-

Posts

5,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

As long as it's my best, I know that I'm getting somewhere. As long as the next one is better, or more advanced, in some way, I can be satisfied, for the moment!? Agreed. I only prep and paint, because I have to, in order to complete my vision. I started scratchbuilding, so heavily, because I loathe cleaning up mold lines! But, also, I enjoy making my own fittings, and things like that. I wouldn't be as likely to do that without the mill and lathe--I have, but it's time-consuming, and very hit-or-miss. I wonder if that's the same Primer King I know?

-

I mean, RIGHT?! Where's the adventure in simply removing mold lines?? Your recent soft top must have been incredibly rewarding to accomplish! It's a work of art, to me, and the new standard. It's that kind of stuff that's fun, for me, as well. You're absolutely correct about shows/contests, too. They're always inspirational, and it's great to be able to visit with other like-minded guys. I always was excited to go home and build! Your reaction reminded me of something Neil Peart once said upon reading that Eric Clapton had seen Hendrix and said he wanted to throw away his guitar. Peart said that kind of thing only made him work harder, and that he couldn't relate to that thought process.

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Those look awesome! -

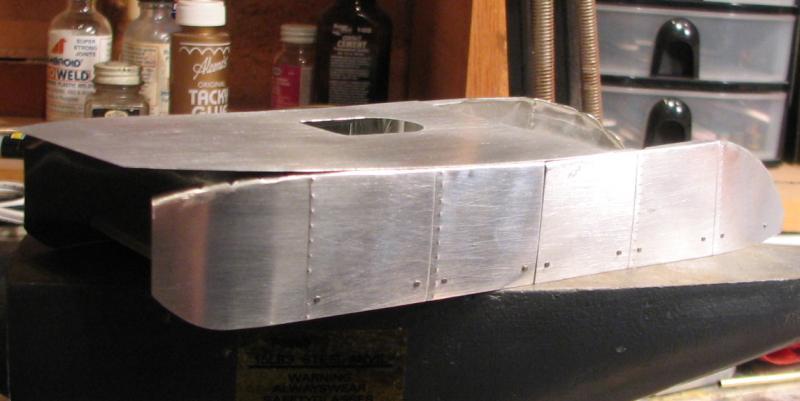

Thanks, Ian! I ended up doing something like that (to the manifold). The biggest problem I was having was clearance, with the mag back there. I ended up going all "Pete Robinson" on the blower end plates, and thinning them down. I have to make a new blanket for it, now, but it fits! I used .060"X.080" styrene for the block, and mounted it on the manifold, beneath the mag. I'll get some photos in the next couple of days.

-

Sometimes (and it took me almost 50 years to get here), I decide that I have to accept those flaws, knowing the next time will be better. Like Charles said, perfection is impossible to achieve, but, it's certainly not impossible to strive for! I've discovered that, since I became able to accept those little flaws as products of trying I've found myself actually finishing more projects, rather than saying "Well, this isn't perfect, so I'll stick it back in the closet, until I can make it that way." I've also finished several of those projects, over the last six or seven years--and, I am satisfied with them! I accomplished new techniques on all of them, so I learned from them. That's all the reward I really need. I don't understand the phrase "I don't build for contests, I just build for fun." I've never built any model, for a contest. I build how I enjoy, and, if it's good enough to win, then great! If not, okay, not today. I'm no less happy with what I've done, because I didn't win. Over the years, I've known quite a few modelers in different pursuits, who've burned out, and quit building. That's something I can't even relate to. I think they were building with too great an eye on competition, because you do not burn out, on something you truly love.

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

It's always good to know, and to find others who freely share the things they've discovered! -

1967 GTX silver bullet

Straightliner59 replied to Vintage chromoly's topic in WIP: Drag Racing Models

Super-nice work! I'm a firm believer of pinning parts. It makes test fitting so much easier, and more accurate. -

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

The headlight buckets are excellent! I'm adding that to the bag of ideas I have stolen from your arsenal!? -

Unconventional Materials - From the jewelry area

Straightliner59 replied to Jiml0001's topic in Tips, Tricks, and Tutorials

That's very kind of you, Les! Shall I PM my address? My youngest sister lives in Scotland, but, I don't recall where. I think it's a more remote area, though. -

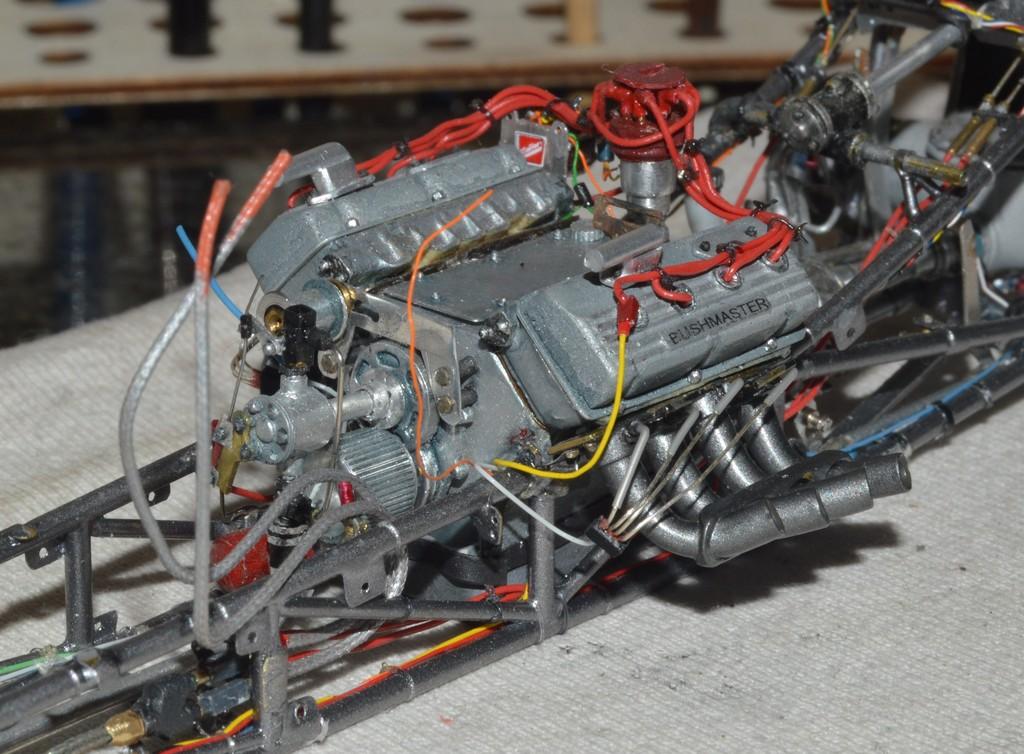

That's a good idea. The wire I used, would have to be annealed, first. It's pretty hard. Progress has been kind of slow, as I have been sorting out the steering, and generally wrapping everything up, so that I can begin work on the blower manifold--which is happening, next! I also mounted the radius rods. I printed new axle tags, too. On to the fuel system! Comments, critiques and questions are always welcomed. Thanks for looking!

-

Unconventional Materials - From the jewelry area

Straightliner59 replied to Jiml0001's topic in Tips, Tricks, and Tutorials

That's kind of my thinking with the .081 coax. If I can slip it off the core, I can use it around other diameters of wire. I got that idea, when I ran across a short section of something larger, and was able to do that. Virtually all of this kind of stuff in the modeling aftermarket comes from somewhere else--some other pursuit. The trick is finding the source!? I'll look around for some of the fly-tying braid. Thanks for the tip, on that! -

1/16th Scale Top Fuel Dragster Eddie Hill 4:99

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

Well, it looks wonderful! Sometimes, the best-looking stuff is very simple to make.?- 78 replies

-

- scratch built

- super shops

-

(and 2 more)

Tagged with:

-

Unconventional Materials - From the jewelry area

Straightliner59 replied to Jiml0001's topic in Tips, Tricks, and Tutorials

That's what I used or the return lines on the Nostalgia Top Fueler. I want to find more sizes, because I love the stuff! The stuff I found is sinking line, so it has a heavy core (feels like lead, but...) which is great for getting it to stay "posed". -

1/16th Scale Top Fuel Dragster Eddie Hill 4:99

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

It's all great, but that rack and pinion! Beauty!- 78 replies

-

- scratch built

- super shops

-

(and 2 more)

Tagged with:

-

I think projects like this are so much fun. We don't have to get carried away, and we still end up with something very cool, at the end! I have a dry lakes/Bonneville project that's very similar, detail-wise, that I need to get back to. It won't be a replica, just an impression. The panels won't be removeable, so whatever can be seen through the cockpit opening would be it. The prototype went on to become the famous Chrisman #25 dragster. Maybe, here in a few weeks, once the dragster's done!

-

Unconventional Materials - From the jewelry area

Straightliner59 replied to Jiml0001's topic in Tips, Tricks, and Tutorials

Thanks for sharing your experience. I now have a couple headed my way. I can remember when the best thing we could find for braided line was solder wick. It was horrible! I'm looking forward to giving this stuff a look. I may order some of the 1.13 diameter, as well. -

And very nicely done!

-

Love it! The engine is a thing of beauty, from the Spaulding ignition to your fine work on the fuel system--there's nothing not to like, here! Very nice work, Niko.

-

Canadian 1961 Pontiac Laurentian conversion

Straightliner59 replied to TheBEAUMONTGURU's topic in WIP: Model Cars

Excellent work, DA! Great looking car, too! -

Primer for Krylon Spray Paints

Straightliner59 replied to midlineqb's topic in Model Building Questions and Answers

I use Krylon's primer. It's worked well, no matter the plastic, or the top coat. I do a couple of light coats, first, then finish with a good one to fill it out. I've been using their products for 50 years, and every time something went wrong, it was something that I did. Every. Single. Time. Following the directions on the can, you can prime and paint a model in a day. Using Parafilm as a mask, I wouldn't shy away from a two-color scheme, in a day. It's good stuff! This is not, by any means a paid endorsement!? -

Looking very nice, Niko. Beautiful work, sir!

-

INFINI MODEL sanding sticks

Straightliner59 replied to NOBLNG's topic in Tips, Tricks, and Tutorials

That's exactly what I use! They wash up, beautifully.