Greg Wann

Members-

Posts

1,268 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Greg Wann

-

1990 Mustang LX - SVT Cobra DOHC Powered! UPDATE! 1/22/23

Greg Wann replied to Dennis Lacy's topic in WIP: Model Cars

Yes, I have poped up out of nowhere. Mike told me I need to visit this thread. Gorgeous build in progress here. Mike is finishing a fresh master for the Hatchback. I have greatly improved my technique of creating a body mold which I should share when I get the body from Mike. I do have a Holy Grail Resin model page on fb too. You are welcome to join. A big problem I have is no help in my shop. I got lots going on. It's tough to keep up. So....these Fox bodies are not rare and can still be purchased for a reasonable price. Don't overpay on the bay!! -

1990 Mustang LX - SVT Cobra DOHC Powered! UPDATE! 1/22/23

Greg Wann replied to Dennis Lacy's topic in WIP: Model Cars

I'm curious why we don't use optically clear silicone. -

Hi All, I now have this gorgeous body in my possession. Mike did a amazing job on this project. He learned some new skills and techniques from this body. Thank you, Mike.

-

This is very cool. Search: Barchetta3500.com I actually now own car number 4. Darryl has been working on it to bring back to as new condition from when he first built it.

-

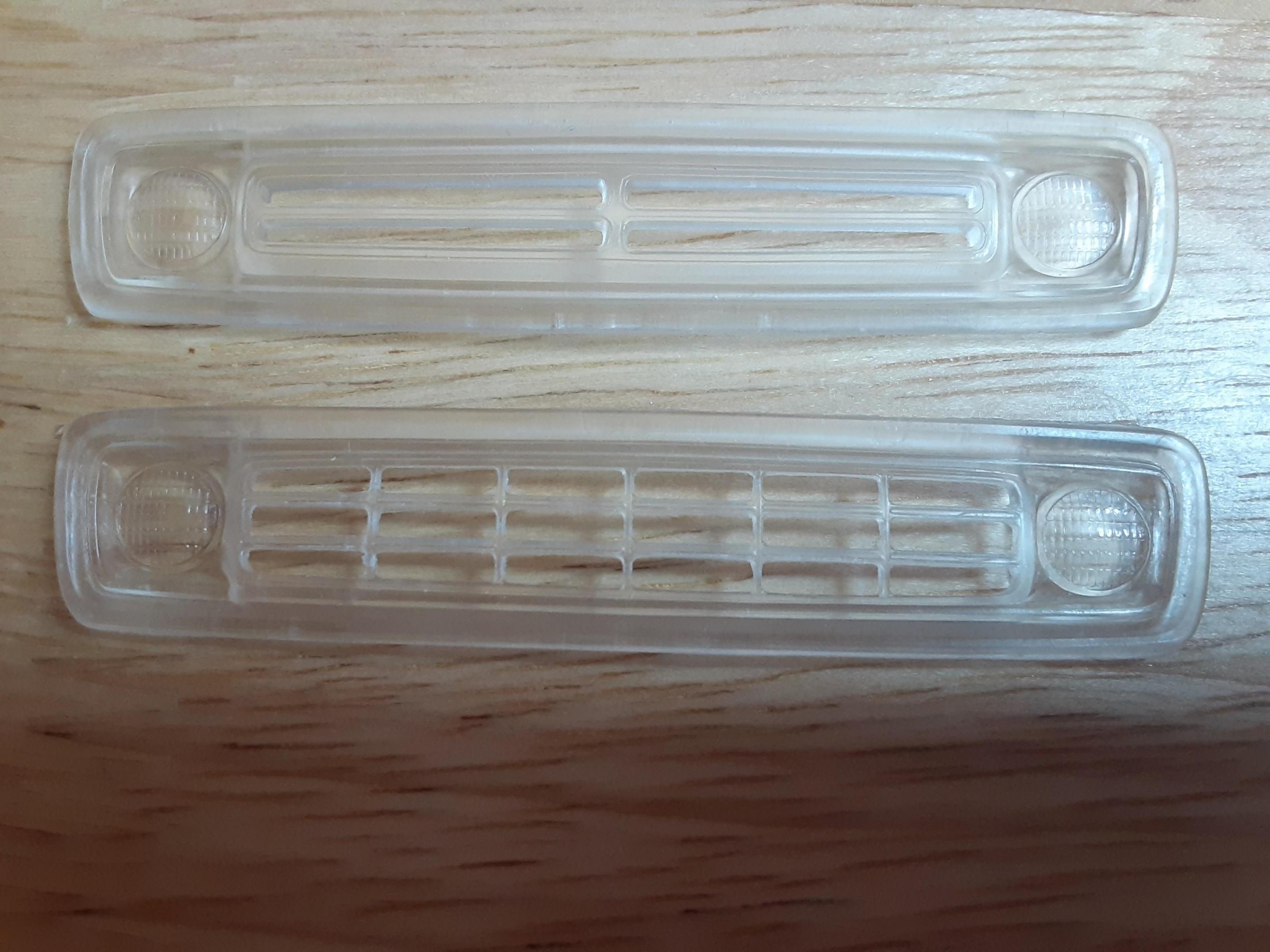

72 dodge truck grille

Greg Wann replied to Greg Wann's topic in Truck Aftermarket / Resin / 3D Printed

Yes, I have some made up. -

Need tire copies made, have master.

Greg Wann replied to Hawk312's topic in Car Aftermarket / Resin / 3D Printed

I might be able to help you. What material is your master tire made from? Got pics? -

Modelhaus prices on the Bay

Greg Wann replied to 1st 700 Quad's topic in Car Aftermarket / Resin / 3D Printed

Someone bought one of my 75 dollar 4dr Nova transkits and sold it on the bay for 300 bucks. If the buyer knew my price I'm sure he would have bought it from me instead. -

Yes, Tom it is. I have helped people monetarily and other means only to get used and actually feel like I have become a slave to them.

-

Wow! Tom, that is lot of great mastering work.

-

Action Modeler resin review

Greg Wann replied to Fantom's topic in Car Aftermarket / Resin / 3D Printed

Those parts look very impressive. -

Eleanor Trans Kit

Greg Wann replied to MININORTHFORDMAN's topic in Car Aftermarket / Resin / 3D Printed

No, I dont do it anymore. The kits above are better deals anyway. -

Modelhaus resin prep

Greg Wann replied to yellowsportwagon's topic in Car Aftermarket / Resin / 3D Printed

Ok, I asked the guy that I do custom work for. He is a professional model builder. He also restores real cars. You need to buy a Du Pont product called Prep Sol. You will have to buy it from a auto body paint shop. It's about $50.00 for a gallon. He has been building resin kits for many years now. He told me that today that the quality of resin kits that a lot of casters is just worthless. He has people send him kits to build and the surface is impossible to even prep to get paint on it! He said it seems that somehow mold release is somehow absorbed in the resin part also there are a lot of fine tiny holes. He got a kit and it is rubbery and it is junk. It came from someone in Tennesee. Some bodies are very thick and a lot of work goes into opening up window openings and pillars and then after all that time consuming sanding and filling windows don't fit right. Having a vacuum chamber and pump is a must have items to make good parts. I vacuum my resin down before I measure and mix the two parts together. Vacuuming or de airing the resin will remove moisture from it. Then I pressure cast the mold with weight on top of the mold. This helps create very thin flash around the part. I spray mold release in the molds but then I let it set for a few minutes for the release to gas out. Spraying release on the mold and making a part right away will cause parts to be rubbery and not cure correctly. There is a lot to know to make good parts. -

Mod Squad Mercury Question

Greg Wann replied to thatz4u's topic in General Automotive Talk (Trucks and Cars)

Not that I know of. -

Mod Squad Mercury Question

Greg Wann replied to thatz4u's topic in General Automotive Talk (Trucks and Cars)

I have one of these mint Mod Squad kits. -

Modelhaus resin prep

Greg Wann replied to yellowsportwagon's topic in Car Aftermarket / Resin / 3D Printed

OK, I called this company and the wonderful lady there is sending me free sample cans of this and a EMI brand A479. Both are are non silicone and food grade rated as well. I should get them next week and I will do some product testing. -

Modelhaus resin prep

Greg Wann replied to yellowsportwagon's topic in Car Aftermarket / Resin / 3D Printed

https://www.emicorp.com/item/ME+514E/A514-Zip-Paintable-Food-Grade-Mold-Release/ I'm not certain why as resin casters of model car parts that need gluing, painting and plating why we don't use a product like this. This product seems to be a good match for what we do. The biggest hurdle of the process is making a two part mold. The release is really important to make certain the two different pours (top half and bottom half don't bond together and become one mold trapping the parts inside. Having to do surgery with a exact knife to hopefully cut the mold up with enough care as to not ruin a rare part. -

Modelhaus resin prep

Greg Wann replied to yellowsportwagon's topic in Car Aftermarket / Resin / 3D Printed

I had not thought about discoloration since I have not actually tried it. I suppose it is ironic that I know how to make nice resin parts but dont know squat about prepping them for painting. I do have some mold release that is paintable and food grade. If casters would use that then all the worries would not exist for prepping parts to paint and build. -

1971 Plymouth Road Runner Grille

Greg Wann replied to Greg Wann's topic in Car Aftermarket / Resin / 3D Printed

Gotcha, I can still make them. -

Modelhaus resin prep

Greg Wann replied to yellowsportwagon's topic in Car Aftermarket / Resin / 3D Printed

It seems bleachwhite is popular but I'm not sure why purple cleaner won't do the job. It is a strong degreaser. I use Zep brand from Home Depot to remove chrome from parts. -

‘72 to ‘76 Dodge Club Cab

Greg Wann replied to tuffone20's topic in Truck Aftermarket / Resin / 3D Printed

-

3d Printed Taillight lens

Greg Wann replied to Steamboat's topic in Car Aftermarket / Resin / 3D Printed

Nice work -

1988 - 1991 Ford LTD Crown Victoria Scratchbuild

Greg Wann replied to DEL's topic in Car Aftermarket / Resin / 3D Printed

Hi, Send a email to: hgresin@gmail.com and Marty will put you on the list. Covid has caused some problems. We got the 4 door Lemans from Dwayne. It is a nicer kit than this Crown Vic. I have the body mold done., but many more parts to do. Thanks, Greg -

Nice work.

-

I found this book in a stack of folders I had never looked at since moving here and working in the shop.

-

A Couple of Pics of the Eleanor Conversion Kit

Greg Wann replied to oldcarfan's topic in Car Aftermarket / Resin / 3D Printed

You should purchase the the kit in another topic here. It is a more complete kit than what I make. I am more interested in doing the four door police cars for Dwayne L.