-

Posts

2,247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by johnyrotten

-

Great looking jeep,nice work with the weathering.

-

Beautiful Cuda. Amazing work throughout. Love the mod top, and the f8 green. 👍👍

-

I did notice after the novus there's still a bit of "swirling". Thanks for the tip, and the compliment.👍

-

What Did You See In Your Yard Today?

johnyrotten replied to Tim W. SoCal's topic in The Off-Topic Lounge

-

Looks great, nice details throughout the chassis.

-

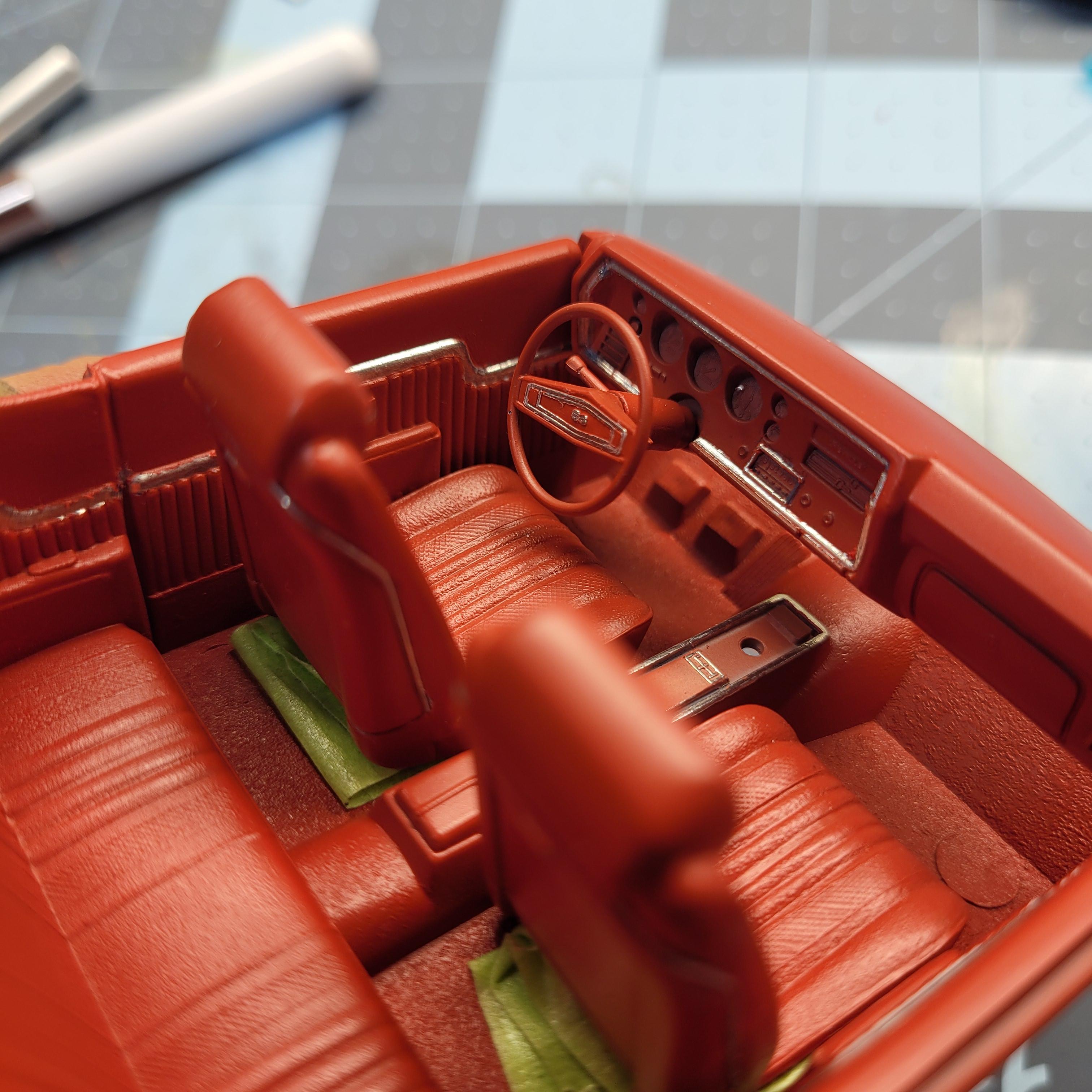

This is more like it. Gotta do a bit of touching up, and finish detailing the cluster, but the foil really pulled off what I wanted.

-

More beautiful work.👍

-

Flocking/ embossing powder not covering

johnyrotten replied to Hondamatic's topic in Model Building Questions and Answers

I believe this is will solve my issues. Thanks for posting it. -

What did you see on the road today?

johnyrotten replied to Harry P.'s topic in General Automotive Talk (Trucks and Cars)

-

Flocking/ embossing powder not covering

johnyrotten replied to Hondamatic's topic in Model Building Questions and Answers

I've tried thinning it 50% distilled water as well as straight from the bottle. Perhaps I'm too light on the glue? Haven't tried any other ratio or products ( mod podge,paint, ect). I was thinking about water-based clear,(vallejo clear varnish in the small dropper)but chemical reactions and all. -

Flocking/ embossing powder not covering

johnyrotten replied to Hondamatic's topic in Model Building Questions and Answers

Ive tried Elmer's glue a few times, spotty results like above. At least it's easy clean up. Paying attention to this. -

Great looking street rod,reminds me of every magazine cover from my childhood. You nailed the look.

-

Patience is something I have a ton of. I no longer get mad if I make a mistake, whatever it cost me(time,money,ect) was the cost of that "education". Things go smoother for me now that I apply that idea to project. Thanks for checking it out.

-

Thanks Zippi.

-

SWAMPY

johnyrotten replied to TopherMcGinnis's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

That looks Awesome! You definitely picked the right name for the truck.👍👍 -

Couple of sweet looking builds. 👍👍

-

Thanks, hopefully I can repaint the rest of the interior, I'm working on my skills detailing dashes and such.

-

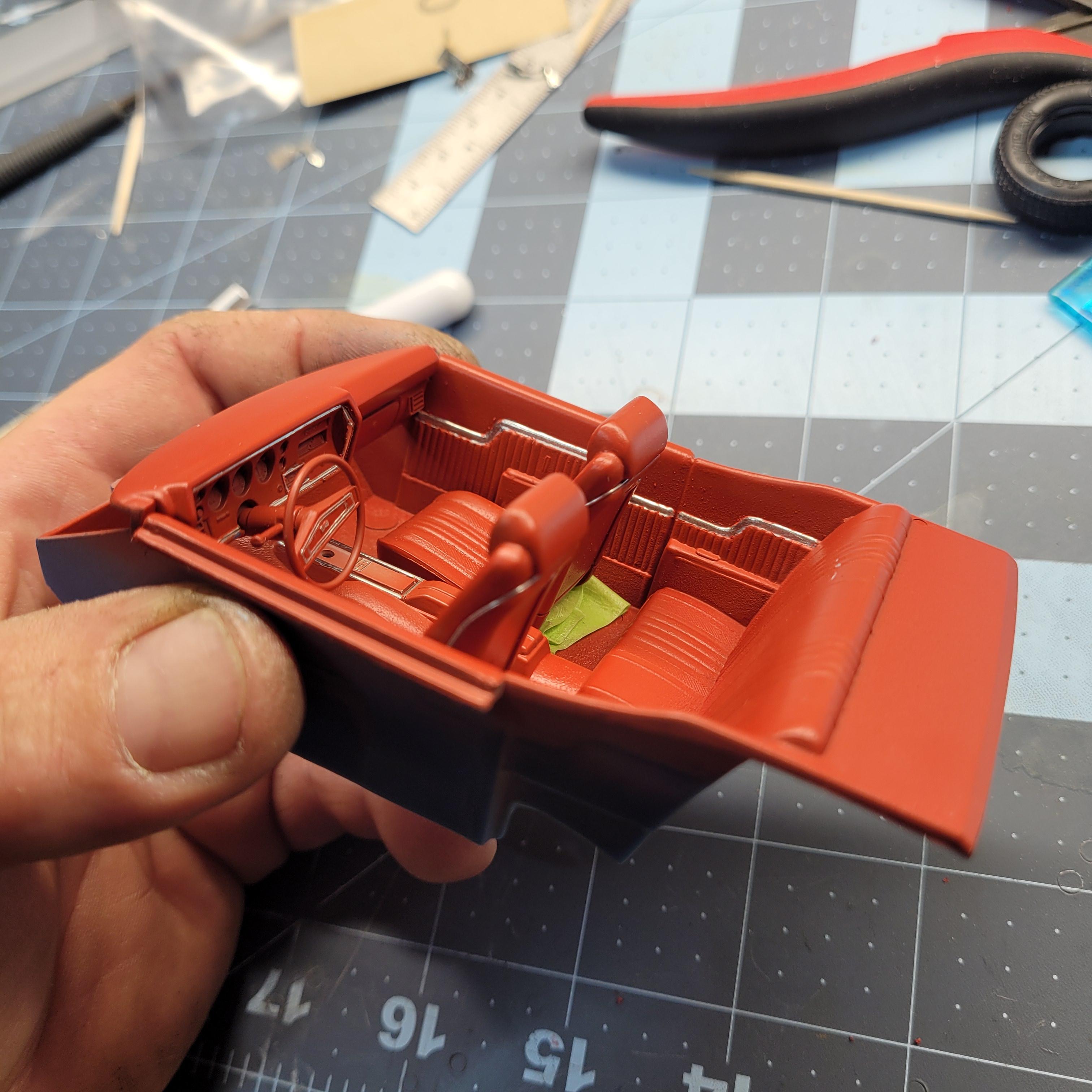

Finished stripping the dash and interior tub. Foiled the door trim and around the cluster/center console tonight. Everything into primer tonight, painting tomorrow. Hopefully I can pull this off like I did the steering wheel. Thanks for checking this out.