-

Posts

1,476 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by GoatGuy

-

Thanks Bill and Tyrone, especially coming from talented builders like you guys. I will try your method Bill.

-

1/16 Scale Army Vega Funny Car - Finished 10/14/2018

GoatGuy replied to Mooneyzs's topic in WIP: Drag Racing Models

Brad and Danno - we're all jealous that you got to see this build in person. -

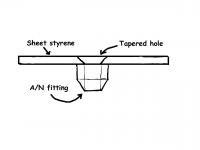

I have struggled with braided line and fittings and think I have found a good way to thread the line into the fitting. I have not researched this much, so probably some of you have good methods of doing the same and have already shared this. I took a scrap piece of styrene sheet, drilled a hole through it that matches the bore of the fitting and then used a larger bit to create a counter bore or funnel shape. Then I lined up the holes of the sheet and the fitting and glued the fitting in place with white glue, let it dry and then was able to thread the line through the fitting. Now I can pull the fitting off the sheet, clean off the glue and continue working. Please share better ideas with me as I have not used braided line a lot. Thanks for looking.

-

You're right Joe. Amazing results.

-

Great build so far. What tires/wheels are they?

-

1/16 Scale Army Vega Funny Car - Finished 10/14/2018

GoatGuy replied to Mooneyzs's topic in WIP: Drag Racing Models

That looks great Chris. Can't wait to see the whole rear assembled. Looks really good. -

'66 Mustang Pro Modified (Updated 10/16/2013)

GoatGuy replied to W-409's topic in WIP: Drag Racing Models

Looks really good. I'll have to get one of those Trumpeter saws. -

Mallory decals courtesy of Mooneyzs. The little things really help. Thanks for checking it out and your support.

-

Niko- thanks for your comments. I always look forward to your builds. Bill - thanks. I learn from all of you. Your work is outstanding. Chris - I got the decals today. They will go on tonight. I appreciate it. Jim - thanks. Your products help us achieve our goals. I will be ordering more in the future. I look forward to learning more from you guys. Your successes and mistakes help all of us improve.

-

Wayne that is awesome looking. Dave - please keep us posted on what you find and build.

-

'66 Mustang Pro Modified (Updated 10/16/2013)

GoatGuy replied to W-409's topic in WIP: Drag Racing Models

I don't see any reason to remake the manifold Niko. It looks fine. -

Thanks John. I just wish the ribs were a little smaller. But hey, it was free. How is sunny California? It was 41 degrees here the other morning.

-

Great start. I have two different C5R builds started. In fact I think all my kits are started, only a couple finished. Looking forward to more of yours.

-

Here is the belt I made from a drive belt I rescued from an epson printer headed to the trash. Not all of the belt has ribs on it. Most of the belt is smooth, so it will come in real handy. I need to add a very small piece to fill the gap at the bottom. Thanks for looking.

-

Roger Lindamood`s "Color me Gone" 68 Charger

GoatGuy replied to John Teresi's topic in WIP: Drag Racing Models

Another terrific build Mr Teresi. -

57 chevy pro mod w.i.p (updates 11/11/12)

GoatGuy replied to tyrone's topic in WIP: Drag Racing Models

I vote for the blue & white, too. -

'66 Mustang Pro Modified (Updated 10/16/2013)

GoatGuy replied to W-409's topic in WIP: Drag Racing Models

High School ? I think I remember what that was........................back in the 70's. -

Thanks Dave. I was just reading your response to my question about nets on wheelie bars. Once you get that coupe on the road, bring it up to Perry county and we'll wake up the cows and chickens!! I'm hoping to make it to Maple Grove for Friday's qualifying. That barrel valve is a challenge. At least the one on the opposite side won't be quite as hard. It won't have as many lines to it.

-

Brad's right - basket weaving looks real good now. Masterpiece work like a couple other guys have said. Those pulleys look spot on.

-

Another pair of Ferraris -- Italeri 365 Daytona and Revell 599 GTO

GoatGuy replied to Matt Bacon's topic in WIP: Model Cars

Looking good. I need to get one of those 599 GTOs. -

57 chevy pro mod w.i.p (updates 11/11/12)

GoatGuy replied to tyrone's topic in WIP: Drag Racing Models

Looks great Tyrone. Can't wait to see more. -

Ted- Chris is sending me some Mallory decals. They need to be small enough to put on the ignition coils. Thanks anyway. PLEASE DO get back to work on your funny car. Looking forward to more. After looking at the pics I took of Bruce Larson's Sentry Olds, I noticed a couple of frame braces that I wish I'd seen before I started. Oh well. Bill - thanks. The updates took time because of other stuff. We all suffer with that "other stuff" disease. I need to check the progress on your car. Thanks guys for the encouragement. Sidenote- I found an Epson printer at work that they are going to scrap and I cut the drive belt off. It's about a half inch wide and is ribbed. It cuts very clean and I'm making a blower belt for the funny car out of it.