-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by my66s55

-

Interior upholstery pattern decals

my66s55 replied to gtx6970's topic in Model Building Questions and Answers

I'm with Bill. I found a fairly straight on picture of a 59 Plymouth door panel. Cropped a section. Tiled it in LibreOffice writer. Printed it out and used it in door panels and seats. Worked perfect. -

3D Printed Part Smoothing Breakthrough

my66s55 replied to StrangerBandFan's topic in Tips, Tricks, and Tutorials

Understanding the print spects will help you understand what causes those lines. 3d printing is done in most cases in layers. When an object has an angle, it creates a situation of lines, Vision a series of steps. The ones used to climb. The greater the angle, the greater the step. The layer size may be 19 micron, but if the xy is 100 microns your going to get steps. X being left to right and y being top to bottom. The black high definition printer is a desktop u.v. resin printer. The same technology I use. If I had to guess, I'd say that it's one of the new fast printers that can do an hour print in 10-15 minutes. The resin is Fun-to-Do deep black which prints in great detail and has a shrinkage of 5% or less. For smoothing, I prefer to use Duplicolor scratch filler whenever I can, but I don't have much problem with lines because I print at 50 micron layer height and 70 micron xy. -

1929 Model A Roadster ArtDeco/Coachbuilt/Streamliner -DONE!

my66s55 replied to Impalow's topic in WIP: Model Cars

I really like this builds design and the way it's being done with the use of desk top 3d printing. 3d printing allows for the ability of parts, like fenders, to be printed as a mirror image of each other. I found this impossible to do by hand. Draw the file or files for one side and hit the mirror key and you have the file for other side. -

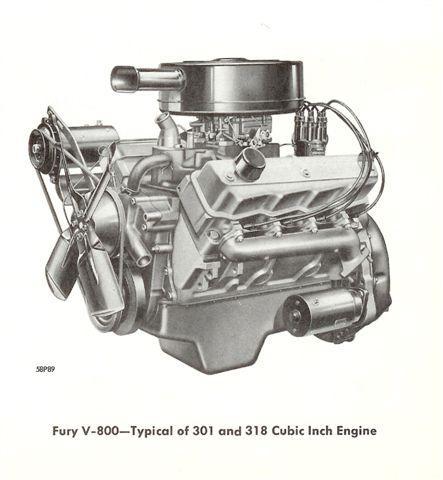

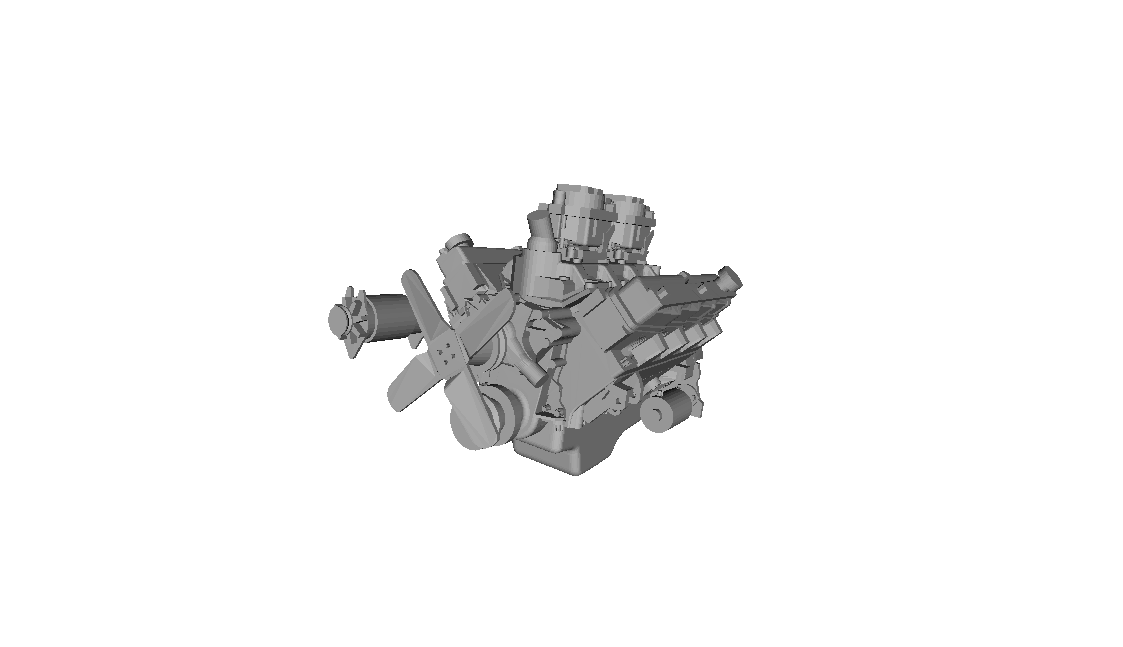

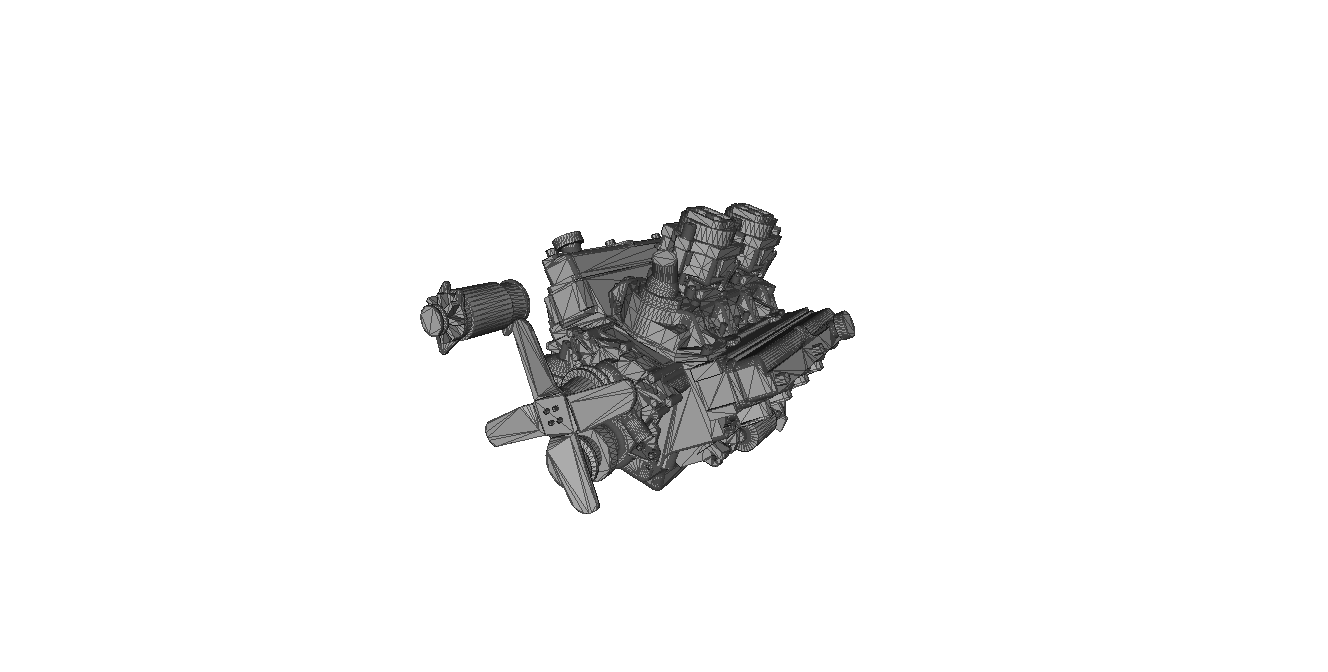

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

No. Just light sanding to get the bottom of the print even and rid support residue. There is no need for surface sanding as the surface is smooth. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

This is true, but that the 57 300 hemi is much nicer in detail and has the A488 trans. I have a Dodge hemi and a Desoto hemi from the Amt 29 Ford roadster and 53 Ford pickup. Based on the availability of someone using an existing kit engine, the 300 engine makes sense. Comparing the size of the 3 kit engines, they are the same length. In real life, going by the 1956 dimensions that I could find when I started this project, the Chrysler width-height are 25"x30". Dodge was 23"x27". Plymouth used the A engine. I'll use the Chrysler. I could modify the A block to the correct specks, but just doesn't make sense to me. -

It is possible to print lettering in those scales as I have done it for someone else. It was the B.F GOODRICH on the sidewall of a tire. That is the only way I know of that it can be done. That is, on an existing surface. To print just the script isn't possible.

-

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

Brian, the 62-66 block was just a slight bit different as it mated with the 727 trans. The starter mounting changed position. I already have this block. Dan, the rtv and casting resin was on my doorstep bright and early this morning. Lets see how I do with that. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

A 325 poly can be made with these heads and valve covers that fit on the hemi in the AMT 57 Chrysler 300. When used with the hemi duel quad manifold in that kit, you have the engine that came in a Dodge D500. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

Bill, the parts are printed with a resin called deep black. As a suggestion from a member here, I started painting them with Rustoleum silver. Also, Plymouth engines of this era, except the valve covers, were silver. -

My Chrysler A 318 poly head engine 3d printed at home

my66s55 replied to my66s55's topic in WIP: Model Cars

Thanks for the positive replies. Yes Dan, I designed these created the files and printed these parts on my 3d printer. It takes a different type of printer to print this type detail. It uses u.v. curable resin and a D.L.P projector instead of melting plastic in layers. John, I am creating this now because there has been an interest in being able to obtain this engine in scale. This version is only good for 56 & 57. 58 needs a different oil pan. The heads and valve covers might not fit the engine block you want to use. What block did you want to use them on to create what engine year? There will be more versions in the future as this block is only used from 56-61. I have the 62-66 Block already. The valve covers from 59 on didn't have the center screw bolt. The torqueflite A488 cast iron trans was used from 56-61 and is the bell housing is unique to the A engine. The trans from the 57 Chrysler 300 is not correct and has flaws. I'm in the process of creating the A488 file currently. Past that, I need to do the exhaust manifolds and air cleaners. Future parts will be a single 4 barrel and a 2 barrel manifolds plus a 2 barrel carb and air cleaners to match. -

3D printing question

my66s55 replied to Psychographic's topic in General Automotive Talk (Trucks and Cars)

It's not difficult to learn if you have the right sources for answering questions and doing how to do plus the time to do it. I've been using it for 3+ years and am still learning new things to improve my files and check them for 3d print ability. Thankfully, all this is easy to find. -

I need this engine for my upcoming 56 Plymouth build and since others have expressed a desire for one, I started creating it. This version is for the 56 & 57 Plymouth. The A engine was only used in Plymouth for 56-58 models. There was an older poly head version used in other Chrysler lines through 58. The heads swapped out with hemi engine heads and and everything else except the valve covers were hemi. I am open to any thoughts, questions, suggestions and or comments on this project. The actual engine My engine in it's current state Shoing the stl. files The printed parts starting with the head valve cover Timing chain cover and water pump- kindly excuse my thumb print on the water pump The water pump pulley, fan and oil filter cartridge The engine block in two pieces The engine block shown as one piece. The oil pan, harmonic balancer and crank shaft pulley, starter, generator, intake manifold, and the 3 sections of the Carter wcfb carb.

-

3D printing question

my66s55 replied to Psychographic's topic in General Automotive Talk (Trucks and Cars)

I.m.o, and many others, one of the best best programs is Blender. It's free open source software and created by users.The down side is the learning curve. I've also heard that Google Sketchup is a good place to start. -

3D printing growing as we speak

my66s55 replied to bbowser's topic in General Automotive Talk (Trucks and Cars)

I have been waiting for this as have many others. As some of you may be aware, I won't post anything on this post that isn't new, and therefore, real 3d printing growing as we speak. This one has just been released in the last short while. https://ru.aliexpress.com/item/wax-casting-UV-resin-LCD-light-curing-Photocurable-3d-printer-with-Raspberry-pi-SLA-3D-printer/32778078602.html?detailNewVersion=&categoryId=200003413. you'll need to translate from your browser. A non standalone version is available for $618. This printer gives a quality as good as Shape Ways best and in some cases better. It's as good as you can get to being plug and play. Why is this , besides cost, such a break through? Let me explain. Current ultra violet, or u.v. curred resin printers that produce high quality prints utilize a D.L.P projector or laser to cure the resin. L.E.D. diodes come in all ranges of the light scale, including u.v. Coupling an L.C.D. panel like the one on your computer and t.v. with L.E.D.u.v. diodes for a back light creates a 3d printer that is low in cost, energy efficient and low level maintenance. As an example, d.l.p printers cost $2k+ and up to $5k. If you D.I.Y it as I did, the projector alone will cost as much or more than this printer. One drawback to D.L.P. printing is that the light projected onto the printer build plate is not at the same intensity. This means that, even though you may have a build area of 5" X 3", only a portion, maybe half, is printable use. With L.E,D. light, the whole build area is printable.Here is a forum showing results from this printer. Much is talk, but work through to the actual results. There is more on the Google form if anyone is interested. As a p.s., compare this printer to that cheap, F.D.M, obsolete printer for a few hundred less, and in many cases,more money. -

Bootlegger '40 Ford

my66s55 replied to ANovaScotian's topic in General Automotive Talk (Trucks and Cars)

The LaSalle short shaft was only used in the 50 Olds, no other years. The actual engine of choice was a souped up flat head. In a few instances a Caddy ambulance engine. -

Bootlegger '40 Ford

my66s55 replied to ANovaScotian's topic in General Automotive Talk (Trucks and Cars)

The reality is that the Olds/LaSalle setup would be much more of a benefit to a rum runner as the Olds was noted for its strong bottom end and the LaSalle for its strength. Drag racers like Stone, Woods and Cook used the the Olds for this very reason. -

Bootlegger '40 Ford

my66s55 replied to ANovaScotian's topic in General Automotive Talk (Trucks and Cars)

A Caddy or Olds is definitely the choice, but a LaSalle trans would be more a likely option over a Ford trans. -

3D printing growing as we speak

my66s55 replied to bbowser's topic in General Automotive Talk (Trucks and Cars)

This is old news Bill. Form labs has been around for a number of years. Laser 3d printing itself has been around since the 1980's. The new kid on the block is are the dlp printers that have numerous advantages over laser machines. Dlp printers will print layers at 20 microns. More important, they will print x/y axis as low as 50 microns. The dot of Form Labs Form 2 is 140 microns. What I print is done with a dlp printer. Those nice AFB carbs are printer on a dlp printer. No contest. The advantages of dlp over laser are too numerous to mention. -

O.K. O.K. My opinion, and it has a lot of validity to it. Harry is on a Mac, I'm on Linux. Windoz does an upgrade, applications need to make adjustments. Programmers work days and thus PB has to shut down to make adjustments. Some other applications may shut down in non high traffic hours. BTW, I have zero problems with PB. Nor do I have to run all these programs to detect virus and trojan invasion. Linus is the desktop version of Unix and Mac is a version of Unix.

-

Just a thought about 3D printing

my66s55 replied to mikemodeler's topic in Car Aftermarket / Resin / 3D Printed

Finally Mike, you have an answer to your original post. Thank you Joseph for chiming in. Joseph is the blue print of how it should be done. He mastered resin casting, then cad drawing. Lastly, he purchased and learned how to use a high res 3d printer. All these skills, he has mastered. The first step to 3d printing is mastering a cad software. Then you can approach the steps Mark brought up in his post. It certainly has a place in our hobby for those who choose to utilize it. -

Moebius Models in path of hurricane

my66s55 replied to Jon Cole's topic in General Automotive Talk (Trucks and Cars)

They are closed Friday 10/7 because all of the Florida counties located in Mathews path have curfews. Their located within a half hour drive to the north of me. We're both in Volusia county and have a curfew starting at midnight tonight and ending at 7 a.m. Saturday. The heaviest brunt of the storm is due to hit my area around noon Friday. -

3D printing growing as we speak

my66s55 replied to bbowser's topic in General Automotive Talk (Trucks and Cars)

Check out number 10 on this list of 3d printed cars. https://all3dp.com/3d-printed-car/ -