-

Posts

5,803 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Your front suspension just made me smile! -

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

What he said!😃 -

49 Ford High and Mighty inspired

Straightliner59 replied to Ferbz's topic in WIP: Drag Racing Models

You're absolutely right. I couldn't remember when they outlawed the plexiglas windows, but, I was pretty sure that windshields were always a no-no. -

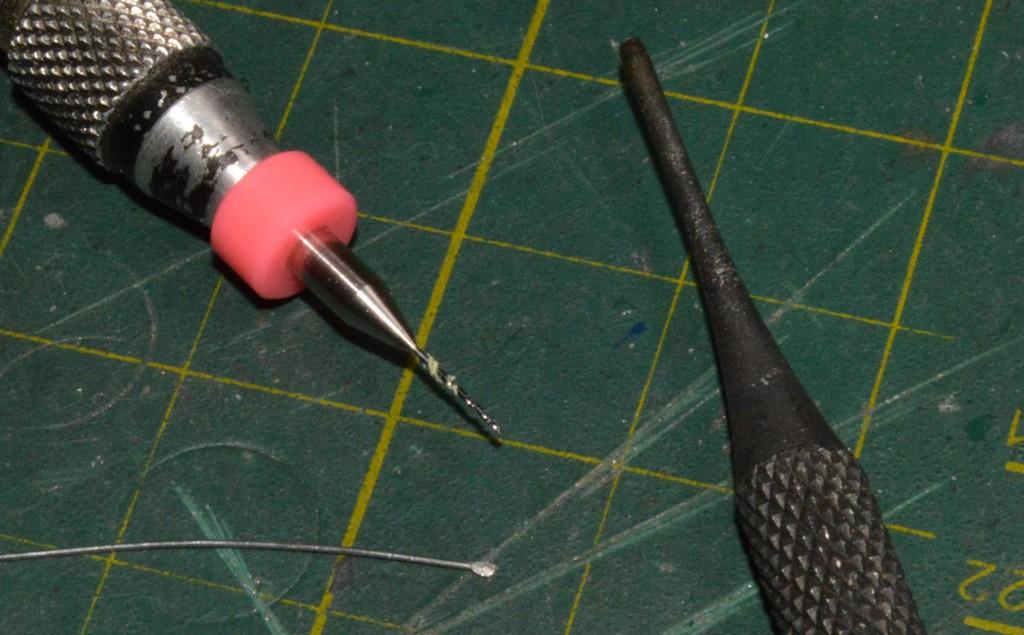

Okay, so, once the pinheads are turned down to size, I need a way to tether them together. I am using some nichrome wire that's .018", to make tiny eyebolts. I place a length of wire on the anvil, and place the end of a 1/16" pin punch on the end of the wire. A light rap with the ballpeen hammer flattens the end, and flares it. Next I drill through the flat, before using 240/320 grit sanding sticks to shape the eye. All that's left, now, is to push it through the head (which, of course is drilled through--no need to complicate things!🙂), then, hit it with a dab of superglue gel. Done! I am leaning toward some ultra-fine wire from an old armature. I think I have some that's about .003"-.005", somewhere. I hope I can get it to take paint. Some of that stuff doesn't like to! Thanks for looking!

-

Pony Express 70s BB/FC ex M/T Pinto

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

I've been making my own decals, the last few years. I honestly think it's one of the things that's made it more interesting, for me. It used to be that I'd be digging through boxes of decals, and still never find anything I liked, as far as race car graphics go. Now, I can think of a name, and start designing. I love that! For the Badman, and the Nostalgia Top Fuel car, I printed layers (maybe a slight drawback, but, Cady did it that way, for years!), then painted, or, in the case of the Badman, applied paint, or leafing adhesive and gold leaf to one layer, then using the second layer for outlines. I am really looking forward to getting the decals on the car, although it's still going to be a while. These look super-nice, Ian!- 63 replies

-

- brass chassis

- not a kit

-

(and 2 more)

Tagged with:

-

Mercedes Benz SSK

Straightliner59 replied to Pierre Rivard's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Excellent work, Pierre! You're off to a fine start, my friend! -

Thank you, gentlemen! I think I have the problem of tethering them together figured out, now. Photos, later! Thanks for checking in!

-

Model building on youtube.

Straightliner59 replied to Force's topic in Model Building Questions and Answers

A4 Garage is excellent! There's Kenji's something or other, too. -

I stopped at a different Walmart, today, to get some more yellow-headed pins. This one had boxes of nothing but yellow pins! I should be set, now.🙂

-

Thank you, Tim! No need for apologies. Other stuff gets in the way, from time-to-time! Caboose was awesome! It was so easy to get lost in there, for a couple of hours. I appreciate you stopping by, my friend!

-

Beautiful work, Tom! Love your finish work!

-

Thank you, Andy! I guess I'll just add, here, that this is my only completion for 2024. I finished it in January, and have been working on a "quick and easy" Badman project, since!😅

- 61 replies

-

- scratchbuilt

- brass

-

(and 1 more)

Tagged with:

-

Well, I think they look pretty, together! I've got a good start on the injector hoses, too. Turns out, I'm going to need more yellow pins, anyway--a couple didn't stand up to the sanding process, even as gentle as I could be. So, I need three. I am going to try my hand at "ship-rigging" to tether to balls together. Kind of interested if I can make it work! Thanks for looking!

-

Scalpel/surgical blade question

Straightliner59 replied to johnyrotten's topic in Model Building Questions and Answers

I get them on Ebay. ten or eleven bucks will get a hundred blades and a handle! I've been using them, the last few years. I love them! -

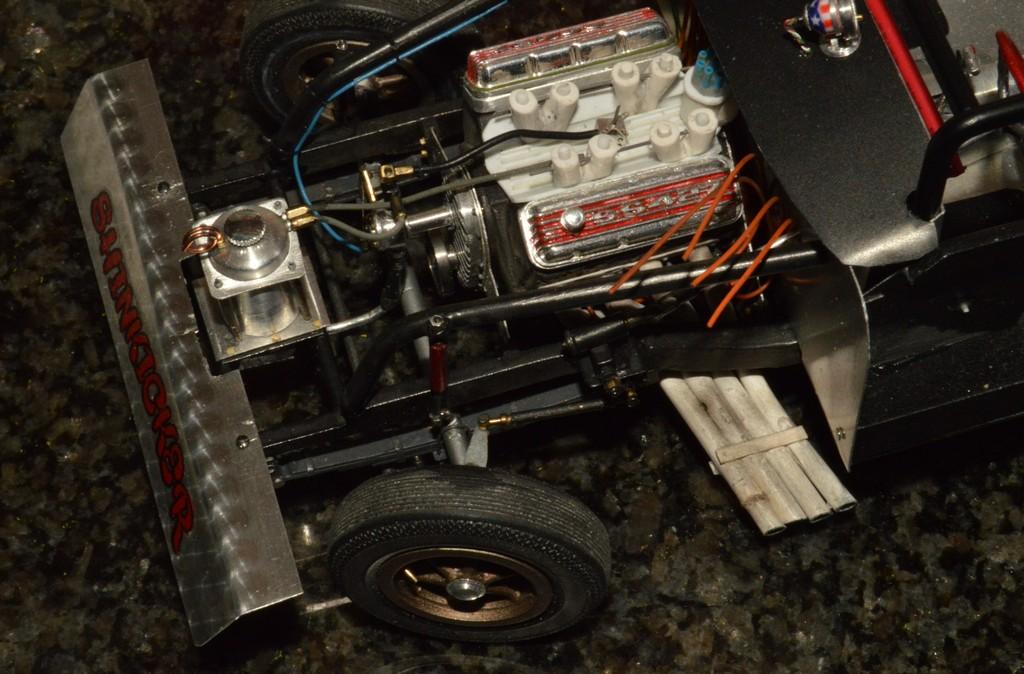

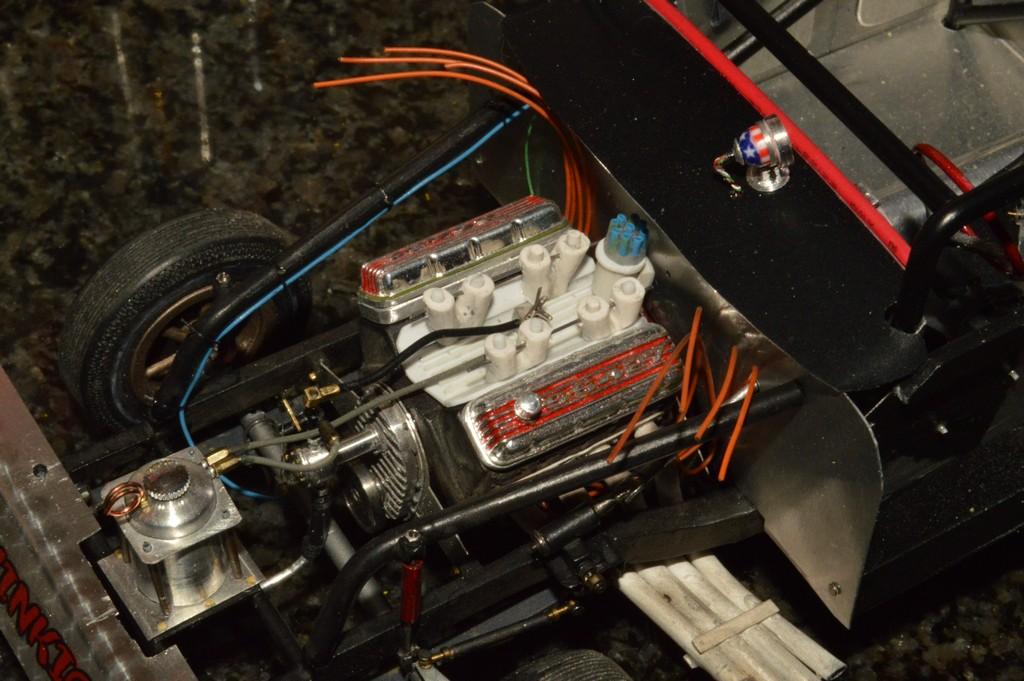

I decided to shoot some metallizer aluminum on the manifold, to see where I stand. I liked it enough to shoot some flat clear, over that. I installed the fuel block, and did a little work on the mag, but, I suspect that'll be redone, completely.😄 Now, i need to drill the throttle bodies for the injectors--I had planned to do that, before I painted the manifold, but, I didn't want to strip the paint, so... I shot clear purple over half of the stacks. The other four will be amber-ish. I used Parafilm to mask the bases. It's perfect for these instances, because it has a straight edge, and it conforms to anything. It's designed, originally for laboratory use, so it doesn't leave residue. I'm sold on the stuff, thanks to Andy Sapiro. I'll see if I can't finish up the injectors and lines, today, along with the paint on the remaining stacks. I was looking for something to use to plug the stacks, to keep objects out of them. Tennis balls seemed logical. I found a box of quilting pins with 3 mm round heads. They're too big, in their natural state, so I chucked one in the lathe, and sanded it to size (regulations call for tennis balls to be from 2.57"-2.70" in diameter--day-glow yellow balls first came into use in 1972, so, we're good, technically and chronologically! The things we learn, because we model!😂). The sanding gives it a look to the naked eye, of a fuzzy texture. Only one problem: the box I bought only had seven yellow-headed pins! Questions, comments and critiques are always welcomed. Thanks for looking!

-

Some might say that "mediocre" is being kind!😀

- 39,065 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Very nicely done! Those parts are beauties, Francis. -

Pony Express 70s BB/FC ex M/T Pinto

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

This illustrates one of my favorite aspects of working with brass. Properly done, there's way more durability. It's easier to make changes, should they be necessary. It's possible to use things like wire, to aid in conformability. Great work, my friend!- 63 replies

-

- 1

-

-

- brass chassis

- not a kit

-

(and 2 more)

Tagged with:

-

It sure is!

-

Yeah, and the properly-sized Monogram slicks had wonky wrinkles on the sidewalls, which would have been fine, except that when you put them on the car, they were wrinkled in opposite directions!

- 39,065 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Thanks, David! My experience working on real race cars is minimal. I've hung out with a lot of guys who do/have, and I've spent a lot of time hanging around the pits at drag races, and picked up a lot of that little stuff, just from being around. Honestly, I kinda hate working on real cars!😅 Until I'm done, then I feel like I accomplished something!

-

Pony Express 70s BB/FC ex M/T Pinto

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

That's a great-looking body, on that car. I usually hate those front wheel bubbles, but they look good, here. This will be cool to watch come together!- 63 replies

-

- brass chassis

- not a kit

-

(and 2 more)

Tagged with:

-

I seem to be having "the trouble" again, in replying to this thread. I've got a few things worked on, the last few days. I washed the fuel fittings with a Vallejo grey wash, to tone them down. I used my doming block to make caps for the pushbar. They'll most likely get painted black. I made and installed the pittman arm and drag link. I used the eraser drill, again, to drill the dash because I forgot to make and install a handle for the fuel shutoff. Duh! Finally, I milled a fuel block from aluminum rod. I think it worked out, pretty nicely! I should be really getting into the manifold, pretty soon! As always comments are welcomed. Thanks for looking!