-

Posts

5,813 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

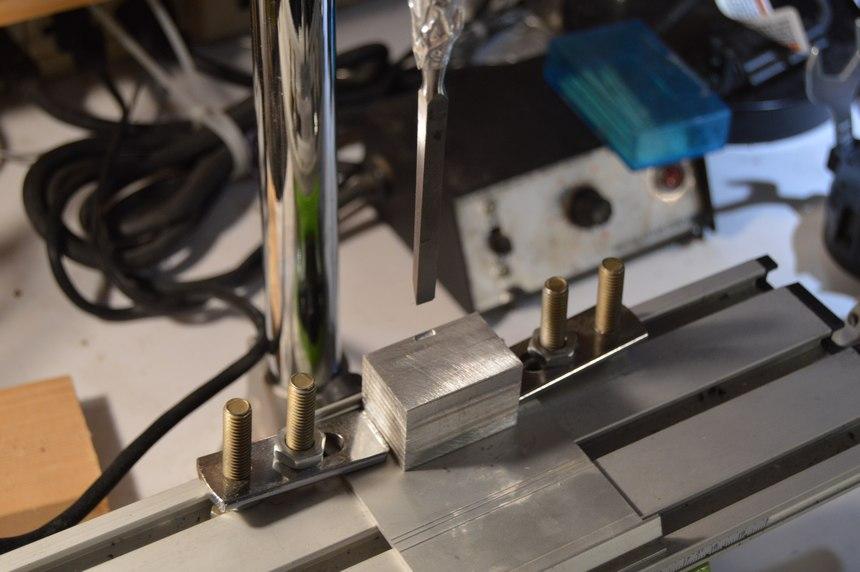

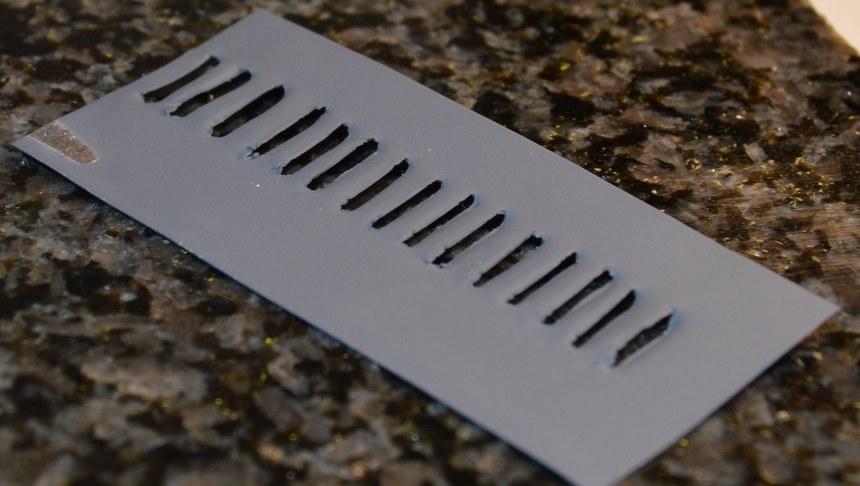

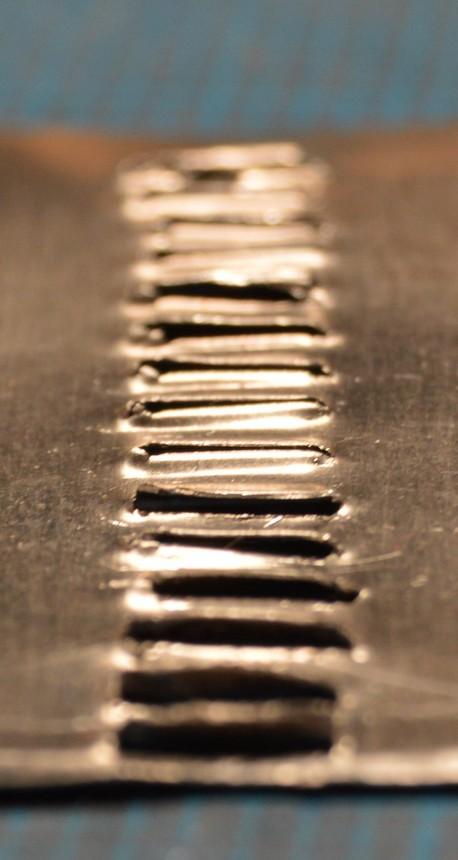

Now, we're talkin'! I cut the handle from the chisel, then turned the tang(?) down, until it would fit into the plunge shaft of my Dremel drill press. Until I come up with something better, I simply mounted it with aluminum duct tape. I milled a slot into a chunk of aluminum as a receiver and stop, to keep the size of every louver (louvre--Hi, Steve! ?) uniform. Preliminary tests are even better than prior efforts, and much easier. One noticeable difference is that the press/die method prefers un-annealed sheet. Still...

-

Thanks, Steve! Hahaha! I see what you did, there. It's good "louvre" wasn't at the beginning of the sentence. I'd have been left wondering what an art museum in Paris had to do with this! Thank you, Francis! For no more than I am going to do, for this project, it will work, just fine. Once I have a little money, again, I want to by a punch press. I think, given that, that I would be able to create them, fairly quickly!

-

It has! Welcome back to the bench, sir!

-

64 Dodge D100 Pickup Pro Street

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Excellent work, as always, Francis! You have a resistance soldering unit, too? I love mine! -

Looks nice, Mike! Do I remember you from a certain Yahoo group, years ago?

-

That is exactly what I intend to use. I've played around with it, some. Wood works okay, but leaves something to be desired. I am thinking of milling a simple, angled slot in a 1/4"X1/2" piece of aluminum, just to accept the tip of the chisel, and keep the depth, and, therefore the shape, uniform. I'm thinking that'll work pretty slick! Meantime, here's the other side panel. It will need to be cut for exhaust clearance.

-

Francis, thanks, so much, for your kind words! I am truly humbled by your comments. Glad you found it! I got the plastic coating removed from the aluminum flashing. I am excited to build the hood. I have a couple of different approaches I can take with the hinge. I am going to see if I can mill a simple die, so that I can punch some louvers--we'll have to see how that works out. ? And, no--you can never spend too much time at the bench! I enjoy watching your projects coming along.

-

"Bring Out Your Dead" Completion Build--ROUND 2 Is On!

Straightliner59 replied to Snake45's topic in WIP: Model Cars

Thanks, Rob. I appreciate that! -

It's on the wheels! I think I got everything done that needed to be, before mounting them. We'll see, I reckon! Next up is sanding the film from a sheet of flashing, so that it can be cut and annealed, and work on the hood can commence. Critiques, questions and comments are always welcome! Thanks for looking...

-

"Bring Out Your Dead" Completion Build--ROUND 2 Is On!

Straightliner59 replied to Snake45's topic in WIP: Model Cars

Well, this thread has been quiet for so long, I had to dig five pages into the archives, to find it! Wake up, B.O.Y.D.! I got this thing on the wheels. All that's left is the hood--which I am going to attempt to make from aluminum. Three pieces and hinged! Oh. And the markings. I've got this! -

I got a Speedball metal leafing kit. I am going to see if I can use it on my Indy car. I used some years ago on this Revell '34 snapper, but, the sizing/adhesive had dried up. I am going to outline these numbers in red One-Shot, one of these days, soon. I may make this one my next BOYD entry, if there's a round, after the current one.

- 39,074 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Only the first couple of times! ?