-

Posts

9,217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by peteski

-

Yes, that clear-coat-like Tamiya metal primer. I have it and I used it, but I'm still l leery about it. Why clear? Primer is supposed to provide a smooth and even color base for the top coat. It doesn't dry flat. Clear also doesn't hide any imperfections or difference in colors between dissimilar metals (like brass and solder). I'm wondering if this is one of those funny Japanese to English translation errors, and it is not a primer at all. I wish Tamiya provided a better explanation or instructions as to why clear is good as a metal primer. As for the vinegar etching rinse, I assume Dave is describing household vinegar. That has a concentration of only 4%. Diluting it 50/50 with water would yield a 2% solution. You probably have to let the metal item in that solution for a week to get any appreciable etching. Having said that, I do sometimes etch my brass parts in vinegar, but I use a 25% Vinegar concentrate, and let the parts sit in the solution for few minutes. Also, like Ace mentioned, they have to be degreased first (acetone works well), or or grease/oil will act as a resist and vinegar will not touch those areas.

-

Resin bodies and paint

peteski replied to DoctorLarry's topic in Model Building Questions and Answers

It is possible that it is the resin that is leaching some chemical out and affecting (softening) the cured paint. Just like the "tire melt" with vinyl leaching plasticizer (thick fluid) which then softens the plastic in contact with it. That also takes months or years to happen. That's why I asked you if you had other models made with the same resin and painted using the same paint to see if they were also affected the same way. Your original post seems to indicate only a single model having the problem, but the post I quoted now seems to indicate "cars" or multiple models, but still no answer as to whether a single or multiple models were affected. -

1948 Cadillac Series 62 Club Coupe 1/25 resin kit by RedWheel

peteski replied to Red Wheel's topic in Car Kit News & Reviews

Ok James, call me "educated". -

Resin bodies and paint

peteski replied to DoctorLarry's topic in Model Building Questions and Answers

My first thought is that since it is your own casting, do you have other models you cast using that same exact resin and painted with the same paint combo? Are those sticky too? Your post also implies that the paint was not sticky shortly after the model was painted, correct? The stickiness developed after a relatively long time? -

How to Smartly Aquire Vintage Kits?

peteski replied to Falcon Ranchero's topic in General Automotive Talk (Trucks and Cars)

Just because some eBay seller lists a kit for $700+ that doesn't mean someone will buy it. If you start watching that listing you will likely see it just sitting there un-purchased for months or even years. You can thank the current eBay fee structure for this. They don't charge for how long the item stays active. But the greedy sellers work that system, hoping that some sucker comes along and buys it for their outrageous price. eBay of today is nothing like the eBay I joined (and used) 25 years ago. -

We have had that problem in USA for decades. I recall that either David Letterman or Johnny Carson used to have segment where they asked people on the street various geography related questions and a lot of the passers-by flunked it miserably. Even questions related to American geography. But yes, the technology dies seem to make this even worse. Why learn things when you can look everything up on the Interwebs? The problem is that your brain atrophies, and the info you get from the Interwebs can be just plain wrong!

-

That is beautiful Les! You're lucky to see the Northern Lights. I'm in Massachusetts and was not able to see any of the light show. Even a month or two ago then the Aurora was even more intense I did not see it. Probably about 15 years ago my mother told me that she was out shopping in town (in the same area I live) and she saw a beautiful light show like that all the other passers-by were mesmerized by it. I missed that one too.

-

Well then, I did offer a "plan B".

-

Assuming kfif was a typo, here is an explanation: https://fileinfo.com/extension/jfif Google (or DuckDuckGo) search is your friend.

-

1948 Cadillac Series 62 Club Coupe 1/25 resin kit by RedWheel

peteski replied to Red Wheel's topic in Car Kit News & Reviews

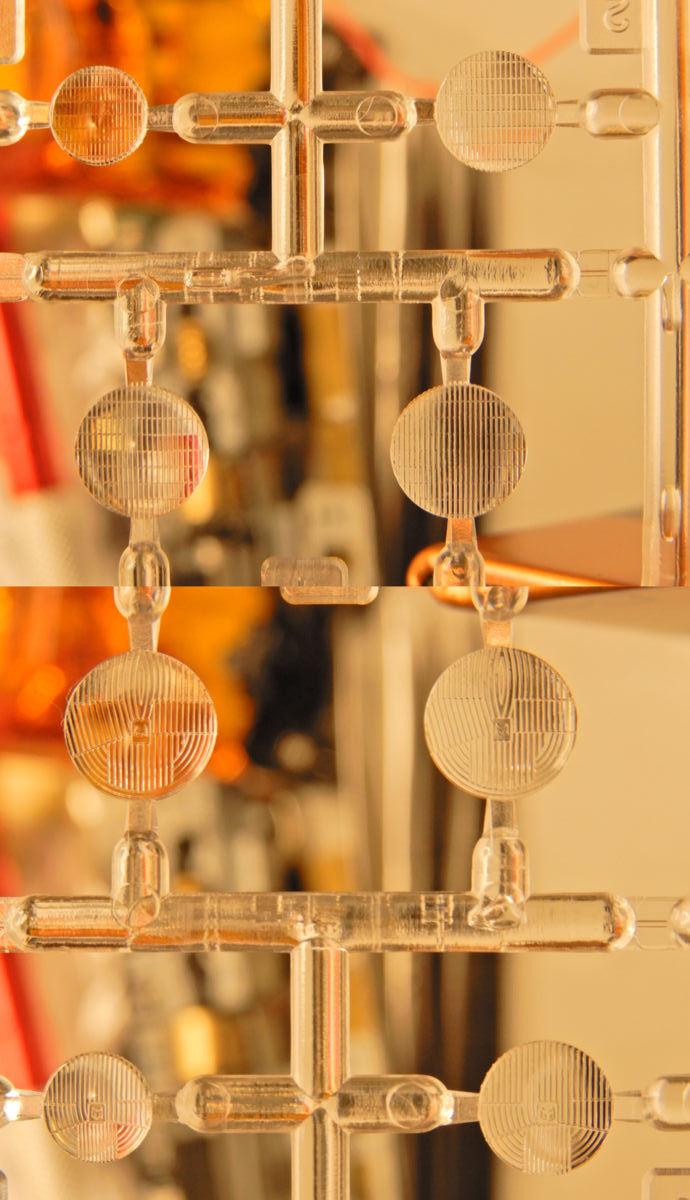

Looks very interesting, but with just the bottom of the engine showing I would not call it it a "full" kit, but a "curbside". However I guess as the aftermarket resin kits go, I would call it a "complete" kit as no additional donor kit parts are needed. This small discrepancy in the description might be due to Ukrainian->English language translation issue, and I'm also just splittin' hairs. It looks to be an excellent quality kit. I might just splurge on this one when it becomes available. I also have a suggestion: Headlights are one of the items which make a big difference in the model's realism. They can make the model look like a model or a fine scale replica of a 1:1 vehicle or like just a toy. Would it be possible to redesign the headlight lenses to have a more realistic texture? As shown in the photos, your headlight lenses just have horizontal lines in them. Those lines are also rather thick and evenly spaced. That to me does not look very realistic. Actual headlights have more complex pattern of striations. Look at the real 1948 Caddy headlight. As you can see, the lens has mostly evenly spaced vertical lines with varied spacing between them, and some horizontal ones too. Lens is quite complex and I don't expect the model to have such complex texture, but it would be nice to make the model headlight a bit more like the real car's headlight. I don't expect that 1:24 scale model will have headlights with such a fine and complex texture like 1:1 vehicle, but they can still be made to look realistic. Here are plastic 1:24 scale lenses made by company called Modelers. To me they are very realistic looking. They have a finer texture than your lenses, and while not as finely textured as 1:1 lenses, the pattern looks closer to 1:1 headlights than your lenses. I suspect that your headlight lenses were designed in CAD, so there is a possibility you could redesign them to look more realistic. That would greatly improve the appearance of this excellent looking model. -

Lacquer thinner for airbrushing enamels?

peteski replied to Steamboat's topic in Model Building Questions and Answers

Be careful with that. Nail polish removers can have skin conditioners mixed with the acetone. Instead of trying to be a tightwad, just get some "real" acetone from the HW store. It's not *THAT* expensive. But I would not recommend using straight acetone to thin (or reduce) paint which will be applied to a plastic model (with or without primer applied first). Also, acetone evaporates very fast - could be too fast for the paint to level properly. -

Thanks for starting another of your very enlightening threads Justin. It is interesting to see the hobby world and the type of stats you are presenting for a hobby shop's perspective. How did the automotive hobby kit sales compare to let's say Gundam or model trains? That might possibly be another separate thread. I believe you had one like that earlier in 2024.

-

Thanks Tim! I was also quite happy with how the wrecker photos came out. I had my Nikon FG sitting on the ground (with me also lying on the ground) to make the photo appear to be taken by a 1:25 human holding the camera at their eye level (how photos were taken back in those days since one had to look through thye camera's viewfinder). I also used a wide angle lens (28mm) to slightly exaggerate the perspective, and f32 aperture to maximize the dept of field. Back in those days you had no idea how a photo came out until you had the film developed. How things have changed since those days . . . The '50s cars are actually 1:32 scale so those are even harder to make them look like real cars. If I recall it correctly, the photo of my 1:8 Mercedes was my first attempt to try this type of photography. Here are few more photos I took during that photo session. I also wrote a magazine article about that wrecker (including these photos among others featuring some construction photos) and sent them into FineScale Modeler Magazine. They accepted it and even paid me, but the article was never published. Not sure why. It was my first attempt writing an article so it probably was not very good, but I suppose the editor could have punched it up a bit. Again, this was around 30 years ago and back then FSM pretty much was into non-automotive subjects.

-

Alternate Fuel Challenge 1970

peteski replied to Falcon Ranchero's topic in General Automotive Talk (Trucks and Cars)

Electric cars go even back much further in time. Here are some examples: And this is my favorite. There are many more examples. Just look for "early 20th Century electric cars". -

Pretty clever idea. Back in the days of film 35mm SLR cameras (about 30 years ago), I used to take my models outdoors to a setting where buildings and vegetation were far enough away to make the model appear like 1:1 scale vehicle. Since 1:1 asphalt texture is too coarse for realistic 1:25 scale look, I placed the models on a sheet of rubber roofing material which looks like scale asphalt. And I agree that natural sunlight/shadows add to the realism. Here are some examples This one is 1:8 Pocher kit. With a larger scale model the 1:1 asphalt (no rubber mat) looks a bit rough, but not too unrealistic.

-

Lacquer thinner for airbrushing enamels?

peteski replied to Steamboat's topic in Model Building Questions and Answers

Your "thinner for marine coatings" does not mention on the label that it is a "lacquer thinner". Pick up a small can of actual lacquer thinner from a hardware store and test it out. Also different brands of lacquer thinners have different formulations, but generally they all work well with solvent-based enamels like Testors. -

Stynylrez Primers and winter

peteski replied to Kromolly's topic in Model Building Questions and Answers

I still mostly use the old-school stinky paints, but I do some painting using water-based acrylics. I have never actually tried to test the "protect from freezing" warning. If you want to try, just got to any hobby/craft store and pick up some inexpensive craft paints. Those are water-based acrylics enamels. Then give them the freeze-test. -

Stynylrez Primers and winter

peteski replied to Kromolly's topic in Model Building Questions and Answers

More and more people are switching to water-based acrylic coatings due to their lower odor and toxicity over standard solvent-based coatings. All water-based paints and other compounds (like wood putty or spackling compound) will have "protect from freezing" warning somewhere on their labels because . . . they are water based, and water freezes. Once the water freezes then thaws, that affects the chemical composition of the paint, making it unusable. In your situation I would recommend buying in warmer months and applying it in temperatures above freezing. -

While I don't doubt that, I believe that the 4-wheel steering is disabled at highway speeds.

-

Rare/unusual auto options.

peteski replied to Chuckyg1's topic in General Automotive Talk (Trucks and Cars)

Those were actually popular for quite a few years on a range of different cars. They also included a washing fluid nozzles and later the wipers were replaced by just high pressure washer fluid nozzles. To me those would be more mainstream than rare, but they were unusual. -

Taillight Quiz #5 - Finished

peteski replied to carsntrucks4you's topic in Real or Model? / Auto ID Quiz

-

Sounds like some extra snuggling sessions are needed to keep the domestic peace. Shouldn't be too difficult. And when the partner is asleep, you could sneak out of bed and be that night owl. If that doesn't work, try knockout drops in hot cocoa.