-

Posts

3,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by AmericanMuscleFan

-

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for following JC! Always welcome! Cheers, Francis I'm glad for keeping you entertained again Scott! I do have so much ideas for this build that I'm afraid about the deadline to deliver that thing... I will try to reason with myself! Cheers, Francis -

Dyno Don Fairmont Pro Stock

AmericanMuscleFan replied to Plasticfanatic's topic in WIP: Drag Racing Models

I do love this uncommon subject! Very nice build and perfect stance! Great Drag Racing beast!!! -

Vintage FED, 1:25, brass WIP, driveline

AmericanMuscleFan replied to Mike Williams's topic in WIP: Drag Racing Models

I'm lovin it Mike! Great build so far and very cool subject! I do love those old school dragster! I'll be back for sure! Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

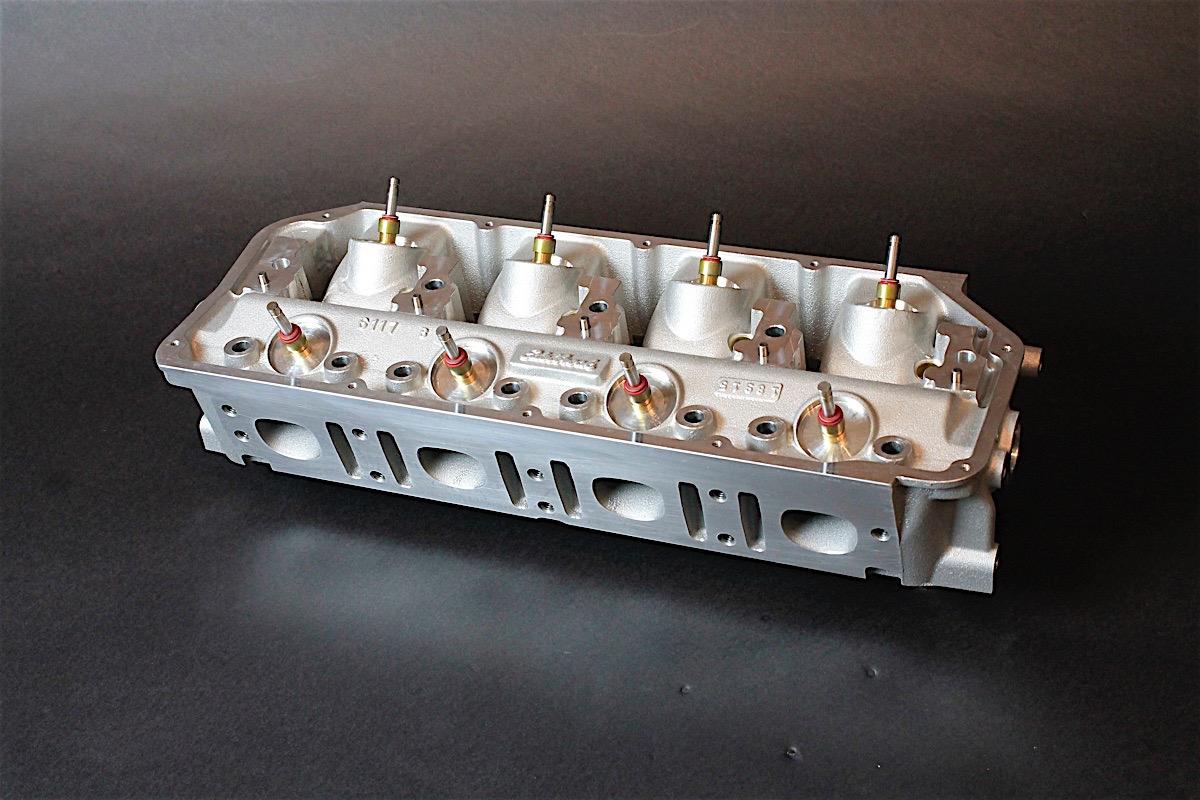

Hello everyone! Today's update is for the engine heads. I wanted to improve them from the ones made for '70 GTX with more accurate details in the philosophy to try to ''always improve things'' on the next build. Since it's a drag racing truck I wanted to soup-up the engine with high performance parts so I tried to reproduce the Edelbrock Gen II racing heads (perimeter only as well...). It's very difficult to reproduce every nooks and crannies but I tried to make them as convincing as possible without going crazy since most of the details will be hidden on the final engine. I spent more than 50 hours on these heads so I hope you'll like them... As usual don't hesitate to tell me what you think about these, your input is very appreciated! Be careful during these frightening days, Francis Picture of Edelbrock Gen II HEMI heads (target pic found on internet). Beginning of the heads machining. Both are machined face to face on the same aluminum piece in order to get them identical. The thin extra part that exceed is for the valve cover housing (Hemi valve covers are slightly longer than the engine block). Front heads details, a 0.093’’ aluminum rod will be inserted to create the extra material were the bolts (both ends) to mount the heads on the block are drilled. Aluminum rod inserted Different sizes of aluminum tubes added in the front to simulate the water plugs and attachment points. I also drilled the exhaust ports using a 0.080’’ drill bit. Headers screwing points drilled using a 0.016’’ drill bit. Note: HEMI heads have square ports but I didn't invest myself in that since they will be hidden behind the intake manifold and headers flanges. Closer view Head separated from the other one and the details elements in progress on the other end. Intake side on the vise to be machined at 10 degrees angle to match the block deck width. The Hemi heads are narrower at the engine block face and larger at the valve cover face. Hemi heads final. Hemi heads final exhaust and intake view. Test fit (will be mounted on block using 0.031’’ copper rivets). Test fit front view. Test fit front view different view. Test fit back view. Test fit side view. -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Joe, your input and replies are always welcome! Cheers, Francis I always have a couple of old chairs behind me but they are pretty dirty and covered of dust from styrene, brass and aluminum... can't wait to add more dust with my airbrush... LOL. Take care, Francis -

Vintage FED, 1:25, brass WIP, driveline

AmericanMuscleFan replied to Mike Williams's topic in WIP: Drag Racing Models

WOW!!! These spoked wheels are gorgeous! Very ingenious trick... Thanks so much for sharing the technique! Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Tim! I didn't add much details because I found most of the technique on Youtube videos. Basically, you can do this with household products with the exception of hazardous and disgusting battery acid for the anodizing bath (I know that we can replace this by the PH- for swimming pool but I didn't test that yet). You need a power source so a car battery charger settled at 2 amps is sufficient but I purchased a variable DC power supply for more accuracy. You need plenty of distillated water and not tap water for all the operations. You can use cheap clothing dye available everywhere but results are variable according to what I read from different stories. I bought the aluminum dye on eBay but you can find everything from Caswell. I invite you to check online videos for the technique but on thing sure, your parts must be spotless (no problem here with you) to get a perfect result... really worth it! Don't hesitate to send me a PM if you want more infos, I will be more than happy to help if you need. Take care, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Andy! I very appreciate your high praises on my build! I'm really devoted to this build and I still have a long way to go so feel free to come back anytime. Cheers, Francis Thanks for the thumb up Mark! -

Awesome build! Really looks like your real truck! One of the best rendition of tribute of an everyday vehicle I ever seen!!! Thanks for sharing this treat during these hard days... Francis

-

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hello to everyone! Hope everything is going well to all of you and your relatives all around our mother earth!!! I just want to share with you my last add-on to the hobby. I wanted for quite a long time making my own anodized aluminum parts so I bought all the equipment and supplies to do so and I want to show you my very first test. I polished a 0.250'' piece of K&S aluminum square rod and I did test the red dye, I'm very happy how it turns-out. The finish is very hard, scratch resistant and shiny and won't hide details as transparent paint. I also bought blue and black dye (product specialized for aluminum) so I will have some other options for my next parts where I want to add colors instead of raw finish. I will post new pics of the progress on the engine next weekend. Stay safe during these disturbing days, Francis -

70 Plymouth HEMI GTX 1/25 Scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank you very much Mike for your compliments on this build it's very appreciated! The GTX was built a couple a years ago but if you love this kind of build then I invite you to check my thread (Drag Racing Models) of the '64 Dodge D100 Pro Street that I'm current building. It's an work in progress build and I'm making a lot of aluminum/brass parts with all the infos and pics of the machining process. I will try to upload pics on a weekly basis until I reach the slow build season (May to September). Thanks for watching and stay safe, Francis -

70 Plymouth HEMI GTX 1/25 Scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Joe! If you like my GTX then you should appreciate my '64 Dodge D100 Pickup too... I think that the drivetrain will be even more detailed. Take care, Francis -

1955 Big Block Truck

AmericanMuscleFan replied to Lorne's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Another great build in the making Lorne! Hot Magenta sound great to me!!! Can't wait to see your next update on this truck! Cheers, Francis -

62 F100 Prostreet

AmericanMuscleFan replied to Lorne's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Superb job, super clean and rare subject...I love that!!! I share the same feeling as you regarding the subject to be chosen for the next built and the rarity of the subject! I live at the other end of the country but it's pleasant to be reunited at the same place sharing the same passion! Keep doing your amazing job, you are a great builder!!! -

Beautiful truck and nice job with the Bare Metal and the paint job! I really love this chevy body style (in fact, all early '60 to '70 truck). Keep doing your great work!!!

-

No matter the time left for the bench you will always find a way to surprise us with your tremendous talent to transform these raw pieces of metal to jewels! Super job on the engine so far Tim!!! Take care, Francis

-

70 Plymouth HEMI GTX 1/25 Scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for the compliment GoatGuy! Hope the class was less boring than the one I remember from my younger days! Cheers, Francis PS: I do have another thread in this category ('70 Dart Swinger Big Block Scratchbuilt 1/25 Scale) so feel free to go check it if you're interested... -

This is a FANTASTIC build Kurt!!! Your attention to details is outstanding and you made miracles with everyday material so this is the mark of a great builder! I just found your build since I don't check very often this category. My current build ('64 Dodge D100 Pickup Pro Street) was first placed in this category on my first post but I had asked to the forum administrator to move it in the Drag Racing Models since it will be a racing truck. I will check frequently for you progress so keep doing your great work and stay careful during these disturbing days! Cheers, Francis

-

Vintage FED, 1:25, brass WIP, driveline

AmericanMuscleFan replied to Mike Williams's topic in WIP: Drag Racing Models

Hello Mike! Superb job on the frame and nice progress on the drive train. I always loved models made with a blend of styrene and brass/aluminum. Furthermore, it has a HEMI so it can't be nothing but a great build!!! Question: Did you weld the brass frame using a small torch or a resistance solder unit; the joints are very clean? Take care, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Glad to get your visit GoatGuy and thanks for your kind words! Be careful during those disturbing days... Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Daniel! You should just see the lathe and milling as an extension of your imagination. Most of these parts might be done by hands with just less accuracy but could be as rewarding. It's just an hobby and each of us must find there satisfaction at it's own way! Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I think I got it with my money change at my last visit at Giant Tiger store... LOL. Thanks for visiting and your kind comments on my build Jim! Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for the compliment Jim! Pistons and crankshaft might be done on my next built if I can convince myself to make an exposed engine out of the body. Cheers, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi Tim, I'm happy to get your approbation on this one! Take care, Francis -

64 Dodge D100 Pickup Pro Street

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi Rooster, glad to know that ultimately you don't hate me for that piece of aluminum... more of the same material to come on the next update! Cheers, Francis