-

Posts

1,395 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by my66s55

-

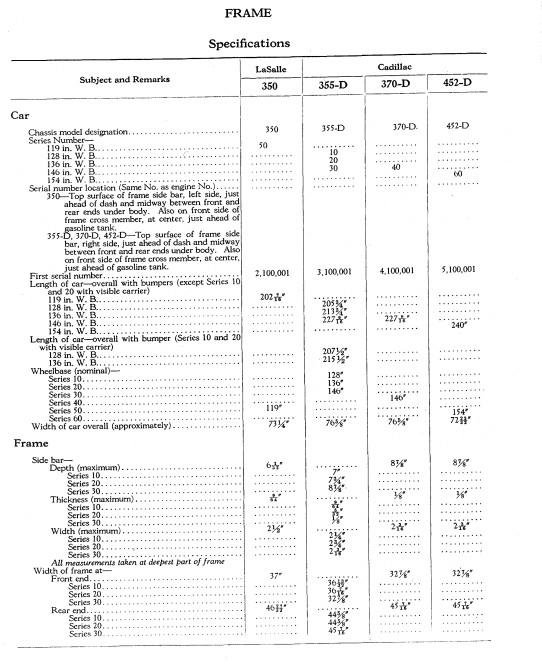

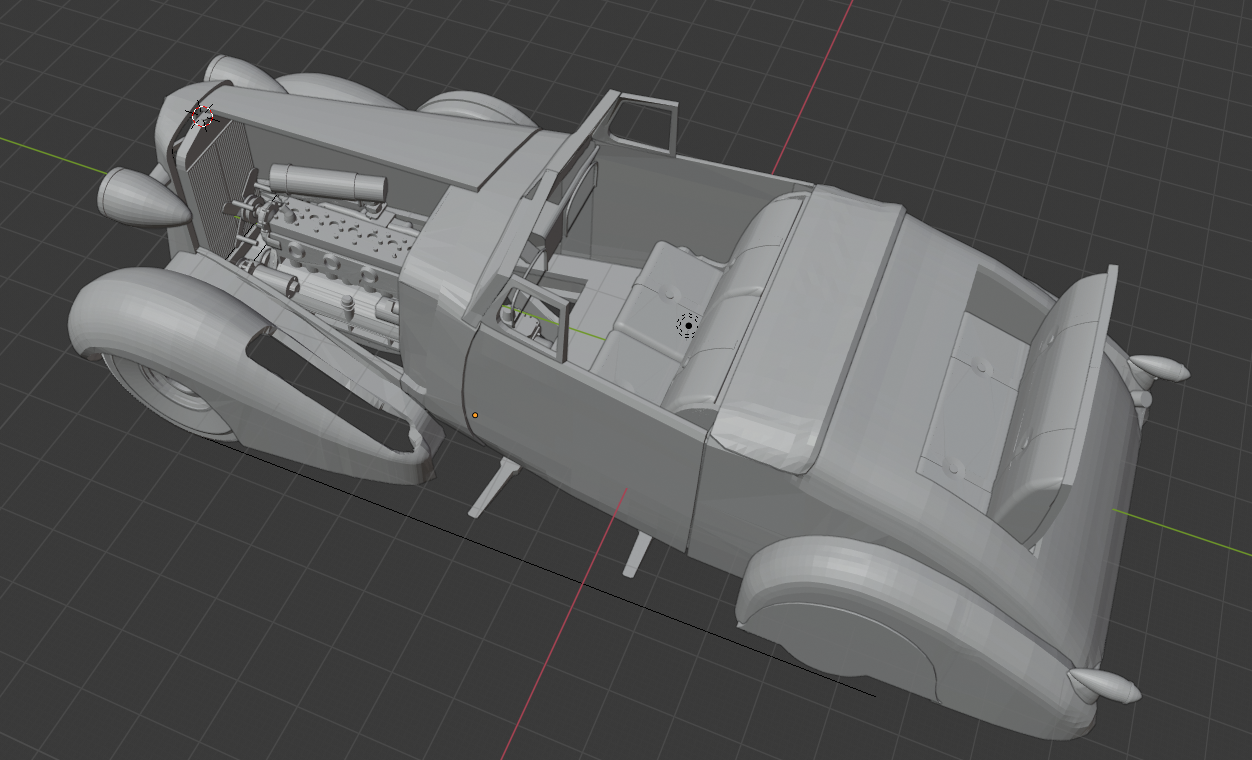

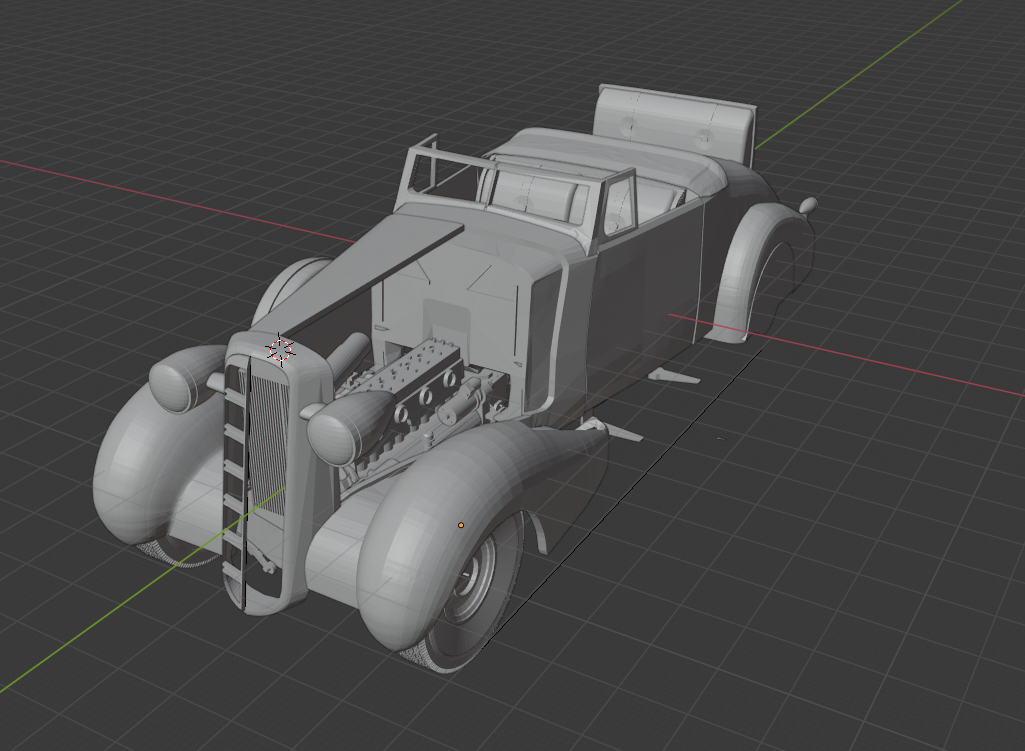

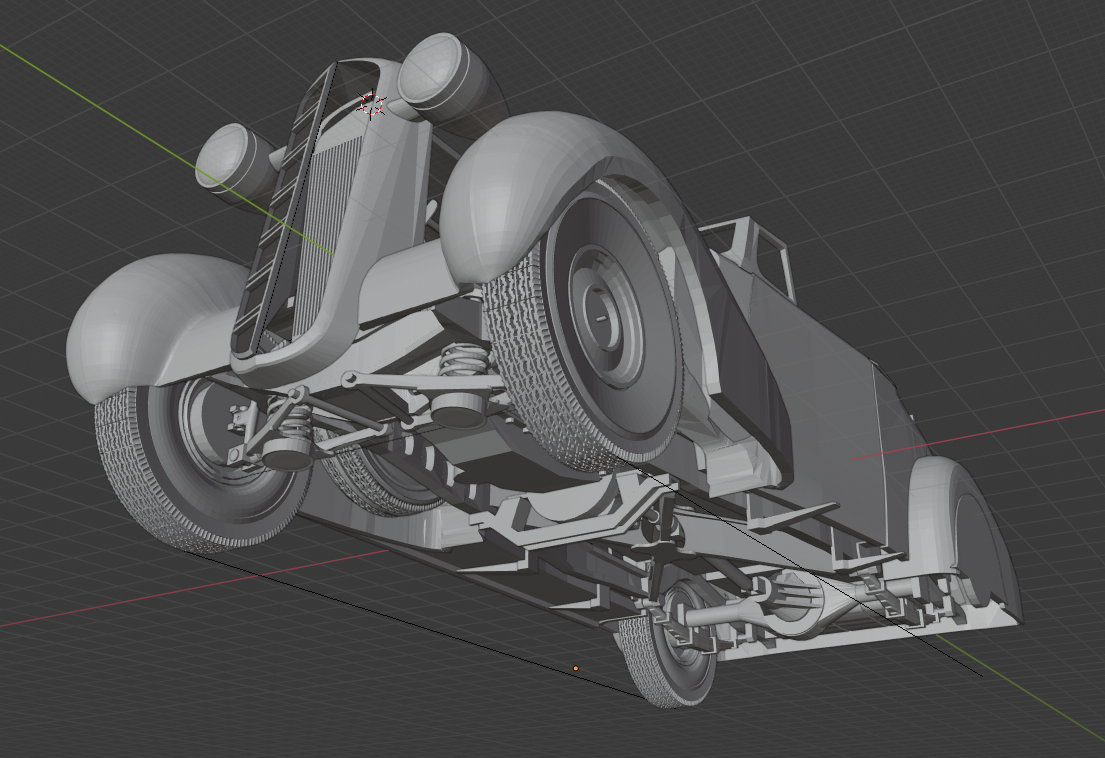

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

The larger prints are printed on my Phrozen Shuffle XL. -

Good choice. 3d printing isn't possible without 3d printable files and about the only way to get most of what you want is to create them yourself. Cost really isn't an issue. Blender is free, but there is a learning curve requiring lots of time. Phrozen's new mini sonic printer is less than $300 and will give you high quality prints in half the time and up to 3 times the life of the lcd panel of other printers in its price range. Plus, it's a Phrozen.

-

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

Thanks for all the positive comments. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

Throw them away. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

I printed out 2 test print of the front clip and body to check for errors and fit for both pieces. Everything looks good. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

Thanks. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

Thanks. I'll check it out and make adjustments. The wheels are listed as 16". -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

Much appreciated. Richard. {lease feel free to chime in any time. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

I have scaled the wheels and tires to size I have for Firestones of the period found. I started this project 2014 and there is a post of such. I'm not a cad designer, so my work is slow and tedious. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

When you work from pictures, you have to collect hundreds of examples. Such was the problem with the poster who created a Delehaye f&f 135. The biggest flaw with photos is the tunnel effect. The only part of the picture that is most accurate is the very closest. The rest suffer from the tunnel effect. That's why you need as many pics as you can find to try to get a more accurate example. You may be correct about the windshield though. Thanks Richard, I value your opinion very much. -

It's my poly A block 318. It is available in it's latest form for anyone wanting one. The A block was create for the 1956 Plymouth as a cost cutting measure and continued in production through, I believe, 1966. The 55 poly head engines were made in an attempt to serve the same purpose. Your engine is a hemi with poly designed heads. Dodge and and Plymouth used the hemi poly in 55-56. I am under the opinion that it was to provide Plymouth with a v8. The Dodge and Plymouth engines were the same, basically. And if memory serves me, Dodge and Desoto used it in 57 & 58. My avatar is my 3d 270 Dodge hemi.

-

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

What are your thoughts, Richard. -

1935 LaSalle convertible coupe-a 3d printed model

my66s55 replied to my66s55's topic in WIP: Model Cars

-

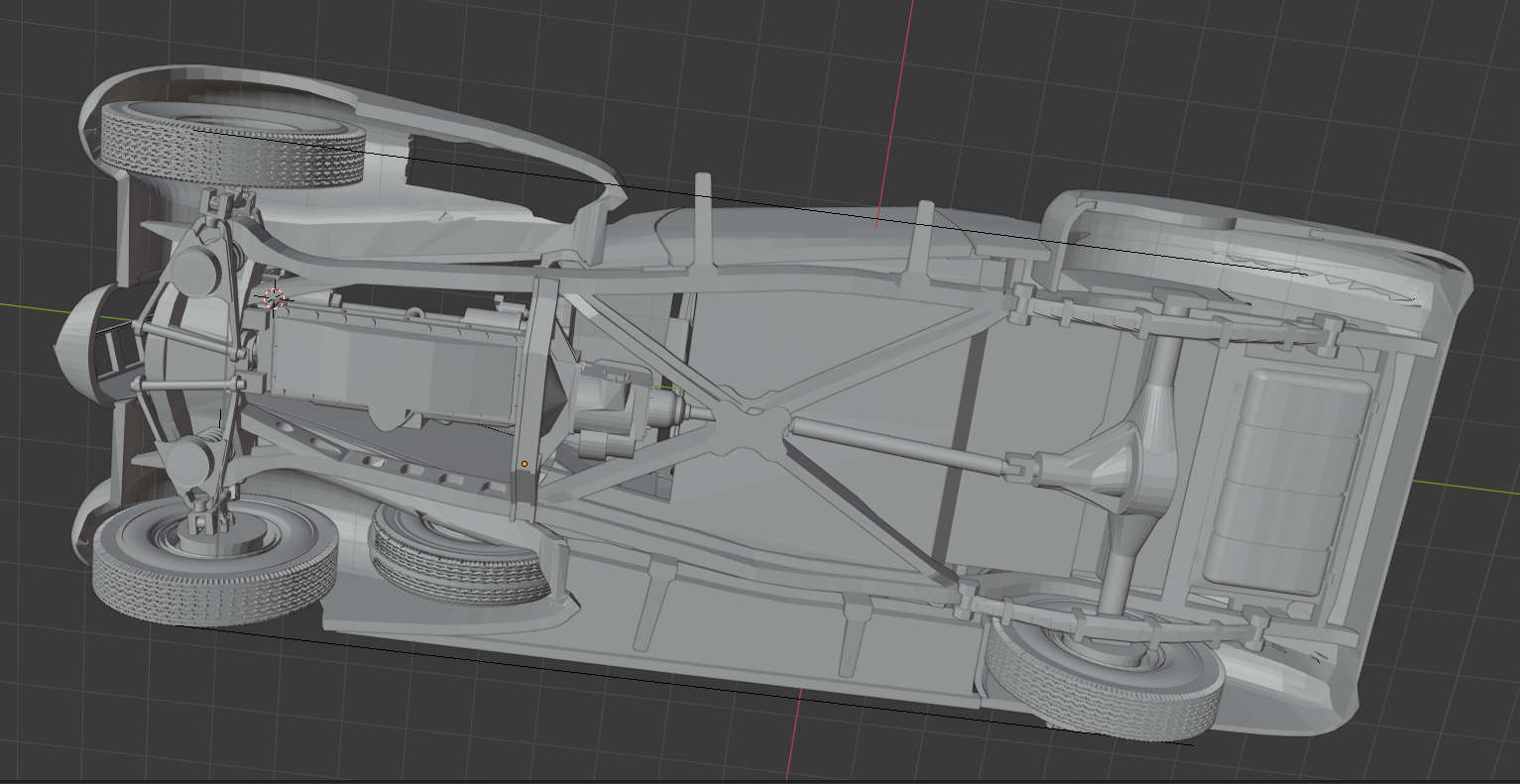

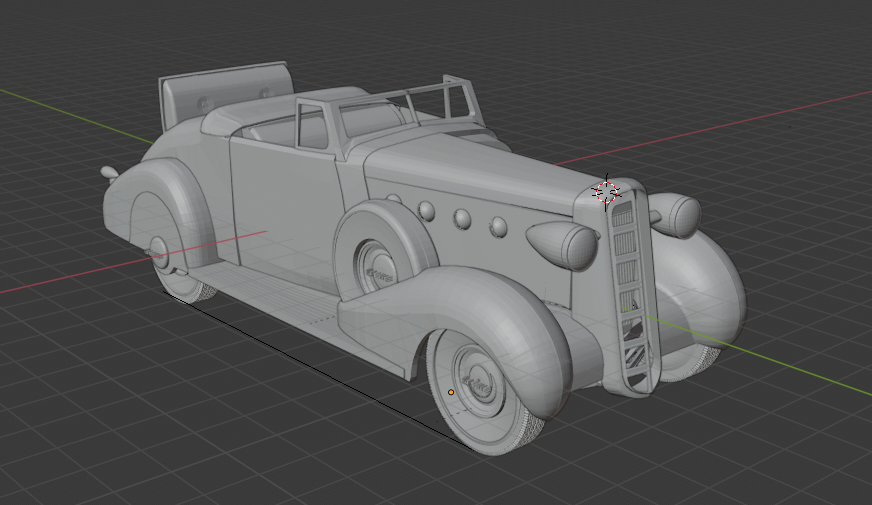

I'm in the final stages of finishing this project. It took 144 separate cad files and 73 files to print. There are 9 small cad files to create and 1 file to yet finish. To create this project, I first had to create it in a complete cad form. Each 3d printable parts in there own file. This is the current composite. I will provide pic's of printed parts as they become available. Don't hesitate to ask questions, comment or suggest.

-

It had it's flaws, but that's why it's called a test print. I have cured what ailed it.

- 39,135 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

As you may remember, I showed you this Skylark in a post awhile back. The files like the ones above are $75 a piece. Buy 3-4 5% discount, yada, yada, yada. These aren't 3d printable.There is only one layer and no depth to them. There is no detailed interior. If you want it 3d printable, it's an extra $300. There is no guarantee that will fulfill your need. These people are not model car people. They don't know exactly what you need. Detailed interior, more $. The Skylark is on my list as one of the next purchases. I can't promise you when, but it will happen.

- 39,135 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

I've posted the front clip before, but didn't save the pic. I fell down and broke my left hip and had a pin and three screws used to repair it 6 weeks ago. I'm just now getting somewhat back to normal. I hauled out one of the test prints from the trash basket and this is the best I can give you for now.

- 39,135 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

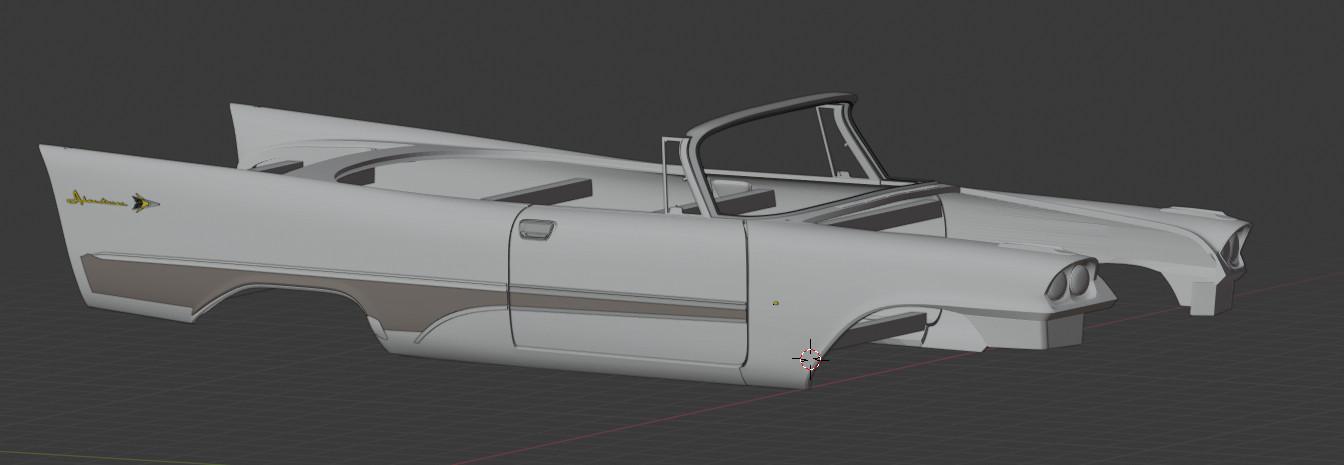

Down loaded these 3 from Hum3d early this a.m. The 55 and 57 will get the same treatment I used on the 57 DeSoto. I turned it into an Adverturer convertible and have already done successful test prints.

- 39,135 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

I run Windows 10 on a VirtualBox set up on my Linux machine. Works great.

-

These files are known as blue prints and can be used to create a 3d printable file.

-

Rattle can suggestions

my66s55 replied to ratherbefishin's topic in Model Building Questions and Answers

If there is a reason for using acrylic spray paints, there is one brand I am familiar with. Liquitex. I use their tube paint with my air brush and get great results. They are pricey though. Mail order seems to be about the only way to purchase them. Walmart has them as well as others. https://www.walmart.com/browse/home-improvement/spray-paint/liquitex/1072864_1067617_1067620_1091547/YnJhbmQ6TGlxdWl0ZXgie -

Yes. I 3d resin printed it. There aren't any lines.

-

AMT has never made a correct Dodge 270 hemi. They used what appears as a Chrysler hemi block and made the other parts fit it. Last year, I created the Dodge 241-270 hemi using the proper measurements from a real engine located at a salvage yard near me. The Dodge isn't only considerably smaller, the heads are different as well as the water pump housing. Below are a print of the engine I created as well as a pic of the reference block. I well post a w.i.p. of it if anyone is interested.

-

Recommendations for and experiences with ultrasonic cleaners

my66s55 replied to impcon's topic in Tips, Tricks, and Tutorials

I have the Harbor Freight ultrasonic cleaner and it works fine. I use it to clean excess resin off 3d printed parts. A car body will easily fit in it. Just be careful about using alcohol in an ultrasonic cleaner. Using heat will cause a fire. -

Fantastic accomplishments Randy. If only I had the ability to photo small parts as well as you. I'm working on and am very close to the next step. The completion of a complete multi part 3d printed model car. A holy grail of mine . The 1935 LaSalle. It's extremely close to reality. Oh, and forget the lines. They don't exist.?