-

Posts

7,921 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by landman

-

I like the sound of that.

-

-

X2

- 25 replies

-

- duesenberg

- rollston

-

(and 1 more)

Tagged with:

-

'32 Chrysler flathead wiring conundrum

landman replied to Jantrix's topic in Model Building Questions and Answers

Wow! That is a nicely restored engine. -

does anyone make a 60's D100?

landman replied to wrenchr's topic in Truck Aftermarket / Resin / 3D Printed

The best bet is to phone:814-337-4250 -

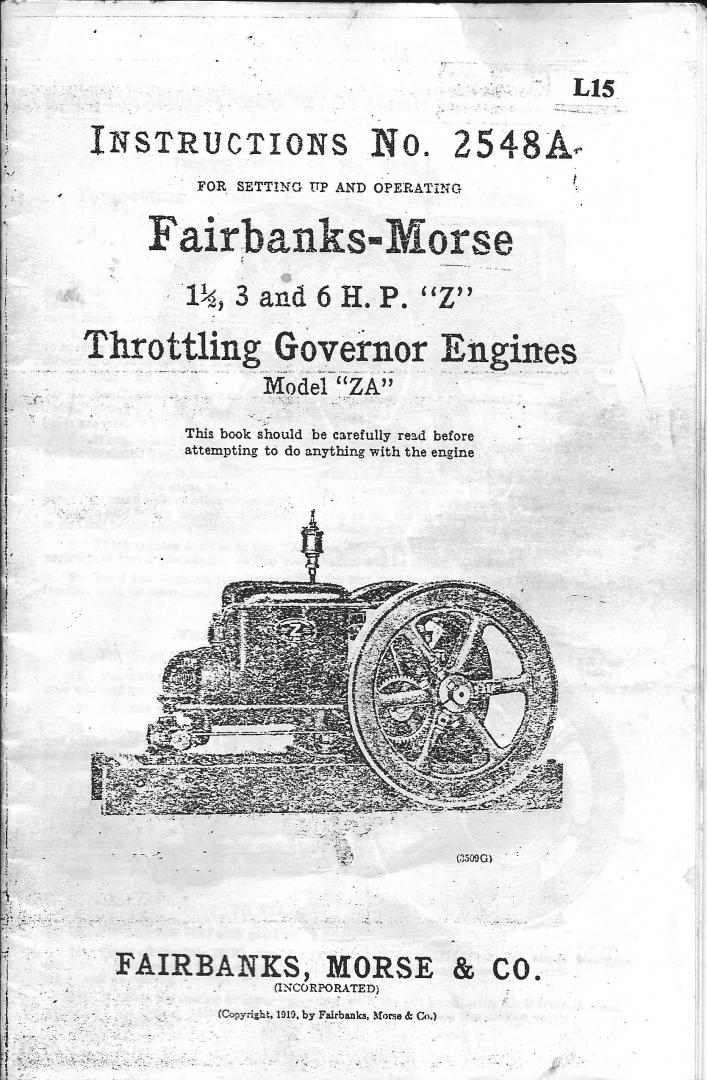

On a Facebook page about garage dioramas there is one which fascinates me more than most. In it there is a beautifully rendered hit & miss engine. I thought if FTB can do them all it has to do those too. So I spoke to a local collector, well into his eighties about where I could find one in town to copy. Right here he says. So I went. I attach photos of some of the memorabilia he collected over the years. I say some because this is what is left of it. He has been giving and selling for several years to get out of the large building where he kept it. He used to run a B/A station with his dad. I photographed and sketched the engine and he even let me take its manual home to scan. It is a 1936 Fairbanks-Morse. One more for the back burner.

-

-

X2. I am jealous of the paint.

-

X2. I remember building one in the early 80's and mounting it on a plaque and donating it to the local car club as a trophy.

-

Welcome aboard Mike. You will like it here.

-

Fascinating.

-

The problem with me though is that I tend to improvise rather than plan. Sometimes I paint myself into a corner.

-

Looks like the front axle is in the right location. Marked the rear one accordingly. I will attempt to match the drip moldings using wire.

-

Only to the ones watching this thread. You use what you got.

-

Beautiful!!!!! I wish I could afford one.

-

-

I have one too, and I was planning to scratchbuild the details.

-

-

-

Getting there with the shaping. Lots of filing and sanding. I want the shape finalized before I attack the window reveals. Looks like the Duesenberg frame will be a better fit than the Rolls.

-

does anyone make a 60's D100?

landman replied to wrenchr's topic in Truck Aftermarket / Resin / 3D Printed