R. Thorne

Members-

Posts

1,276 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by R. Thorne

-

Steve should be back in February. Currently in rehab and doing well.

-

1.

-

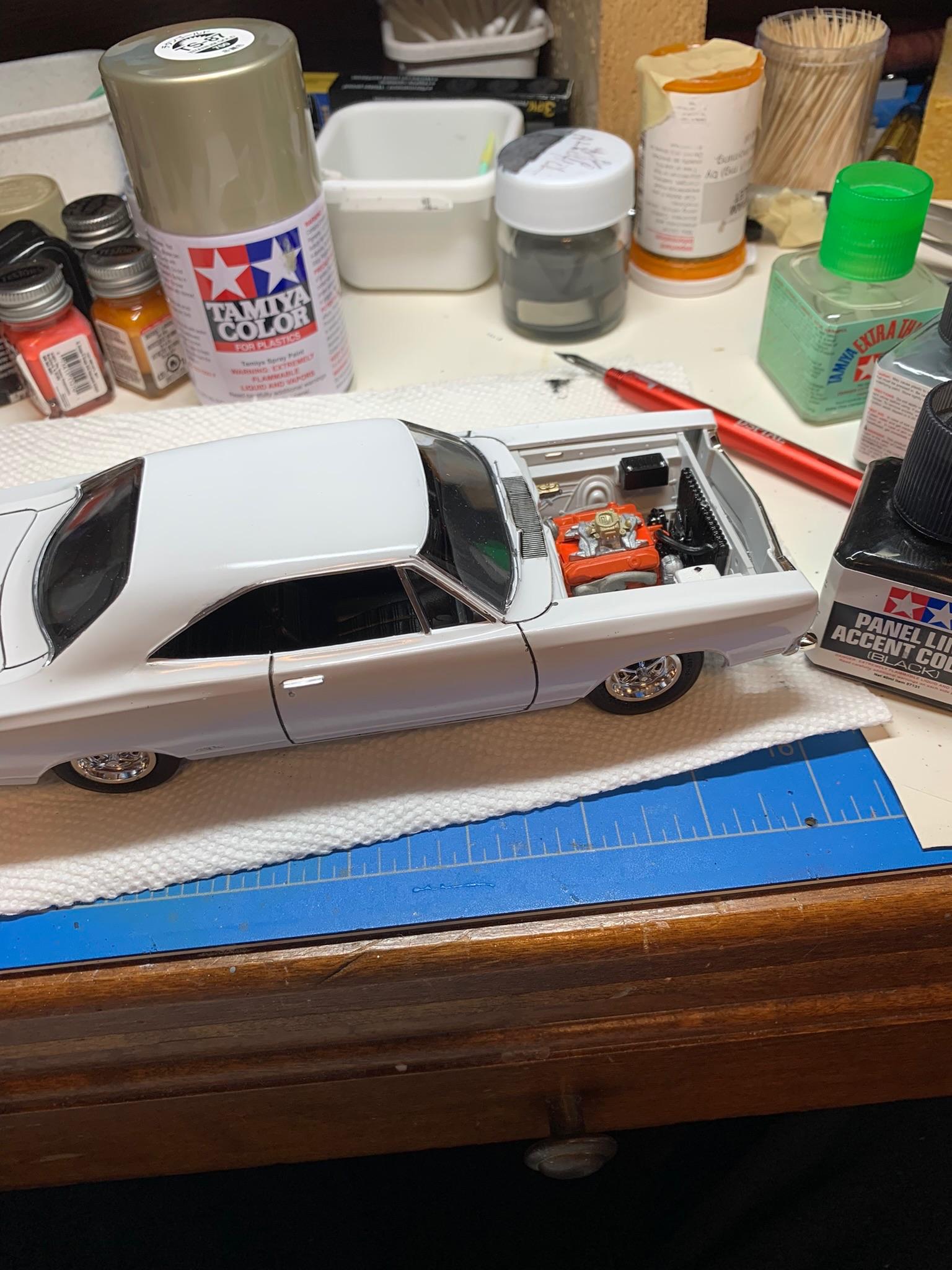

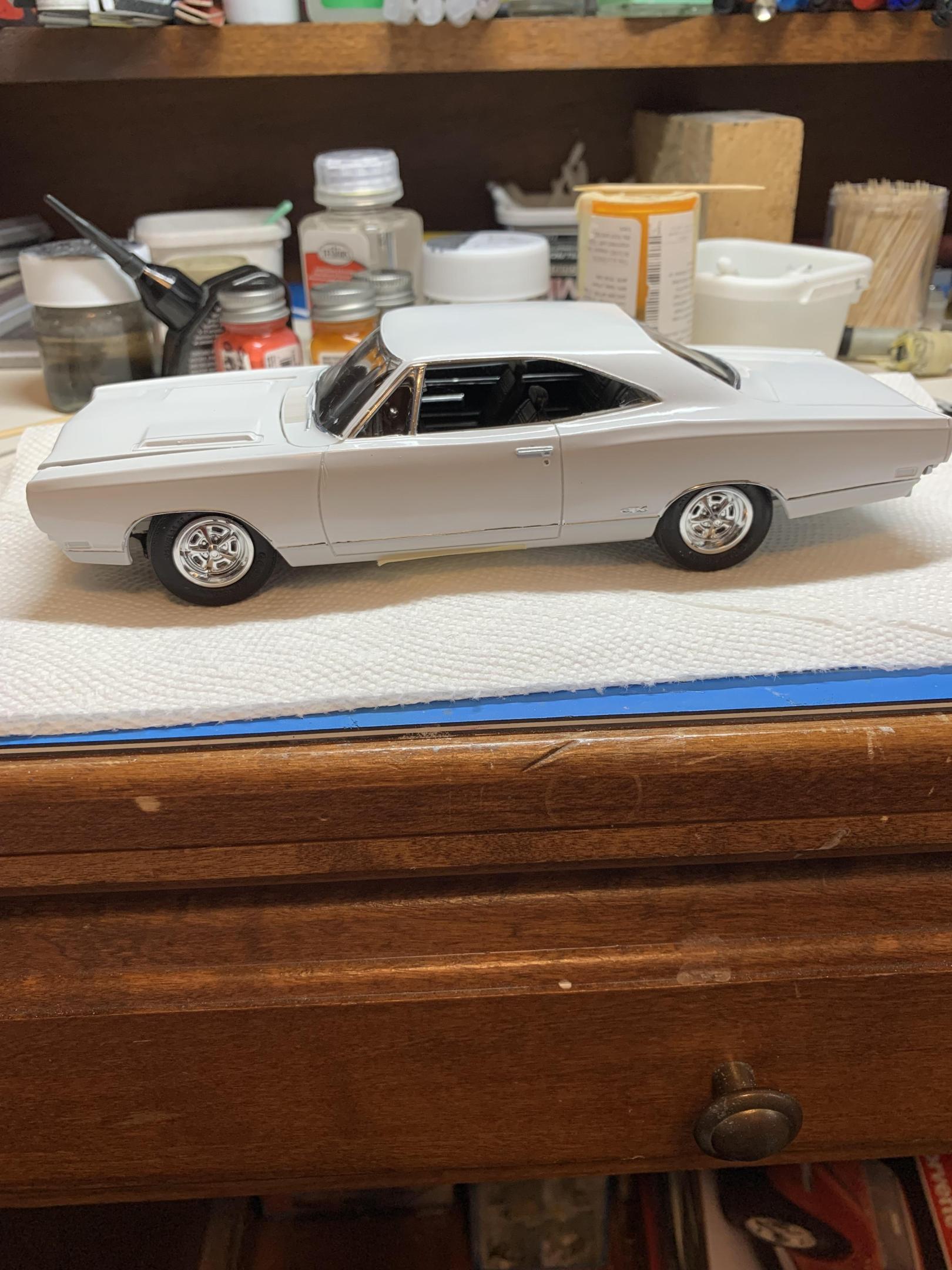

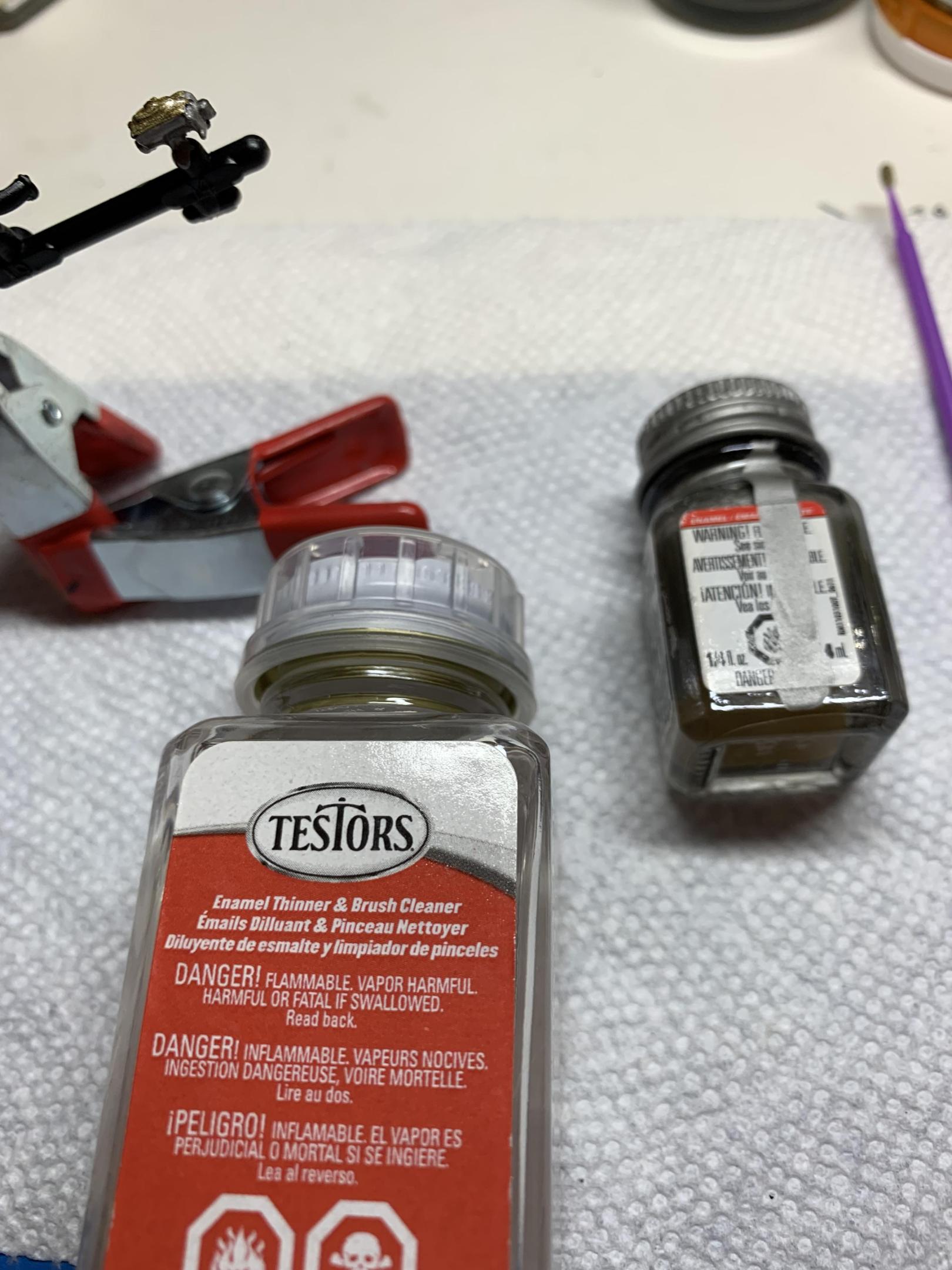

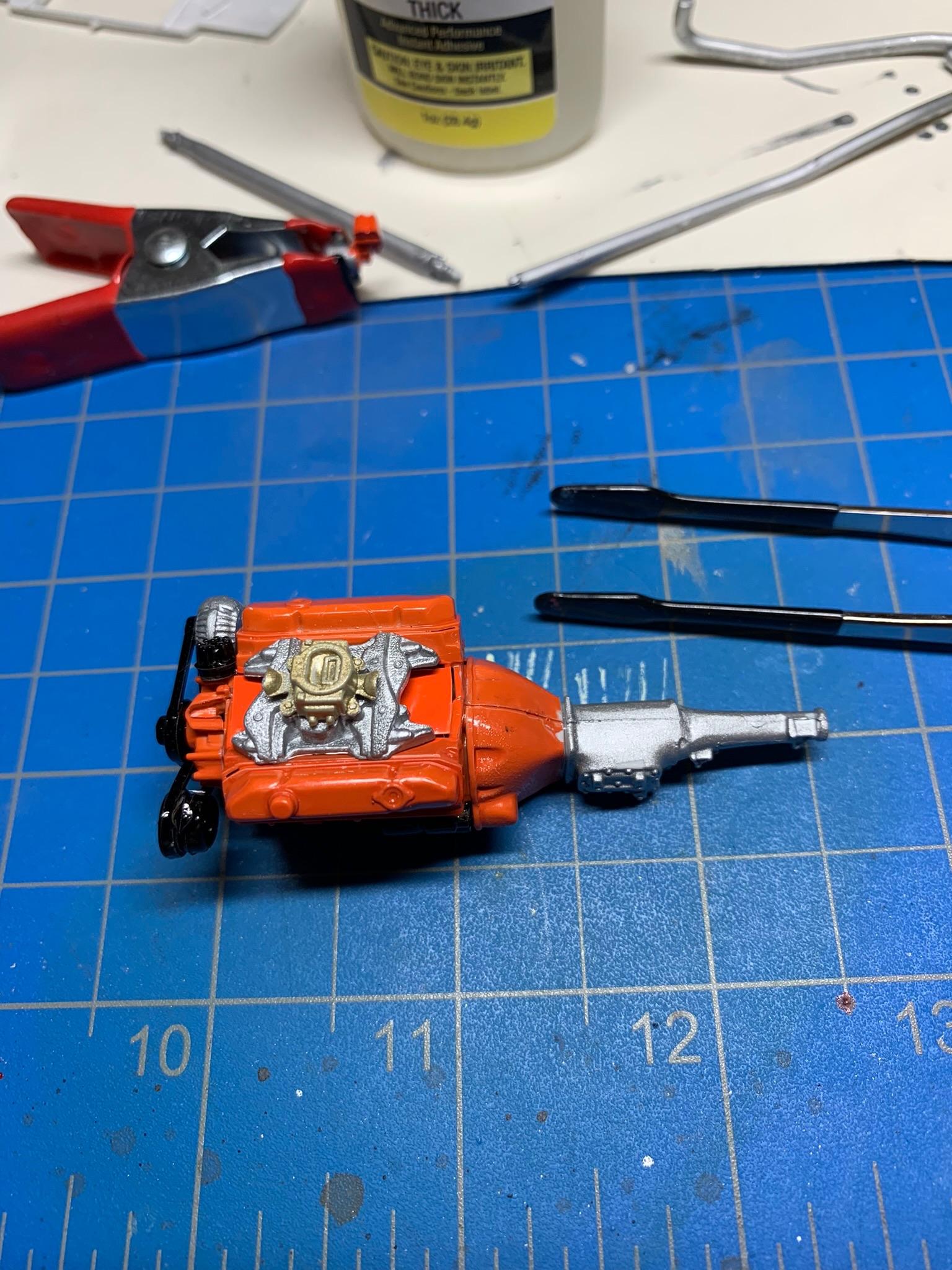

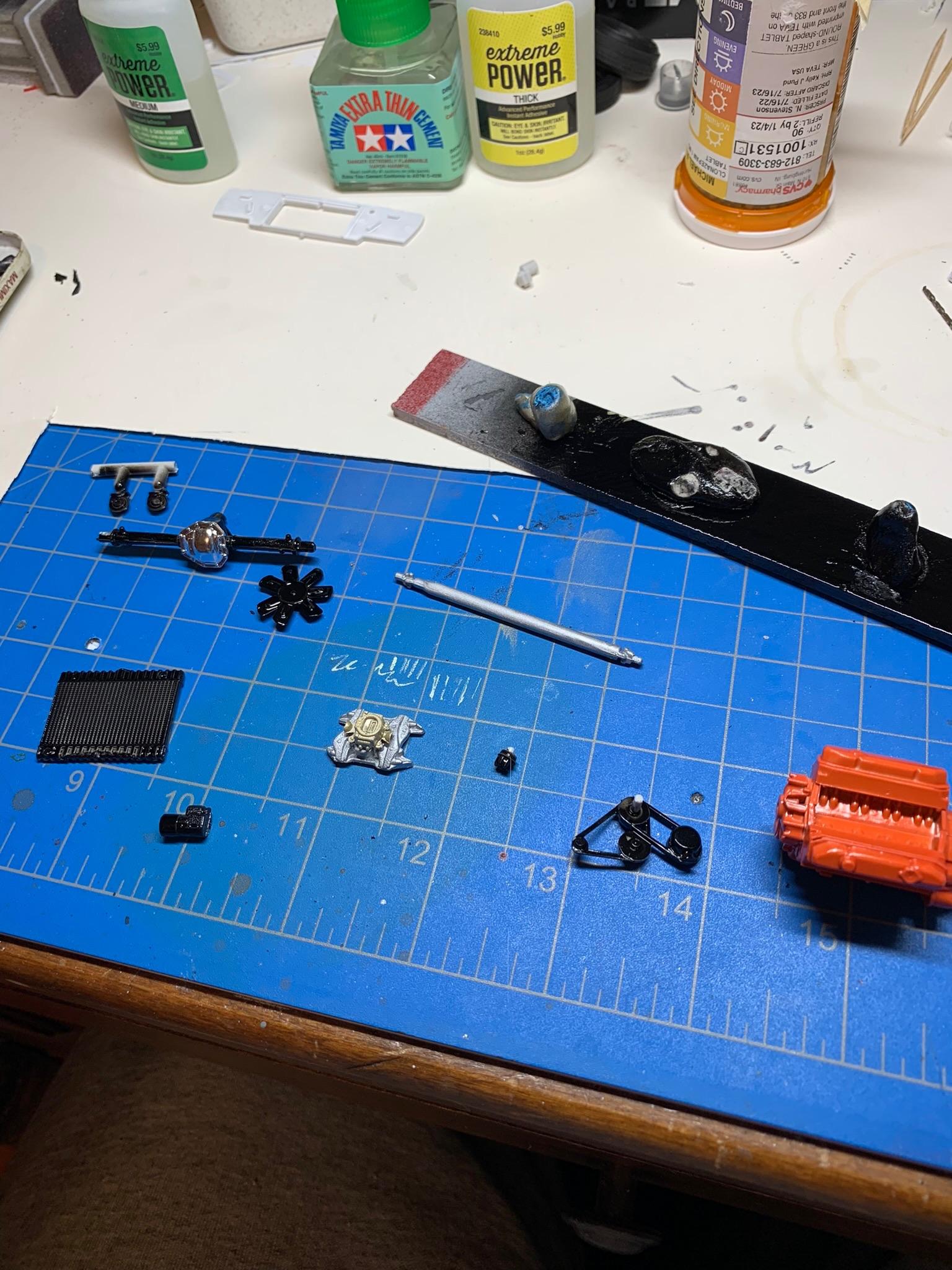

Tried some gray Tamiya panel line accent (too light), then black (too dark). Next time on a light car, perhaps a mixture of the two. Used my Dspiae fountain pen like tool to put it on instead of the Tamiya brush that comes with it. Works pretty good. The brush tends to flood it. I let it dry, then cleaned up the inevitable spots from old, shaky hands with the Testors enamel thinner/brush cleaner. I used the flat silicone nub instead of a q-tip as they tend to soak the accent color out of the panel line. Tried the air cleaner/under hood induction system. Would not shut all the way. Will try some stuff tomorrow to rectify that. Done for today and very close to the finish line for this one.

-

Painting with the hood on or off?

R. Thorne replied to av405's topic in Model Building Questions and Answers

I guess I just don’t get it. I always paint with the hood on (attached with a tiny bit of adhesive or tape) . Why make painting harder? I have painted 1:1 cars in the past and would have never dreamt of painting them with the hood off. Yes, on a lot of cars, it would not show up, but why take the chance when all you have to do is take 5 minutes to fasten it on.? -

Thank you, kind sir. Open that box and have some fun with it.

-

-

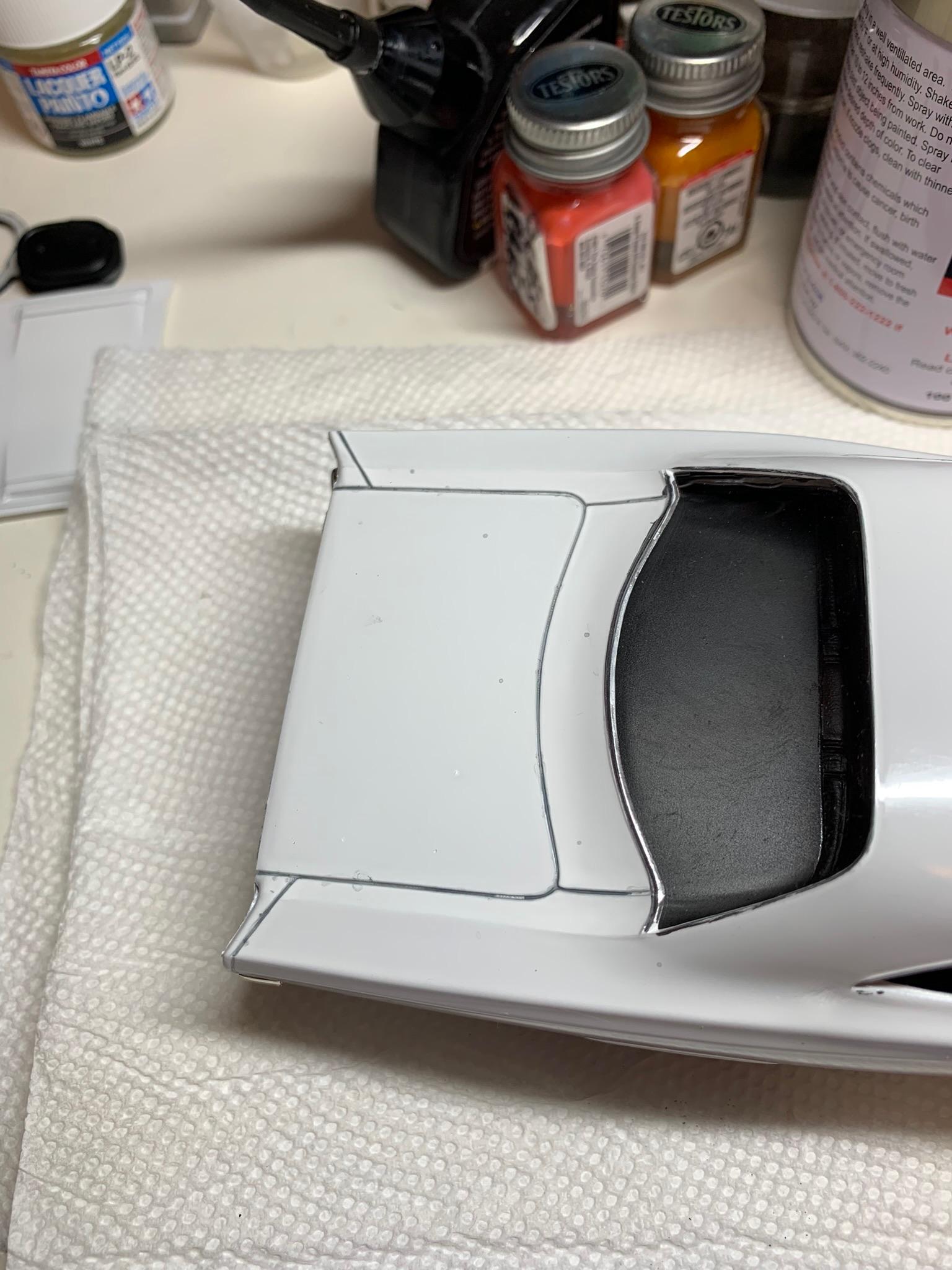

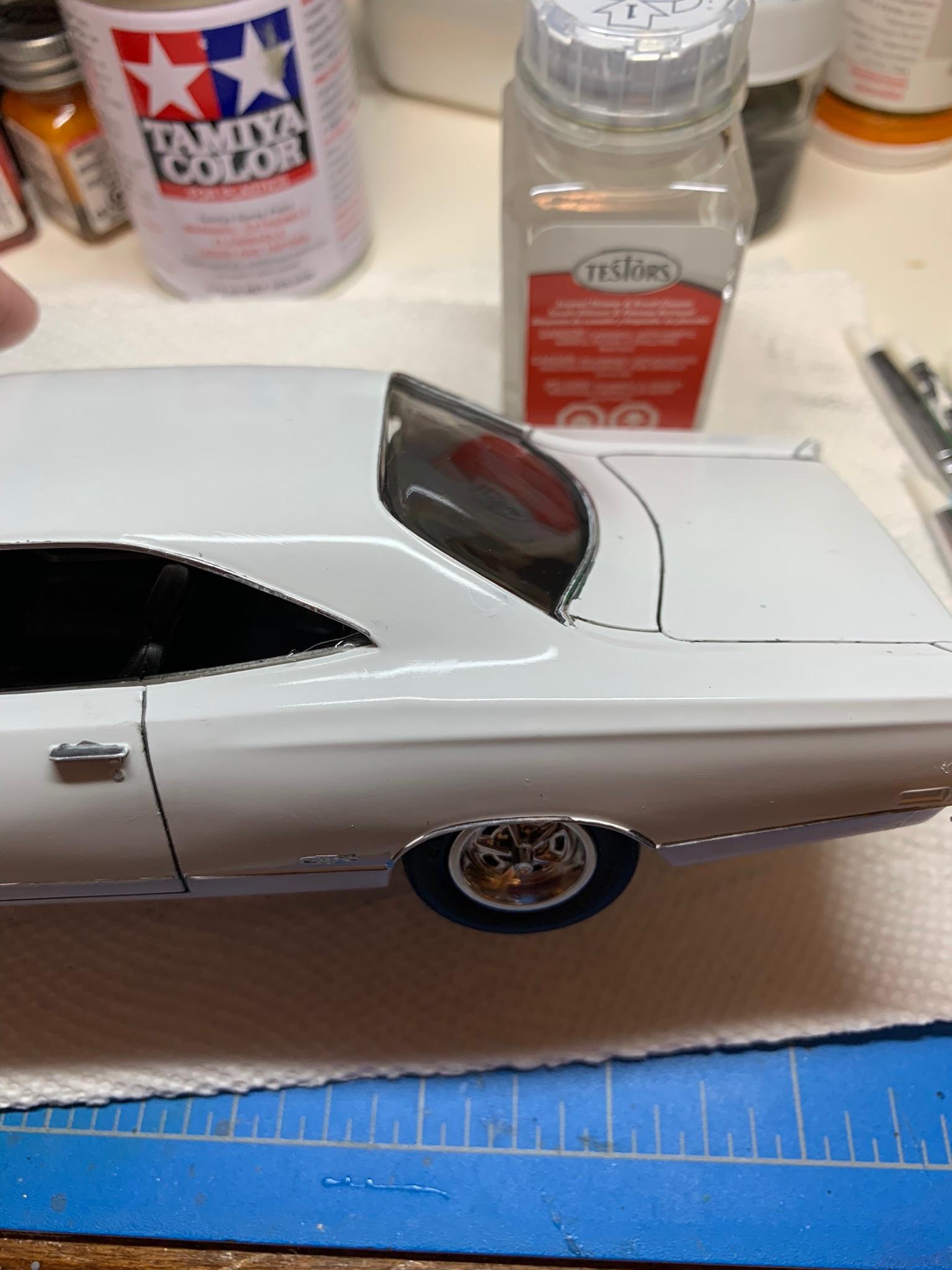

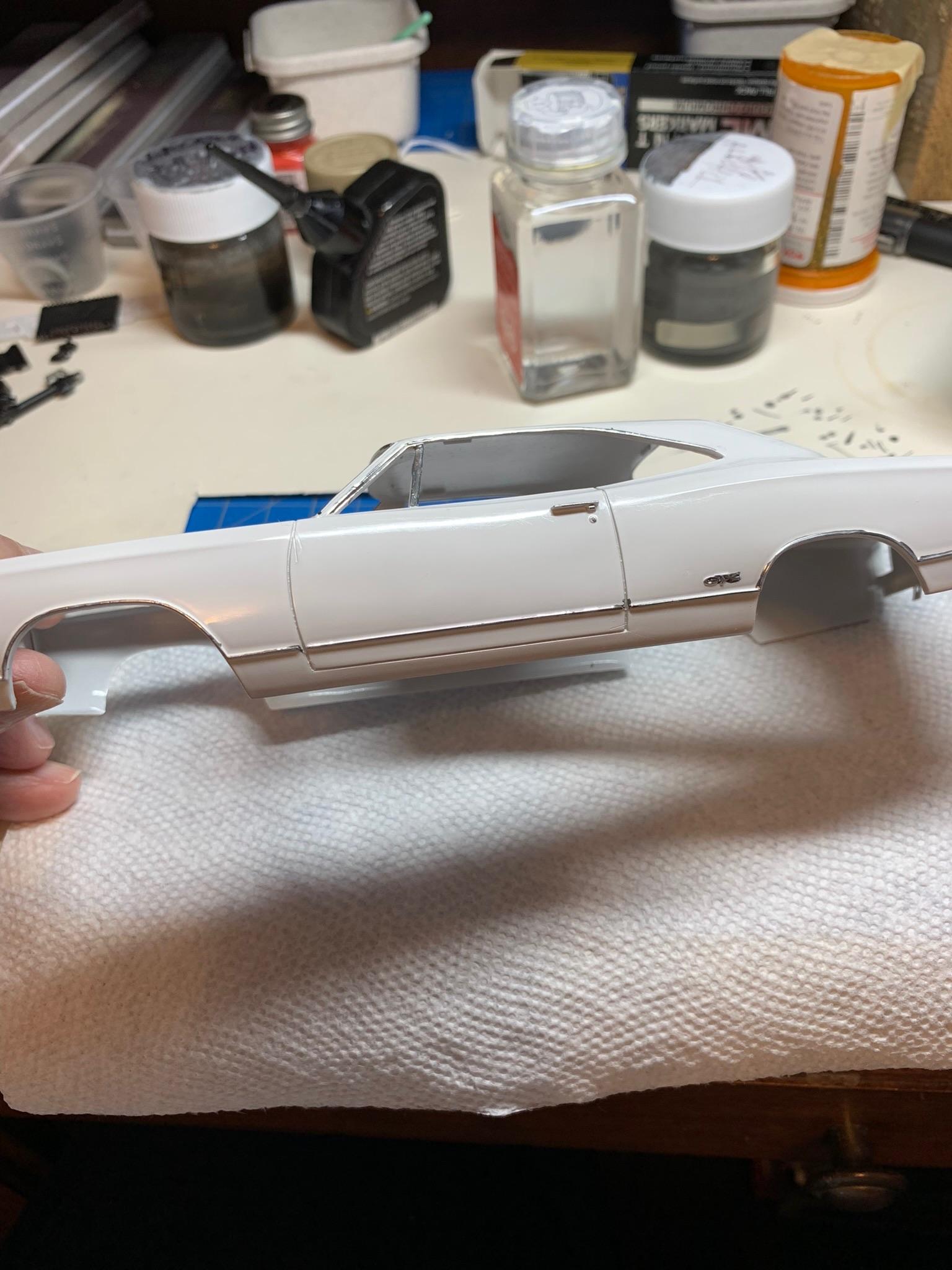

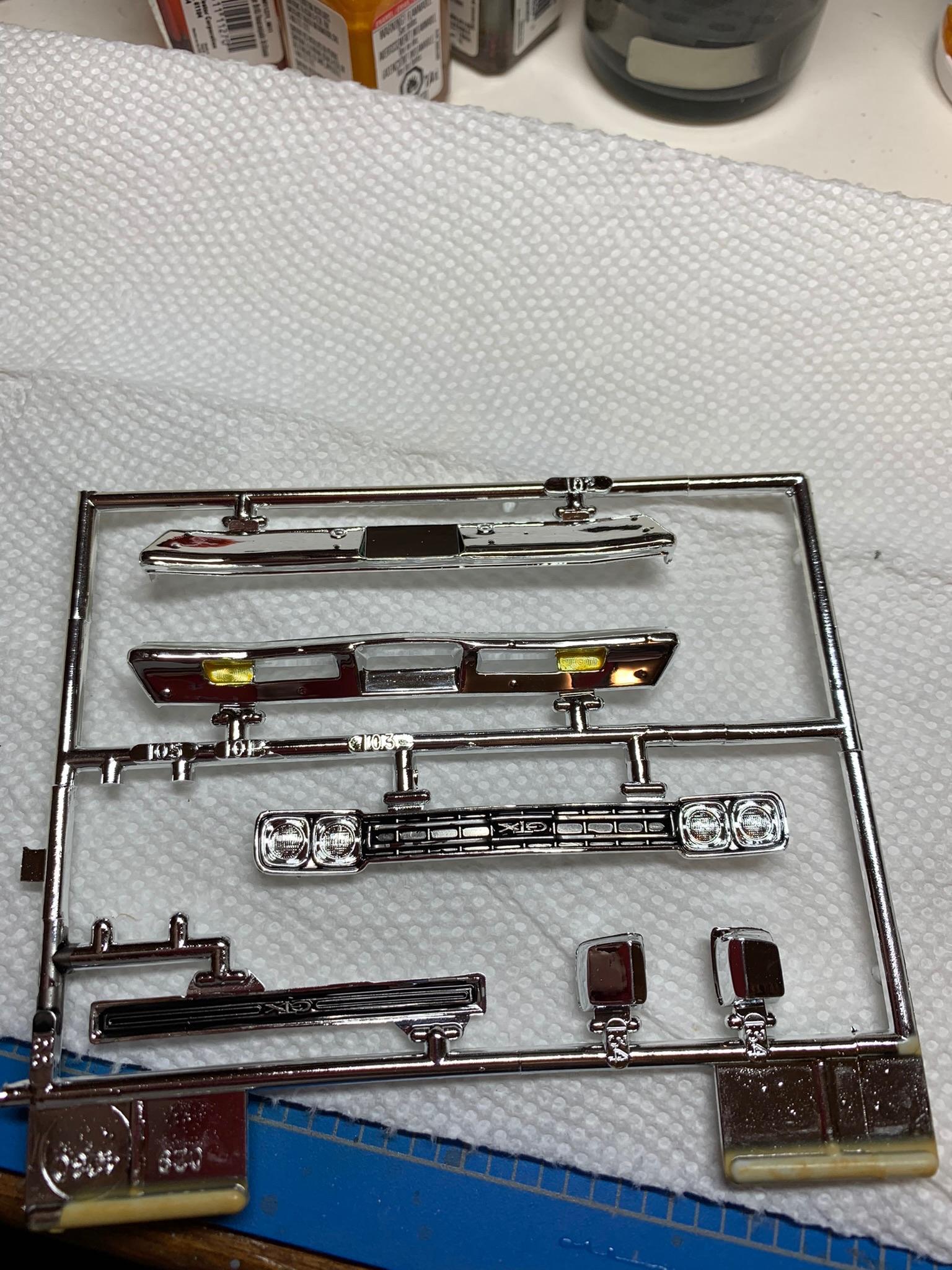

Trial body fit, painted on some license plate (or backup, not sure) lights, super glued rear taillights, rear grille, and bumper. Succeeded in touching wet white pain and smudging rear bumper (will remove later with lacquer thinner). Decided to walk away from bench for a while before I screw something else up.

-

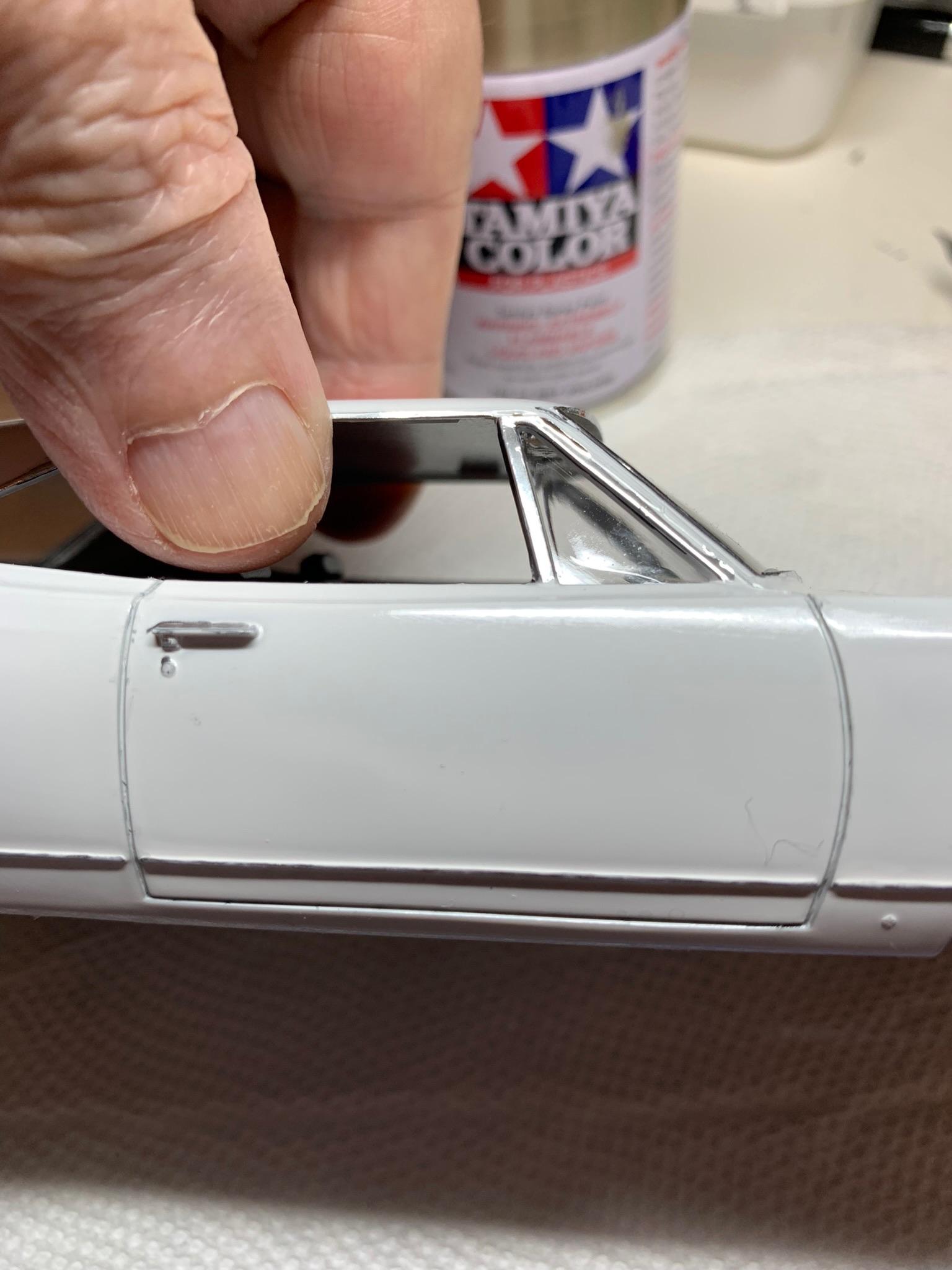

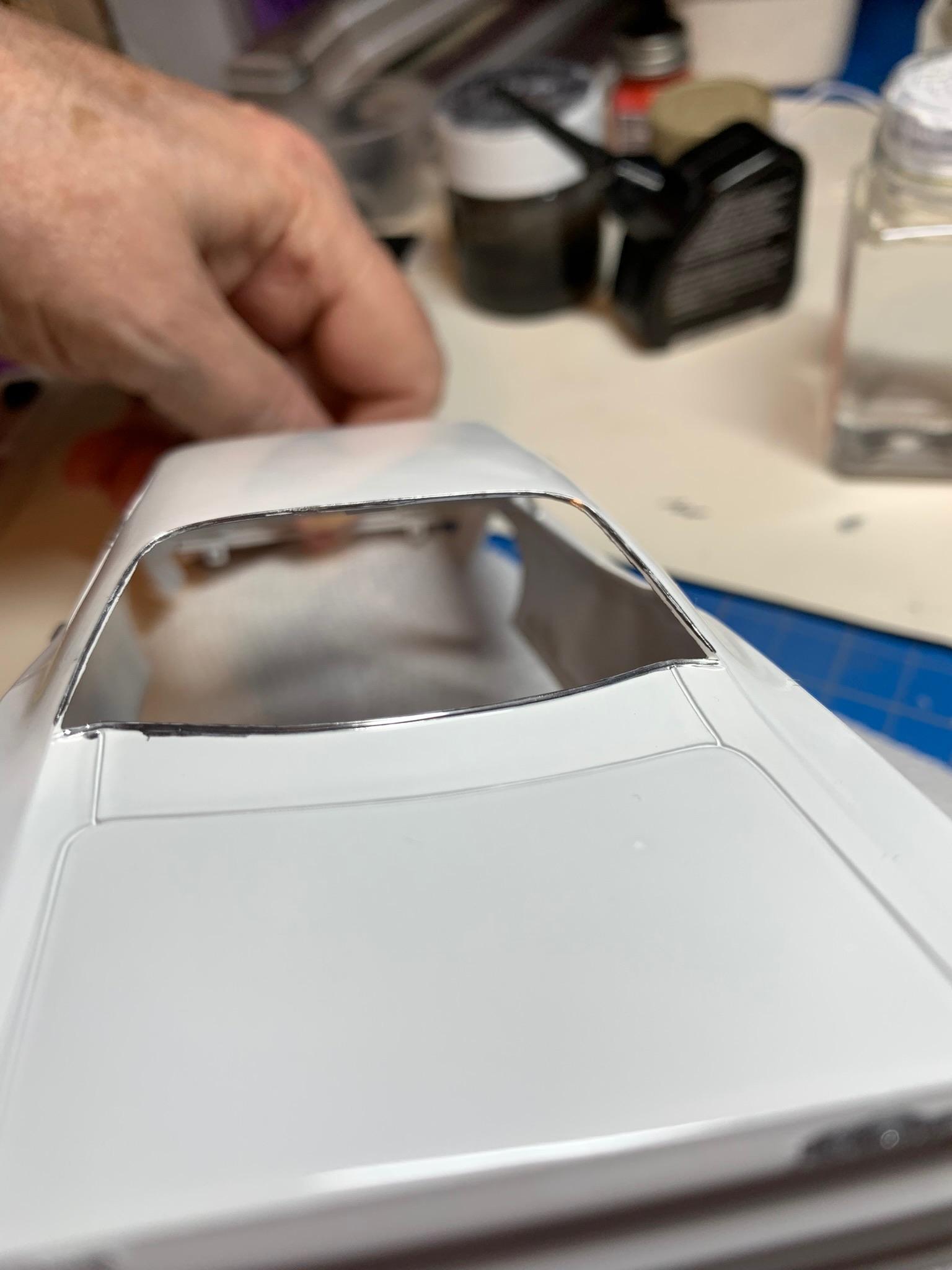

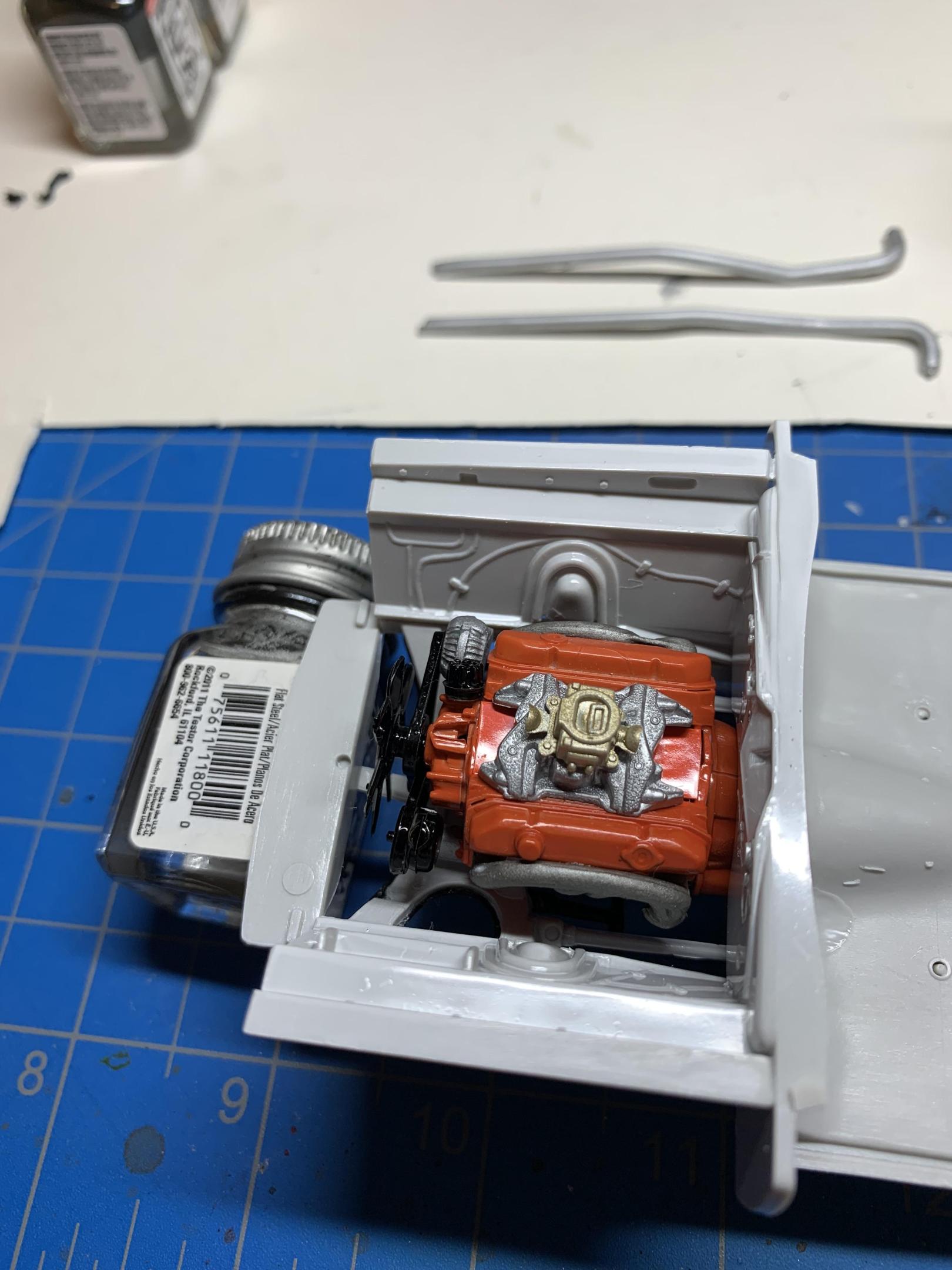

Well, the side windows that came with the kit didn’t turn out very well, so, I popped them out with my handy dandy tool. Thanks, Carl & Will. Taped in the interior for a trial fit and so more engine compartment stuff.

-

Nice work and good thinking.

-

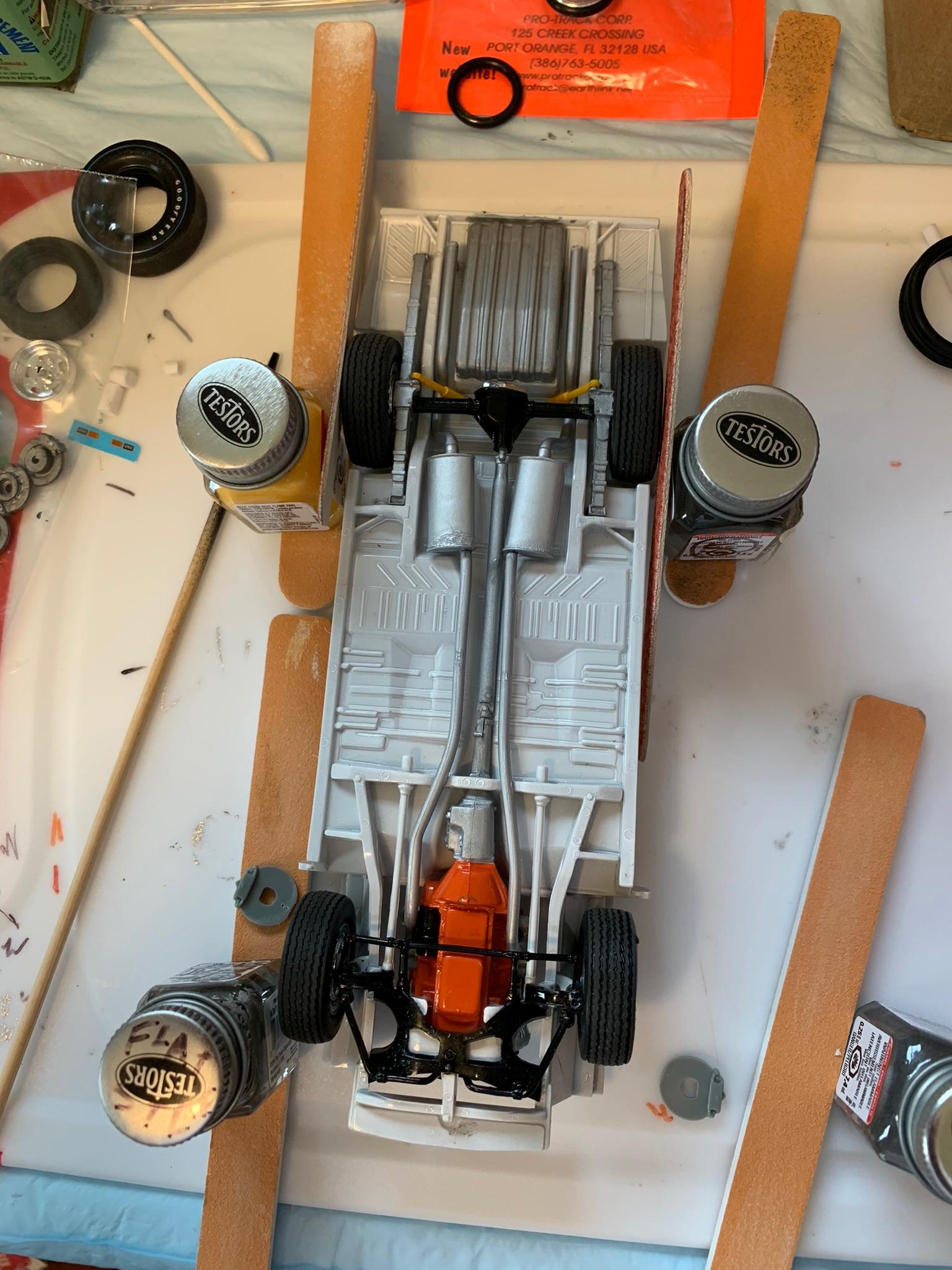

Made the mistake (there’s that word again) of not trial fitting the wheels on the axle stubs before installing the rear and front suspension. Took a lot more time fitting them on and finally glued them on with my high tech alignment jig (Testors bottles and finger nail files because the center of the wheel hit the side of the “jigs”). Dipped the windows in floor polish, used a chrome pen on the trim with less than spectacular results, installed master cylinder and wiper motor, Testors turn signal amber on front turn signals ( kinda redundant, huh?), some black wash on front and rear grill (will need another coat). Installed windows with Mod Podge (gonna let them sit overnight. Getting close to the finish line, that’s all tonight.

-

-

Not much done lately. Couple interior pics . Semi gloss black with some chrome highlights. Spent a lot of time trying to clean up this goopy mess of silicone mold that would not harden after a week. Got most of the parts cleaned up, but threw the silicone pad away.

-

1930 Model A Five Window Coupe Full-Fendered B/G Project

R. Thorne replied to tim boyd's topic in WIP: Drag Racing Models

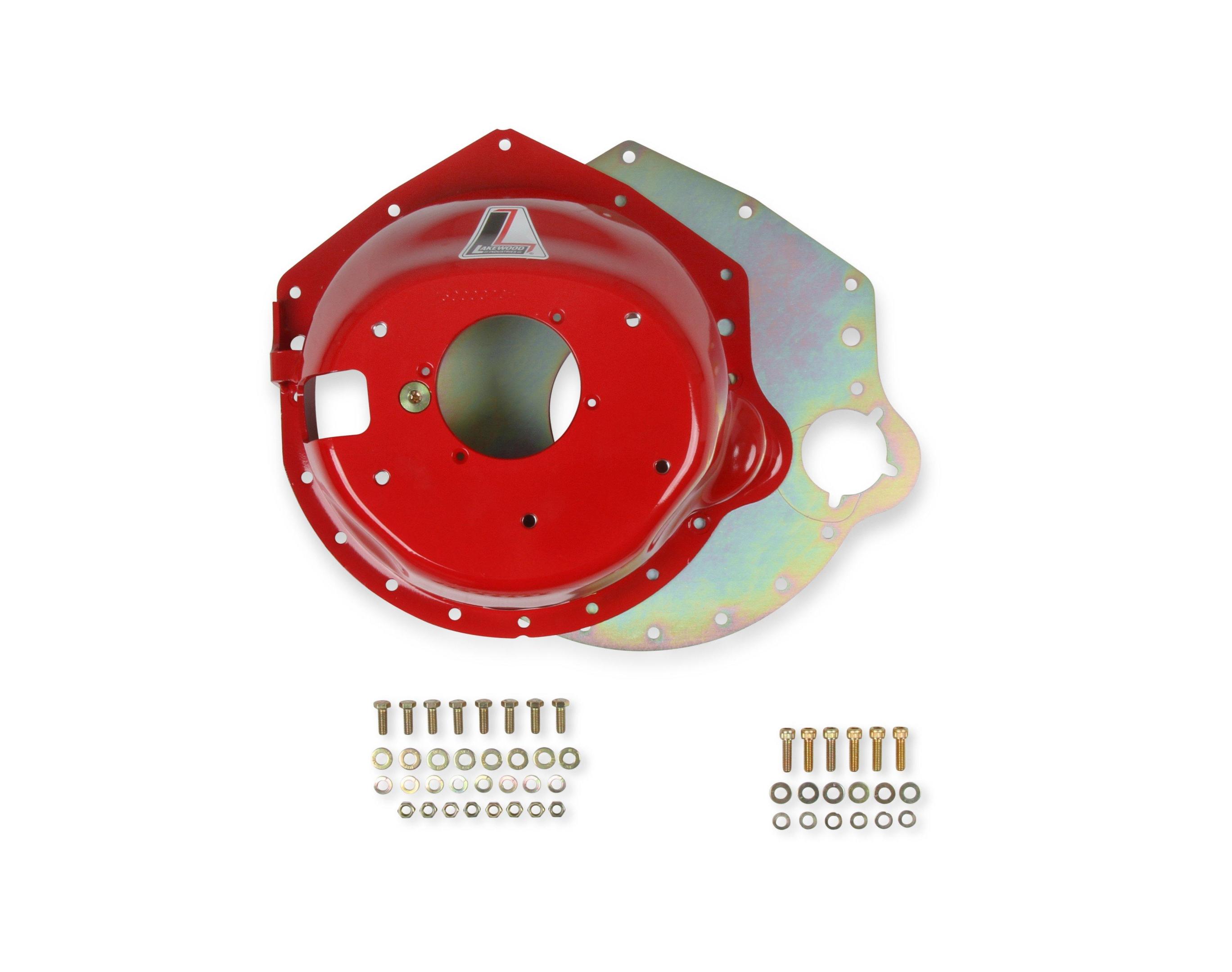

Still another pic of an early Lakewood bellhousing I believe on John Barkley’s D/S 57 Chevy (circa 1968) with the bolt on inspection cover. -

Further research has disclosed that the color was a metallic color used on Chevy trucks. My brother got the vehicles painted while I was working for Uncle Sam, so I was not involved in the color choice. Again, deepest thanks to all who responded with possible colors. I have ordered (from MCW) Laurel green and yellow green metallic colors. We shall see which one looks the best. Thanks again. You guys are the best.

-

1930 Model A Five Window Coupe Full-Fendered B/G Project

R. Thorne replied to tim boyd's topic in WIP: Drag Racing Models

-

1930 Model A Five Window Coupe Full-Fendered B/G Project

R. Thorne replied to tim boyd's topic in WIP: Drag Racing Models

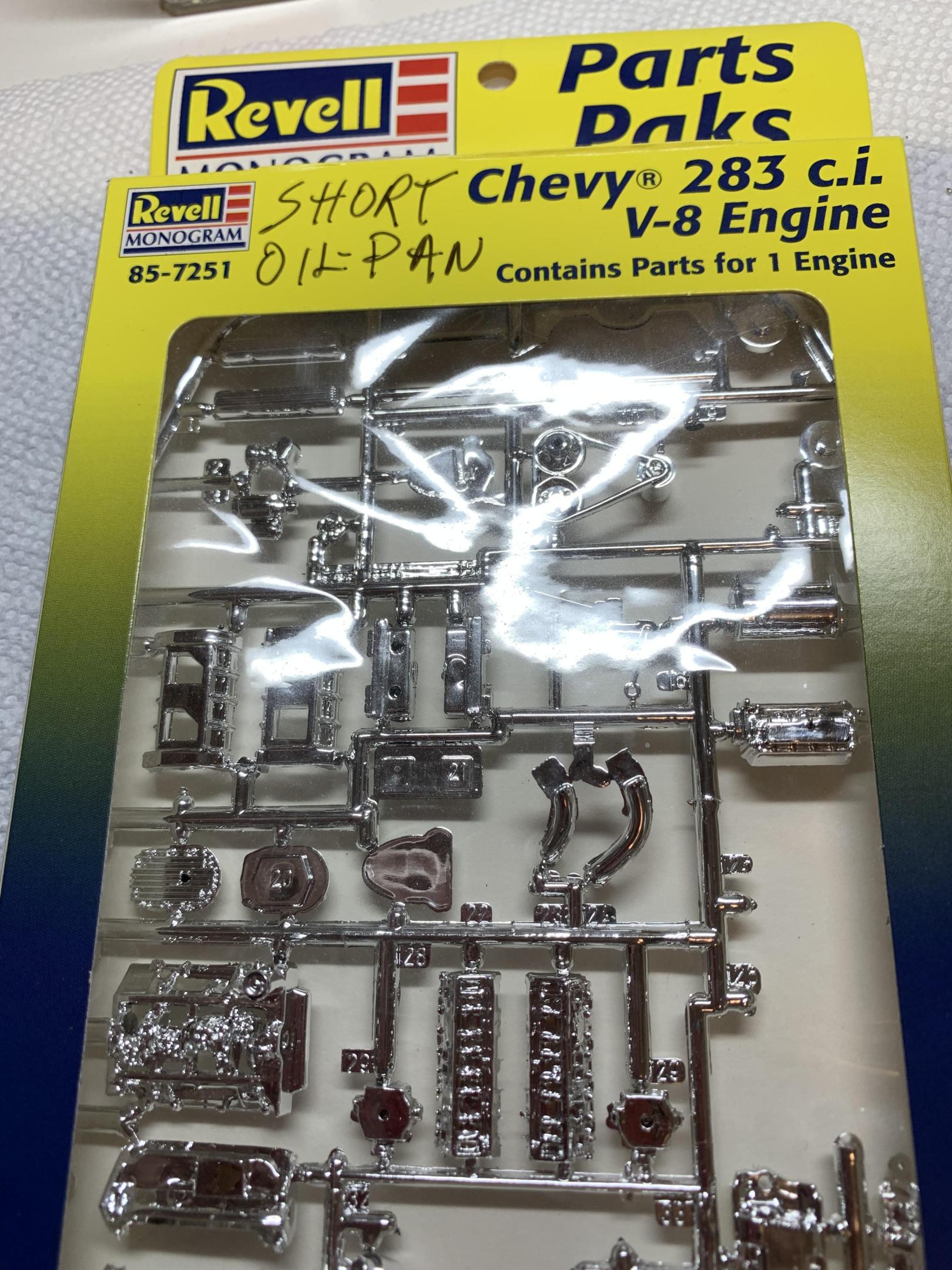

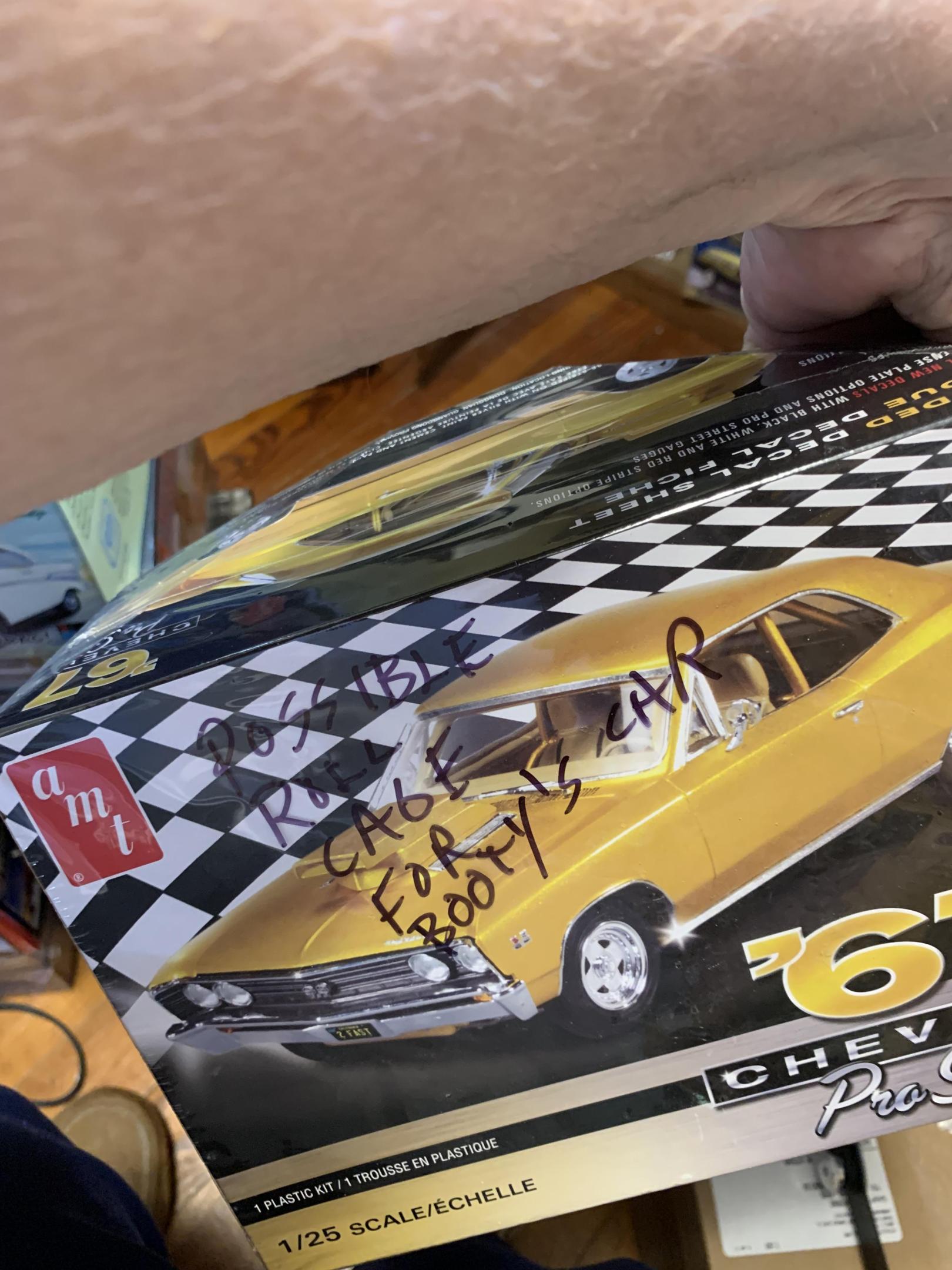

The Revell parts pack looks similar to a Lakewood Bellhousing/scattershield. I don’t have a picture but I am 99 percent sure I used one on this P/S 55 Nomad. Of course, in the early 60’s, the cast iron Ansen scattershield with the bolt on cover (had to weigh 50 lbs) was an option. The Chevelle pro street is somewhat similar to a Lakewood (no bolts, of course). Just another one of those head scratchers in the modeling industry as every tech man in the country checked all the cars coming in for a scattershield. -

Identify these wheels and tires

R. Thorne replied to Hi-Po's topic in Model Building Questions and Answers

Weld Drag Lites. Very popular on older drag cars. -

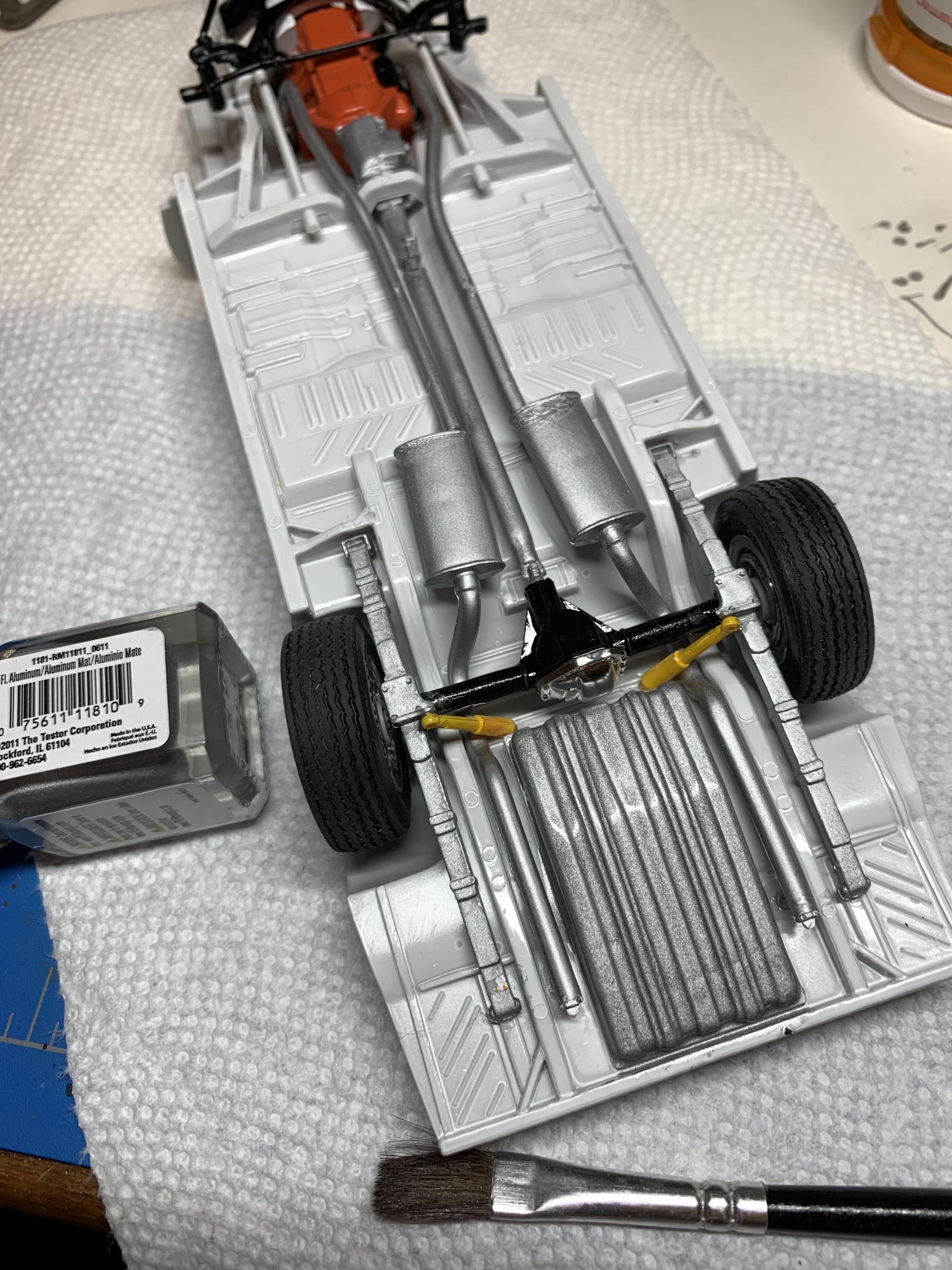

Assembled interior, painted gas tank flat aluminum with my cheapo 1/4” camel hair brush (looks glossy here, but still wet) . Best way I have found to clean up brush after painting with testors enamel is the testors thinner (better than lacquer thinner). Painted master cylinder with one of the micro brushes that I don’t know what I would do without.

-

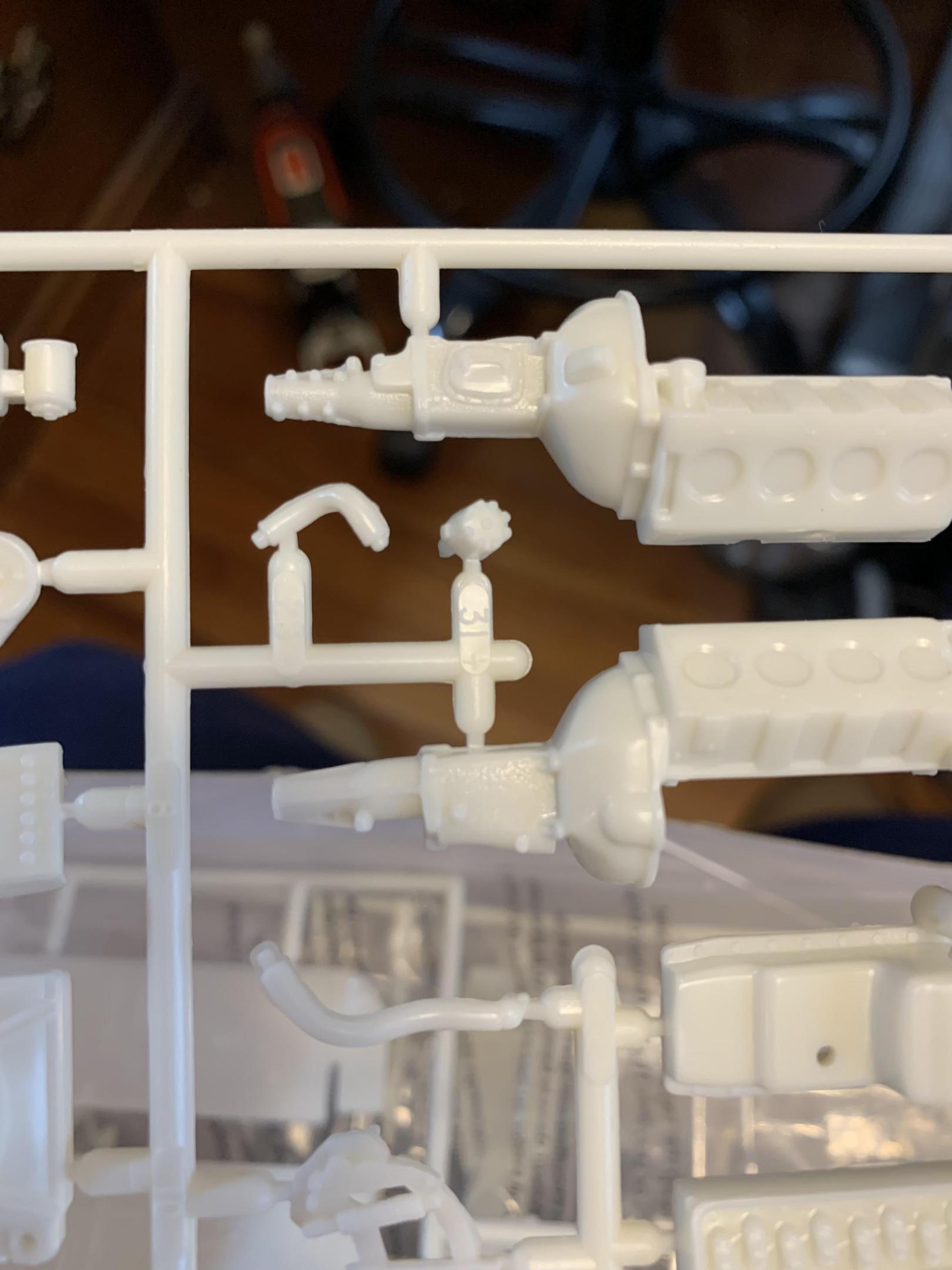

Exhaust system installed and made smaller diameter rod for the steering wheel as the kit supplied one would not fit the dash. Also, could not find any rear arm rests that instructions called out.

-

-

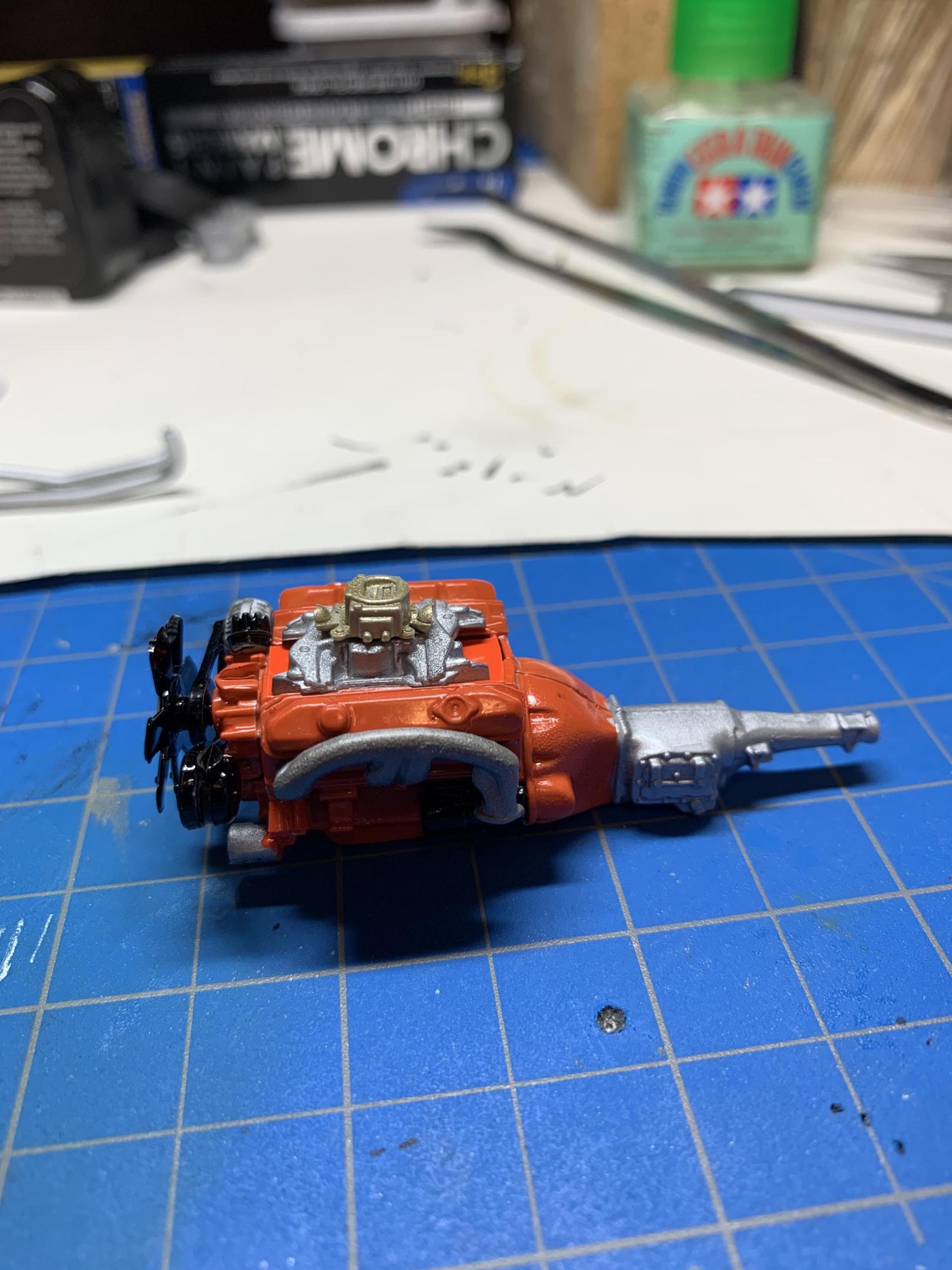

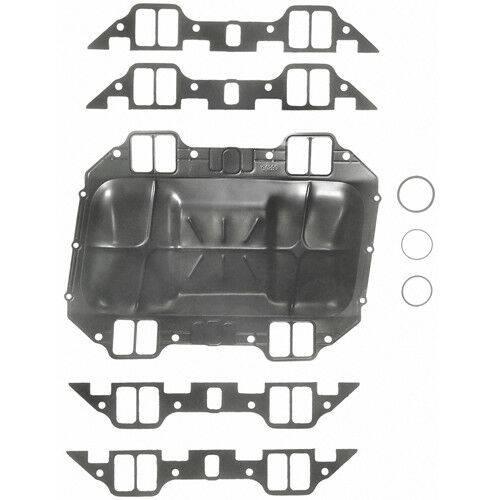

Thank you all for your kind comments. Since this was an out of the box build, I used the carb that came in the kit. Well, it certainly doesn’t resemble an afb, nor a Holley either, so the color is a moot point. As for the black brackets?? On the valley cover ends, this is a steel shim type of intake gasket with bolts on the ends. While the cover that I made is not great by any means, I couldn’t bring myself to build a model with an open crankcase.

-

Why is my clear coat coming out textured?

R. Thorne replied to Milo's topic in Model Building Questions and Answers

Please use modeling specific types of paint (Tamiya has the best spray can nozzle ). Your dunk tank will thank you. -

-

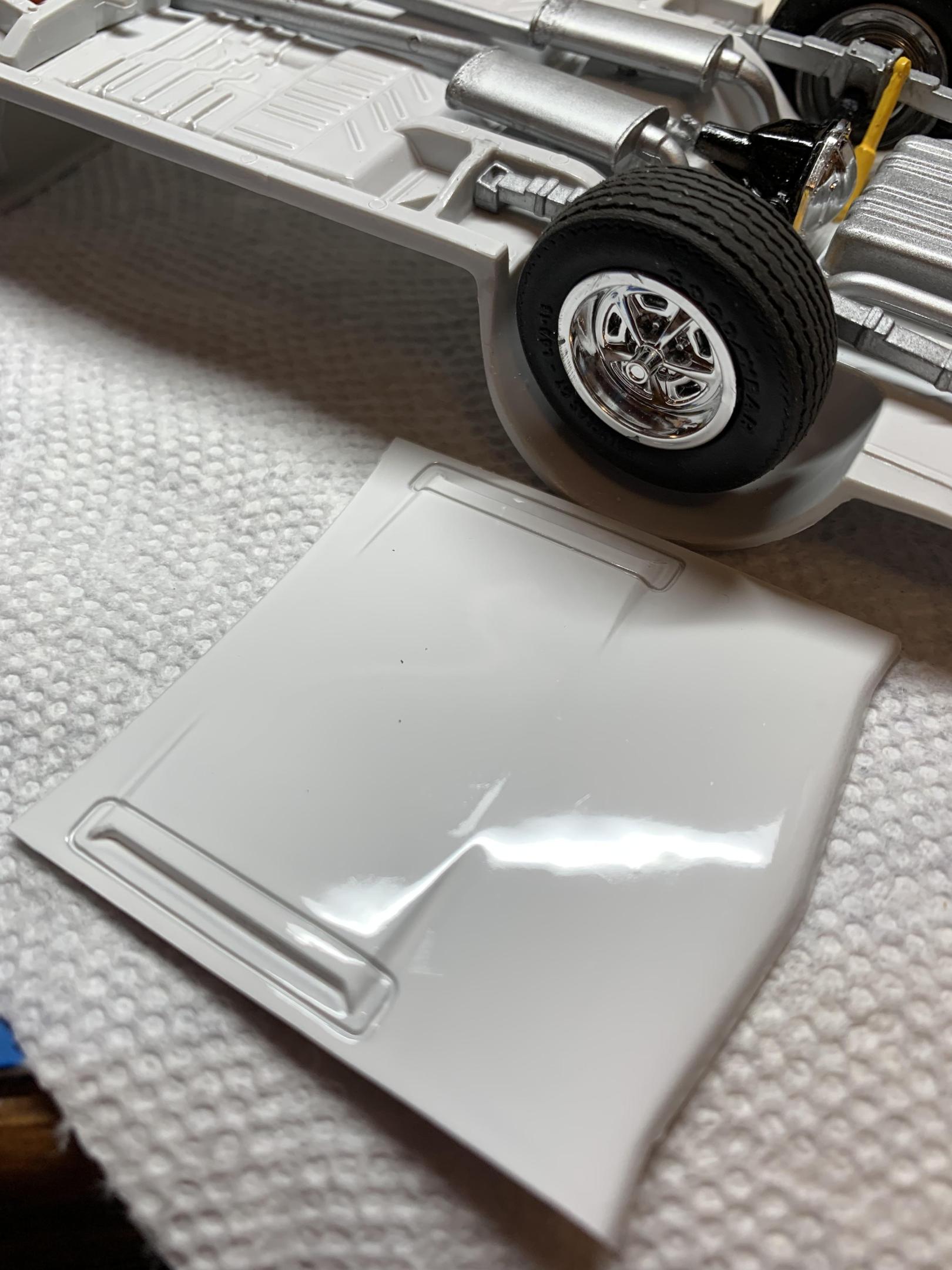

Did some more painting and made a valley pan out of .010” styrene. I like these thinny sanding sticks to clean off paint in tight areas.