strips. I also made center pins and brass bushing at the attachment points. Assembly done. Test fit. View from a different angle. -

I really love your new project Ian! As for Pro Stock, I prefer this era of Funny Cars where the body shell was more similar to their original version. I'm getting on board with your project and I have a feeling we're going to have fun! ?

- 190 replies

-

- scratch built

- brass chassis

-

(and 1 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Will, I'm going to start by putting it on its four wheels and I'll see later! ? Thanks Scott, I can't wait to start making the more substantial parts, I feel like I'm not making progress but I must not deviate from my goal, patience is essential! Thanks Claude! I can just tell you that I would not have refused to put this '70 Challenger in my garage regardless of the quality of the original parts. What little I was able to see of the work you did on it was impressive and a testament to your enormous skills. ? Thank you for each of your comments, they are greatly appreciated! Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks James! Thanks Mike! I can almost see your smile in real time my friend...! ? Thanks Charles! I too am discovering new machining or fabrication techniques with your fantastic projects my friend. Obviously, this forum fulfills its mission and I am delighted! ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Steve! I have to admit that many of the parts I create are the result of ideas that come to me suddenly or that have been simmering for a long time. Obviously, I'm limited by my arsenal of tools, the scale and the thickness I can make, but in the end, if it all produces something plausible or not shocking to the eye, I think the initial idea is achieved. In any case, I have a lot of fun making them! ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

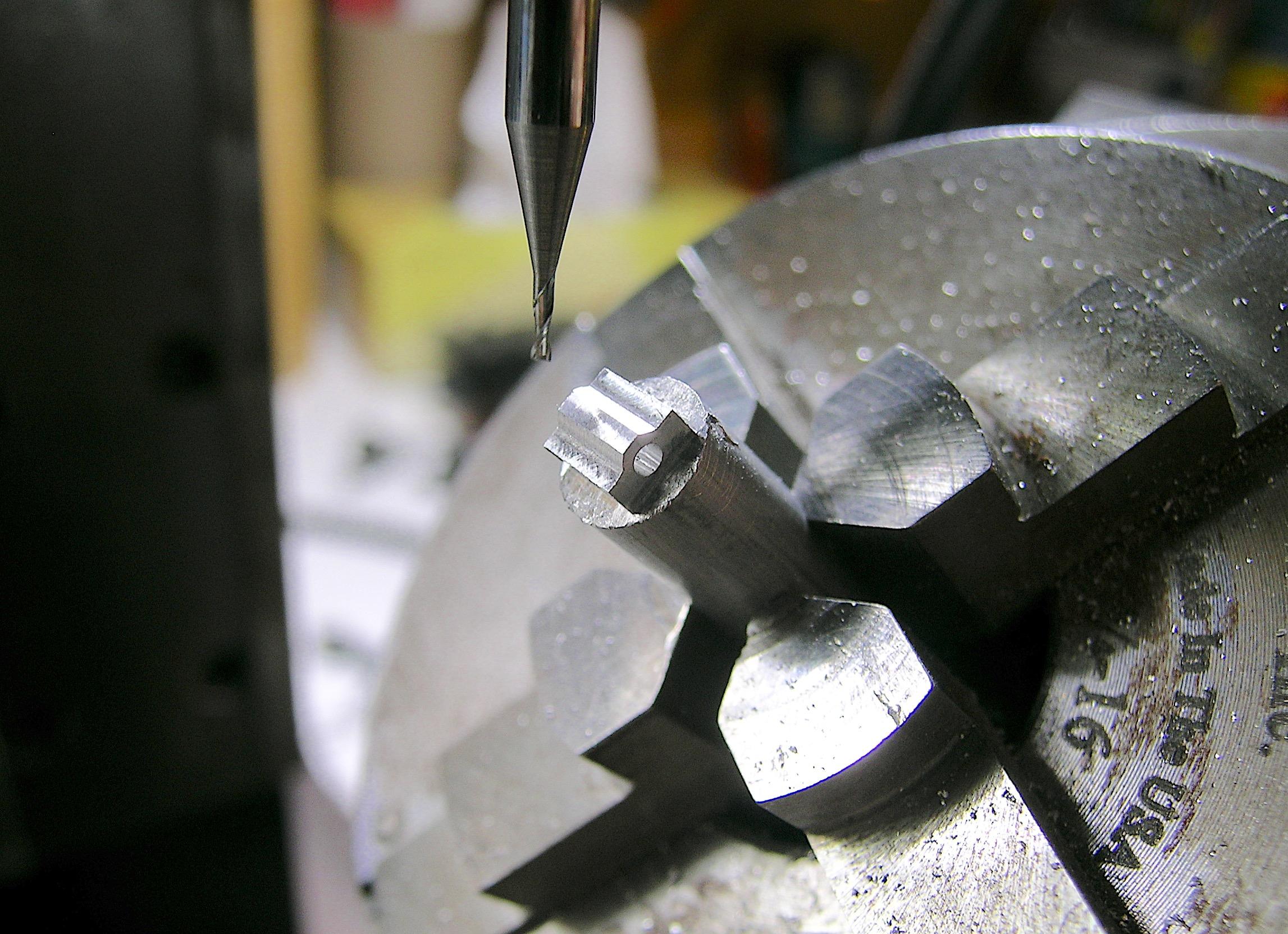

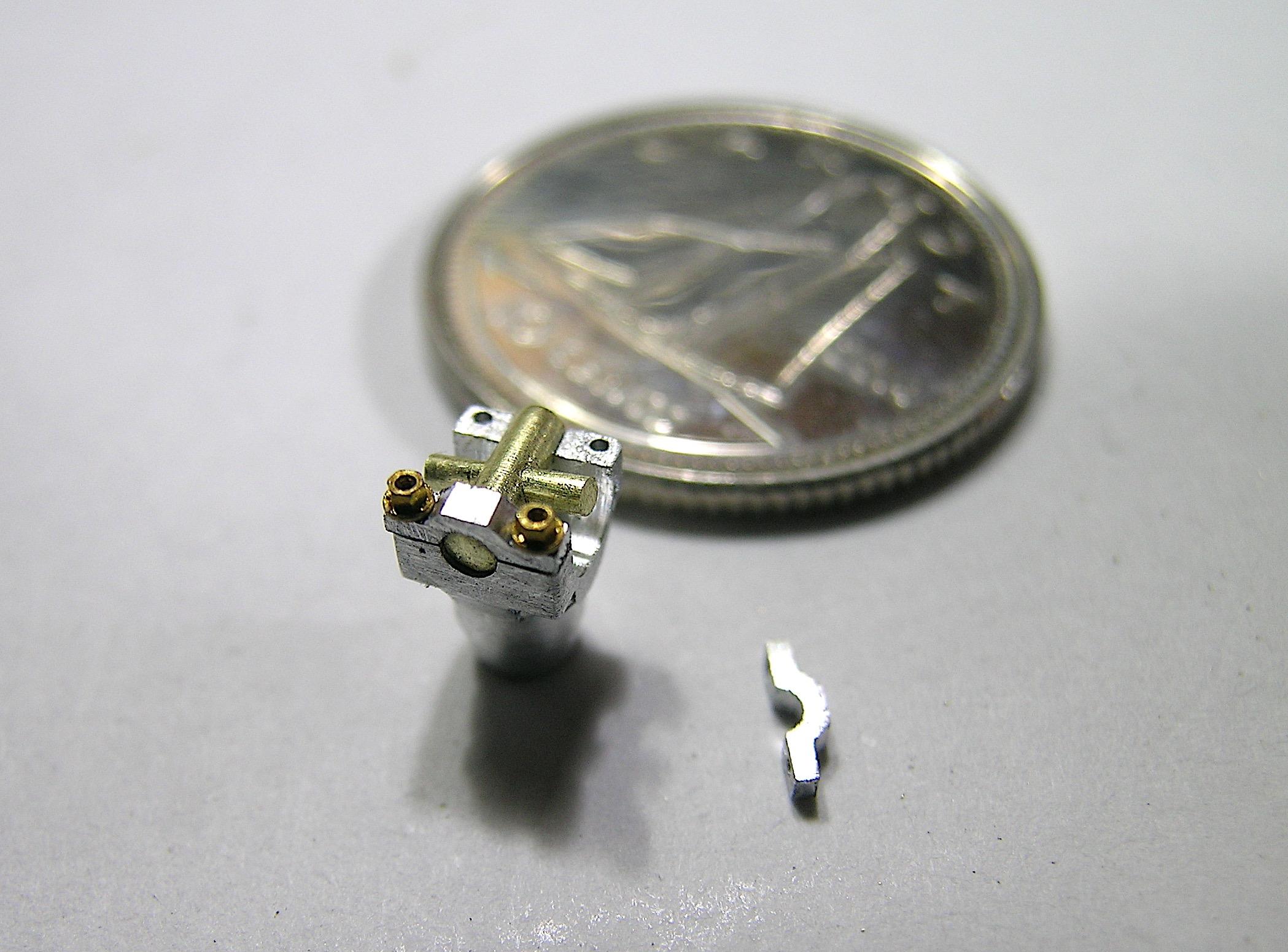

Thanks Rich! They would be much more fragile than the real steel ones however... ? Francis Thanks Daniel and Andrew! I separated them on the mill (oriented 90 degrees) with a .030" end mill. They are a bit on the thick side, but I still wanted to keep them thick enough so that the pins would stay straight and parallel after soldering. I have several sizes and thicknesses of Sherline slitting saws but I hate using them, I'm always afraid that they will come apart and fly from one end of my work room to the other... or in my face! ? Francis Thanks Trevor! Other gadgets to come next week or nearby... ? Francis -

1964, Brissette FED. 1:16, brass, scale build.

AmericanMuscleFan replied to Mike Williams's topic in Drag Racing

I'm very happy to see this beauty resurface Mike! I remember seeing you working and posting your updates on this one and it was a great source of information (and still is) for anyone who loves brass construction and ways to work with this wonderful material. The effect of the red paint on the bare brass is incredible and your wheels are pure art, the way you went about making them is just brilliant. ? -

Good job Rich! As they often say, no pain, no gain! Your determination will be rewarded. ?

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

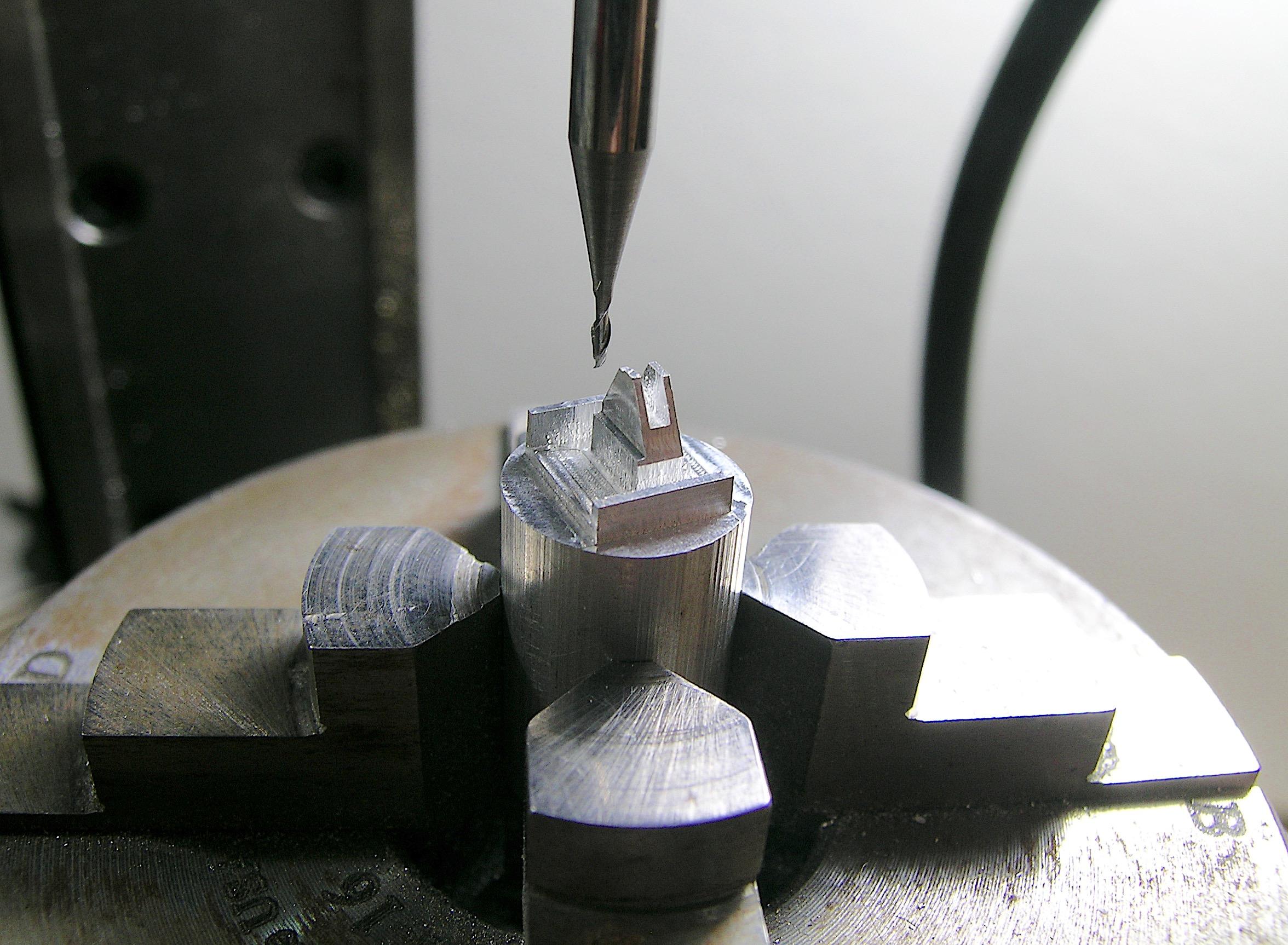

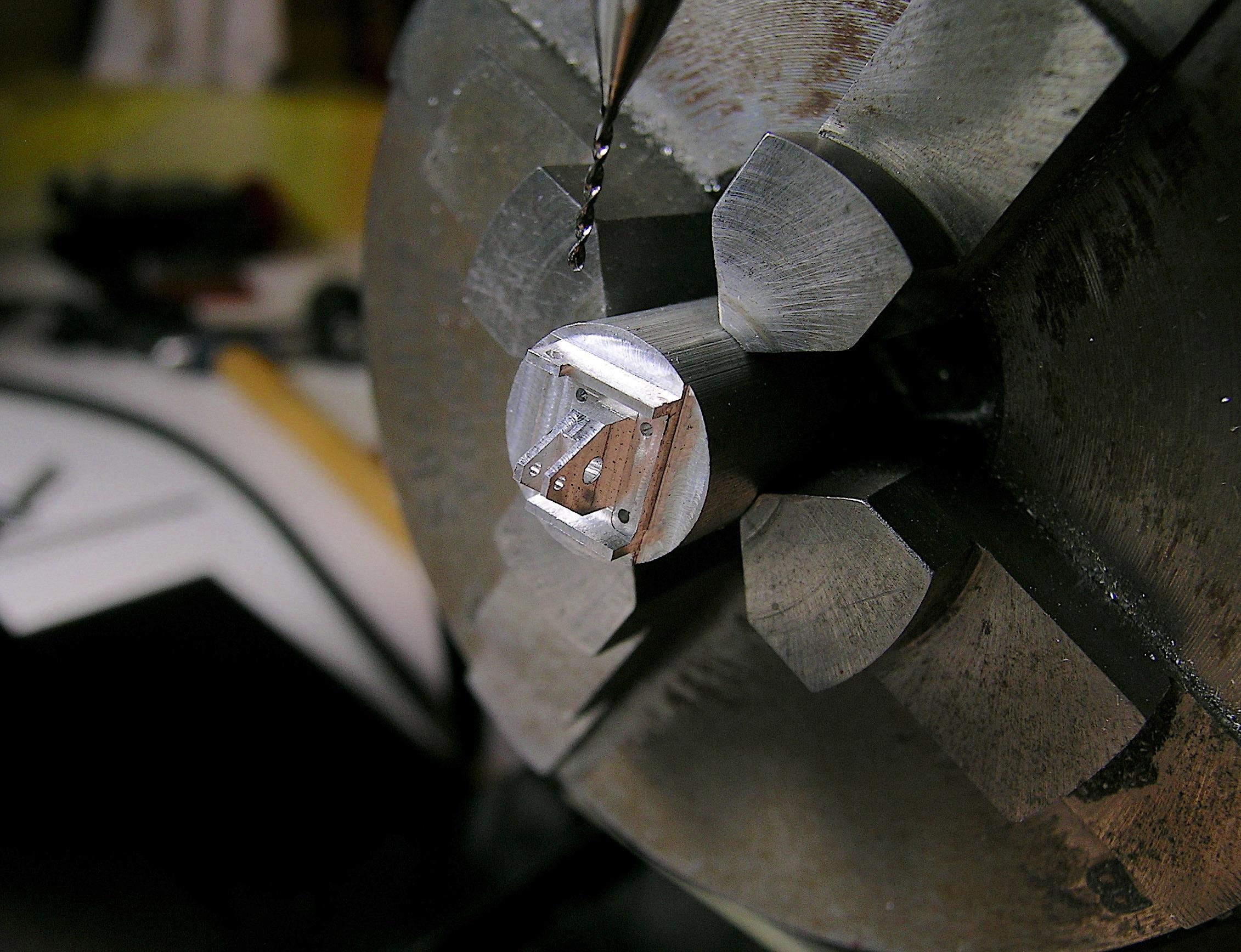

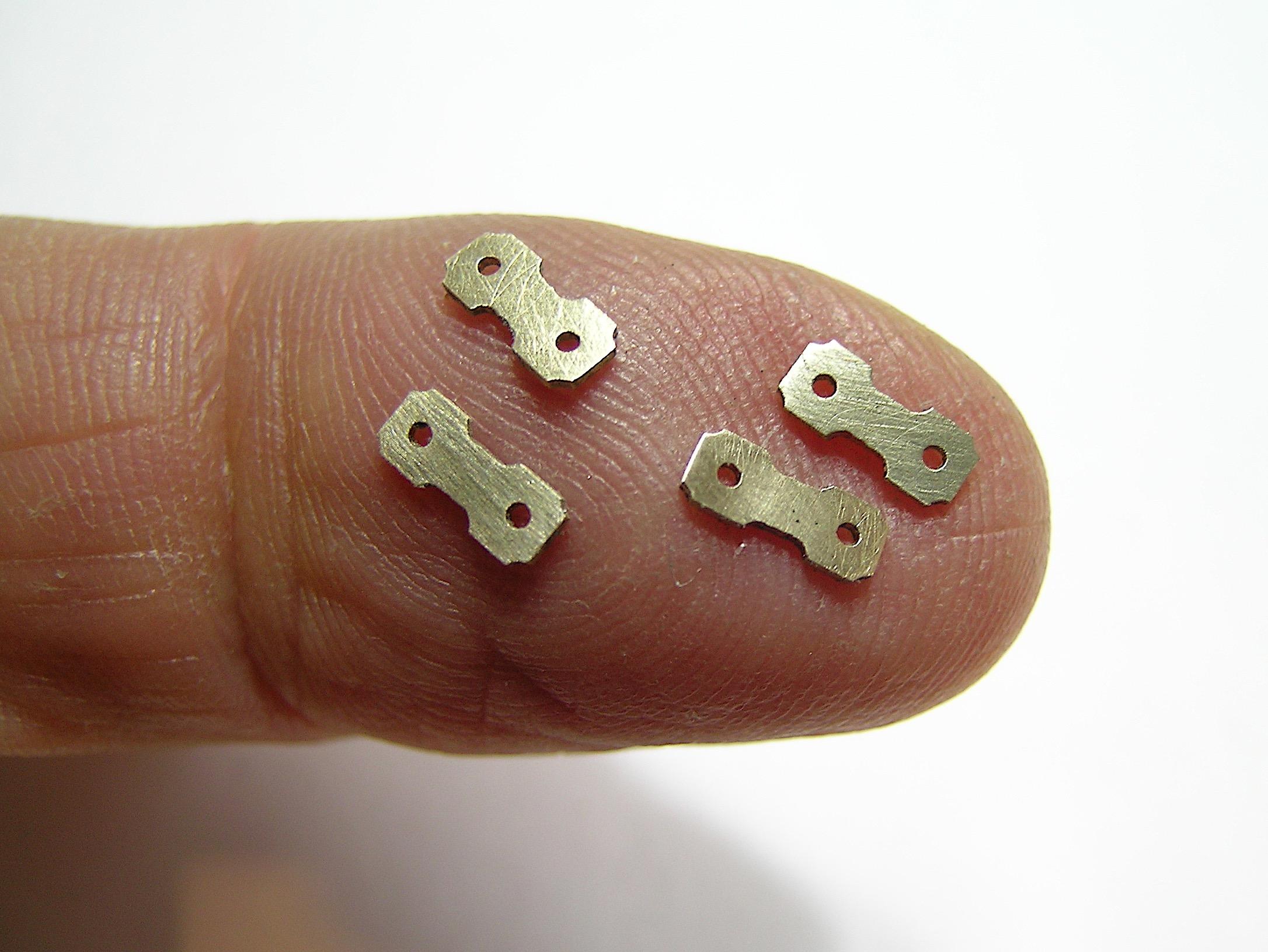

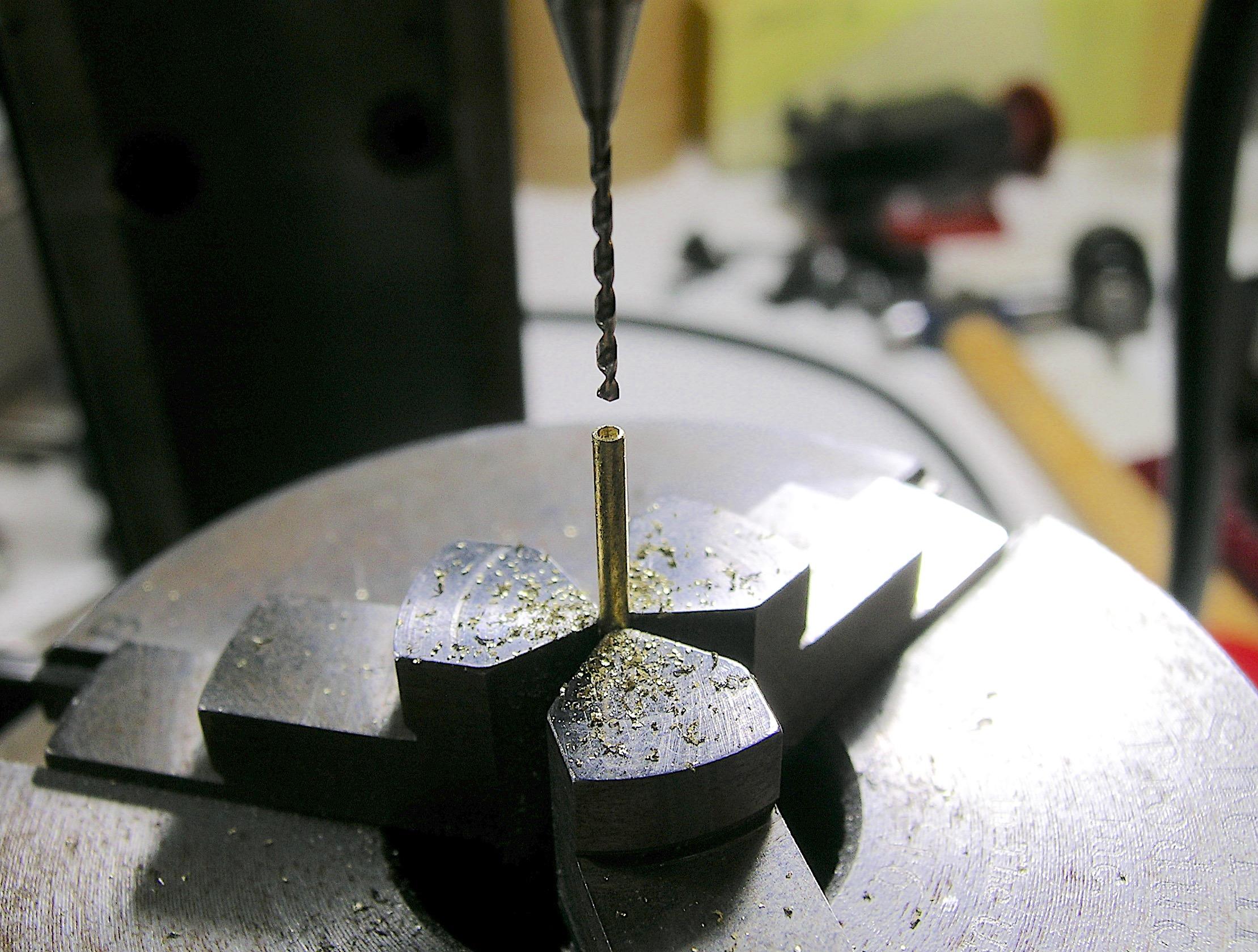

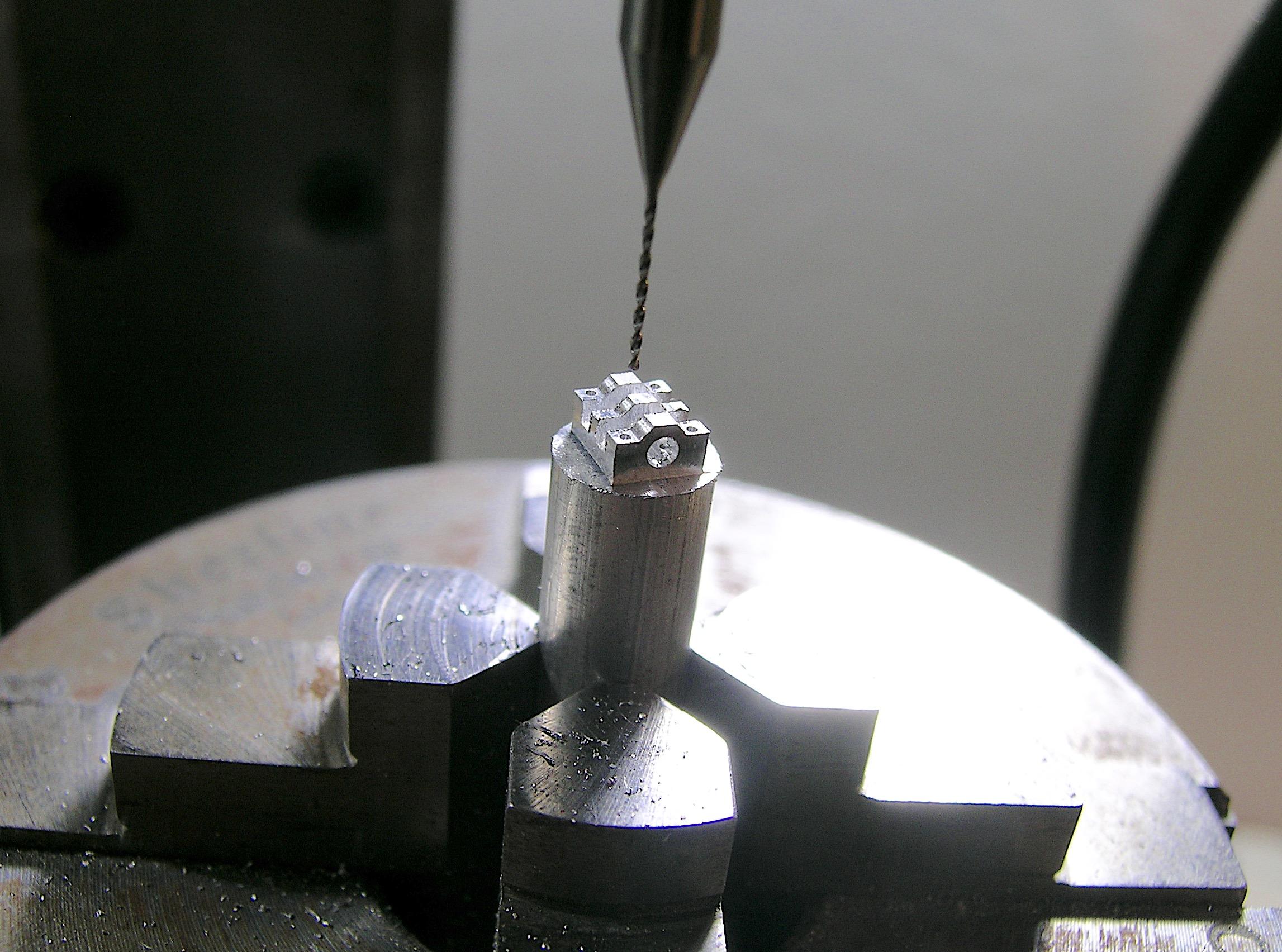

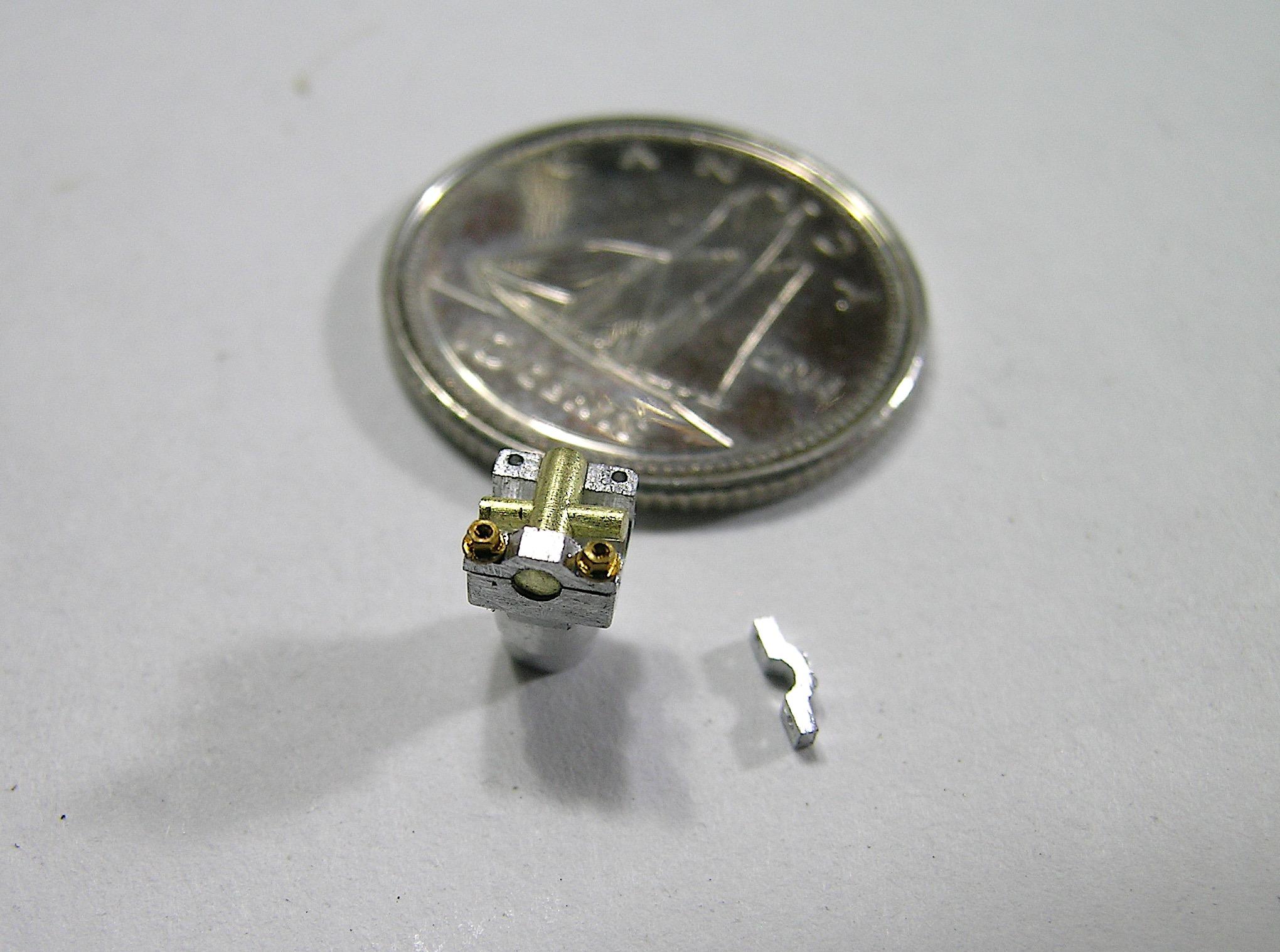

Hello everyone, Back on the lathe and mill this weekend, I started by making a set of leaf spring brackets for the Demon. I have already made the same kind of parts for my GTX '70 but I wanted to add a new detail to them by making a version with CalTracs. This feature adds a more drag racing look to the car and the challenge of making the brackets in one piece was, dare I say, interesting! I will have to make a special attachment point for the leaf springs near the torque boxes because the CalTracs requires a different attachment than the stock ones. The second parts I made were the leaf spring shackles, I could have made some very simple rectangular shaped ones but I wanted to recreate a look closer to the original ones. I made them in brass because I wanted to be able to solder the pins in order to obtain stronger parts and to please die-hard brass fans! ? I didn't take many photos during the machining but I think the results are what's important to show you. Don't hesitate if you have any questions, It's always a pleasure to help anyone who would like to embark on this kind of madness... ? Francis Leaf spring support in the rotary table after several maneuvers and cuts in different angles. With the rotating table oriented 90 degrees I drilled the necessary holes for mounting the CalTracs and the shock attachment point. Both sides are done and are on their raw rods before separating them definitively. After a bit of sanding and polishing, all that remains is to make the pins for the shock absorbers. Leaf spring shackles early in machining, sounds like mysterious codes to aliens but I'm following my plan. You see where I'm going! Now separated into 4 individual pieces after a bit of sanding. The brass pins are soldered on one side like the real ones, luckily the brass solders quite easily. From a different angle you can see all the components. -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks James! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I'm really happy to hear from you in "real time" Mike, all brass enthusiasts will benefit from this as well as the wonderful world of scale models! ? Speaking of brass I will try to use it as much as possible and your advice will always be welcome, the "real time" aspect will only be an added advantage! ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Keith, I don't know the Louise in question but that must mean you like my update so I really appreciate your comment! ? Francis Thanks Charles, on the ingenious side, you don't give up your place and I learn a lot from your updates, all my crazy things are there for those who would like to try them! There is more than one road to get to your destination but there are less bumpy ones, you just have to find them... ? Francis -

Nice job Claude! Drag Racing is not a section where we usually find you but this build makes sense on several points even if it is fictitious. Knowing your love for AMC cars, the fact that you were a great FM radio host and the love of Quebecers for Metallica gives meaning to this! Nothing should be wasted, especially not an old Jo-han kit (or what's left of it...), I also see here in this your good conscience in not wasting anything and a good excuse to make your magic work! ? You never cease to impress me my friend!!!

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Rich! No I don't have a microscope but a good magnifying glass and I must admit that I frequently hit my nose on the vice... ? Francis Thanks Daniel, I must admit that I have a little thought for you while doing this! ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Bob! I'm going to have to pick up the pace to finish this thing, all these little parts take a lot of time and there are a lot to do! ? As long as I don't tire you with my endless updates, I'm reassured! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

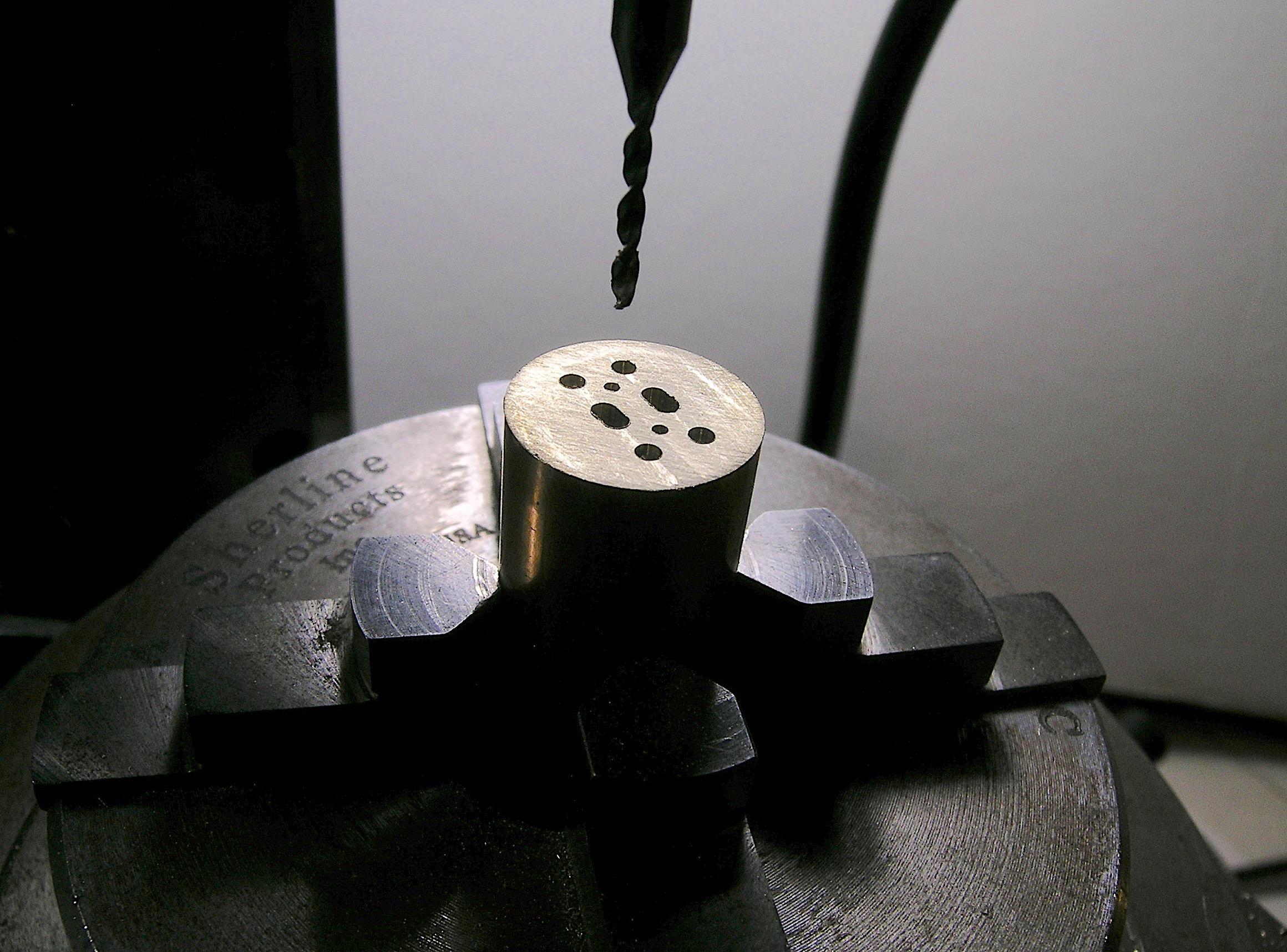

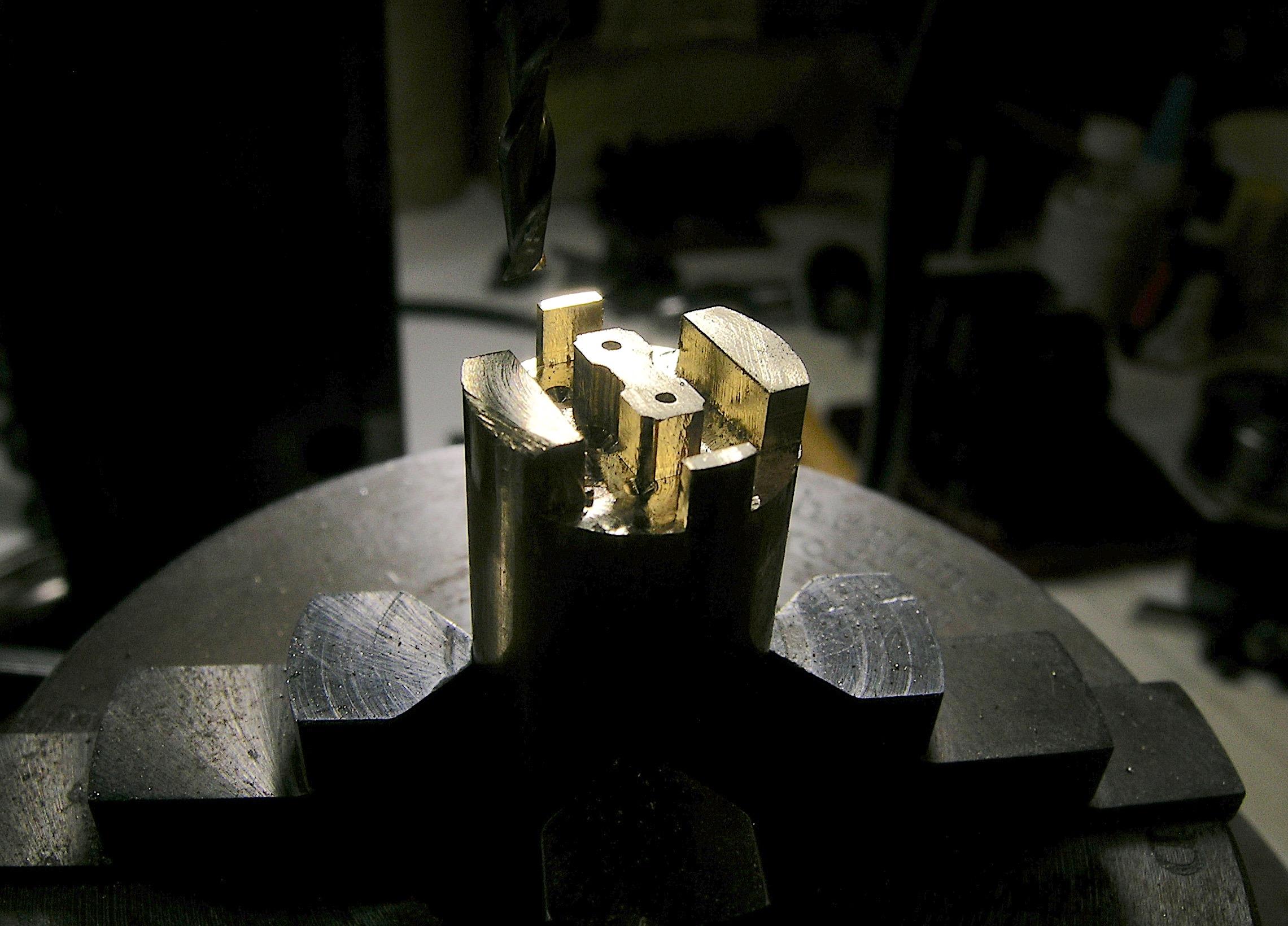

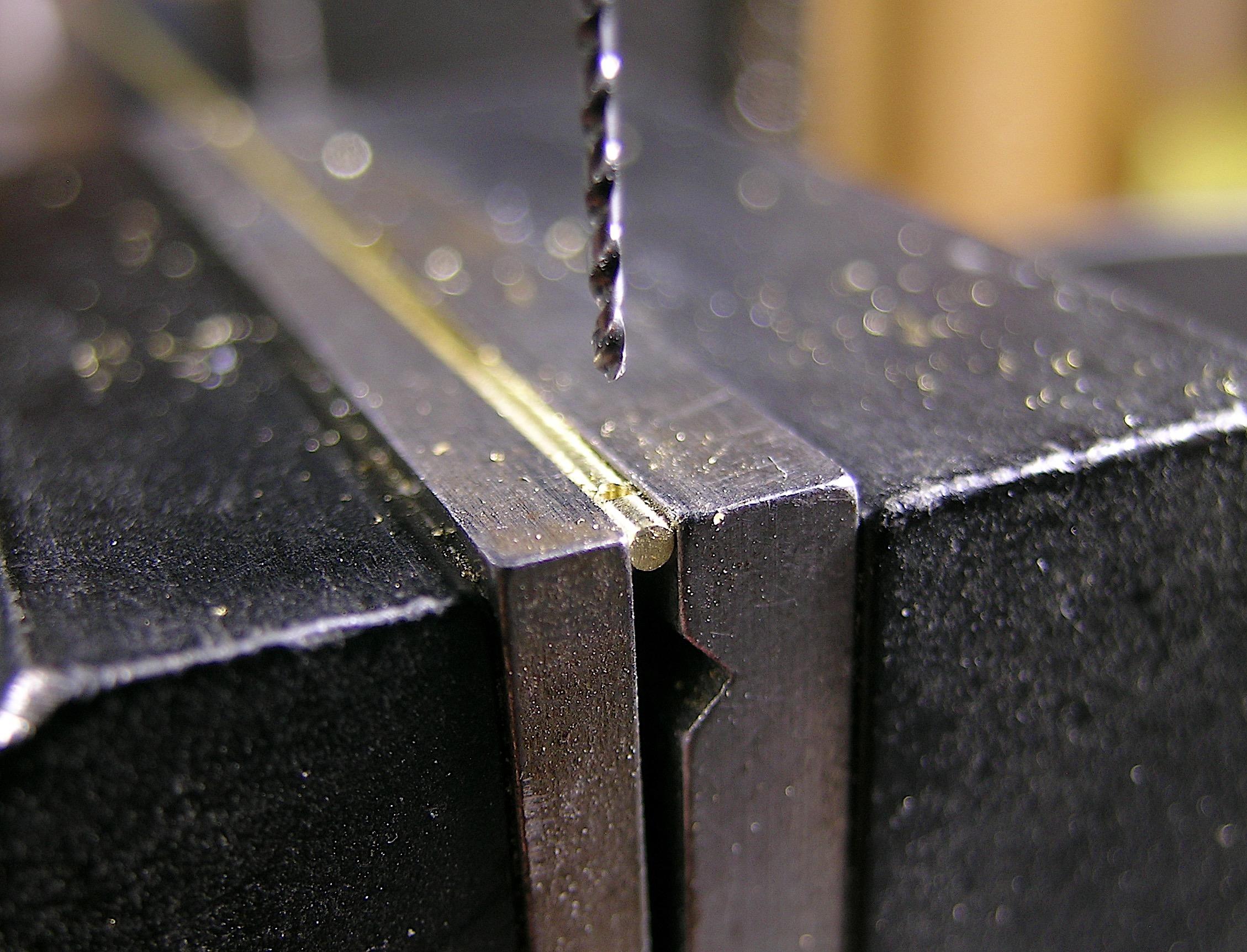

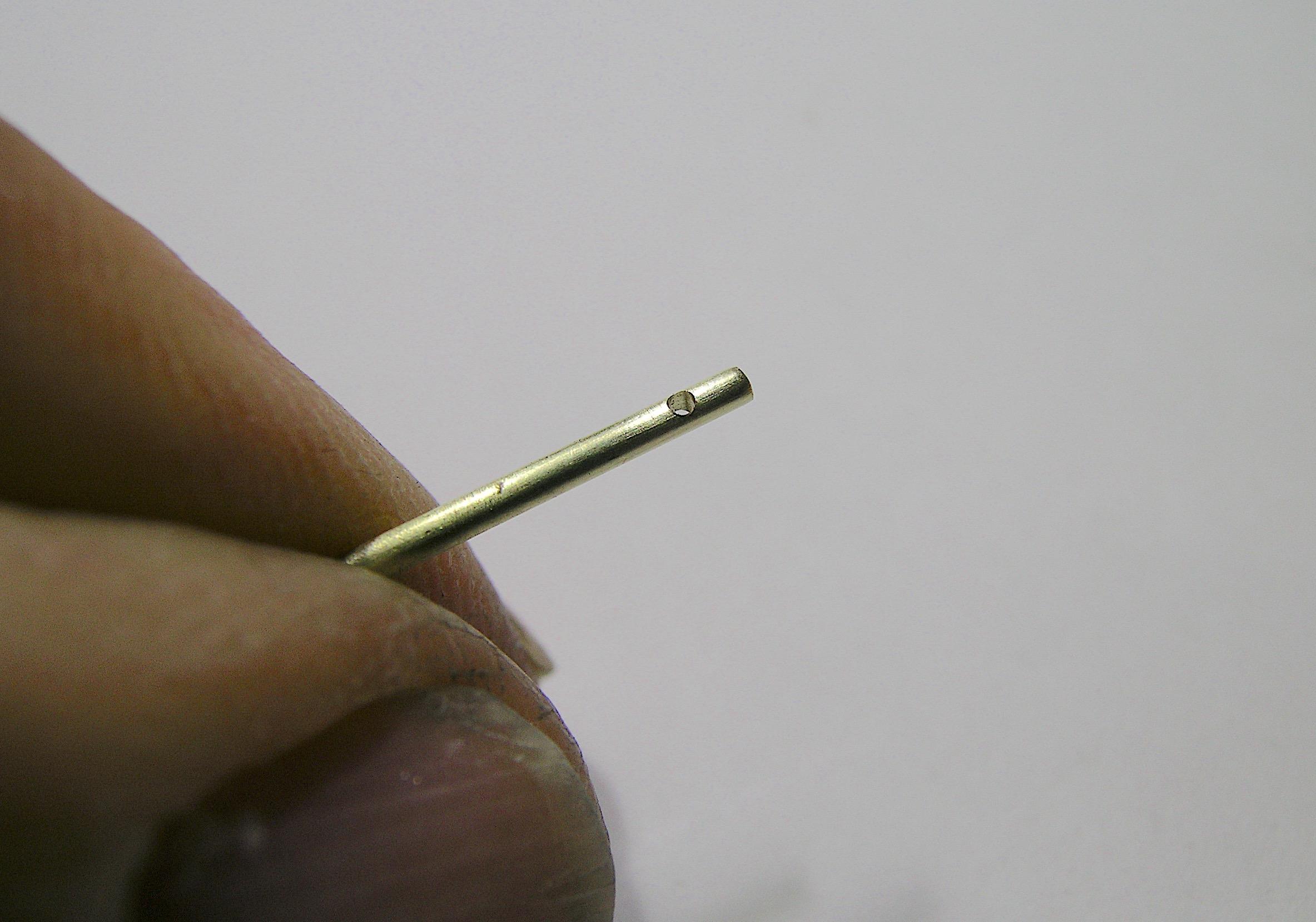

Hello everyone, I didn't have a very productive weekend because I had a visit from my little sister who has lived in the Rockies for several years and who was in the area for a few days. What I am offering you this evening are a few very small elements which largely complete the part that I showed you last week. Once again, I tried to improve my way of doing things by trying to make pieces smaller and more representative of the real ones. Parts not very visible on the final product but you should start to know me, it will become my trademark, I have a hard time preventing myself from doing so. I will soon be able to make more interesting parts for those who like this type of project. I can't wait to be able to show you a complete differential with all the details that I will finally have machined. Francis I started the universal joint by drilling a 0.032" hole in a 0.046" brass rod. The hole need to be perfectly centered to avoid any vibration at high speed. ? I cut a piece of .032" brass rod and inserted it into the other to create the basic shape. I tried to simulate the bearing end caps. Since the universal joint will be almost invisible, I limited myself to making ends on two ends only. U bolt straps on the rotary table. I drilled bolt holes using a #80 carbide drill bit. I used bolts to check alignment but will probably make studs and use small aluminum nuts. Different viewing angle. -

It's an understatement! ?

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Ace, then you will have plenty for your hollow tooth! ? Thanks Tim, I’ll wink at you with the eye from the other side (I couldn't find the emoji unfortunately)! ? Thanks Randy, It's not stealing if you say it first. ? Anyway I will do the same with your updates!!! Thanks Claude, you don't have to stop for details like that! ? Francis -

Great work Rich, you've made a ton of progress and this build is going in the right direction! ?