-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by my66s55

-

Rotary Tool Suggestions

my66s55 replied to iBorg's topic in General Automotive Talk (Trucks and Cars)

I have a Harbor Freight variable speed with cord and cordless. They comes with a bunch of tools plus my Dremel tools work also. It does all I need for $27 minus a coupon if you have one. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

Brian, Blender is free open source software that is cross platform. I was made by and developed by people in the trade. There are tutorials on youtube: as one example. Their web sight has more help. There is a free Blender for Dummies that is downloadable, The software has functions to help make your file 3d printable. Shapeways mentions Blender on their websie. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

I am very incuraged by the amount of interest. I used the 2 websites I listed in post 16 of this thread for the majority of my referrence. It helped having the experience of building the fdm printer. I already knew how to set up the electionics and software, plus getting it working and calibrated. The dlp printer is a very simple machine and quite easy to construct. The beauty of building your own is that you can it make how you want. I will be 70 years old in a couple of weeks. There is not a lot of empty desktop room in my house. I wanted to be able to stand while using the laptop, so I built my printer 48 inches high from 2 pieces of plywood I had in the garage. I left the ends open for access and cut an opening in the side for access to the vat and easy repair, build, etc. The height also enable me to put a large container under the vat incase of spills. I would be elated to have the opportunity to print some of your files. Here are and example of a wheel I created and a tire from Grabcab. I didn't clean the dust from them before painting and it shows. The resin I am using is ver soft and breakable. It shows in the prints and is not caused by the printer not printing correctly. The tire broke while I was cleaning it. Alcohol is used to remove the excess resin. The stl. also needs to have the tread raised as it didn't print. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

So true Jeremy. Can you imagine though,going to a web site and finding files like these already drawn? http://www.cgtrader.com/3d-models/car/antique/delahaye-135m-figoni-and-falaschi-convertible-1937 http://www.cgtrader.com/3d-models/car/standard/buick-skylark-convertible-1964 http://www.cgtrader.com/3d-models/car/antique/delahaye-t165-1939 http://www.cgtrader.com/3d-models/car/antique/bugatti-type-57sc-atlantic-1936 http://www.cgtrader.com/3d-models/car/luxury/cadillac-eldorado-convertible-1953 http://www.cgtrader.com/3d-models/car/antique/oldsmobile-88-1957-convertible--2 http://www.cgtrader.com/3d-models/car/antique/oldsmobile-88-1958-coupe--2 I didn't create the file for the ls engine block. I down loaded it and other files like the tire in the response below. They were free on the grabcad website. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

I don't recall, Brian. It was done as a part for the front suspension of the 1935 LaSalle convertible coupe model I am printing. At the time, I was still learning to use Blender and didn't know all the shortcuts. It wouldn't take that long today. Here are the files. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

The resins appear to be chemical based, Charlie. Go here: http://www.buildyourownsla.com/forum/viewtopic.php?f=13&t=68 if you would like a like of suppliers. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

-

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

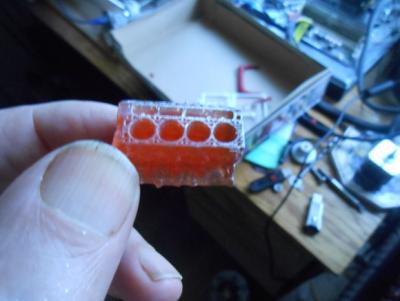

Here's a good example of the difference between a part that's printed on my filament machine and the dlp machine. Last picture is the stl file,first is the filament print and the other 2 are the dip print. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

Until the resin won't print good anymore. There are guys reporting 2 and three weeks and everything is still good. The resin and salt water don't ever mix. If you stir the vat up, the resin only rises to the top. The resin can also be drained off the top. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

Thanks Chief. I looked at both bottom up and top down pros and cons and decided to do a top down. There has just been too much in the way of problems with the flex vat. The main draw back originally with the top down was the high cost of resin and the fact that you could only built to the depth of the vat. The flex vat bottom up has a high print failure rate due to tearing of the print during the flexing. Also problems with larger prints not being able to separate from the vat. The cost of resin is now less than half what it was 2 years ago. You fill the vat up to about 2 or three inch from the desired resin height with salt water and then top it off with resin. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

Resin is resin. Cut it. Sand it. Paint it. Isn't harmed by chemicals including break fluid, acetone, alcohol, yada,yada,yada. You can electroplate it. Doesn't contains any v.o.c. Just resin. Comes in a variety of colors and consistency. Soft and flexible like you would want for making tires. I'm printing one out now, as that is the resin I bought. General purpose which is hard, but not brittle and castable for making thing like jewelry. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

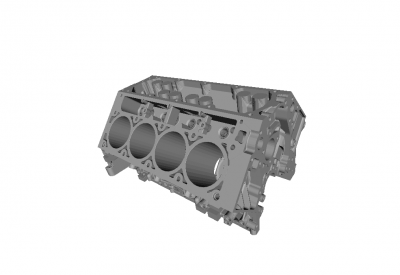

Chris, I built the printer. I have less than 1k in it. The most expensive purchase was the Acer 6510db dlp projector. It ran $607, but is considered one of,if not, the best. Makerbots are filament layering printers like my diy Prussa I3 in my avatar. Not really something you would not want to consider. Formlabs1 is an sla printer. That is, it uses a laser to cure the same uv resins that the dlp beam does. The B9 creator will go to 25-30 microns. Where it can get confusing is understanding 3d printing and these numbers. I may very well get to a 10 micron layer height, but that isn't really needed unless you like to wait a long time to print something. My engine block was printed at 100 microns layer height. The height is the z axis. x & y are the side to side and front to back axis. A filament printer uses all three. The laser printer uses all three. that is what creates a non smooth surface. It is also very time consuming. A dlp printer projects a beam of uv light that cures an entire layer in 3 to 6 seconds. There is only an x axis that moves. It took 39 minutes to print this engine block. I could easily add 3 to 5 more on the build platform and print 4 to 6 engine blocks in the same 39 minutes. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

There you are William. This print and this post topic was done with you in mind. You kept asking to see a detailed, usable 1/25 engine block and I kept trying to tell you it was out there. Now you can see it for yourself. No, this is a different style printer than the one in my avatar. I finished the one in my avatar a year and a half ago and have done some amazing prints with it, but it could never do a print like this. It is a filament style printer. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

Believe me or not Bill, It took 40 minutes for the software to slice 169 layers @ 100 microns and took 39.19 minutes to print it. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

All DLP 3d printers are based on open source development from this blog: http://www.instructables.com/id/DIY-high-resolution-3D-DLP-printer-3D-printer/step1/Basic-design-properties/. Mine, which I built, the B9 Creater, etc. The software, Creation Workshop, was developed by Steve Hernandez. Steve started this forum: http://www.buildyourownsla.com/forum/ last December. You should be able to answer any inquiries by resourcing this info. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

The pictures don't do the print justice. The detail is incredible. This is the same type printer as a B9 Creator. Jewelers are using the B9 to make jewelry. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

No. It's the color of the resin. The resin is uv light cured. This is not done on a filliment printer. -

3d printed LS engine block

my66s55 replied to my66s55's topic in General Automotive Talk (Trucks and Cars)

-

-

It looks real to me.

-

Whoa ho. Ego, ego, ego.

-

I refer you to Snakes post here http://www.modelcarsmag.com/forums/index.php?showtopic=93829 . I think you and the op are bright enough to figure it out from here.

-

My vote goes for model.

-

Wecome to another local guy.

-

Wecome Snake. You know me from the retro board. You will enjoy it here.