-

Posts

1,464 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by mr68gts

-

I'd probably be good for a couple sets depending on price.

-

Not coming up on mobile

-

These were actually done using the old Straightline Modeler method that is no longer available online sadly. Quite labor intensive as you clean up the rings. build hub halves from scratch and lay individual spokes made up of .010 round stock from Plastistruct following a pattern laid down. Works pretty good but they are extremely fragile!

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

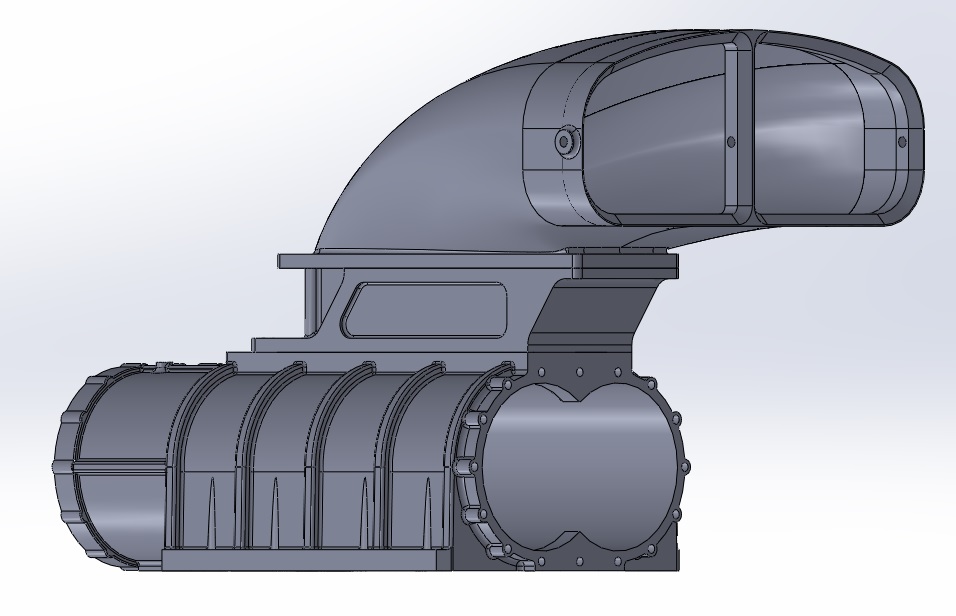

Thank ya brotha! Pretty nice to be able to concentrate on this now that we are all moved out. I finished up the spacer and the scoop this morning so onto the oil pump I go! I will holler at you this weekend if your going to be around. Paul -

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Tim, thanks, sometimes it gets a bit busy lol. Little bit of an update. Got some time on the computer finally! Managed to get the hat spacer almost done. (i need to move the top foward lip out more to match up with the scoops flange.) Oil pump is next. Hopefully by the end of the weekend I can put in an order at Shapeways for these parts. I think that's all that is left of the engine parts anyway! Paul -

http://scratch-builder.blogspot.com/2012/07/jd-wheel-spoke-lacing-19th-scale.html

-

Dave, Flow numbers I have seen on the W9RP's have been 380 ish to 400 range. There are 2 types of P5 heads. The first or early style was the non Hemi and the later version is the hemi style head. Although they are both a Polysphere and not a true hemi. The later head requires a split lifter pattern (48 and 59 deg angle) The block I have is a straight 48 degree block. Also the P5's have from I have seen moved bore centers and require an R4 block. I actually almost pulled the trigger on a new in crate R4 block but they are all short deck and iron so I chose this block instead. (9.6 deck height vs the R4 of 9.0 roughly) Yeah the lifter valley is completely closed in on my block but the bottom of the cam tunnel is open to the crank case so there can be some oil flung from the crank but I don't know how much the dry sump under vacuum is going to control that. Maybe low vacuum would be best. I was thinking a 4 stage with one being in the valley but a 5 may be better for me. (do they make an H beam rod with pin oiling?) I have an idea for a oil pan that can use the windage to help shear the oil from the crank. Dunno if it will work or not but I will design it and talk to maybe Olson and see what they think. I also need to design up my intake which once I have the heads I can figure out something for that. I think I can run the machined parts through work but I will talk to them and see once I get closer. I've got a lot of research to do yet on this thing, that's for sure! Will do on that scoop. I was reworking it when things went haywire again so I think it was close when I stopped. We thought last Monday the house was going to be someone else's but their lender didn't like something so it fell out of escrow literally right at the last minute! I wish this roller coaster ride was over lol. Won't be until we have our own place again though. Happy Thanksgiving BTW Paul

-

LN8000 transporter updated 11/19

mr68gts replied to mr68gts's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Little bit of an update. I've spent the last few hours building a door jam for the drivers side. I decided to go ahead and cut out the door last night. Kinda nice to be back on the bench. What little bit of it I have as we have completely moved out of our home in the mountains to put up for sale. I am doing what I can with what I have to work with. I still need to do the passenger side, mirroring what I have done on this one. It has taken a while to find enough reference for what I needed to make the door jams. I may go ahead and make the door frame also at this time, later today. I also need to add the ribbing to the floor pan. I did add the framework to the underside of it to try and tie it all into the firewall. I want to cut the hump off the firewall and make it like it is removable. (won't actually be removable but there is a lip missing and it also needs to go into the floor some.) Still lots of work to go. Paul -

Dave, I really like the Olds covers! Things look bad A$$ on there! Dang I like tunnel rams and Dominators but the temptation to go EFI twin turbo is too great lol. I guess I figure if I have a 2000hp capable block I might as well use it right? lol. The um, Dart is going to need some "restructuring" though haha. With your dry sump do you run a scavange in the valley? I'm researching dry sump systems for mine at the moment. Some have said that if the pump is pulling to much vacuum that they have had to run piston squirters. like the updated front end btw. I will be back in action ont he SW parts soon enough, got a lot of catching up to do on some things. Paul

-

outstanding work my friend! Can't say enough about the way this thing is coming out! I haven't said much and mostly lurking due to some constraints on my time but I have been keeping track of a couple of peoples projects and this is one of them! Paul

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Brad, initial answer to your question is yes but that may change. I dont have anything but we will see what how I feel come Saturday lol. Chris, thank ya brotha! It will be good to take my mind off of things while building. Dave, christmas came way early lol. I really need to put the block on a stand. There isnt much in the way of heads worth a darn for a small block mopar unfortunately. Mopar w8 or w9's seem to be it. The new Eddy victor heads flow decent but are not 18 bolt pattern. (Dummies used the 10 bolt pattern lol.) Either mopar head will run me over 2500 for cnc'd castings bare. Victors about 2500 complete without the potential or clamping. Just have to see. Was thinking 450 inch but turbos like under 400 so maybe 3.79 stroke with the 4.130 bore. One part at a time....lol -

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Back after a brief recess.... little bit of life has gotten in the way of this for a while. We have finally as of Sunday completely moved out of our house in the mountains. ( I swear everything multiplied every time we left and went back for more stuff.) The house has been sold and should close soon I hope. (nothing on our end of things) Then this shows up on my doorstep he he. I am a car guy after all! What you are looking at is a Mopar 410 Sprint Car block! Only it is NOT going into a sprint car he he! Hopefully twin turbo it will be my longest build yet....lol. (and most expensive too!) This block came from Mopars back room storage. It is a small block, all aluminum (with water capacity) I did buy the special gear drive and cover for it also. Just gotta collect the rest of the parts.....$$$$ Any who look forward to having some bench time soon! Just in time for the holidays right? lol. -

Warning! DO NOT USE RED FROG HOBBIES!!

mr68gts replied to superbike-shaun's topic in Car Aftermarket / Resin / 3D Printed

I ordered all my Albion tubing from Red Frog a little over 2 months ago and no problems from them. They did have a mix up on one pack but that's an easy mistake and I got hold of them of told them don't worry about it as I will need to order more anyway. I got a fairly quick response back within 12 hours of my emailing them of the mistake. When did this change of ownership take place? Paul- 21 replies

-

- red frog

- BLAH_BLAH_BLAH_BLAH

-

(and 1 more)

Tagged with:

-

This is about as close as I've been been able to get as far as used Magnesium dow coated. Its Alclad Mag over white primer. Of course the make up of the Magnesium will change the color of it somewhat.

-

Howard Competition mags avail , source ?

mr68gts replied to gtx6970's topic in WIP: Drag Racing Models

once upon a time there was a resin caster who's name shall remain nameless offered them on his website. I actually have a pair that I truly received from said caster. While I do not have access to said parts or model due to the great relocation of 2017, (move off the mountain into the city) they were available. I do not however know where he got them from or if he himself masted them. I have never personally seen any in plastic but if they are out there I would like to know! -

The kits is nice and goes together well. Only issue I had was with the rear suspension. I built the clear view version but painted the front half of the body. What you have done looks good and you have made good progress! Paul

-

1/16 Beach City Corvette: On the bench 8/19/17

mr68gts replied to John Teresi's topic in WIP: Drag Racing Models

ah, finally an update! Great work buddy! Can't wait to see this one done! It's always been one of my favorite floppers. Paul -

-

For some reason I believe that is a Logghe chassis. (I seem to recall they built the colt chassis for some teams.)

-

1/16 Scale Army Vega Funny Car - Finished 10/14/2018

mr68gts replied to Mooneyzs's topic in WIP: Drag Racing Models

nice job Chris! How thick is the printing plate? Paul -

More resin problems ????

mr68gts replied to cobraman's topic in Car Aftermarket / Resin / 3D Printed

Ray, what exactly is missing? just the chassis or is it the bottom of the tanker body? Paul -

I like it Chuck! It has the gotcha factor! Paul

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

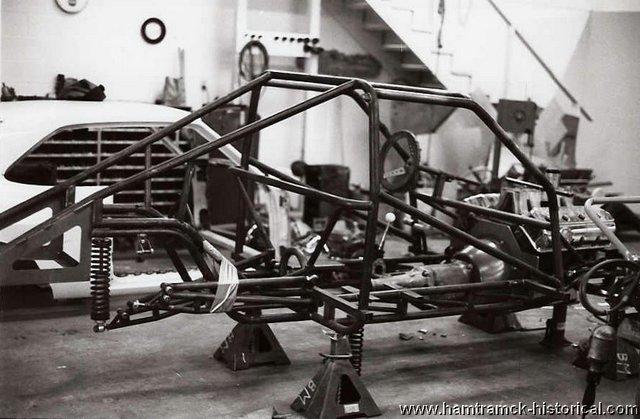

mocked up the engine some more (trans) and got the correct placement and height for it so I made a mock up tube in plastic to keep the engine in place. Makes the engine easily removable while I add more tubes.... back to the bench I go! -

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Can't imagine why that hat would look familiar? lol. I needed a hat for looks and yours is sitting in my 3d printed parts organizer bins so it got set up there he he. Not the one I will be using but it gives me a good idea of looks anyway. I decided to do the hoop before I went to bed last night so it's in place now too. Looks pretty good on there. Need to finish up the floor tonight though and then I can do the uprights for the firewall. The main rails, and hoop are Albion 2.5mm solid rod which is the only thing I could find close to .101 dimension and is a real bear to cut compared to their thin wall tubing. I may contact them at a later date and see if they can run some 2.5mm tube but for this chassis it will be solid. Usually the front of the tubes are capped off anyway. They do custom orders so they may do it for a nominal fee of course! Can't wait to get home and get some more done after work.... Paul