-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by my66s55

-

3-d printers ... $180-$200???

my66s55 replied to tedd60's topic in General Automotive Talk (Trucks and Cars)

Instant gratification to start with. No waiting for parts. The ability to create your own parts. Take my Chrysler 318 poly engine build. People have expressed interest in getting one from me. There is really, currently, isn't anything on the market. I am now in the process of making molds and casting the duel quad engine. That's time and money. If could sell the files right now, it would be cost effective for both parties. Also, another advantage of the sla resin printers besides quality is that they as have very low, if any, maintenance. -

3-d printers ... $180-$200???

my66s55 replied to tedd60's topic in General Automotive Talk (Trucks and Cars)

Yes, Davo, Ted showed these cheap fdm filament printers in his opening post. He, who knows little about desktop 3d printing, wanted to learn more. The 3d printer in my avatar was built by me. It's a Prusa I3 that I built in 2013. I know quite well what the limitations of this style printer are and I just showed people some. As far as sla being quite expense, guess what. The latest release is a whopping $399. -

3-d printers ... $180-$200???

my66s55 replied to tedd60's topic in General Automotive Talk (Trucks and Cars)

I totally agree that 3d printing is a great thing for our hobby but, as Bruce knows and Eric pointed out, this is a poor choice of printer style and is not suited to make parts in the detail that is required. As Davo pointed out "be prepared to do some post-print cleanup similar to the preparation you would do on a bad kit - some sanding and maybe some surface filling". Also, you will not get good detail. Let's take a look at what Davo was talking about. Using his figure printed on his printer, I zoomed in to show you the surface you will have to deal with. As a comparison, take a look at this 35mm high print taken of my u.v. resin dlp printer. It wouldn't be fair if I didn't show a close up. No post print clean up required. Which would you rather have. Try printing this on that cheep filament style 3d printer. Selection_135.bmp -

Replicas & Miniatures Co. of MD

my66s55 replied to Ramfins59's topic in General Automotive Talk (Trucks and Cars)

This may help some: Public Home > Replicas and Miniatures of Md > Replicas And Miniatures of Maryland -

Mopar A series 318 "Poly" V8

my66s55 replied to Atmobil's topic in General Automotive Talk (Trucks and Cars)

Thanks Bill -

Mopar A series 318 "Poly" V8

my66s55 replied to Atmobil's topic in General Automotive Talk (Trucks and Cars)

If you want a correct accurate, check out my 3d printed on on page 7 of the On the Workbench section: My Chrysler A 318 poly head engine 3d printed at home. -

It isn't anything. It is supposed to be a B block with a single 4bbl carb, but it isn't. The block, heads, valve covers and oil pan are B block. The intake manifold and distributor location are wrong. This is one of the reasons why I created the poly 318 engine. The body of this model also has glaring errors. The 318 poly with a single 4bbl was available in the Belvedere. The enginr should be silver with gold valve covers and air cleaner.

-

The u.v. curable resin I use to print my parts will take all the different kinds of paint well. They adhere well without using primer.

-

Thanks John. I just recently checked the 59 Plymouth brochure and learned that a 4bbl 318 poly engine was standard issue in the Sport Fury. That means that I have to create the 4bbl intake manifold for this project. It'll give me a chance to check the fit in a model as the frame is from the AMT 58 Belvedere.

-

Dang. I like watching the CBS Thursday night series "Training Day" which he stars in.

-

Here is the pattern I created from a screen shot of a 59 Plymouth door panel jpeg: I just printed it out, cut it to fit and glued it on the seats and door panels.

-

Bill, They are, believe me or not. not decals. Let me find where I put them and I'll message you a copy. If I cant find them, I'll recreate a file for you.

-

This project has been shelved since, well, pretty much since the last post. What happened was that I unknowingly left the body in 91% alcohol overnight. As you can guess, complete disaster. Last week, I scored a perfect Excel hard top on the bay and received it Saturday. Today I have a beautiful resin copy I cast and am now ready to finish this project.

-

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

The blocks have the same dimensions, but other differences. You would also need the poly heads, valve covers and intake. Be patient, you'll get the proper engine for your Dodge truck. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

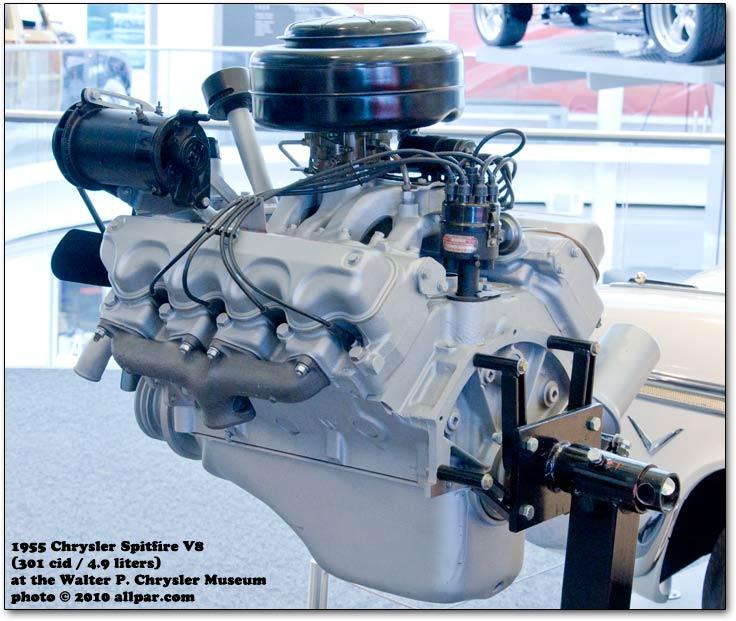

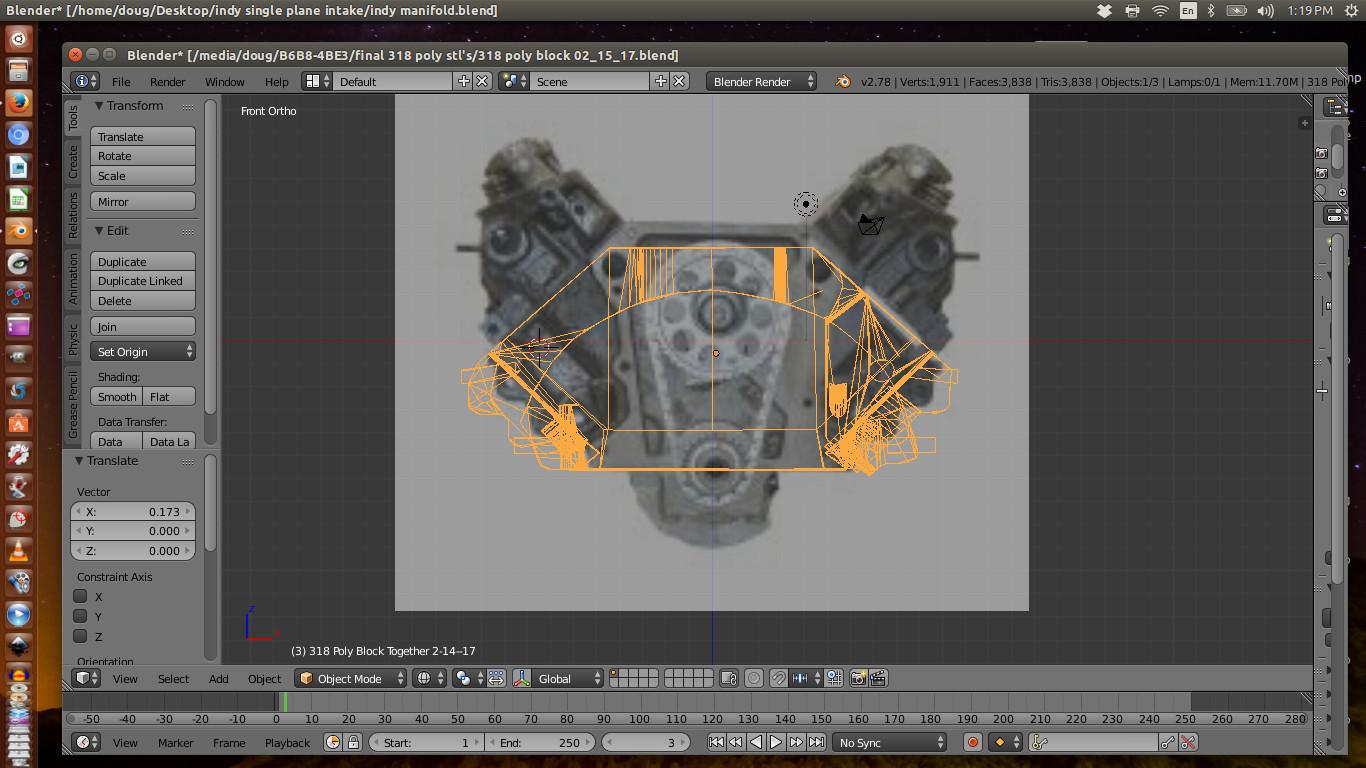

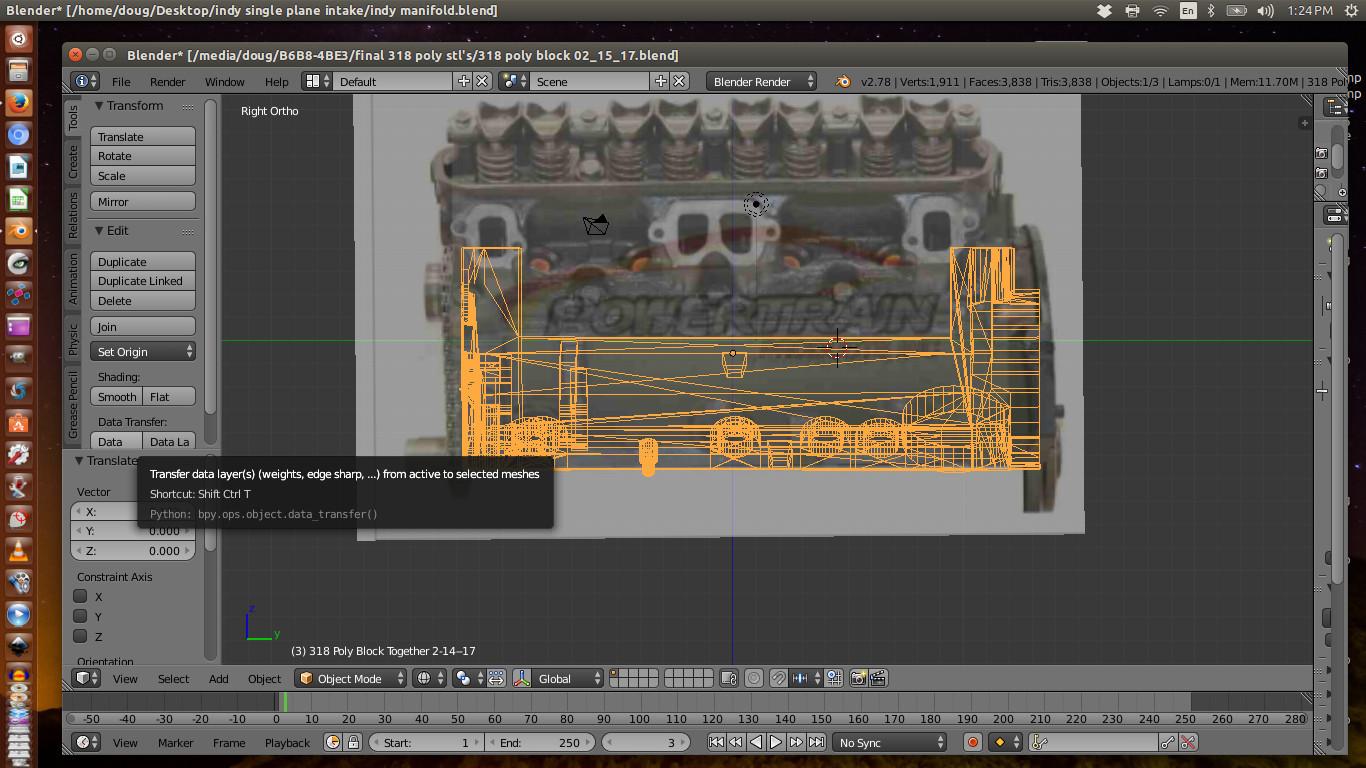

The difference between the image size and stl. outline seen in the front view is due to adjustments made to compensate for resin shrinkage and printer calibration. After the block was printed, it was checked against the 340 LA engine in the 71 Duster. Same size. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

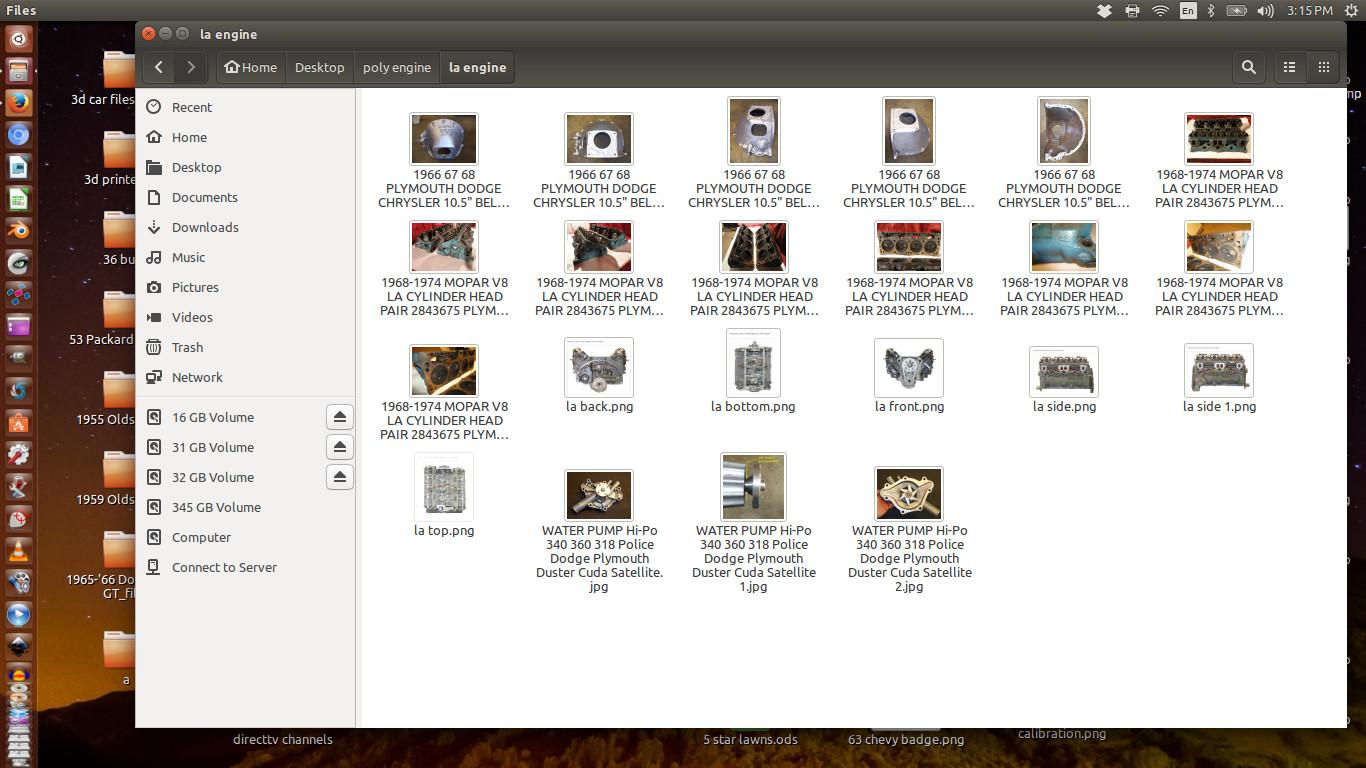

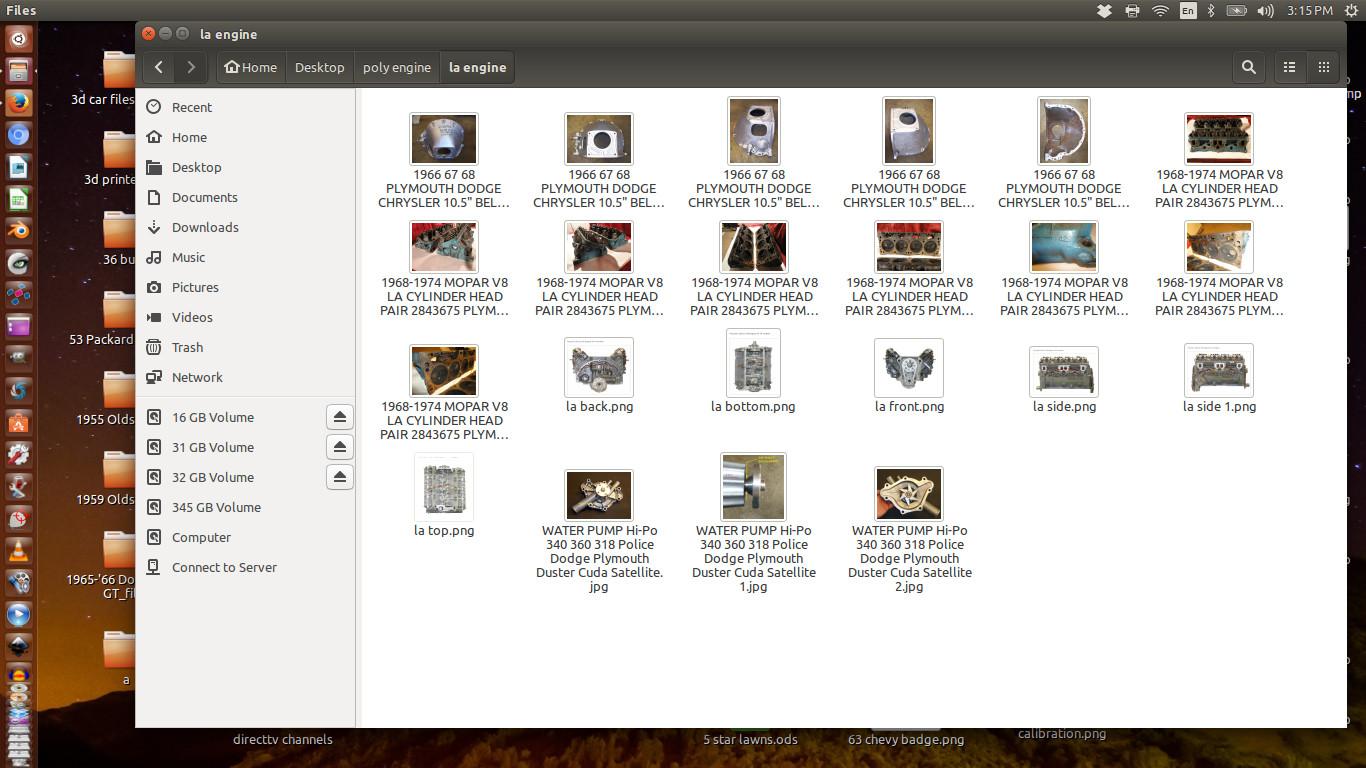

Since I knew that the A & LA engines were the same size wise, I used the LA block pic's in the LA folder to LA engine folder as background images to create the stl. file: -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

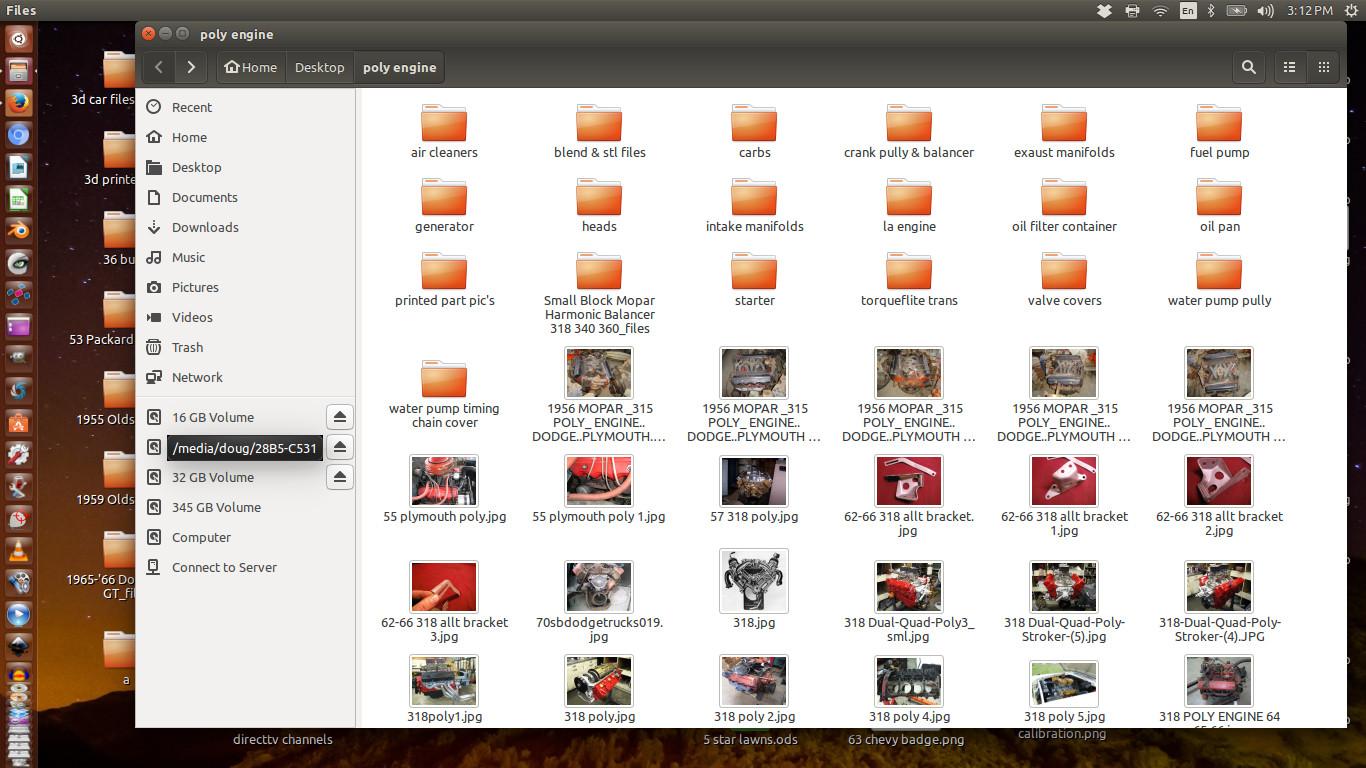

So because of this I would bet the 392 block would be pretty close the same length of that Poly is its done right as they were built to interchange! There was only 2 Poly-Head block that were unable to interchange with Hemi Heads, the 277 and the 318..... And there was only ONE Hemi block that Poly Heads weren't made for, and that was the 392...... Just because the deck height of the 392 block was higher and that makes the need to have a different intake! The 277 & 318 Are A engines. My engine is an A engine. Per your on words, the heads won't fit. In creating a usable 3d file, mega research has to be done in order to make it as precise and accurate as you can. Here is the contents of my poly engine folder: -

Opinions; temporary glue

my66s55 replied to aurfalien's topic in Model Building Questions and Answers

I use Aleene's Tacky Glue. The quick dry sets fast and is easy to disassemble the parts. It just peels off the part also. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

The Chrysler 392 hemi is a long engine measuring 30" and won't work. The A engine is inches shorter. To compensate for the shortness of the poly A engine, the heads were designed with the upper most part holding the rocker assembly larger than the deck length of the block. The LA engines are most likely longer. Here are the 318 A engine poly heads: Here is the poly engine using the old poly heads. -

Apple Barrel acrylics

my66s55 replied to smhardesty's topic in General Automotive Talk (Trucks and Cars)

I use Apple Barrel a lot. Brush and spray it. Flat and gloss both. Works well for me. The body on this 40 Ford sedan delivery was Apple Barrel sprayed on and coated with Future.. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

The Christine had the B engine with wedge heads. This is the A engine with poly heads. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

Which block are you thinking of using? Tell me so that I can check to see if it will work. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

What cad program did you use? Blender If you make a 2-bbl intake for this, put me down for at least 2-3 of these. I'll make the manifold and either Carter ball & ball or DDB carb. Maybe both. Will there be transmission or is the idea to use the 300C unit? I used the 300 trans as it is available now. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

I see it a little differently. The big hangup is the creation of the files. The printer I made and use as is the one Joseph of Fire ball Model works use u.v. resin cured by light from a d.l.p. projector. Within the last 2 months, 2 Chinese companies have released a desktop printer using l.e.d light projected through an l.c.d. panel. One retails for $620 and $690 while the other sells for $399. They are however, not plug and play yet. I created this engine out of a need I have for a certain build and because someone else expressed a desire for one. I think people will have a printer and either be able to purchase files on line or have a third party create them. As far as my investment into this particular project, it breaks down as the following. Time spent creating files: 60 - 80 hrs. It take about 10 minutes to load the file into the print program, slice it and start the printer. I don't have to babysit the printer. When it is done, 10 minutes to detach it from the build platform. 5 minutes to put it into a container of water and take it outside for 15 plus minutes of post curing by the sun. 10-15 minutes to bring it back inside and remove and build supports. It takes about 27 hrs of total print time to print this engine. About $25 of u.v. resin was used. I would much rather make the files available than go through creating resin copies. A lot less time consuming and less headache. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

Here is the complete engine minus the air cleaners. The are cleaners are 90% complete. I have not sanded some parts such as the bottom of the air cleaners for perfect fit. The AMT Chrysler 300 A488 mates up perfectly. I need to know who is interested in a resin copy of this engine and if so, which intake manifold and carb and which year. There are 20 pcs. to this engine. This is the real deal in a 59 Plymouth.

.thumb.jpg.fa34550c23b35095ee69ce748b5b8f60.jpg)