-

Posts

3,981 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Pete J.

-

PSI for airbrush and House of Kolor

Pete J. replied to DrewCfromSC's topic in Model Building Questions and Answers

Ok, this is going to be a little wierd science here. The humidity that we are all familiar with is "relative" humidity. It is a percentage of moisture saturation at a given temperature and pressure. Since you can not do anything about the pressure, I will not bother discussing it. So that means that with local humidity, you can lower the relative humidity by raising the tempurature, or put a heater in your space. You can also buy dehumidifiers, but the room needs to be close and that is not a good thing when you are painting. Sears sells them but they are not cheap. The other option is to use an air conditioner and a heater(which is what a dehumidifiers is). You cool the air off and the moisture condenses on the coils of the AC unit, then you warm the air back up and your humidity it lower. Frankly, none of these is a great choice when you are talking about model building and airbrushing because of the small scale of the operation. -

PSI for airbrush and House of Kolor

Pete J. replied to DrewCfromSC's topic in Model Building Questions and Answers

A post script on my prior posting. I have been experimenting with HOK urethane automotive clear with mixed results. I mentioned it the last time I was a Coast Airbrush in Anaheim and they said they absolutely mix that with equal parts reducer and paint instead of the 3:2:1 that is used for full sized guns. You have to keep the hardener the same ratio to the paint. I have not tried it yet, but they are definitely experts on the stuff. -

PSI for airbrush and House of Kolor

Pete J. replied to DrewCfromSC's topic in Model Building Questions and Answers

Ray mentioned the "holy trinity" of painting as viscosity, pressure and distance. Add temperature and humidity to the equation and you have all the factors that affect airbrushing. Unfortunately if you are looking for a single answer to each of these, that doesn't exist. They all interact and a change in one requires adjustments in the others. This is the one piece of advise that I give to all beginners: START A JOURNAL! Get a notebook(or your could use a computer with a spread sheet if you want to get all geeky on us) and make a column for each of these and one for comments. Each time you paint do the following. Measure(and I don't mean eyeball it.) the ratio of paint to thinner(viscosity), and spray with a fixed pressure. See the result and comment on it. Then try the same thing but change the pressure and see what happens. Do this multiple times and you will find a sweet spot for pressure at a given viscosity, temp and humidity. If you do this every time and write it down, you will have a guide for painting that you can follow. Since you can't generally control the temp and humidity, you need to do this over time to get a feel for what happens. Never change more than one variable at a time. Otherwise you will just get confused. I know a lot of builders use the back of plastic spoons to test paint and that is good and cheap. However you can go online to different paint shops and they have a thing called a speed form. It is about the size of a small model car and is great for testing paints. If you have been in a paint shop, you may have see them mounted on a board showing off a manufactures paint. You can often find them on sale for less than ten cents each. I buy them in packs of 100. That many will last you for a long time and they give you a good view of what your paint will look like on model. -

Please keep Grandad away from the tools!

Pete J. replied to Daddyfink's topic in General Automotive Talk (Trucks and Cars)

Kind of looks like a lego version of a Superbird/Daytona. What I can see is the grandson saying, "Look what I built grandpa!" -

Replicas & Miniatures Co. Of Maryland

Pete J. replied to Tye Brown's topic in Links to Aftermarket Suppliers

Ok, I want to weigh in on the computer thing. There are a lot of folks who build models that are, to put it politely, eligible for Social Security. I am one of those as are Norm and Harold. I will not speak for them but I will speak for myself. I am computer literate. I took my first course in computer science in 1968 and have been involved with computers ever since. My wife uses computers but that is about the extent of it. Her current computer recently took a dump and I have had to replace it. The old system was running Windows 7 and was running an early version of office and other programs. Her new computer is a Windows 10 model and I had to update Office and other programs to make it work. Then began the fun. Trying to get the computer so it was usable for her was a challenge. My wife is not a stupid person. After 40 years in big city emergency rooms as a nurse she is among the smarter people I know, but she just doesn't like computers. She doesn't understand them and can't grasp how they work. When she approaches one she expects the same thing every time. Trying to get her to adapt to new programs and different approaches is like trying to teach a fish to ride a bicycle. In other words I have spent the last week trying to make the new computer work and look like the old one and it is very frustrating. The builders of technology seem to believe that everything new has have all the fancy bells and whistles. Every thing about it must be new and fresh. Unfortunately, it makes it unfamiliar and confusing to those who don't keep up with technology. Many older people I assume like Norm and Harold have been doing things without computers their whole life. I have a number of friends like that. They have no concept of what the web is like and how it functions. Starting to get them up to speed at this point in their life is fruitless. They have tools that they know how to use and are comfortable with. They like pen and paper, telephone conversations and the US Mail service. It is like their shops. The shop is full of old style craftsmans tools for making molds and pouring resin. They know these things and they are comfortable. They don't need CAD or 3D printers. They know how to do things with manual tools. In short, small garage shops like this is not likely to upgrade to any computer based selling system. If you want the quality products that they offer then you need to do things their way. They are not likely to adapt to your needs and wants. -

Replicas & Miniatures Co. Of Maryland

Pete J. replied to Tye Brown's topic in Links to Aftermarket Suppliers

Oops! Right you are. They are both in the Baltimore area and I tend to get them confused! -

Replicas & Miniatures Co. Of Maryland

Pete J. replied to Tye Brown's topic in Links to Aftermarket Suppliers

Picked up a set of his Rudge rims for Tamiya's SL not long ago. Superb castings. -

Divided by a common tongue

Pete J. replied to DonW's topic in General Automotive Talk (Trucks and Cars)

Don't forget the tools- US-wrench UK-Spanner -

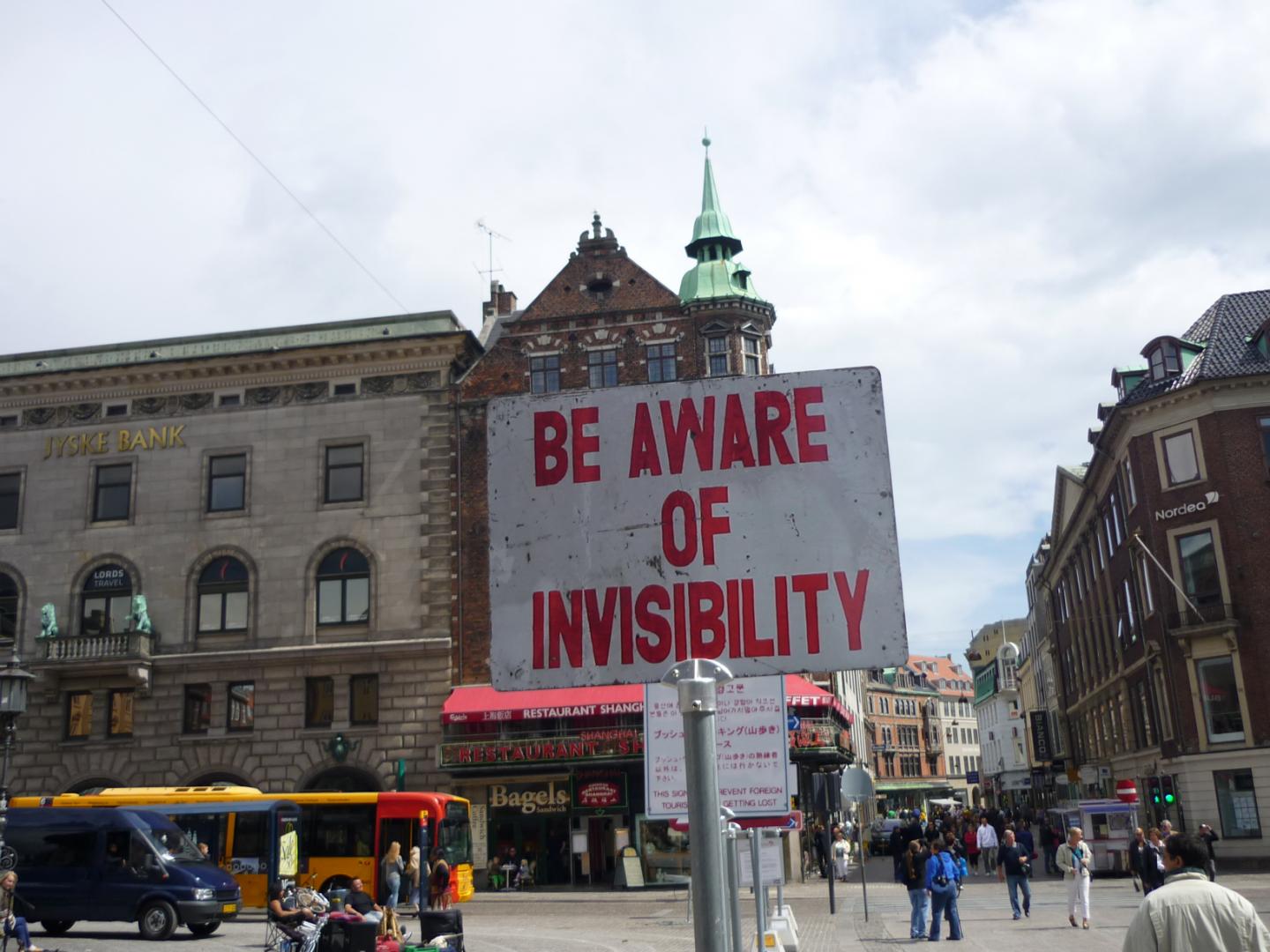

I know that languages often don't translate well, but I have always wondered about this sign. What is the original intent!

-

That is why San Diegians said hell no! I have been to maybe 3 Chargers game in the 27 years I have been here and one of those was because my son got free tickets that were given away when the city made a dumb deal to guarantee ticket sales and got stuck with thousands of tickets as a result of government stupidity. There is no reason for public funding for a pro-sports team unless they actually share revenues. A city is not defied by it's sports teams. If they can come here and make a business work, then fine, but they are not a public entity. Go Chargers! No, seriously, go, go to LA. See if they buy your mediocre to lousy product!

-

Tamiya has been making bike kits for years and they are some of the best in the industry for fit, finish and accuracy. They do 1:12 and 1:6 scale. The most amazing bike kit I have ever seen is their Honda RC 166 kit with upgrade accessories. One of the accessories is a set of rims with stainless steel spokes and machined aluminum nipples and rims. You can also get a individual link drive chain. They just don't get much more detailed that that! If you look at that real bikes, 1:12 scale is actually and inch to a foot. Therefor a real bike that is 4 feet tall scales down to a model that is 4 inches tall. 1:24 scale is a foot to two inchs thus a 4 foot bike is 2 inches tall. A relatively easy conversion.

-

Tim, a lot of people assume that larger scales are easier because the parts are bigger. I learned years ago that this is a myth of modeling. I my view, it actually makes it harder. At 1:12 scale you must have much more detail and it must be right or it looks odd. In the smaller scales you can actually get away with eliminated some small details. For instance, at 1:12 scale you need to consider safety wiring nuts and bolts, cotter pins on castellated nuts and adding crimped fittings to the ends of wire. Gage faces need to be legible. Switches that you could get away with a piece of wire and a washer, now need to be round on the end and tapered with a knurled washer. Bolt heads need to have the slight taper at the edges, and on and on. Granted as our eyes age and we can't see as well, we think that it would be easier but it really isn't. Good luck and I look forward to your future builds. This one has been spectacular! Keep it up.

-

I wish I had saved it, but here in California the Payday candy bar has such a warning on the label, as if the pictures of peanut and wording "peanut caramel bar" aren't enough. Come on folks! Take some responsibility will you!

-

For some one who needs different sized tips for different paints, I would suggest the Badger Crescendo 175. It is a very reasonably priced brush and you can by kits that have three different sized tips. It is a good middle of the road choice for someone who spray with different paints . I have had one for 15 years and the main problem I have with it is occasionally dropping it. The tip is not protected at all(except with a metal cap you have to put on) so if it lands on the end, you are replacing the needle or tip. The good part in all of this is that like the Paashe VL it has been around for ever so parts are readily available. With three tips it is probably one of the most versatile airbrushes out there.

-

Buick did have a flair for cars back in the day!

-

This has got to be one of the dumbest moves I have ever seen. Spanos has been threatening this for 15 years and thank god the city never caved. Last time the Chargers were any good, they got a ticket sales guarantee from the city and then went on to be a mediocre team in the best of years. They are the only business that seems to feel that they can sponge off of the local tax payers for huge profits. Had the Chargers fielded a decent team they might have had some bargaining leverage but they only made the playoffs once in the last 8 years. The last couple of seasons they haven't even won 1/3rd of their games and over the last 10 years have just barely eked out winning more than half of their games. Can you imagine going to your boss and demanding a raise with the argument, "I did my job half of the time!" Oh and by the way, they have only made it to the super bowl once in their history and lost that. Great product! No, it's ok to go to LA and compete for the market with another loosing team in the same stadium. Yea, great decision. We won't miss them. Go and don't expect a following from San Diego. We ain't driving up to see your crappy team loose any more.

-

Took me about 2 seconds. My aunt had one of these when I was a kid. I'll bet she wishes she still had it!

-

Adventures in soldering:The GT40 project New pics 2/13/17

Pete J. replied to Randy D's topic in WIP: Model Cars

-

Master Modeler?????

Pete J. replied to curt raitz's topic in General Automotive Talk (Trucks and Cars)

This is why I like the idea of a master designation coming from a group of peers. Nobody knows better what you skill level is better than those who also build. In this respect, that is why I think national contests are a better judge of building skills. Yes, I know, there are some biases in that method and we may not always agree that what won should have won, but as a measure of skills, someone who has been awarded top honors at a national level has shown some serious building skills. The negative is that there are a lot of equally skilled builders out there who don't choose to compete. -

Master Modeler?????

Pete J. replied to curt raitz's topic in General Automotive Talk (Trucks and Cars)

If you do a little research in the history department you may find a bit more comprehensive definition of "Master" or "Master craftsman". It is interesting and has some application to today. For thousands of years there have been guild systems that were used to train and "certify" people in the trades or crafts. Simply put, a young person or apprentice was selected to join the guild an study under a master. This was not a slave or an indentured servant, but someone dedicated to learning a craft. America was founded on such a system and many of our trades grew out of this relationship. In years gone by after the apprentice was deemed worthy by the master, he could submit a work to the guild along with an approval letter from the master. This piece was his best work in the the craft he had chosen. This is the origin of the the word "Masterpiece". If approved by the guild, he could then hold himself out as a master. If you want to see what type of work a masterpiece is I can think of nothing more appropriate that the work early carpenters submitted. These were often their daily tool boxes. If you are interested google "early masterpiece woodworkers tool boxes". After you pick your jaw up off the floor, you will have an appreciation for what a master craftsman was. Within the modeling community we have the rudiments that could easily be adopted to that system. We have clubs and organizations that gather for the purpose of pleasure for sure, but also to improve the skill of the members. These clubs hold reviews of work aka contests which people submit their best work for evaluation. They give out awards that could be labeled as skill awards. Every club also has a few members recognize for their skills and ability to pass on skills to others aka master/apprentice. What we lack is a standardized recognition system. We do have large national and international contest that could be construed as master competitions. Some of those competitions might be GSL, IPMS nationals, Tamiya/Con(while it was running) AMPS nationals and the Telford show in the UK. I am sure there are others that you can name as well. I would be strongly tempted to label someone who had won those shows, or even won them multiple times or in multiple contests, as "Masters". Perhaps there needs to be a organization recognized as the Modelers Guild. IPMS tries to fill that roll, but there is much resistance to that in our automotive building community. Now I am not saying that there are not masters out there who have not competed and deserve that designation, such as Randy and Tim, but if we are to have some standard to measure the "Master Modeler " against, this would be a good one. -

INSPIRED THINKING- Cheap Tips for Frugal Modelers

Pete J. replied to 62rebel's topic in Tips, Tricks, and Tutorials

I will make a simple contribution to this thread. Spend some time on the internet and you can find often find the OEM manufacturer of many hobby products and buy them direct cheaper and in larger quantities. My best example is "Polishing kits". Typically you get a couple of foam backed pads of Micromesh abrasive, a small tube of polishing compound and some cloths. I discovered the source of Micromesh some time ago. It is made by a company called Micro Surfacing. They make all kinds of abrasives and are a quite large company. Their specialty in polishing abrasives for clear plastic aircraft parts like windscreens and canopies. However, they are more than happy so sell you a few of what you need to make your own polishing kits. Also, like most of this stuff, the more you buy, the less the shipping costs and lower the per unit cost. I buy their sanding sticks 100 at a time and they are much less that the neatly packaged stuff you find in the cosmetic aisles or hobby shops. We all use sand paper, so putting together a large order with friends can be an effective way to save money. Oh, and buy the way, this way you only get what you need. Polishing kits seem to have stuff I never use. -

Tim, stunning little part. This it the stuff that sets the best models apart! Seriously, between you and Randy, you have inspired me to get back to work on some long overdue project. I've got two Bugatti engines that need to get built. Thanks for the poke!

-

All Right! He's back at the bench! Nice work Randy. Nickle silver wire eh? Looks like I need to go on line again. My gift to myself for Christmas this year was two 12"x12" sheets of nickle silver. One .010" and one .020". Going to be doing some slicing and dicing soon. Thanks for the inspiration Randy. Between you and Tim, you got me going again. I am going to fire up the mill and get to work on a couple of Bugatti engines.

-

Hi gang! After the worst political season on record I thought you all might enjoy a different dual. This is the US Navy Band and I love this bit. Merry Christmas, and if you are someone who celebrates a differant holiday, Happy Holidays! Enjoy!