-

Posts

3,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by AmericanMuscleFan

-

Great work Greg! I really love the 56 Chevy and your new version with the white roof is perfect. I am impressed with how the chrome turned out with this Revell paint, the effect is just right and looks perfectly "in scale'". ?

-

Great work Pat! The 428 Cobra Jet is definitely a good way to “fill” the engine bay of a Mustang. ? I like the way the Detroit automakers saw things back then; always put the biggest engine that can fit under the hood! ?

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Roger! I appreciate your kind comments and rest assured that your own work amazes me every time I visit your threads. Francis Thanks Terry! I think the best (and hardest) part is yet to come with the fabrication of the mechanical components so check back frequently, if you are interested in aluminum and brass parts, there should be plenty of them. ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank you Daniel, we certainly share the same passion and working with these precision tools only fuels this same passion and the desire to surpass ourselves. ? Francis -

Thanks for your great suggestions Andrew and know that I have already been back working on my Dodge Demon for a few weeks now. You know, I don't hate winter, it's just the best season for building model cars here in the far north... we have tough thick skin here in Quebec. ? I'll definitely dig deeper into this category, there seem to be plenty of enthusiasts here. As for building an 80 year old race car, I have to say I don't know but I really like these old Ferrari and Maserati. However, I think that would be my nemesis knowing that it will take the rest of my "modeling" life to deliver the finished product, these jewels command respect. For the moment, I will watch the masters apply their knowledge on these subjects about which I do not claim to know anything! The photos on the web site are art by the way, it just make the subject more intimidating to me. By the way, welcome to my thread, but the subject is not that spectacular or historically relevant if I may say so. ?

-

Superb scratch building Sir, an amazing, impressive and very complex project you have invest your self with! Have you ever consider nickel silver tubes available from Albion Alloys, they are more on the silver color than aluminum and you can weld them to brass. However, I don't know if the size you need is available. https://www.albionalloys.com/en/copper-tube/nickel-silver-tube/

-

Sorry to be a light year late but I haven't yet seen what motivates you Andrew and I see that the details are clearly part of it. ? We like different subjects but I can only admire your talent sir. ? Oddly enough we love racing cars but the speed at which we achieve them is inversely proportional... ?

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

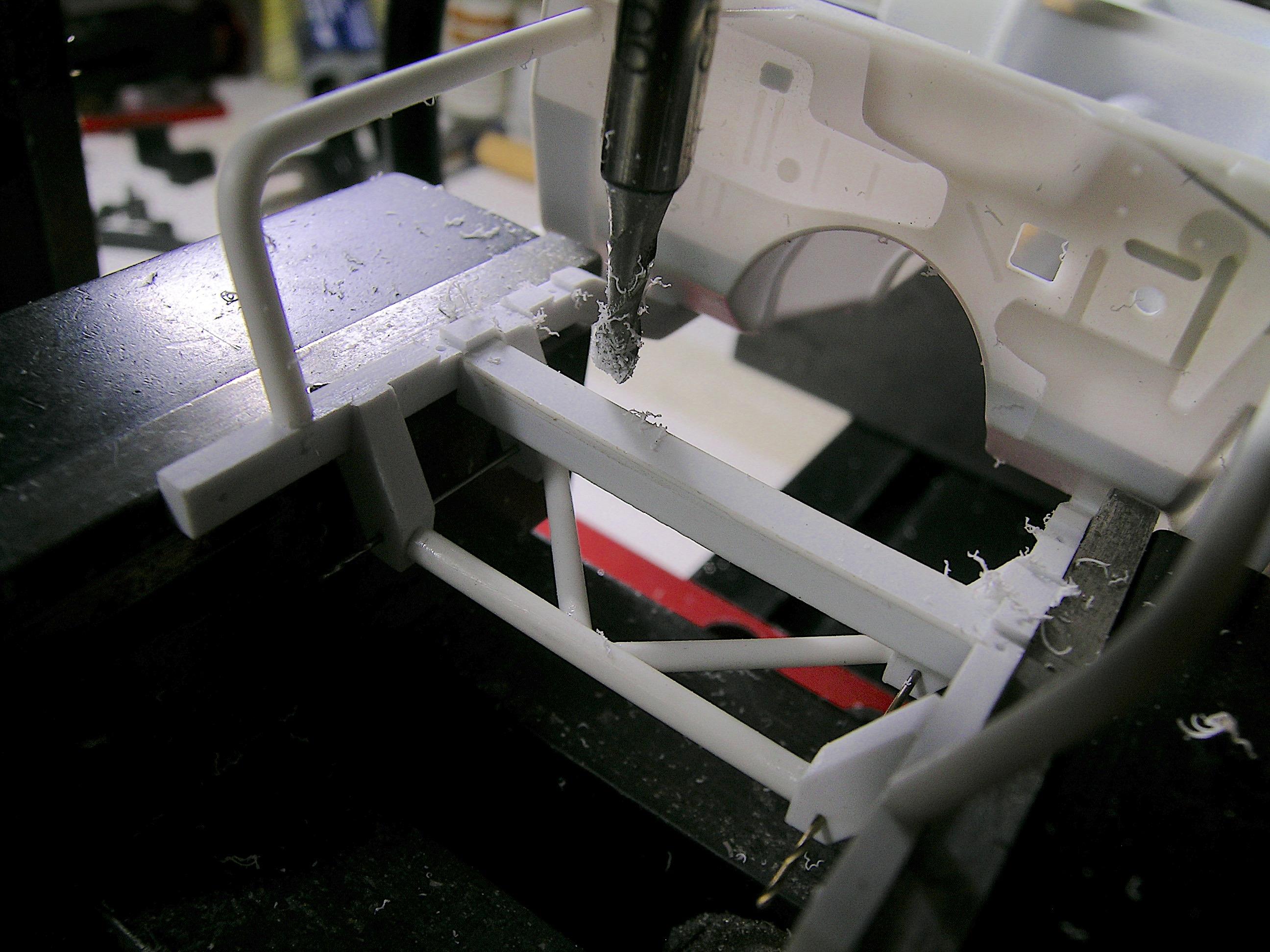

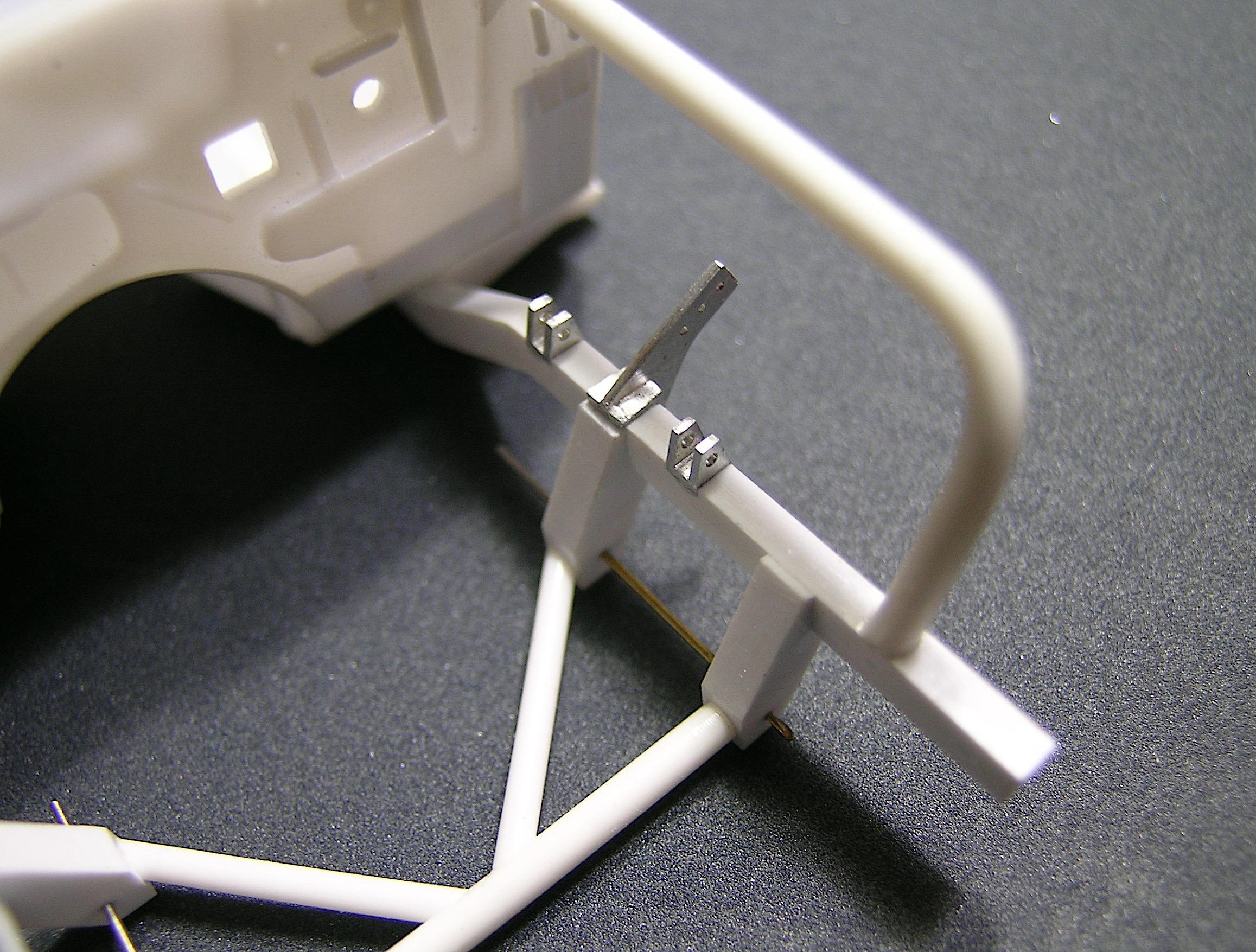

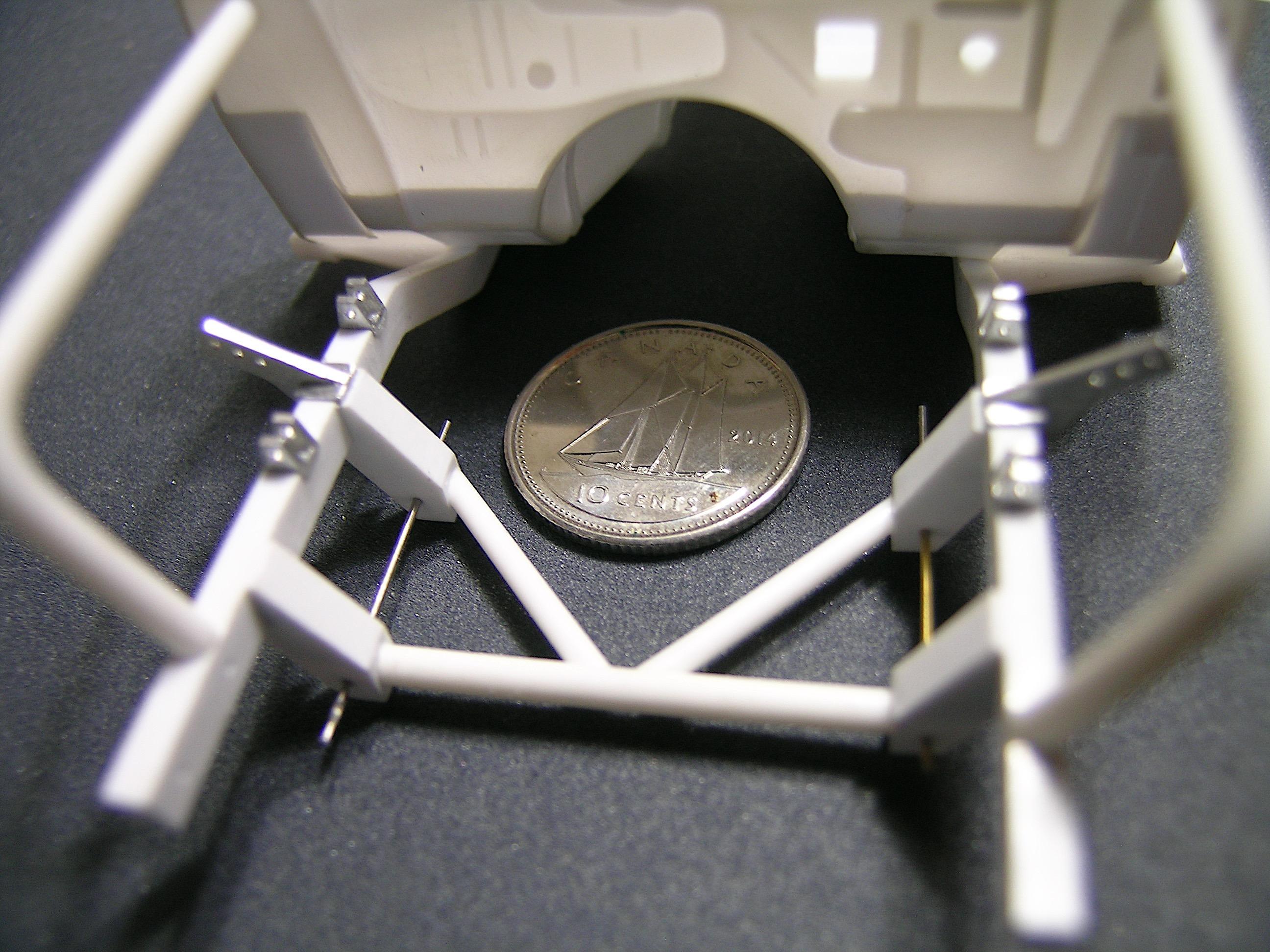

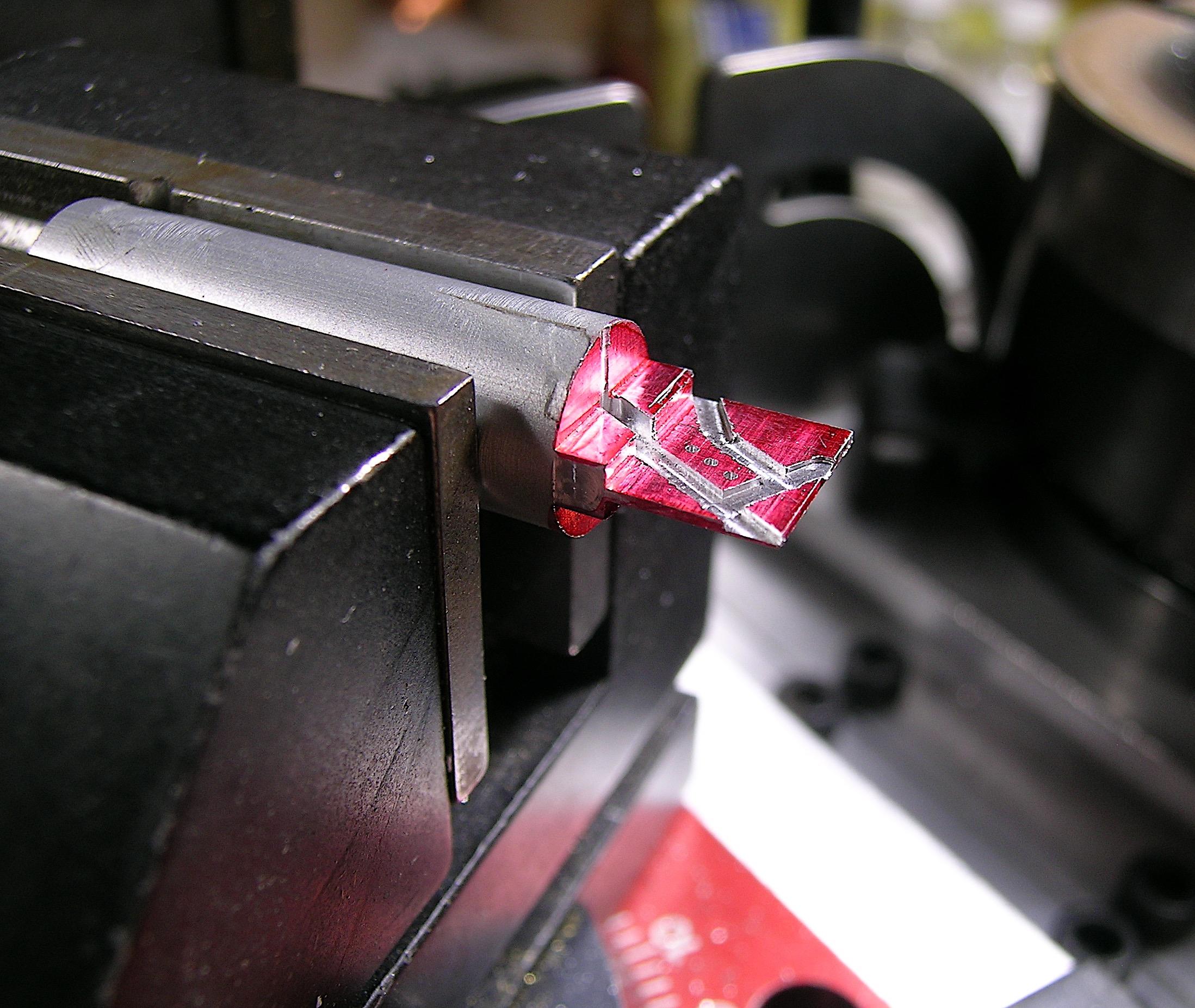

Hello everyone. Just a few pictures to show you the installed hardware on the frame rails. I have already started working on the panels to dress the engine bay, I hope to show you something at the beginning of next week as I will be kept away from my workbench for the next 3 days. Comments and questions are welcome. Francis In order to have a perfect alignment, I decided to make the grooves with the milling machine. As you can see I put a piece of styrene between the frame rails so as not to risk breaking them during surgery. Luckily I had just enough room for the cutter and the supports lined up perfectly. Different point of view (sorry for the blurry picture). You can notice that the attachment points for the upper A-arms are flush with the frame, I wanted it that way because they are tabs welded onto the frame rails on the real car. If you look closely, you can also see the tiny brass bolts I added to the shock mounts for added strength. -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Charlie! Not much aluminum and brass so far but I'll fix that in the next few weeks. ? -

Billy the Kid Demon Pro Stock

AmericanMuscleFan replied to dragcarz's topic in WIP: Drag Racing Models

Great job Roger! I had already done the same thing for my Demon project (remove the section under the hood of the new Duster kit to graft it to the Demon body). I did this operation for my 70 Dart Swinger several years ago and it is a perfect match. After second thought and to make different, I'm going to build a stripped down version so as not to hide the steering/suspension elements I planned to make. However, the path you took is the right one and will produce an impeccable result. ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Oh yeah! I knew there were ingenious builders on this forum, now my patent is burned... I should have done more research... ? Thanks for the kind words on my return and recent progress Ian, I hope to start the milling machine and lathe soon for the countless aluminum and brass parts to be made. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

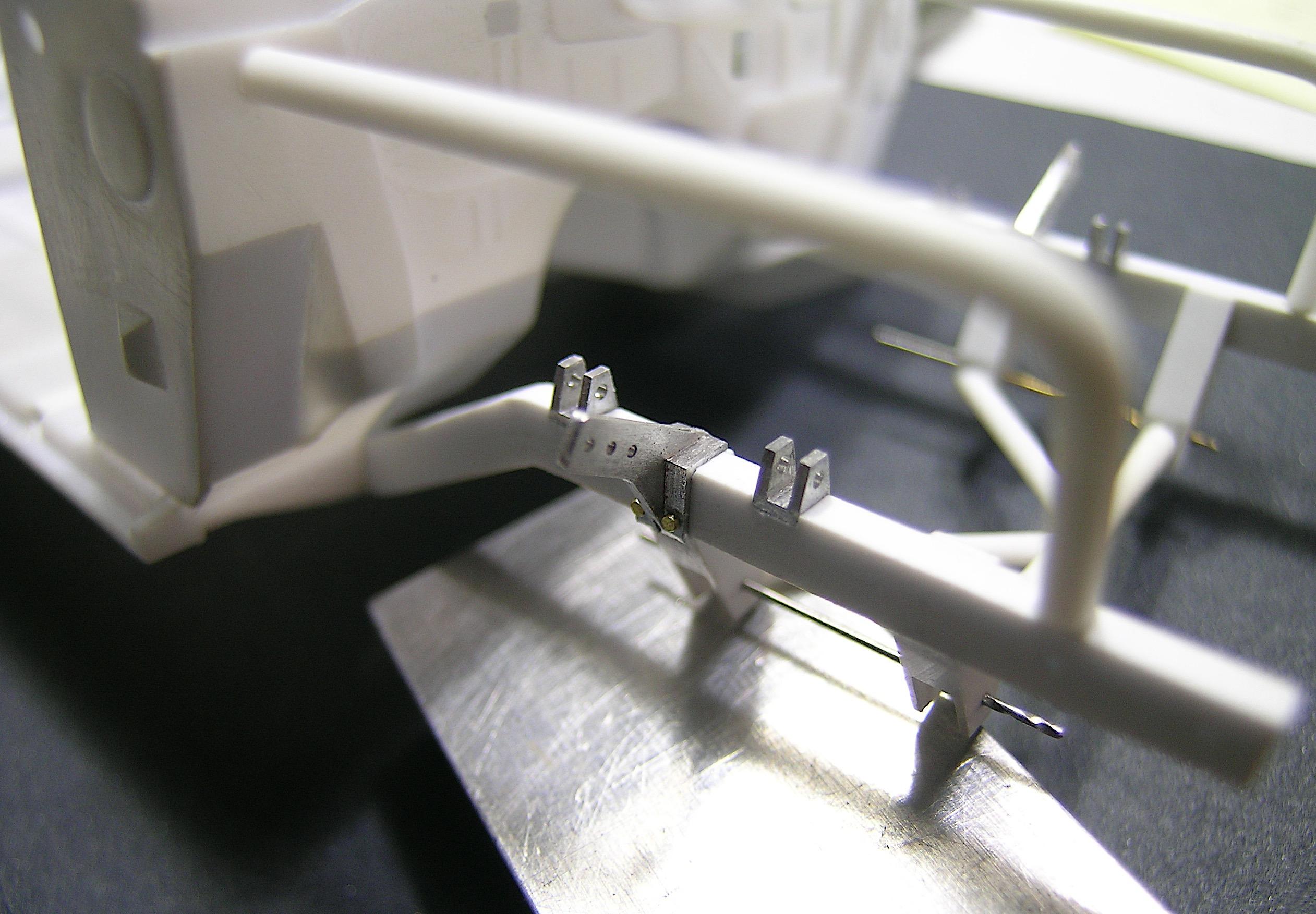

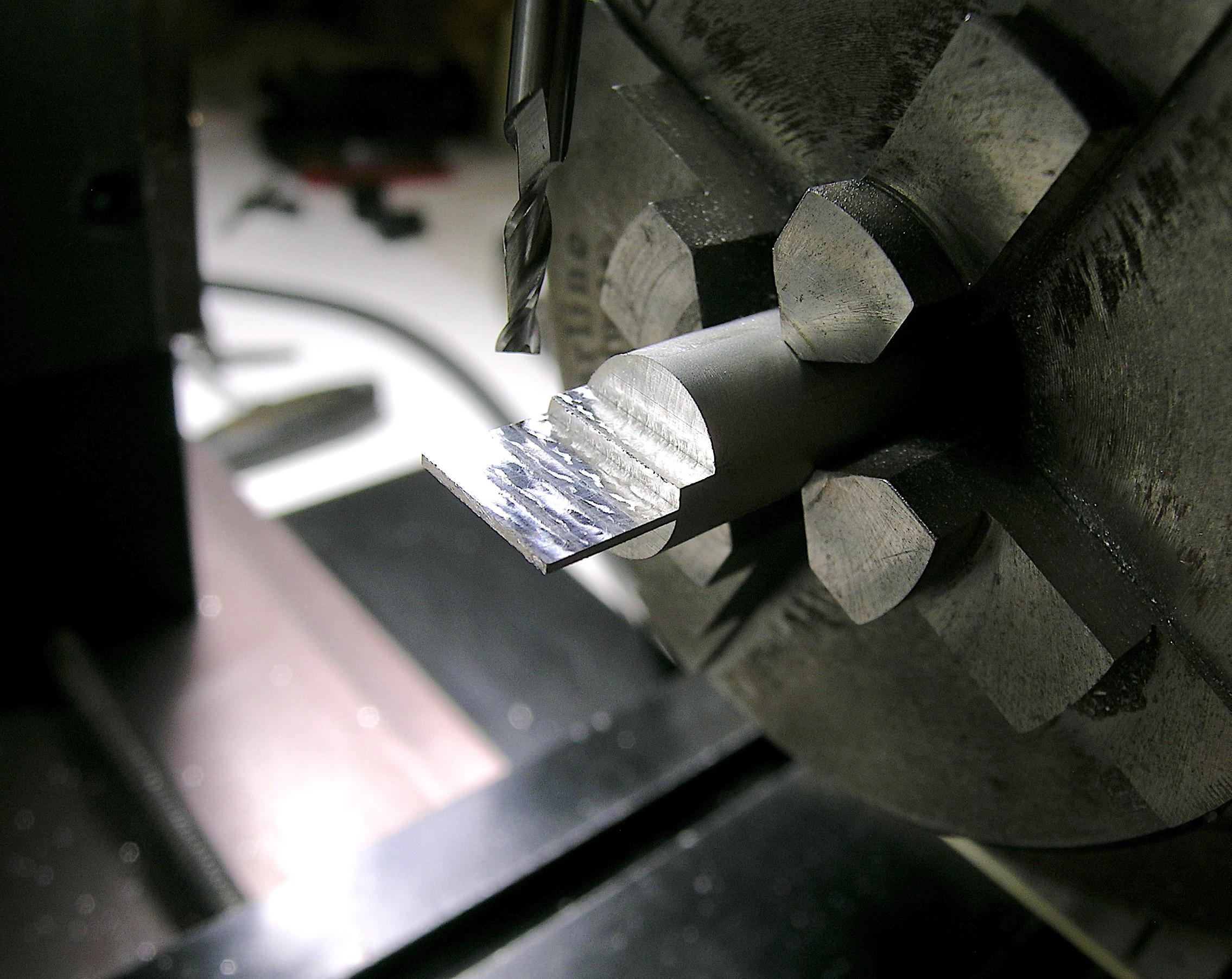

Hello everyone! Now that the basic fabrication of the front frame is satisfactory to me, I wanted to complete this part of the project before focusing on the rest of the bodywork under the hood. I won't be making the upper A-arms and lower control arms right away because I need to machine the wheels first to be able to estimate the measurements. On the other hand, I made the attachment points for the upper A-arms and the coil over shock brackets. Instead of styrene, I used aluminum because it will be stronger and it's high time to add some metal to this build. ? I will still have to graft them to the frame and I will do that next before continuing on other aspects of the project as mentioned earlier. Comments and questions are welcome. For aluminum lovers (I am one of them ?). Francis Upper A-arms attachment in the rotary table (Sorry if I didn't take a photo of each step to get there). One down three more to go! Coil over shock bracket at early stage of machining. At later stage. It's starting to look more like a bracket. The final product. From another angle. I drilled two holes to add brass bolts, they will help secure the bracket to the styrene frame. I don't completely trust adhesives, I try as much as possible to add reinforcement when it comes to gluing dissimilar materials. -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi Claude, It's nice to have left some for the others but anyway, with inflation and interest rates, it would be expensive to extend your house to store all the trophies you have and those to come! As for the patent, it might be a waste of time because I must admit that super glue and liquid cement are just as effective. ? Francis -

Billy the Kid Demon Pro Stock

AmericanMuscleFan replied to dragcarz's topic in WIP: Drag Racing Models

You don't have to be embarrassed about what you do Roger, you are a damn good modeler and all your builds are potential trophy winners, you have that in your blood and it shines through in all your subjects. You'll probably cross the finish line before me because I spend a lot of time making barely visible details but that's how I'm made and I can't help it. There is room for everyone on this forum regardless of how we work and it is beneficial to perpetuate this hobby. Keep up the great work! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks JC ! I feel the same way about race car conversions, but I think most prefer to see replicas of the original versions. The purpose of this hobby is to do what we love and it feels good when our project receives appreciation from our peers. I'm only at the beginning, so you'll have plenty of opportunities to come back whenever you want. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Aluminum is a very handy material for holding brass parts in place when soldering as you mentioned, I have tried it before and it is very effective. It's almost impossible not to have repairs to make when you are in a very complex build like the one you are currently in, it's part of the game and it just tests our determination. ? Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Claude! Yes, it's TIG, I managed to invent a unit that uses styrene rods to weld styrene parts together. I cannot share photos of this invention at the moment because I am waiting for the patent to be approved and the process is very long as you know. ? Did you manage to make just one trip to bring your trophies when you returned from the exhibition in the Eastern Township or were you forced to return there to make a second trip? ? -

Billy the Kid Demon Pro Stock

AmericanMuscleFan replied to dragcarz's topic in WIP: Drag Racing Models

Nice project Roger! I am very delighted to see the little brother of my Dodge Demon project. I was actually thinking of building the same car, I had bought the Slixx Billy the Kid decals a few years ago but I opted to build a fictional version instead as I couldn't find enough references for a detailed build of the real car. I know what you're capable of so I'll be following your build with interest, I love what I'm seeing so far! ? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi Roger, this doesn't help speed up a project but it certainly helps get nice, straight parts. You have the advantage of living in the USA so you pay at least 40% less (exchange rate) than us in Canada. You shouldn't deprive yourself of the essentials but if your budget allows it, treat yourself and what's more you support an excellent product made in the USA! ?? -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank you Daniel, as you know too well, effective direction starts with straight and parallel elements! ?