-

Posts

5,814 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

"Bring Out Your Dead" Completion Build--ROUND 2 Is On!

Straightliner59 replied to Snake45's topic in WIP: Model Cars

Yup! -

This is really impressive work! There's a certain satisfaction that comes with creating something from raw material, that I cannot imagine living without. This is inspirational, to me. Like Charles said, craftsmanship is a beautiful thing, and it's happening here, in spades! I will definitely be following this project.

-

Monogram 1926 Mack

Straightliner59 replied to Straightliner59's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

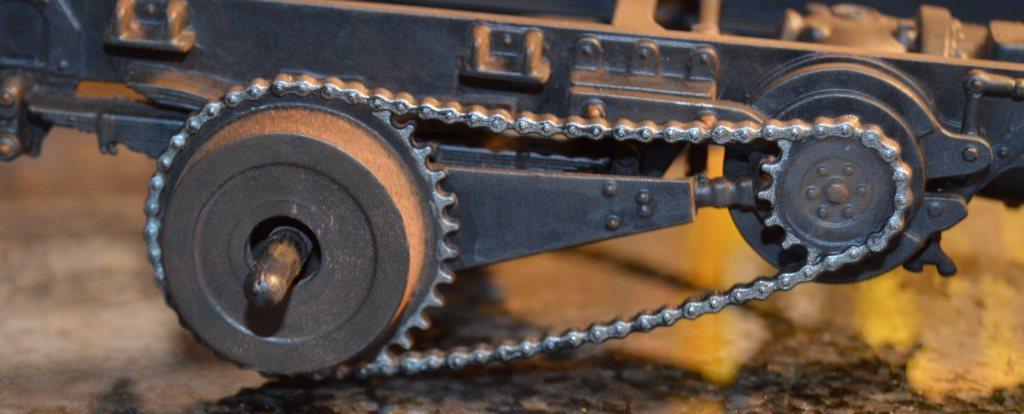

You are correct, Charles. The "slurry" I mixed for the chains looked much darker, when I applied it. When it dried, it was the same shade as the Testors "Steel" I used on the inside surface. I shall get that fixed! -

Yeah, I can see how that could be an issue.

-

Autocar Dump Truck

Straightliner59 replied to Tankman's topic in Model Trucks: Big Rigs and Heavy Equipment

Excellent work! Seems like I might have seen one of those on the road, back in the day! The weathering is beautiful. Nice job, Mike! -

It sure has! ? I know a thing or two about this affliction. I had forgotten all about this one, Art. What beautiful work you've done with the chassis. That has made a huge difference, for me. I have likely put more completed projects in the display case in the last four years, than over any other four-year span. There is one other major factor, but, having a shop that's set up and well-outfitted has led to much more progress, for me. I've also found it to be a comforting place to be. Being able to shrug off the outside world for a while leads to more creativity, it seems. Excellent work, sir. Carry on!

-

Oh, man! I love this! You know what would look really good on it? Louvers! ?

-

Indy-ish Monogram Midget

Straightliner59 replied to Straightliner59's topic in Other Racing: Road Racing, Salt Flat Racers

Thank ya', Danno! -

Monogram 1926 Mack

Straightliner59 replied to Straightliner59's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you, Lee! Appreciate it! -

Monogram 1926 Mack

Straightliner59 replied to Straightliner59's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks, Jim. I'm building the '95 release of the dump truck. This kit is beautifully molded! It lends itself well to detail paint, and such. -

Indy-ish Monogram Midget

Straightliner59 replied to Straightliner59's topic in Other Racing: Road Racing, Salt Flat Racers

Well, thanks, Art! It was mostly fun to build, too. I think the most frustrating thing were buckles for the hood straps. Man, did those things fight me! -

Monogram 1926 Mack

Straightliner59 posted a topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I just started work on this, on Christmas day. Since I finished my "Indy-ish" project on Christmas Eve, and I got the original, stake bed issue on Christmas morning in 1973, I thought it would be a perfect time for a little nostalgia. Well, without the finished in a day part! ? My focus on this project will be on paint--on duplicating colors and textures to create a realistic finish for a truck that sees daily use, is fairly well maintained, but has been around the block, a few times. I'm no going for crazy patina. The only modifications I'm allowing myself (cough, cough) are plug wires and a poseable steer axle. Not too far along, yet. I have the chassis and rear suspension put together. I am in the process of paint detailing. I really like the effect I was able to get on the hubs(?). Anyway, here is my start. Questions, critiques and comments are always welcome! Thanks for looking. -

"Bring Out Your Dead" Completion Build--ROUND 2 Is On!

Straightliner59 replied to Snake45's topic in WIP: Model Cars

I hope there will be. Even though I will be sitting this round out (should it happen, of course), I already have an old project in mind for the round that would begin in March. I love this thread! It's prompted me to finish at least three models that likely would have continued to languish, had I not committed to getting them finished, here. I know it's kept my mind from wandering, so to speak, in that it keeps me focused on the commitment. -

We both got 'em done! I just started a brand new project, so, I'm out for this round. I should have the new one done in time for the round that begins in March, should the thread continue. I have a Monogram Don Edmonds' Modified that's been sitting for 25 years, or so. Thank you, Bernard. The first thing off the bench, this year will likely be something a bit outside of my normal stuff. I've started working on one of the Monogram 1926 Macks. It's intended to be a "canvas" for me to work on paint/weathering stuff. Hope all is well, with you, too! Thanks to everyone for taking the time to comment! I really appreciate it. I am very happy with the midget--I learned a lot, in its creation. It's satisfying to see the response it's gotten from others.

-

"Bring Out Your Dead" Completion Build--ROUND 2 Is On!

Straightliner59 replied to Snake45's topic in WIP: Model Cars

Way to go, Tom! Looks good, sir! -

Thank you, Pete! Glad you like 'em! Thank you, David. The most taxing part of the paint on the Firebird was hand-striping the blue. Even that wasn't too bad, using Sign Painter's One-Shot enamel. You can see the whole process of discovery regarding the louvers, here:

-

Thanks, Les! I'm pretty dang happy with it!

-

Forklift

Straightliner59 replied to tiking's topic in All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

That's very cool! Excellent paint effects. I will refer to your photos as I work on my current project. If you only knew my history with forklifts! A shin meeting the tip of a fork, on a cold winter day? Way too many times! -

Final Completed Models this past year 2020

Straightliner59 replied to steveracer's topic in Model Cars

That looks very nice! I asked about it on the other thread, because I do have one. I have several of those Matchbox kits. I always found them intriguing. Thanks for pointing me in this direction! -

Bella's 34 Ford P/U

Straightliner59 replied to speedy5963's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Guilty! -

Hi, Steve. Not to hijack this thread, but, what are your thoughts on the Matchbox kit?

- 84 replies

-

- auto union

- c

-

(and 2 more)

Tagged with:

-

Both of these were "entrants" in The "Bring Out Your Dead" thread. Probably my biggest accomplishment in 2020 was figuring out a setup so I can punch louvers.Those are my favorite aspect of the "Indy-ish" Monogram Midget. Looks like I need to take better photos of the Firebird.

-

Showcasing my spectacular modeling achievements of 2020...

Straightliner59 replied to Ace-Garageguy's topic in Model Cars

I'd like to know how you did your photo setup! That's awesome!?