-

Posts

3,981 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Pete J.

-

Looks like they arrested some of the people here in the US that were handling the money end of this scam. Glad they are getting after them here and in India. Now if we can just get them to go after the good ol boys in Nigeria.

-

-

This the so sole reason I have a land line. I also have caller ID that goes through my cable TV. I do not bother answering any phone call that I do not recognize. People who I know and businesses I want to talk to contact me through my cell. I get calls with scamed ID's from all over the place. They can call all they want. Not going to bother picking it up.

-

Inside of a Tamiya rattle can(photo)

Pete J. replied to Pete J.'s topic in Tips, Tricks, and Tutorials

Yup, that is the reason. Tamiya paints are synthetic lacquers and I won't even go into how those are much better paints for spraying through an airbrush. Yes, I use to be able to get lacquers down at my local automotive paint store and I still have some quarts left that will last me the rest of my life. Automotive lacquers thin down at a rate of 4 or 6 to one thinner to paint. Unfortunately, here is the Peoples Republic of California, you can not buy either auto grade lacquer or even lacquer thinner any more and it has been a long time since they ban it. You would not believe the goat rope I went through to get a gallon of the real deal thinner and the darned stuff is made just a 10 minute drive from here. I had to order it shipped to a friend out of state and they turned it around and shipped it back to me. So now I have a couple of years of thinner. At any rate, rattle cans are the only source here and that requires decanting. -

Dave, I really don't want to hijack Tim's thread with this subject. I will send you a private message with photos that explain it better. Anyone else who wants information can pm me and I will answer questions.

-

By the way, I have done a lot of non modeling work on my Sherline. That was not the intention when I bought it, but it has been very useful in doing other things. Example: rather than toss and old fan, I turned a new bushing for the motor and it is good to go!

-

I will say this again as it bears repeating. Buy the best tool you can. It is better to spend more on a good tool than buying a lesser quality tool, getting frustrated and then spending the money on the tool you should have bought in the first place. Every craftsman I know(including me) has learned this the hard way. I have spent far too much money on ok tools and then when I wanted to better work spent the money again on a good tool. It is actually cheaper in the long run to spend the money right the first time.

-

There are a couple of recent builds here on this kit. I just finished one. You are right this is an old and poor kit but it looks like you are off to a good start. You might want to look through a couple of the other builds that will give you a heads up on some of the issues others ran into. Mine is here http://www.modelcarsmag.com/forums/topic/113782-i-dont-do-hot-rods-well-maybe-i-do/ and I think that there is one under 54 panel also. Good luck, this was a real challenge.

-

Reproducing a decal

Pete J. replied to fairlane1320's topic in General Automotive Talk (Trucks and Cars)

White or metallic decals need an alps printer to do it yourself. No one makes a white ink cartridge. Other wise you need to get someone else to help out. -

They modified one I already owned, however they do sell them that way, but for a reason I do not fathom, it is not in the catalogue. You have to call and order it. They haven't had much call for them, but then, if no one knows you have it, then I wouldn't expect much in the way of sales. I strongly urged them to put it on the web site.

-

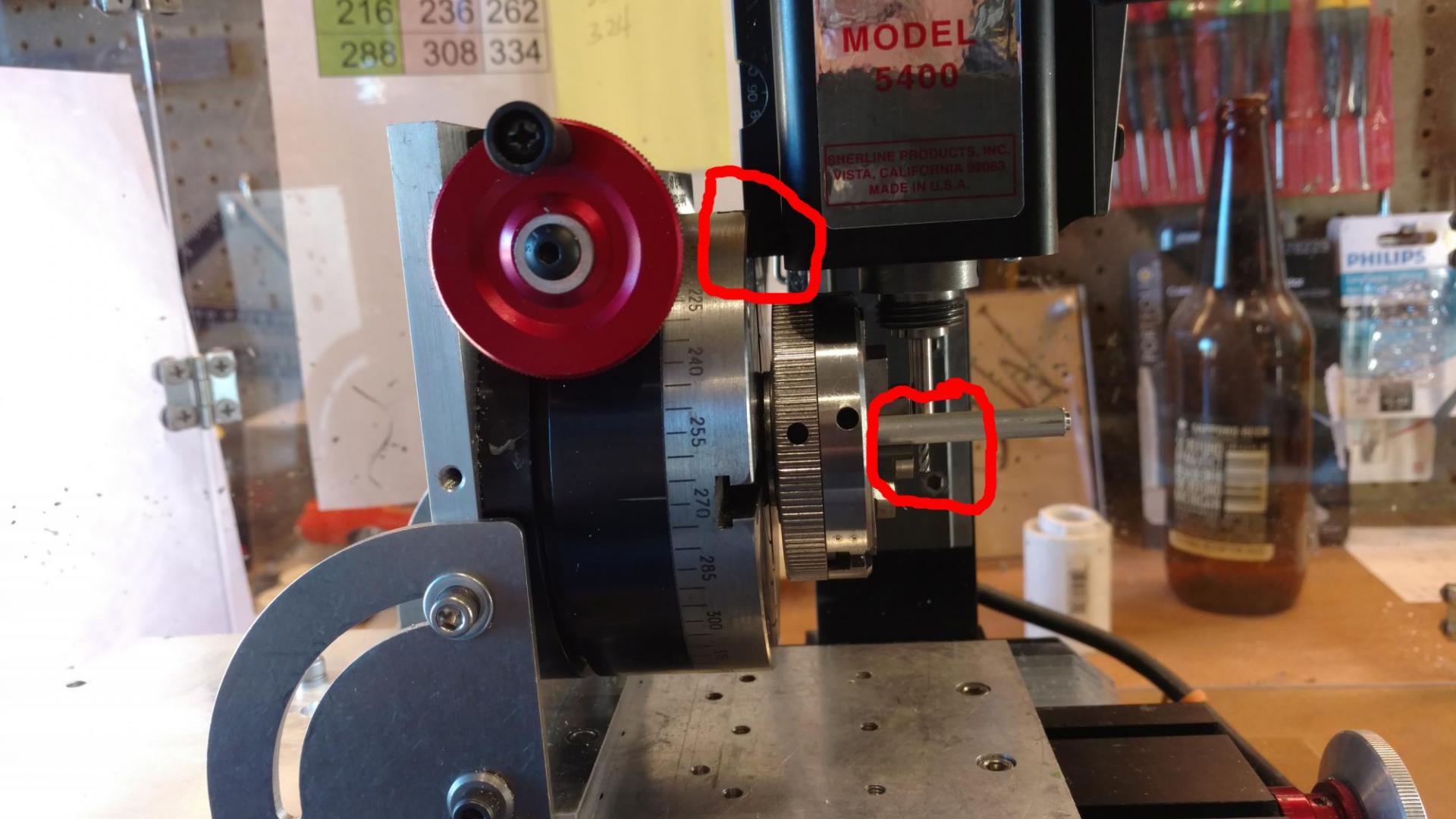

Ok, this is a follow up for Chris and Tim. I got the rotary table back from Sherline a couple of days ago and I am very pleased with there modifications. I can now get a bit within .5" of the top of a piece and almost flush with the end of the jaw with a collet used to hold the bit. The head contactling the Rotary table is still the limiting factor but it is much less of an issue. The first picture is the after and the second is before. You can clearly see the clearance difference.

-

Art, they are actually in the San Diego area. Vista to be precise. Unfortunately for my billfold within 15 minutes of my house.

-

You are on the right track but there are the same pitfalls. A "better" drill generally means more power and heavier duty, not closer tolerances. You can easily spend a couple of hundred dollars on a really nice drill, but why would you? You are half way to the cost of a used Sherline. Over the years I have learned that it is less expensive to spend the money for they right tool first time rather than spend less money but have to buy two or three tools before you realize that they just won't do the job. I will also add to that that I have tried to jury rig a tool to do something it was not intended to do and it works occasionally, but I would guess my success rate with that is quite low. I generally get frustrated and go get what I need. If you have a spouse involved in tool purchase(and I did) then I solved the issue when I explained it this way. "I could build a house with a Swiss army knife, but why would I want to?" Good Luck!

-

I use hand held tools on my Sherline all the time but they are very special tools and used in a special way. The tools are commonly used by watch and clock makers. They are called gravers and they are used on very small parts and with a specially made tool rest. They take very very small cuts but with practice, leave a highly polished surface. Here is a video of a graver being used. Notice how little material is being removed. https://www.youtube.com/watch?v=IVhdlfE0oDE Lets talk for a minute about the forces on tools when cutting. The forces on lathes is very very high at the point of a cut. Machines for table top machining are designed for these extreme forces and need to be very robust. Sherline uses tools made from 1/4" tool steel. They are held in solid blocks about 1.5 " square. When turning I try to keep the tool extended beyond the block to a minimum. If you extend the tool too much or try to take too much of a cut or run the machine at the wrong speed, the tool starts to vibrate. This is called chatter and leaves a very uneven surface. If you want to understand the forces involved, imagine taking a bar of tool steel less than 1/2" long and taking a cut of .010" deep by .020" wide and bending a quarter inch bar and making it vibrate. Those are the level of forces involved. To get another idea, look at a video of wood workers turning wood. Wood turning tools are typically 2 to 3 feet long for leverage and the steady rest is kept as close to the wood as possible. The leverage to work has to be huge. Typically in feet on one side of the fulcrum(steady rest) and fractions of an inch on the other side. Leverage and force are the typical reasons using a drill in a vice is almost unmanageable. You will also notice that the chuck in a lathe is a totally different animal from the Jacobs chuck in a drill. A drill has very loose tolerances in both the chuck and the bearings of the drill. Pieces in a drill do not run very true and have a wobble know as run out. That wobble makes digging in much more likely. Don't get me wrong. You can do some work with a drill and a file but to do the quality work that you want with model, you need the precision and quality of a machine made to do this type of work. Right tool for the job!

-

That is some serious brass work! Very nice

-

Good deal! You never know what someone else doesn't know and I like my friend alive and well!

-

Carefull with that MDF! Some of that has some really nasty chemicals that come off when burned! Particularly cyanide and formaldehyde. The stuff that comes in from overseas can really get toxic in a hurry. Don't breath it if you can avoid it. A good resistance soldering unit can cut down on fumes quite a bit. Might be worth looking into if you are going to be doing this much soldering.

-

Chris- PM sent

-

I have been using a Sherline for years now and it was money well spent. Great piece of equipment to learn metal turning on. No mater what you get, you should buy Joe Martins "Table top machining" book. It is available through Sherline. He was the founder of the company and really knows the subject. It is not a cover to cover read but a great reference manual. It talks about all the factors that go into machining from the very simple to the very complex. It is the kind of thing you can grow with. Oh, one other piece of information. The lathe is just a start financially. You can easily spend more on tooling than you did the original lathe. They also make a sweet little mill, which is much more versatile but you don't want to start with a mill. You need to learn the basics of metal work with a lathe first. Another suggested reading is one of Gerald Wingrove's Complete Car Modeller books. This is very complex work but it will give you inspiration to do more. Good luck

-

Ok Tim, I sent you a private email about the rotary table as it is just too long to post and it may wind up boring the heck out of the others.

-

Tamiya sells two pieces that work well for me. They have some very sharp scissors and a diamond file for cleaning up the edges. I also like their side cutters for this. To keep the metal from bending cut off the sprue as far from the piece as you can get and once it is off, you can get in close and trim it up. Finish it off with a diamond file.

-

Tim, I spoke to Fred at Sherline about it. He is the one that put me on to it. To my knowledge there is no regular part number as they are done on request. I have not ordered one yet, but he said they were the same price as a regular one. No markup. Now that was in the factory face to face, so I assume that they would do it for anyone. They are really great to work with. Oh and by the way, Fred is really worth getting to know. He is a very experienced machinist(read well past social security age) and is one of the most helpful recourses I have for machining questions. I think I will go over tomorrow as get one. I am going to take mine over and see if they do a conversion also.

-

Coast airbrush http://coastairbrush.com/ has a wide variety of bottles in both glass and plastic. There plastic bottles are coated. I have been using them for years for lacquers and everything else. You can get them from 1oz to 6oz. They also sell lids separately along with siphon feeds. They are very reasonable. I am lucky in that I live nearby. When ever I am in the area I go in and pick up a half a dozen in different sizes. I would suggest calling rather than trying to find what you want on the web site. They are very knowledgeable and will help you get what is just right. Oh and if you happen to be in Anaheim Ca. it is worth a trip over to the store. It is literally the Disneyland of airbrush shops.

-

Ok, I will try to bring this back on track. This is a photo of an issue I ran into with my mill. With the rotary table mounted on the angle plate I have a clearance problem with the motor mount on the right side of the mill head. This only happens when I am using end mills that require the use of a collet to hold them. You just can't lower the head far enough to make contact with the part. I am bring this up to you because I discovered something. As you probably already know the rotary table can only be mounted one way on the angle table and that is to the right. Well, Shurline will custom make a rotary table with the controls on the other side so you can mount is on the left side of the head and avoid this issue. They don't charge extra for it, but it is definitely not in their catalog. You have to call them and order it special. If you ever run into it, you know they have the solution.