-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by my66s55

-

Molotow liquid chrome marker. There are recent posts on in the this general forum.

-

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

They are not scans. They take "blue prints" of the front, side, top and rear and use them. Then they obtain pictures of the subject that show other views. There is no he. It's a company and I'm not too sure that the files aren't free lanced. Go here to see one source of blue prints. https://getoutlines.com/car-blueprints?utm_source=cbinfo&utm_medium=cpm&utm_campaign=cbinfo&utm_content=bar . Hum3d want $50-$60 for the same prints. -

Yawn!!!!!

-

-

Mopar Torqueflight Tranny???

my66s55 replied to lizardlust's topic in Car Aftermarket / Resin / 3D Printed

I already said that George. -

Mopar Torqueflight Tranny???

my66s55 replied to lizardlust's topic in Car Aftermarket / Resin / 3D Printed

If your looking for a 1962 and up 727, Morgan Automotive:http://www.madmodeling.com/Item/mopar727 -

I created this thread as an education piece to keep those who are interested in desktop 3d printing abreast with current products. In doing so, I use terminology that may be foreign to some. The size of 1 micron is 1/1000 of a millimeter. There are 25.4 millimeters in 1 inch. A piece of copy paper for your printer is 9 microns thick. A 3d printed layer of 100 microns is about 11 sheets of compressed copy paper. A 20 micron 3d printer layer is just over 2 pages of copy paper. The photo below gives you an example of the difference of 4 difference 3d printed layers. Starting with the top one at 100 microns thick, the second 50 microns, the third 35 microns and the bottom is 20 microns. You can see the difference if you count the layer lines on the right hand section of the oil pan. These "steps" are what causes the non smooth surface of a 3d print. The lower the level, the smoother the angles surface. When you print at 20 micron layer height, you can't run your finger nail over the surface and and feel any ridges.

-

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

-

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

Other things to keep in mind is that none convertible is like an early promo. No interior or frame.The files I want are: 1935 Auburn Boat Tail Speedster Bugatti 57sc Atlantic 1964 Buick Skylark convertible 1938 Buick Yjob 1953 Cadillac Eldorado convertible 1940 LaSalle convertible coupe 1955 & 57 Lincolns 1956 Lincoln Continental 1939 Olds convertible coupe 1938 Talbot Lago Teardrop coup 1957 & 1959 DeSotos -

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

The rear fenders were one of the few parts that were one layer and are easier to fix. You just high light it and create it 3d by extending the surface inward. The result is this: In the case of an already file that is 3d, you have to high light the inner face and make the part thicker: -

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

-

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

It's not that easy to explain but, I try my best. First of, it's like a model. It's assembled in pieces. This is the total car: here are some brake out shots: -

Hum3d - Large Source of 3D Modelled Autos

my66s55 replied to Erik Smith's topic in General Automotive Talk (Trucks and Cars)

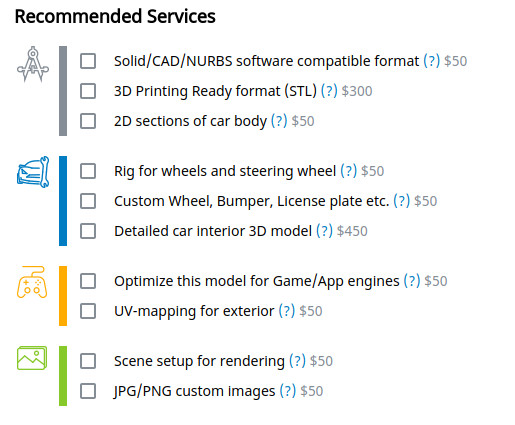

Let me enlighten you on Hum3d. I use them and the models are very good. At $75 a pop, their worth it to me. The 37 F & F Delehaye 135 I'm working on is from them. If you want a 3d printable file, it's $400. Since I am able to use a cad software, I can make the $75 file printable. -

.200 millimeters is 200 microns. 200 microns .01 inch.

-

A new printer needs to have print specks established before any real printing can be done. In this case, it's the lowest light exposure per layer that will give you the best quality print. So you use a calibration file and start testing with differing numbers. Each layer thickness calibration used will have different numbers. The one on the top was 35 microns layers and the one on the bottom was 20 microns layers. If you look just to the left of the letters 5,6,7, you can can make out the letters that are very small and spell breaking.

-

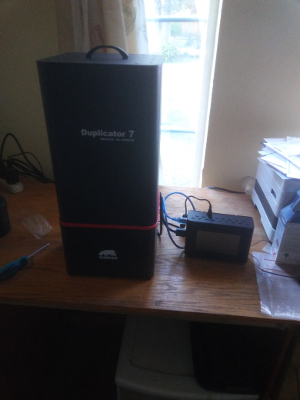

Over the past couple of years the 3d printing community has been active in perfecting a different type of s.l.a. d.l.p. printer. The conventional style, as was the one I built and used, cured u.v. resin with the light source from a d.l.p. movie projector or laser beam. The new type uses the light produced by an l.e.d. diode that passes through an l.c.d. light panel such as is done on a computer screen. This difference in the light source did two things. The best resolution from a d.l.p, projector is 1920 x 1080. This creates a pixel count of 12 per square millimeter. The l.c.d. panel used in the new printers have a resolution of 2640 x 1440 that produce 27 pixels per square millimeter. Over twice the resolution. Secondly, a d.l.p. projection costs $600.00 plus. An l.e.d diode and l.c.d screen costs less than a quarter of that. End result, lower cost and higher quality printing. One year ago, two Chinese companies introduced a version of he l.e.d. printer. One of them being Wanhoa. Improvements were made through the year and the result is two well made printers. Wanhoa, who is a large, well know producer of desk top 3d printers, is the least expensive. They still weren't plug and play until this last October when Wanhoa introduced the D7 Box. There is a Wanhoa Duplicator Facebook page with 5061 members and tons of help. I purchased mine on November 2 and it was shipped DHL from mainland China. It was received November 7. Full tracking was provided. My cost was $495.00 for the printer and $125.00 for the box. Shipping was free. The box runs the printer and eliminates the need for a computer. It's basically plug and play although, there is still a learning curve. Here's what it looks like. Next, I'll show some print results

-

3d printed spark plugs on my new printer

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

They are a little larger than 1:24. I didn't print them any smaller as I wanted to be able to take a picture to post. I use FunToDo Deep Black resin. It, imho as well as others opinion, gives the greatest detail and least shrinkage of the the available uv resins. The Shapeways is printer is laser cure based like the Form One and uses a different blend. FunToDo offers a blend for the Form One in black and it wouldn't surprise me if Shapeways didn't use it. -

Yes, your right John. I looked it up real quick and miss read the wekipedia.

- 33 replies

-

Ford used that same basic frame for Ford and Mercury at least through 66. I know this because the 66s55 in my sig is for my fill size 66 Merc. The engine in the 58 Pacer is a mel. They look basically the same as the fe.

- 33 replies