-

Posts

4,782 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

Garage 56 Le Mans 2023 Camaro

absmiami replied to Phildaupho's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Per Gramps earlier post - get R & T’s vol 16 lemans mag - excellent article on NASCAR ‘s earlier Lemans adventure … -

Garage 56 Le Mans 2023 Camaro

absmiami replied to Phildaupho's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This is getting serious … -

This is the Aurora kit ??

-

Nostalgia Fuel Dragster--Blower Manifold (01/28/23)

absmiami replied to Straightliner59's topic in WIP: Drag Racing Models

You’re welcome … -

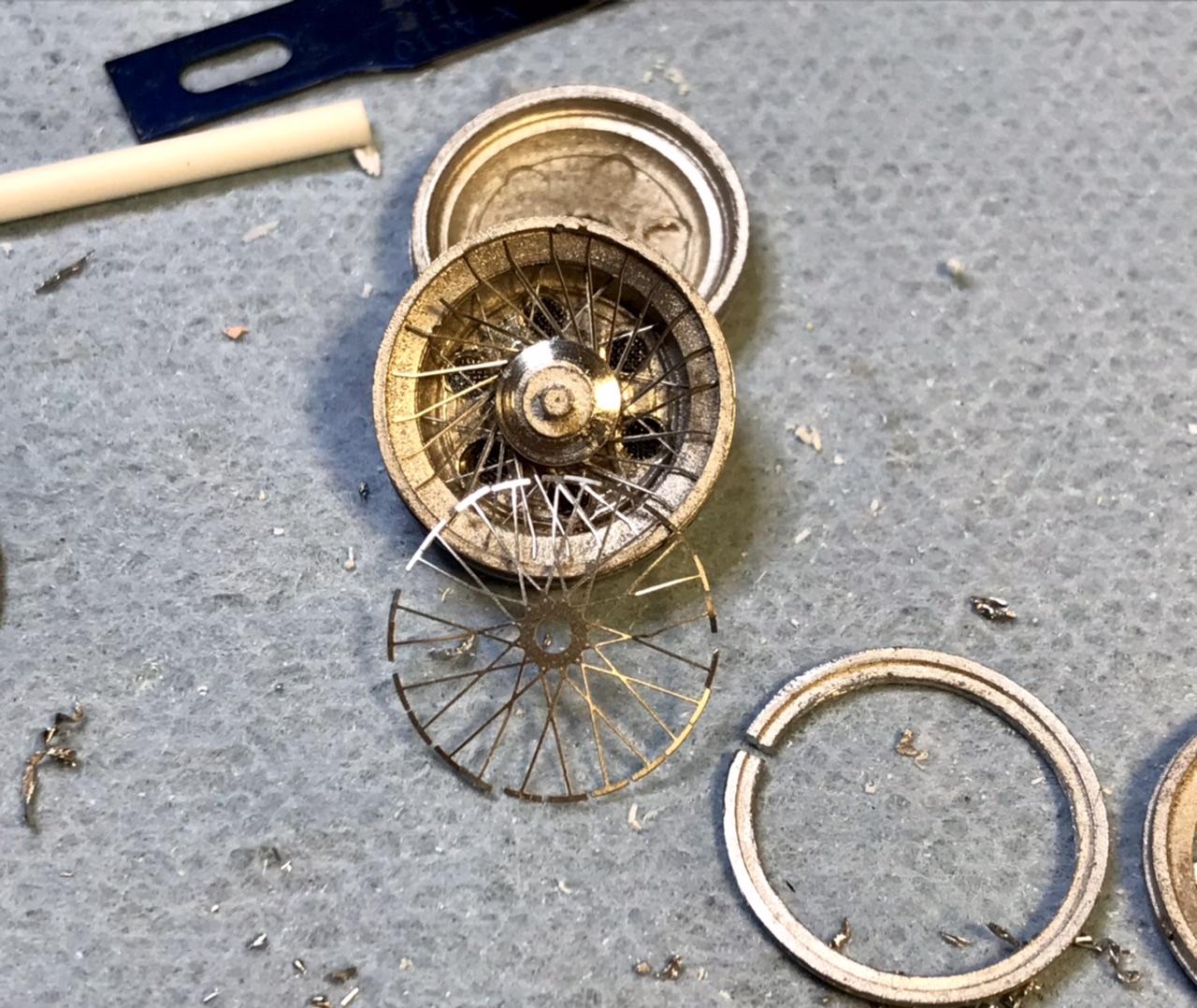

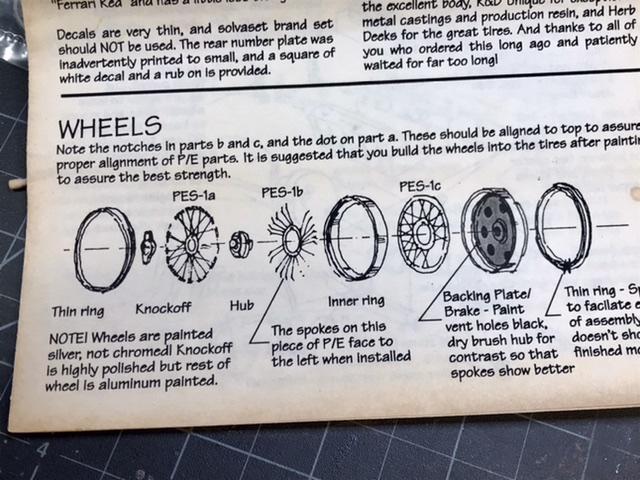

The first wheel assembly was predictably mediocre - but now that i’ve actually READ the instructions- and figured out how to cut the spoke rings off the sheet without mangling the spokes - i think the second wheel will look better … we’ll see - after vacation…

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

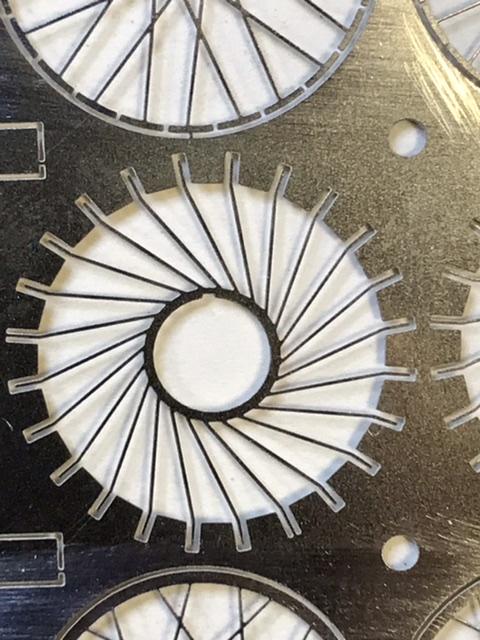

The wheels are made from 5 white metal castings and 3 rings of spokes - its a bear - the instructions state that you can align the spoke rings using the notches on rings A and B - and the hole in ring C - what hole ??

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

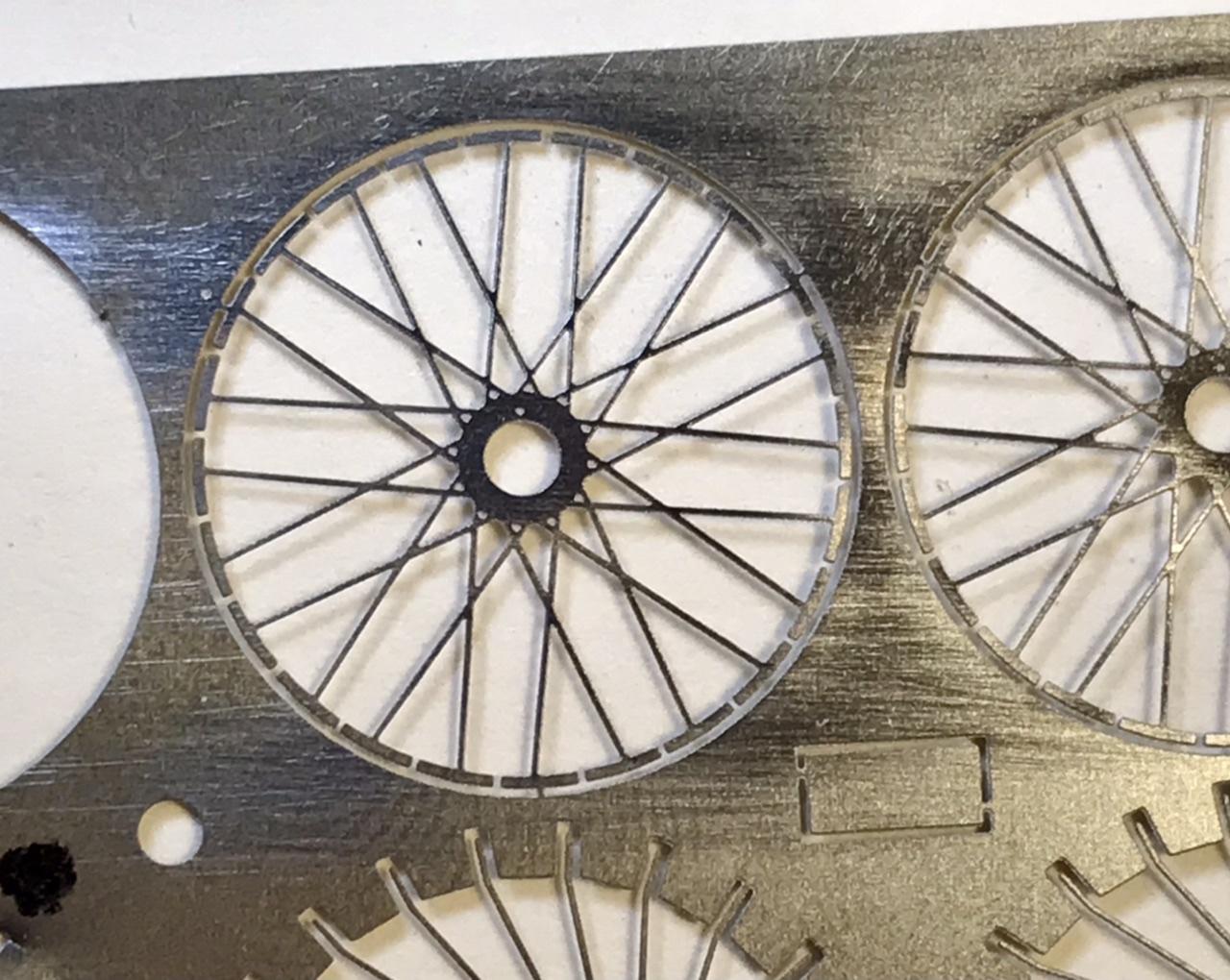

Before i complete the trunk - its off to the wheels …. This kit had 3 sheets of photo-etch - to make a terrific grill - the photo-etch for the dials and the windscreens - and a large sheet of etched steel spokes - now ive been making model cars for - er - a long time - and i stopped reading the instructions back in the seventies - which I occasionally regret …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

1969 Porsche 917 PA spyder

absmiami replied to Rich Chernosky's topic in Other Racing: Road Racing, Salt Flat Racers

Yup -

Gracias - guess i could put a pair of bass speakers in , right ? ? but then there’s no room for the spare …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

1:16 Scale 1962 Ford Consul Cortina by FROG kits

absmiami replied to Anglia105E's topic in WIP: Model Cars

Never seen a 16th scale Froggie …. ive got a couple of 24th scale Frogs - an Alfa and … something else - all mastered at least 50? Years ago - nice to see that this is scale accurate - their 24th scale kits were kinda vague … you’ll like T’s paints … -

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

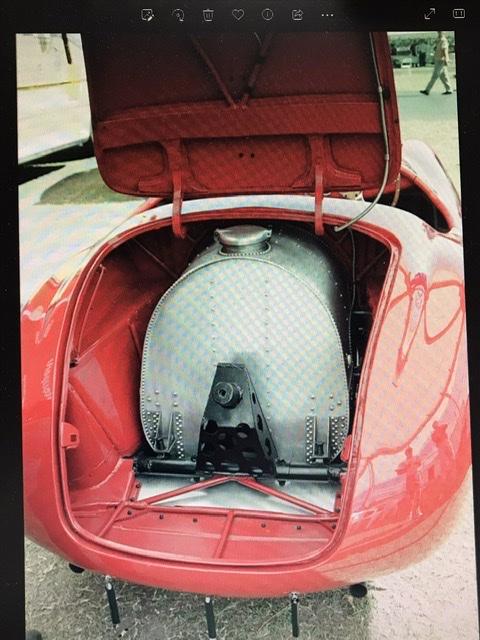

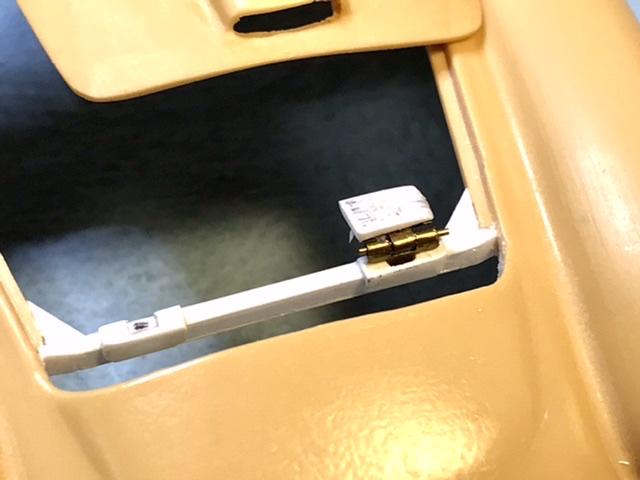

By attaching the assembly closer to the leading edge of the trunk - i should be able to open/close said trunk w/out interference …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

This hinge assembly was a fail - had to remove the hinges and move the assembly ….

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

The hinges are fastened to the trunk lid in odd shaped brackets - the parts are reasonably large - i don’t think I will need to make these parts fr brass - the plastic should have adequate strength …

- 565 replies

-

- 1

-

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

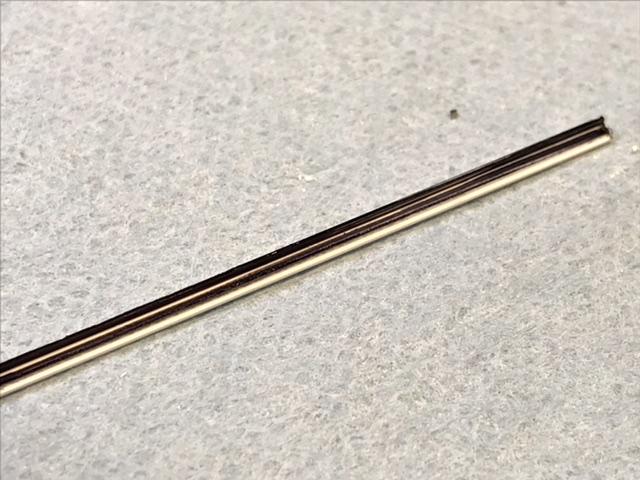

The strip should run back to the trailing edge of the bonnett - but the engine bulkhead doesn’t have scale depth - so the shape of my supports are a compromise - a scale casualty …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

The underside of the bonnett has some support ribs - these w were made fr L shaped Evergreen strip - modified by reducing the dimension of one surface - hard to see on the photo - i temp glued some .015 strip into the “L” - and used that as a guide to scrape material fr one surface - clear as mud? - so one surface is .060 and the facing surface is about .040 …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

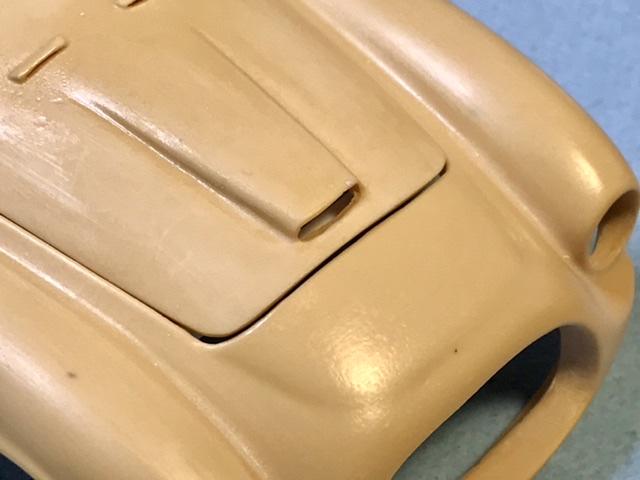

In the closed position the leading edge of the bonnett sits about .030 above the trailing edge of the nose cowl - i think there is a fix for this - would anyone like to hazard a guess ???

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

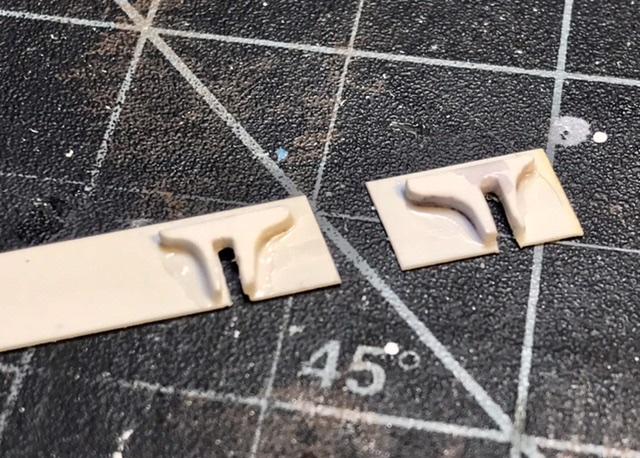

The tabs on the hinges allow me to slip the hinges in and out of the brace as i fiddled around with the fit - and eventually got a reasonable alignment that allows me to CA glue the hinges to the bonnett …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

So i removed two short lengths of the piano style hinge - and glued on a strip of Evergreen and shaped the hinge to slip into the openings in the cross brace that i made two months ago …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

So 0010’s bonnett uses two door style hinges that are attached to a cross brace in the forward eng compartment - the Shirley family went to great lengths in their restoration of 0010 - so this is probably accurate …

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with: