-

Posts

1,942 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Rockford

-

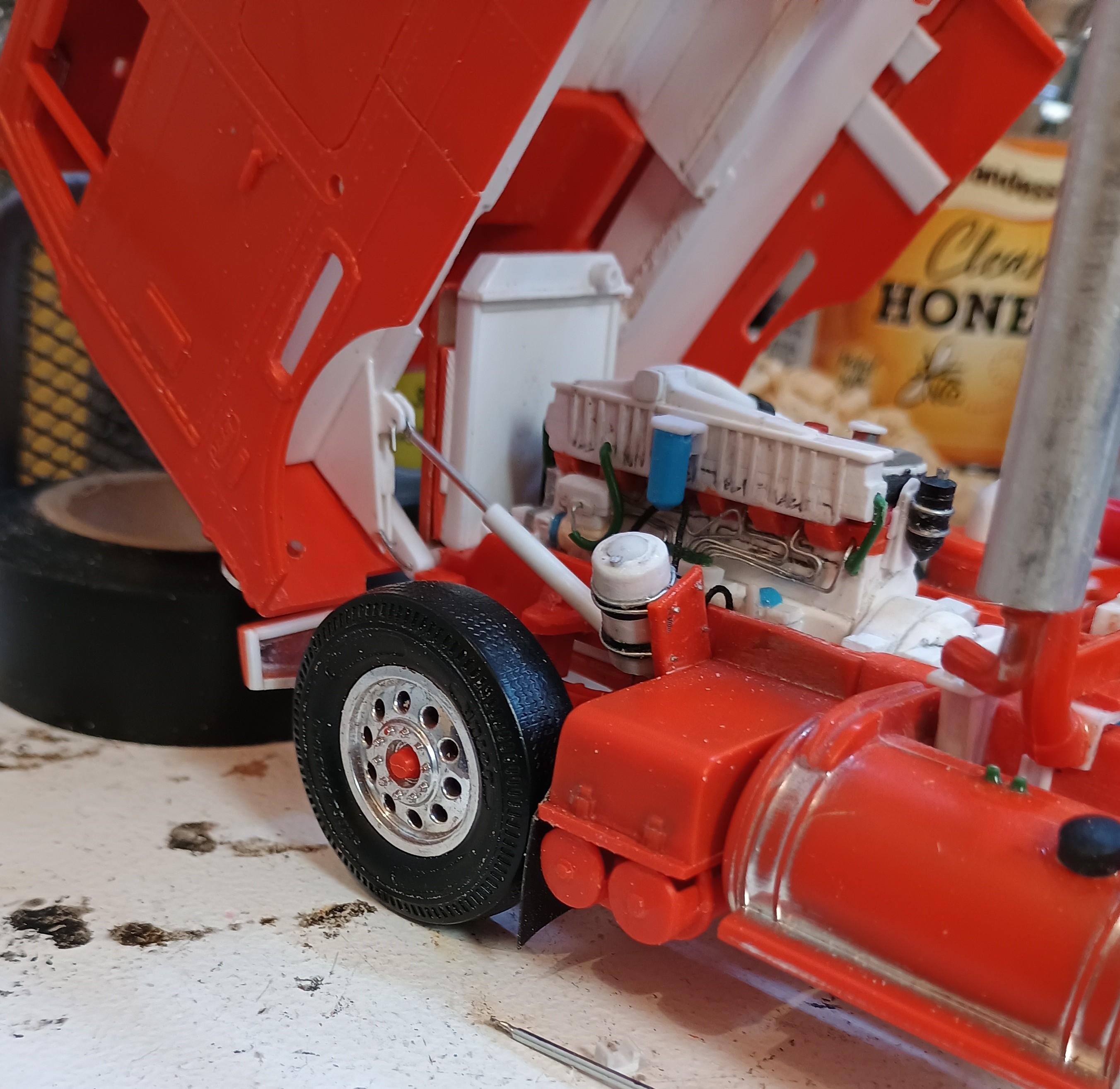

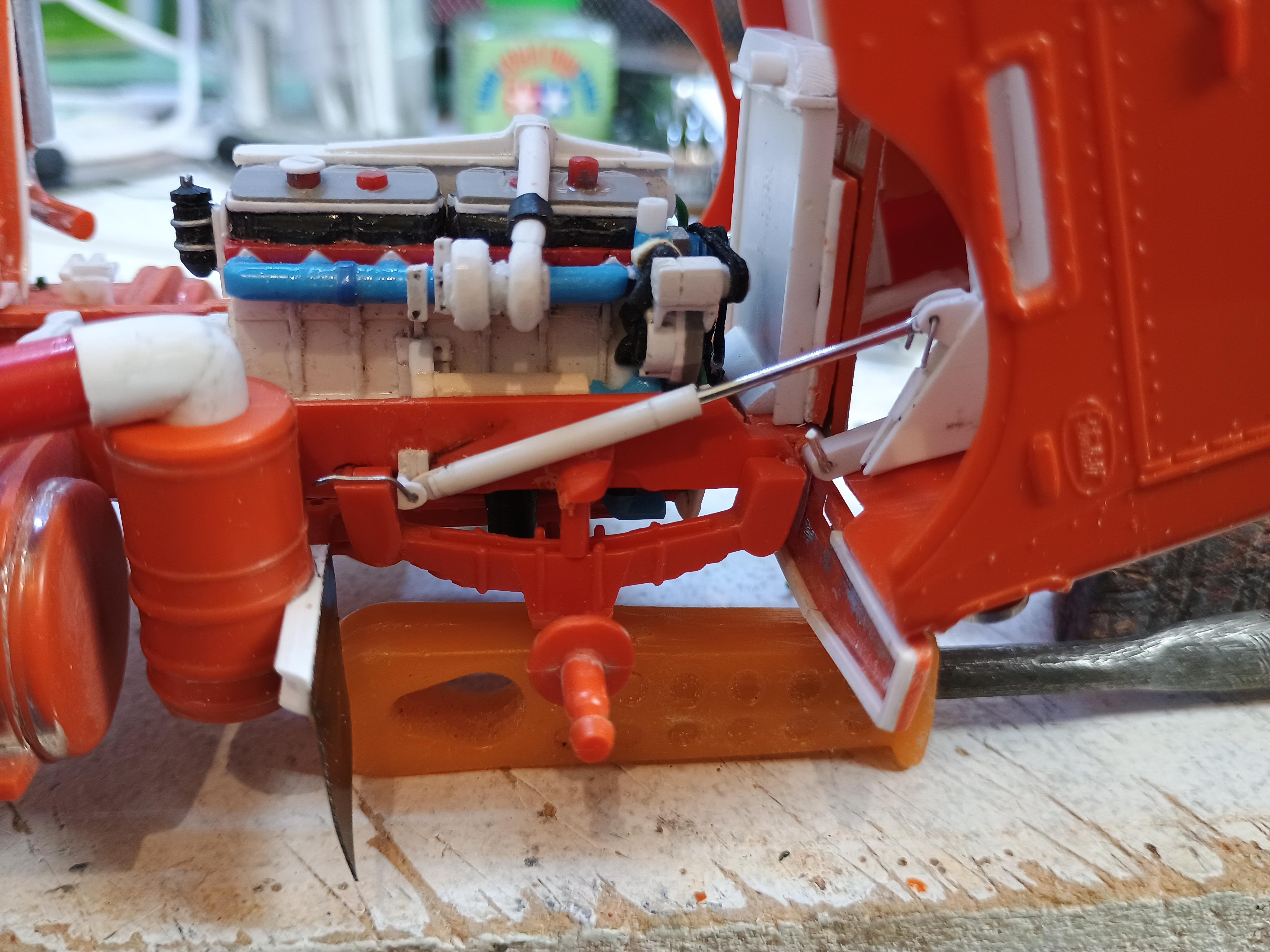

Finally found this on the web. You can see the length of the ram, it goes all the way back to the rear hangar on the spring, massive!

-

Resto Rod Autocar

Rockford replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Oh mate I'm so sorry to hear that. No, getting old isn't for wimps. I'm going to that many medical appointments there's no point being well, I'm never free! Hope you're feeling better soon and they get you sorted. -

1962 Marmon-Herrington HDT

Rockford replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good idea on the smaller wheels and tyres. Looking great though, either way. Looking at it, could you narrow the track of the front axle too? You could alter the wheel backspacing so they sit further into the wheel well? Just a thought. I'll give myself a smack if you feel I'm out of order. -

A few UK trucks had them too, they were Kysor Air Shutters. They were most often a dull aluminium, mostly because they weren't visible in the UK, the rad was buried under all sorts of bodywork. We used to cut a section out of the upper radiator hose and fit a section in with a temperature sensor. That fed a signal to the motor on the shutter to adjust the slats. Clever idea.

-

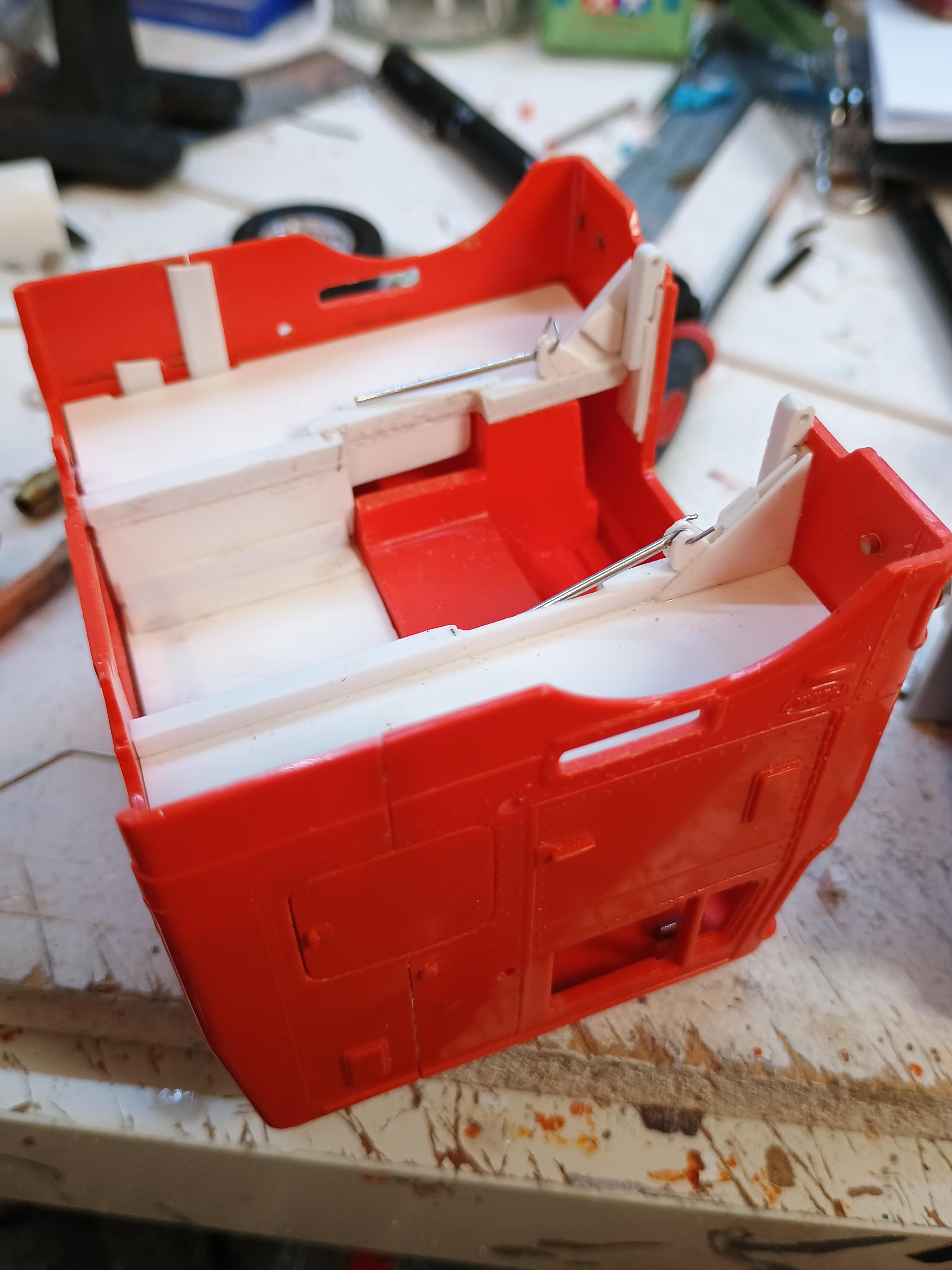

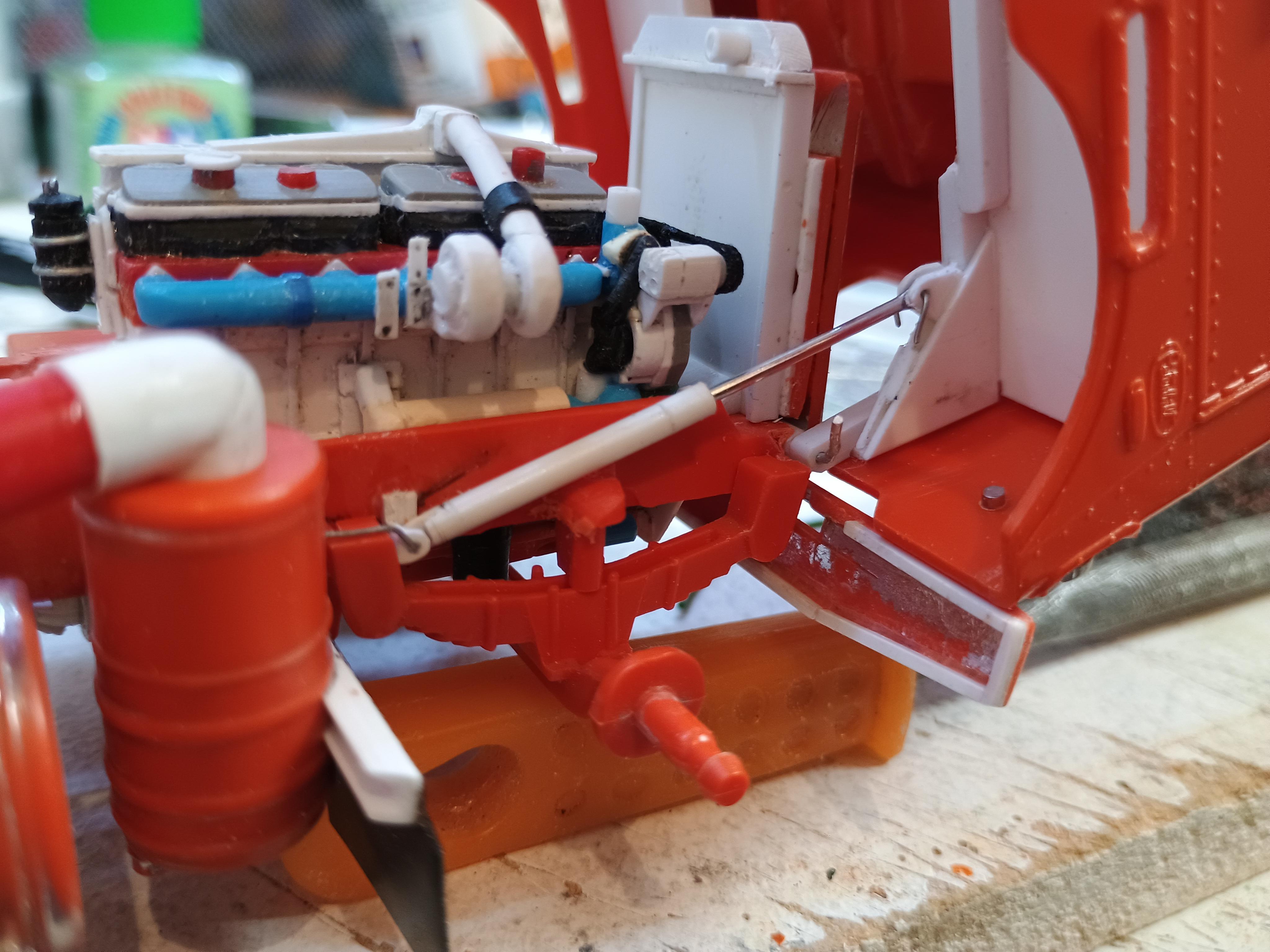

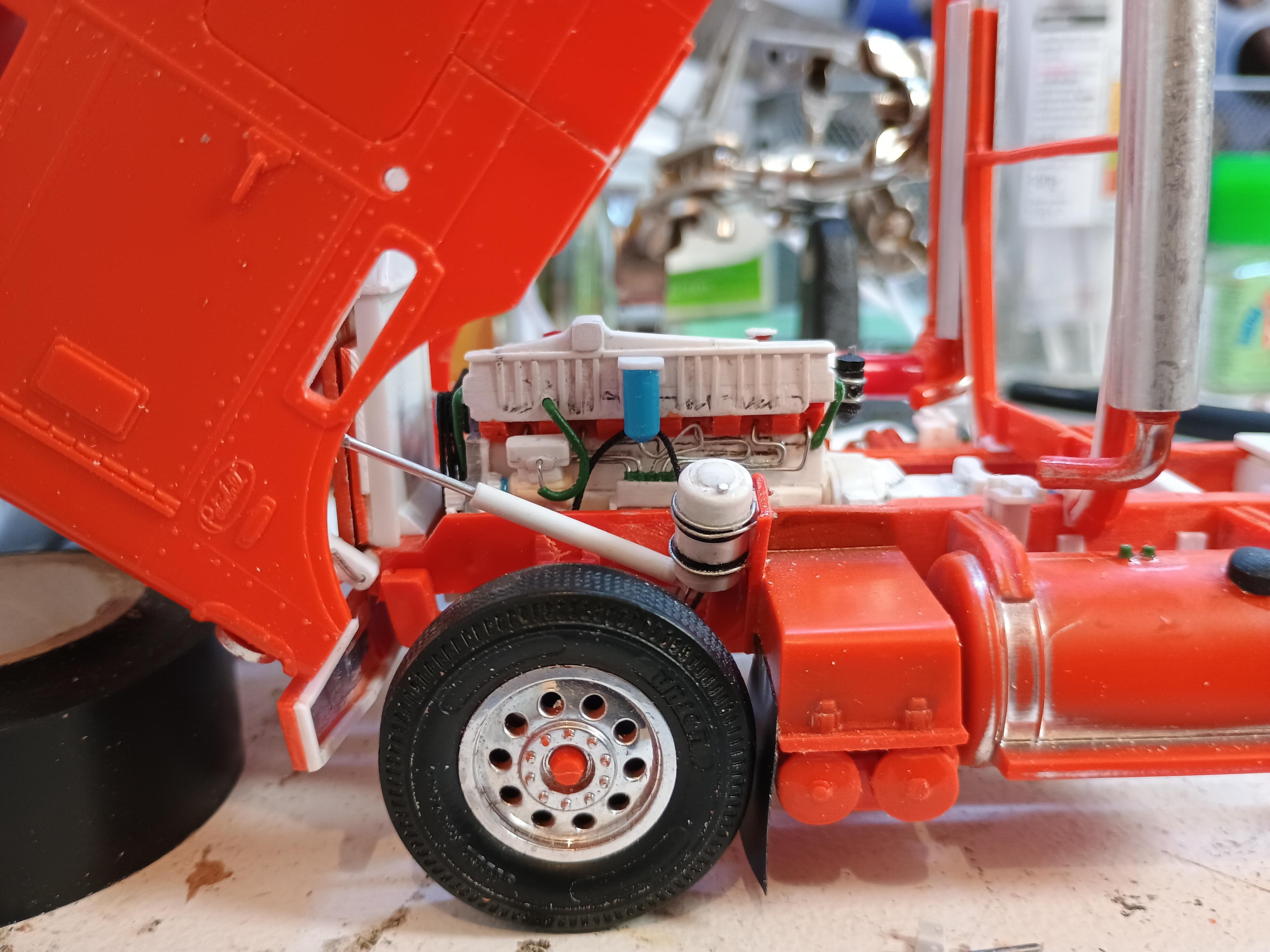

All I've done is copy the real thing. KW, IH, Freightliner etc... will all have a slightly different approach. I just noticed that the AMT 352 is lacking any cab substructure when I was looking for examples on the forum. The cab on your current truck does definitely tilt because you can see the locking pawl at the rear of the doghouse in one of the photos online. Packaging is an issue. The Pete rams seem awfully long and are at a very shallow angle. Others I've seen are shorter and more upright. The biggest obstacle is the steering box, they're often spaced away from the frame rail to position it under the steering wheel and also gives space for the ram to pass between the column and the frame. It's bad enough on full size stuff to at 1/32 it's a nightmare. I know many UK trucks only had one lift ram, usually on the passenger side because they only had little cabs. USA truck cabs were much bigger in comparison.

-

No need to ask mate, it'll be good to see what you come up with. There's very little information on each manufacturer's setup. YT channels dealing in restos are about the best.

-

I know what you mean but I like giving there snappers some dignity. 😀

-

I think the K100 system is far more compact. The rams are much further forward and smaller because they're more upright. Makes more sense mechanically too.

-

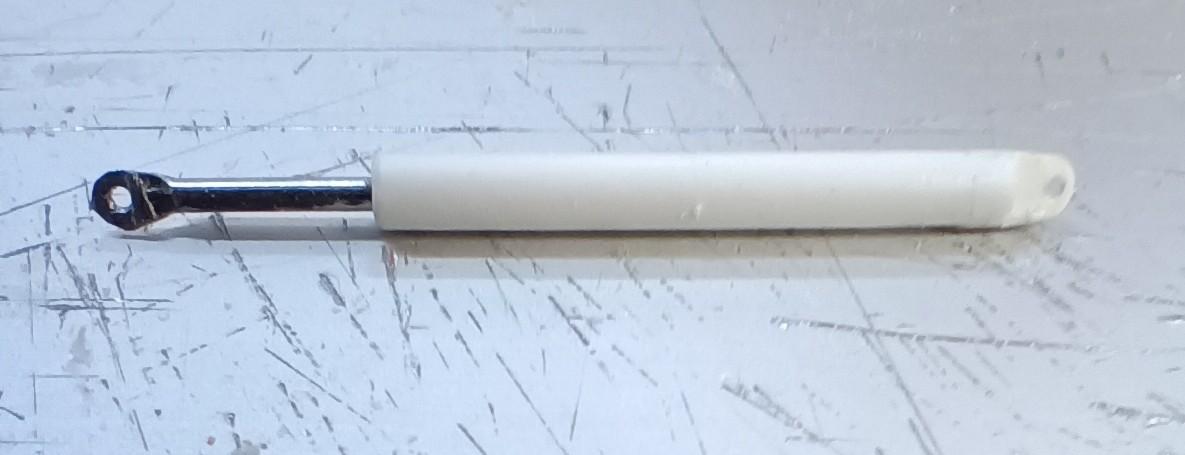

Looking at the 352s on the website something occurred to me. The AMT Pacemaker has no effort at replicating the cab jack details other than the pump on the chassis. That led me to searching for images of the undercab setup on the real thing. There's pretty much nothing on the web. I managed to find one image on Fotki that showed a massive lift cylinder going from the rear spring shackle to a bracket on the cab chassis. I garnered other details from various images but there was still a few educated guesses involved. I squashed the end of a piece of dismembered paperclip with Vise Grips, cleaned and drilled it to form the ram each side. Built the cylinder from plastic tube and card. Fabbed chassis brackets and added reinforcement to the front of the cab with the cab brackets mounted. Had to butcher the "damper mounts" moulded into the chassis for clearance (they're going altogether soon) and relocate the fuel filter from the frame to the intercooler. Calculating the length took some time but got it eventually. Works ok. Might add some hoses to the rams later.

-

KW 86 inch Aerodyne

Rockford replied to k100's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good choice on the Cummins, it won't leak oil all over your bench. I don't ever recall having to address an oil leak on an 855cu in Cummins. -

Farm Floater Truck 1/24th scale

Rockford replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That's unbelievable! Fantastic stuff. Watch you don't soak your bench with LIC10 hydraulic oil! -

Very nice job. I like the colour too, a nice mellow creamy colour.

-

KW aerodyne cabover

Rockford replied to Bronzekeg's topic in Model Trucks: Big Rigs and Heavy Equipment

Excellent work, looks fantastic! -

Engines of Color In the mid 1960's through 80's Peterbilt would order engines from the engine builders to be painted white. The engines were painted white by the engine manufacturer, not at Peterbilt. The engines would arrive on a pallet in white. Due to availability, supply-chain issues or other problems there were times when the engine builder would not be able to supply enough engines in white and Peterbilt would take what was available - which meant that some engines were white, some were engine builder color. The rule: If your truck had a white engine when new, if it gets restored the engine should be white. If your truck had an engine builder color when new then when restored it should be engine builder color. Cummins was the first to stop painting them in white, then Detroit Diesel and finally Caterpillar, but Cat continued to ship white engines up until the end of the 359 family in 1986/87. Cats in the 379 Familar (Successors) were yellow. Here are various photos of new engines in various colors at the Newark, California factory from back in the day. "In the mid 1960's through 80's Peterbilt would order engines from the engine builders to be painted white. The engines were painted white by the engine manufacturer, not at Peterbilt. The engines would arrive on a pallet in white. Due to availability, supply-chain issues or other problems there were times when the engine builder would not be able to supply enough engines in white and Peterbilt would take what was available - which meant that some engines were white, some were engine builder color. The rule: If your truck had a white engine when new, if it gets restored the engine should be white. If your truck had an engine builder color when new then when restored it should be engine builder color. Cummins was the first to stop painting them in white, then Detroit Diesel and finally Caterpillar, but Cat continued to ship white engines up until the end of the 359 family in 1986/87. Cats in the 379 Familar (Successors) were yellow. Here are various photos of new engines in various colors at the Newark, California factory from back in the day" Found the above whilst randomly trawling through the interwebs about Peterbilt. Just what you need. I did post photographs from the page but I noticed I shouldn't do so without permission. Sorty.

-

Yeah, BP colours I think.

-

I've just counted 187 pieces have gone into making the engine and transmission. Still not quite finished.

-

KW 86 inch Aerodyne

Rockford replied to k100's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Detail looks great, the end result will be brilliant. -

I had a little Matchbox version of this truck when I was little. Looks great!

-

Build of IH Pumper

Rockford replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Fantastic scratchwork here. The finish is top notch! -

Western Star 4900 FA plow truck

Rockford replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Absolute work of art! Bodywork is my nemesis, hate it. Fully respect what you've achieved here. -

1962 Marmon-Herrington HDT

Rockford replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Excellent stuff, hit the ground running as ever! -

Wow! What a systematic analysis of the issues with this kit. I've never built this kit, only the later 359 with the newer cab but I remember the wheels felt small on that too. Indeed on a KW900 I built I used the ERTL wheels and tyres from the IH Transtar for a better stance. Yes the engine should be white, something I balk at with my Paccar builds. It could always have had a service replacement at some time.... 🤔 The older AMT kits are definitely an experience. You'll make a great job of it though.

.jpeg.2931341788becc011ad0364661090cd5.jpeg)