-

Posts

3,487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Anglia105E

-

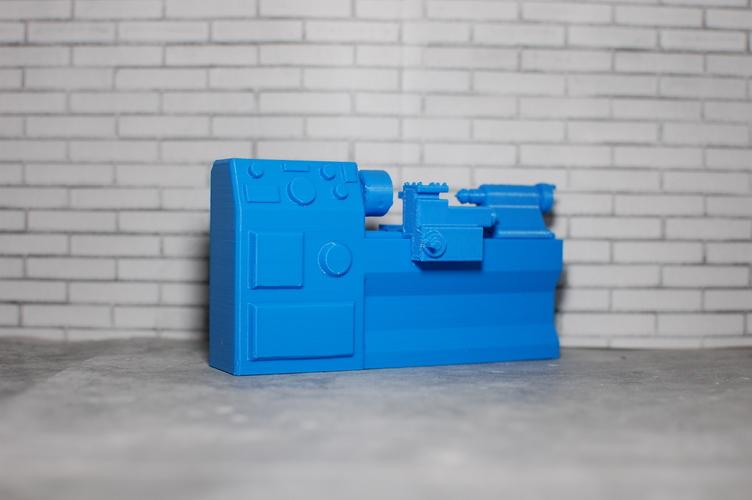

Someone suggested that I could use the two printed lathes that are too small as bench mounted lathes, which I probably shall do, but the model that I am trying to print is actually a full size engineering shop machine that would stand on the floor. Today, I have doubled up all of the dimensions for the five parts of this lathe, and I shall try printing the model this evening. This will bring the model to 1:24 scale, so not sure where my calculations are at fault, working from the 1:10 scale model. What I did Pat, was to multiply the figures by 10 to give me the 1:1 size of this machine, then I divided each measurement by 43 to give me the 1:43 scale measurements. That seemed like sound maths to me, but somehow the lathe has come out half size ! David

-

Thank you, Raymond....... and that is precisely what I needed to know. You have confirmed my view of the lathe's dimensions, and Harold is absolutely right! David

-

Having downloaded an STL file for a Lathe, the idea came to me that I could have a row of lathes as factory machinery for the Hooper factory interior. The 3D printed model is 1:10 scale, and it has 5 pieces, which when assembled create a partially working model. Among the following photos, you will see one of the Acton factory interior, also one photo of a belt driven piece of factory machinery (not Hooper's), and one of a railway engineering works interior, which does show a row of lathes at the back, and this was what gave me the idea really. Well, I did 3D print the 5 pieces of the lathe model successfully, and it only took 33 minutes to print. Once I had removed the pieces easily from the raft, and assembled them using Revell Contacta Professional (not super glue), I went ahead and printed a second set of lathe parts. It was later when I took the model downstairs, in order to photograph the lathe with a 1:43 scale figure (Harold) and a British Railways 400E Ford van, that something became apparent. Harold cast his expert eye over the lathe that was unloaded from the van, and observed... "What good is that? This lathe is too small." Does the lathe appear to be too small, in anyone's opinion, in relation to the 1:43 scale figure? Maybe I have miscalculated the scale dimensions. Might have to go to 1:35 or even 1:24 to get it right. Although I would like to print the 1:10 scale version, there is nowhere for it to fit in as regards my existing dioramas....... I could always build a small 1:10 scale diorama around the lathe, I suppose.... possibly a workshop? David

-

Hello Paul...... I am not wanting to hijack your thread or anything, but I can see that you are clearly knowledgeable when it comes to engineering equipment, so I was wondering what you think about this 3D printed lathe. The link takes you to a seller on Pinshape, and the price is in US $., which is a 1:10 scale lathe. I am wanting to 3D print some factory machinery for my 1:43 Hooper & Co factory, so that I can photograph some Rolls-Royce car bodies in production, with some machine tools displayed inside the factory building. I would have thought the 1:10 scale model could be scaled down to 1:43, before I print it. Does it look like the sort of machine that you would have seen inside a Rolls-Royce factory during the 1950's, in your opinion? Photos below this link...... https://pinshape.com/items/40054-3d-printed-scale-110-lathe David

-

Pleased to see that someone is amused...... !

-

Recent work from the 3D printing factory has produced this Porsche 911 Turbo, in 1:43 scale. Harold is casting a critical eye over the new technology...... You can see from Harold's stance that he is not impressed with this modern engineering. "What on earth is this heap of blue plastic?" His Ford Cortina MK1 is a subtle shade of blue, and Harold has nothing against blue in moderation, but this is BLUE gone mad! "Those blue tyres are never going to catch on, and how are you going to see out of those windows?" No, he decided right there..... Harold was never going to buy such a thing. What is the motor manufacturing world coming to? David

-

Some excellent work going on here, Paul......... I always like to see a model builder using old scale drawings, old reference photos and then scratch building a particular model that simply isn't available in kit form, or even a diecast version. Once you have completed this derelict AC thresher you will have a truly unique scale model for your diorama, and something to be very proud of, I'm sure. David

-

Thanks a lot, Doug...... your clear explanation is just what I was looking for. Are those ' Tree ' supports in your picture? David

-

Realistic looking downpipes, and the detail is in the wall anchors. Those gutters could almost take real rain water ! David

-

Just to let you guys know, that I did succeed in printing the 1:43 scale Rolls-Royce Silver Cloud III model, and I was really pleased with the result as the window apertures were all open. I was expecting them to be flashed over. It was necessary to add a rectangular base under the car. which forced the raft to extend 3 mm all around the car body, and also supports were essential because the front of this car was not printing at all. On a different subject..... I have started preparing a 1:24 scale Rolls-Royce Silver Cloud III for 3D printing, and as the car will not fit horizontally onto the printer bed, the obvious solution is to print the model vertically. My question is this.... although my model car body is straight up vertical at 90 degrees, I notice that most 3D printed 1:24 scale cars are at a slant from the vertical. Can someone tell me what the reason for this might be, please? Will I have to slant my object before printing, or is it safe to continue with the absolute vertical stance? Many thanks, David

-

There you go, Pat...... I learn something new every day! Thanks.

-

Eavetroughs and downspouts always look good, on any diorama building, although we English folk call them ' gutters ' and ' drainpipes ' ( downpipes ). David

-

Friday night I succeeded in 3D printing a 1:43 scale Rolls-Royce Silver Cloud III body, which I had been struggling with for the last 4 days...... this model car may find its way into the 1:43 scale dioramas at some point, and I might be able to print a Silver Cloud I later, which has the single headlamps rather than the twin headlamps setup, from 1962 onwards. David

-

With the right lighting and a little weathering here and there, your idea should work fine, Pat. David

-

All of this tinkering with 3D printing has distracted me from the more important aspects of the Hooper & Co diorama project. It does seem a quite a while now since I was working on the interior of the Hooper factory, and somehow the Rolls-Royce Phantom III bodyshell has ended up on the roof of the factory! From the following photos you can see that the traffic has become very congested on the streets of the dioramas, and somehow a 1:24 scale London bus has found its way onto the 1:43 scale roads! Pretty soon I must turn my attention to the wider aspect, and concentrate on the buildings, the cars and the figures. More advanced photography is planned. Some of the 3D printed models will be used as part of the Hooper & Co project, in one form or another. Thanks for your patience, and I hope that members continue to view this diorama project. David

-

Looks like a good strong construction for the shelter, Pat, and I can see that you are enjoying yourself with this build. I am temporarily distracted from diorama work at the moment, while experimenting and learning 3D printer stuff in the workroom ( loft ). Here is this morning's work in two photos..... the blue Dial Gauge holder is the 3D part that I printed. David

-

Fascinating stuff, Doug..... and I am very much in favour of the open source concept, especially when it concerns 3D printers. The CAD software package that I use is the one called FreeCAD, and I quite like the way it works. Once I had taught myself how to use FreeCAD there was a 2 year period of uncertainty, while I waited for the price of 3D printers to come down. At that time during 2017 - 2018, I could not afford even an entry level printer to get started. Then I saw the Prusa i3 being assembled on a YouTube video, by Thomas Sanladerer and I decided to see if there was a Prusa on Ebay...... As it was, I ended up with an Anet A8, but it's okay because I still cannot afford a genuine Original Prusa machine. David

-

Now THAT would be interesting, Mike...... or even Tamiya..... David

-

Thank you, Doug..... I have used Netfabb previously, when I uploaded my design for a Rolls-Royce engine to Shapeways in Holland...... my design file had errors in it, and they suggested that I try Netfabb before they finally fixed further errors. Certainly I will make use of the old Netfabb link that you have sent me, and hopefully the Silver Cloud file will become printable at some stage. My Anet A8 printer was described as a Prusa i3 on Ebay, but of course it is not an Original Prusa i3, so merely a cheap Chinese knockoff, as they say! However, it does seem to be a reasonably competent machine, which I enjoyed assembling myself. This is a good way of understanding how the technology works, I think. Myself, I am a self employed technical support engineer, having working with computers for almost 40 years now. The satisfaction of building my first 3D printer was just as scary and exciting as when I built my first computer. David

-

Thanks a lot, Doug..... and your reply post helps me a great deal. You have done some excellent work there with the Dodge, and I do take your point that the files include all the component parts of the car, not just the body shell. I agree actually, that this would be too much money for my cheap Anet A8 printer, so I have managed to find a Rolls-Royce Silver Cloud III body shell on the Cults3D website. The file to download was only £8.97, which is US $. 11.83, and the object when imported into the Cura software that I am using is massive. I calculated the scale is 1:3..... so I resized the object down to 1:43 scale and sliced the file for printing. When I tried to 3D print the body shell the printer produced a perfectly flat raft that was only 4 cm x 2 cm, and then the nozzle just wandered around the bed not printing anything. When this file is opened in Cura it gives me an error message, which says...... "Model errors..... Your model is not manifold. The highlighted areas indicate either missing or extraneous surfaces." ( There are lots of highlighted areas actually. ) Is it possible that perhaps the downloaded file is somehow corrupt? The Silver Cloud III does have twin headlamps, but I could modify this to the single headlamp version for the Silver Cloud I Three photos for you. David

-

I do have some photos, David but I am having difficulty finding them at the moment....... thousands of photos on my computer, and just changed computer. Will have another look later! David

-

Sorry, I forgot to include this link to the Hum3D product page in my previous post...... https://hum3d.com/shopping-cart/?add=ec7cedf9faa5b9e75a5ce2fb8b4a4017 David

-

I have purchased and assembled an Anet A8 3D printer that I picked up on Ebay as a DIY kit of parts. Having gone through the process of learning how to use this printer, I have successfully 3D printed a 1:43 scale Ford Anglia / Popular 103E body and wheels. My question is regarding the company, Hum3D...... they are ready to sell me a .STL file for a 1:24 scale Rolls-Royce Silver Cloud, which would cost me 95.00 Euros, or £85.22 or US$. 112.39....... Hum3D say that this .STL file is not print ready, which I understand, but for them to sell me a print ready file they would charge me 300.00 Euros, or £269.13 or US$. 354.86 However, if I was to purchase the .STL file from Hum3D and then import the file into the Cura software, as I did with the Ford, surely I could slice the file to produce the Gcode ready to print the Rolls-Royce model? What worries me is that if Hum3D have somehow rendered the file non-editable, then I would not be able to slice it and also wasted my money. I really would like to try 3D printing this Silver Cloud, and I don't mind paying that sort of money to obtain the .STL file, as long as I am not buying a less than perfect file. Don't worry if this is something you have no knowledge of, but I cannot afford to pay 300.00 Euros for the Hum3D version of the Gcode print ready file. I have dealt with Shapeways of course, but not had any dealings with Hum3D previously. The following photos show the size of both the Ford and the Rolls-Royce on the 3Dprinter build platform, which has the dimensions 220 x 220 x 240 cm. David Watson (England) - Anglia105E

-

Sorry, I forgot to include the link to the Hum3D product in my previous post, so here it is...... https://hum3d.com/shopping-cart/?add=ec7cedf9faa5b9e75a5ce2fb8b4a4017 David

-

I have purchased and assembled an Anet A8 3D printer that I picked up on Ebay as a DIY kit of parts. Having gone through the process of learning how to use this printer, I have successfully 3D printed a 1:43 scale Ford Anglia / Popular 103E body and wheels. My question is regarding the company, Hum3D...... they are ready to sell me a .STL file for a 1:24 scale Rolls-Royce Silver Cloud, which would cost me 95.00 Euros, or £85.22 or US$. 112.39....... Hum3D say that this .STL file is not print ready, which I understand, but for them to sell me a print ready file they would charge me 300.00 Euros, or £269.13 or US$. 354.86 However, if I was to purchase the .STL file from Hum3D and then import the file into the Cura software, as I did with the Ford, surely I could slice the file to produce the Gcode ready to print the Rolls-Royce model? What worries me is that if Hum3D have somehow rendered the file non-editable, then I would not be able to slice it and also wasted my money. I really would like to try 3D printing this Silver Cloud, and I don't mind paying that sort of money to obtain the .STL file, as long as I am not buying a less than perfect file. Don't worry if this is something you have no knowledge of, but I cannot afford to pay 300.00 Euros for the Hum3D version of the Gcode print ready file. I have dealt with Shapeways of course, but not had any dealings with Hum3D previously. The following photos show the size of both the Ford and the Rolls-Royce on the 3Dprinter build platform, which has the dimensions 220 x 220 x 240 cm. David Watson (England) - Anglia105E