-

Posts

1,462 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by mr68gts

-

Tim, The Ti really isn't needed for the model even though there is a slight difference in color from Al to Ti. (which I can easily replicate with candy color in light coats if I choose.) I have a probably 6 inch piece of 1/2 round bar that has a unfinished knee joint piece on it and a couple of cut offs. (didn't pass initial inspection for first article.) Neat thing is I have had it for 10ish so years and it still looks like it came out of the 5 axis this morning! It is a pain to machine, worse to press something into! THe slivers are horrible to get out of your hands and they always breaks off trying to pull them out. Best to leave the m in a fester out so to speak. We had Sunnen spray to press planetary pins into the Ti planet case. (Lenco uses 7AL4V normalized) It sure makes pretty bright white sparks when grinding it. Bright white and highly flammable/combustible I would guess you say. We always used lots of coolant when machining the parts so I don't think the combustion was an issue since it was flooded most times. Not necessarily spontaneous combustible, still needs a spark of some sort. Magnesium was entertaining to machine.....needed lots of sand in buckets or you could catch the lathe or mill on fire! Sand is the easiest way to suffocate a magnesium fire. No liquid! I'm not sure what grade of Ti I have but it's pretty hard I noticed. While I can machine it with a different insert in the holder, I don't think anyone really cares if the half shafts are Ti or not. Not sure if the standard carbide end mills I have will hold up to the ti or not. Everything we used was indexible tooling. I'd have to hit the books and see what insert is required and truthfully don't want to spend a whole lot of time doing that while I have at least a little momentum going lol. Thank you Art! Ready to pull out that brass modified you were working on again? he he. Cal, Last piece of raw Titanium I saw the price on was $900.00 (back in mid 2000 mind you) for a 7 inch diameter, maybe 4 or 5 inch tall chunk of round bar. What you are looking at are real deal 70's factory Porsche Works half shafts. That along with the price of Ti makes it the price they are. And the price of raw unmachined Titanium is highly volatile depending on current markets for military and/or medical. (mostly military drives the prices up or down depending on demand.) The 934 was a little bit different from the 935 but some of the photoetch would or should work on the 934 and I know a few people at least have done just that. I worked aerospace for a while that also did medical stuff so we'd get in Ti here and there for knee parts or eye socket parts. I had to debur eye socket replacement pieces under a microscope....talk about a headache...lol. That's how I ended up with the Titanium. Saw some really cool stuff doing that job. Some I cannot discuss, but I know why certain things cost so much when the military says this costs x amount.... Back on track, so far what I have been posting is stuff that has been completed and sitting in bags forever now. (seriously, ask Pete! LOL) I hope I can have a current update on something for it soon but there is a lot of stuff that would be missed so I will occasionally upload more pics to get everyone up to speed as to what has been done up to this point. Paul

-

They were pricey to begin with and limited in numbers. Mine happens to be #319 of 505. I believe Matthew had enough parts to produce a few more but do not know if that materialized. They have been out of production for probably a decade at least. I myself haven't seen one for sale in a long time. I know not all have been built so someone is hording them. Kind of like the 956/962 super set they did. Also limited in numbers. I wish you luck in finding one. Im sure you will end up paying more than original retail price if one does turn up. With that said, the kit itself with some minor detailing can be made into a show stopper even considering it is a very old kit! Paul

-

So, I have been researching the half shafts for this model to accurately machine. Dunno if anyone knows this but many of the 935s used titanium for the half shafts. I decided to play on the lathe for a bit. Dug out the titanium bar stock I have laying around. (Dont ask....lol) I use inserted tooling (indexable tooling as its called) so I have the ability to machine it IF I wanted to. I am not going to use ti however but I did want to see if I could machine it. Aluminum will work just fine for this model.....maybe....lol Paul

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Thanks Chris, I think that's what is going to happen. I found a bunch of brass available in close to the dimensions required to go brass so yeah, it may not go back...lol I actually contemplated it when I started redoing the chassis this go around. I suppose 3rd time is the charm? Nice crown lol. I'm not stealing it though. It may be a while however. Maybe instead of printing it we can make it a virtual crown? lol. This way it won't get lost going back and forth between us ha ha. I got your message. I'll get with ya later today. Paul -

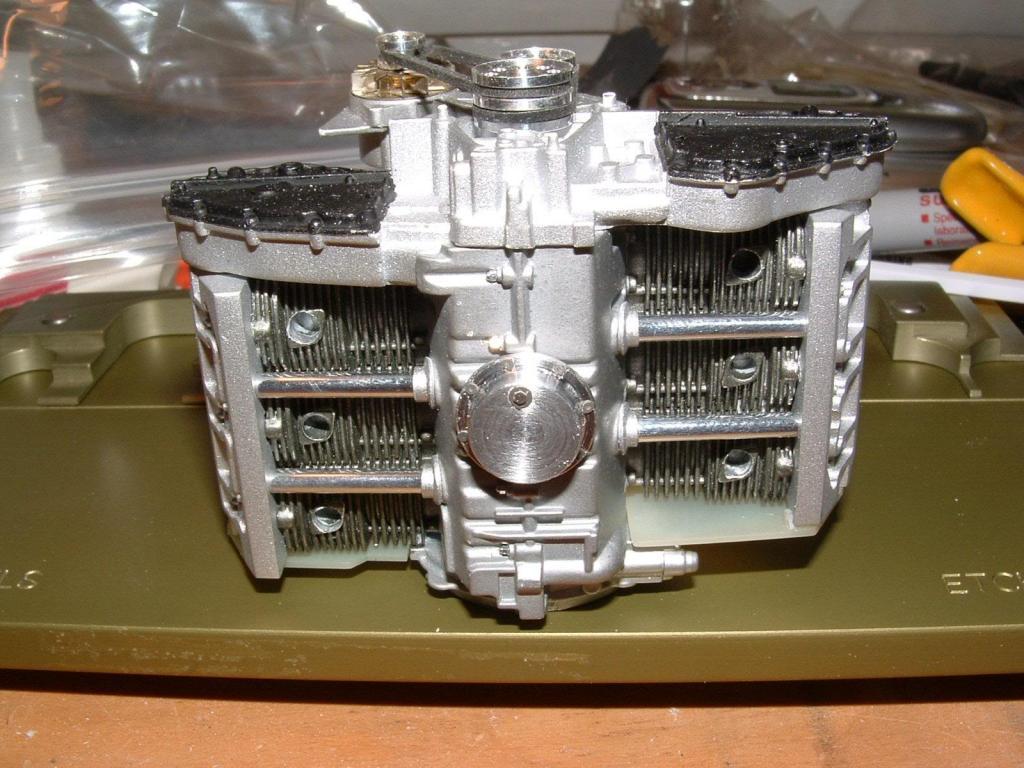

The front bonnet with most of it stuffed in there. No room for a spare....

-

Pete, The half shafts has been the hang up on this the whole time actually. Now that I have the mill, it is the first thing I want to tackle. I couldn't bare to put the plastic shafts in it.

-

Pete, Thanks. It should look familiar lol, it's the same one I've set aside for almost a decade? lol blow off valve assembly. Only kit parts in this piece is the tube and the cover. The rest is all scratchbuilt. (faster than trying to clean up kit parts!)

-

With the promod on hiatus it is time to get back to this long stanging project. The 935 Porsche with SMS set and many macbined parts by me and Robert at RB Motion.

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Thanks Randy, Not an update but this will be on hiatus for a while. The chassis got pretty busted up when I dropped something on it pulling it out of the trailer after GSL. There is a looong standing project that has needed a mill to complete to the level I wanted. Now that I have that I will pull off of this for a time. The other project is pretty far along actually so its feasable to be back on this by the end of the year.....maybe....lo Paul -

Maybe out of brass and 3 parts.... The basic shape of the blower case with the base, then ribs, then the injector mount. This way it can be soldiered maybe?

-

Several times with no problems. Great place to order!

-

Current race car decal question

mr68gts replied to NYNS Franky's topic in General Automotive Talk (Trucks and Cars)

I would clear over any kind of stripe or basically anything that would or could be painted on, and then apply the sponsor decals. Gentle waxing usually doesn't affect the decals left out and if it does, it is a race car so it gets banged up. I have done mine this way for years with no ill effects. -

Hot wheels hiway robber replica in ,1/25th scale

mr68gts replied to Kazual's topic in WIP: Model Cars

Ah yes! Something I have had in mind for years to do. (Just not that particular hot wheels.) Looks good. Maybe round off the corners of the cab some more as a suggestion. -

Your own building on your property would be the best bet if you were not in an apartment. To have to pay the overhead of rental space and such makes it too costly to operate something that is a very little money maker if any at all. Even then there are insurance costs involved with a home business. Home owners insurance does not cover the business side of things. And small time operators may not get the best deals on kits and such as there I am sure different levels of discount. I have looked at doing something similar but in truth would really only be a playground for me and an outlet for my hobbies. Probably not something I want to do on my days off. To convince a chain to come in would be more work than worth. There are I am sure certain criteria that must be met in order for them to even consider looking at an area, The company will not want to start up a new location if the retail structure isn't there to support it. Unfortunately for many of us who would like to have a retail store of our favorite hobby, it is a pipe dream that takes more work and money than most people are willing to put into it. Not saying you or anyone else wouldn't succeed and I certainly hope you or anyone else does but the likely hood according to statistics tells otherwise and quite frankly, numbers don't lie, unless you are lying to yourself about the numbers. Paul

-

I can only imagine what Chris said.... lol! Beautiful work and great inspiration as to not only how to do something in scale but also the ability to be able to do it in scale. I can only reiterate not only what I have said in the past about this model but also what others have said about it. I was going to take a picture of the Chevelle sitting in the waste dumpster as a funny but am on the road for a while longer and the only waste dumpster I have has food in it at the moment lol. (yes I have the Chevelle with me as I displayed it at GSL) Paul

-

nice job. what did you use for the lug nuts on the front wheels? Paul

-

Also vital and something I do as well.

-

I do the same thing as you guys. I will edit post quite often and sometimes because of using 2 different photo management sites have difficulty remembering which link to use lol. So I edit a lot for spelling and other screw ups not related to any kind of language etc. Really like to see this back. And as for the inappropriate conduct I am with who ever said it. Kick them off the board and done. Easy peasy. Paul

-

Any of the later pro stock kits will work. They havent changed much and the only thing you may need to change is the cage to fit the body. Also depending on how much of a stickler you are for detail and correctness, there may be some reworking/updating to the cage. (Added bars to frame structure for safety and strength.)

-

Much of the color depends on the make up of the magnesium itself I think. Alodine is uses on mag also and even "pickleing". The Dow7 coating we used (had magnesium trans cases dipped) came out a greenish hue that turned greyish with age. You should see a mag part polished abd then dow7'd! Stuff looks cool. Almost like a dark greyish candy green!

-

65 Mustang promod /streetracer coming soon

mr68gts replied to ShakyCraftsman's topic in WIP: Drag Racing Models

Here's that FORD Jimmy is doing! -

65 Mustang promod /streetracer coming soon

mr68gts replied to ShakyCraftsman's topic in WIP: Drag Racing Models

Ron, They do. They are stock type engines if you wanted to go that route. I found the guys name and some pics so if Photobucket is operational I will get them up of his Ford he is designing. It's a pretty nice piece. Guys name is Jimmey L Fogolini. Scroll through facebooks TDR site and you can get hold of him that way I'm sure. Here's the clicky... https://www.facebook.com/groups/1441607229444690/ I know in my case, my 481x long block set is 38.00 in 1/16 scale. There's a lot of material in there and that jacks up the prices quickly. D Depending on how much of a stickler you are for parts in scale, there are parts out there that just simply are not correctly scaled. Rons chassis while I'm sure is a nice piece, there can be no substitute for scratchbuilding it as it will fit your body correctly. It may be a headache to build it yourself but at least you will know it's right and not have to shell out money for something you will possibly have to rework in the long run anyway. Chassis aren't that bad, one tube at a time....lol Paul -

65 Mustang promod /streetracer coming soon

mr68gts replied to ShakyCraftsman's topic in WIP: Drag Racing Models

Someone was designing a pro mod/ pro stock Ford engine recently in scale. I will see if I can find them. Want to say they are on Facebook on TDR's facebook page. I'll take a gander and find out. Also, Yellowbullet has a ton of pictures of what I believe is this very Mustang through pretty much all the stages of the build. (that place is a huge invaluable source for pictures!) Between them and Dave I'm am sure there can be enough pictures to make it happen! Paul -

Tim, Thanks for the tip on the cutting oil! All the brackets are looking phenomenal! Can't wait for the next update. Paul