-

Posts

9,215 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by peteski

-

Thanks guys! The model is a Gunze Sangyo 1:32 '57 Chevy Hardtop (curbside). Yes, a 1:32 scale kit. It is part of a series depicting cars of the '50s. The kits are really well done and seem to have good proportion and very nice detailing (especially for the smaller scale). I have few more built and few still waiting their turn on my workshop bench. The '59 Ford Skyliner was also featured in few BMF ads. Here are some rear views.

-

Finally! Nice Headlights!!

peteski replied to StevenGuthmiller's topic in Tips, Tricks, and Tutorials

Excellent idea but the headlight still looks a bit dull. Headlights in 1:1 cars are sparkly like cut diamonds. I wonder if you could use a mirrored rhinestone (as a reflector) behind the resin lens? That might brighten it up. As far as Bondic goes, I bought mine at a local Target store. They have a while end-cap of one of the isles dedicated to "as seen on TV" items. -

For developing the photoresist I have built an UV light chamber using UV fluorescent tubes I bought at a local electronic supply store. But that cost me quite a bit more than $15. Before that I uses an antique sun-tanning lamp (from the '70s).

-

AMT '77 Pacer Wagon - a new loser out of box!

peteski replied to Faust's topic in Car Kit News & Reviews

I asked one of the aftermarket resin casters if they would make those wheels (since the '77 Pacer was just released and it includes different kind of wheels). He didn't say "no" so I figured that would try to gauge interest in those wheels. But It seems that there isn't much interest (probably not enough for the resin caster to make it worthwhile for him). It makes sense that '77 Hornet used the same wheels (those were actually wheel covers for steel wheels, correct)? -

Yesterdays dashboards

peteski replied to BIGTRUCK's topic in General Automotive Talk (Trucks and Cars)

Don't forget touch screens and integration with your "smart" devices. -

Another voice against the Ultra-Bright foil. Actually it was the reason my model ended up on the BMF packaging. It was in the 1990s when BMF started having competition. Detail Master started producing their own foil and the sales pitch was that it was much shinier and brighter than BMFs. I bought some of the Detail Master foil and it stunk! Yes, it was brighter and shinier than BMF chrome foil, but it was also much thicker, less stretchy and didn't adhere well. I only tried to use it once and ended up peeling it off and using the BMF chrome foil. After that BMF introduced their new Ultra Chrome foil. They also touted it as being more like real chrome. I suspect that was their answer to the competition. So I bought a sheet of BMF Ultra Chrome. It was almost as crappy as the Detail master. Same problems as I described above. I still have the unused sheet (I should chuck it). Seeing BMF producing the Ultra Chrome foil made me worry that they will discontinue their regular Chrome foil (which while not as shiny was a pleasure to work with) and I wrote them a letter including couple of photos of my models. I asked for them to continue producing the regular Chrome foil and showing them that it looked great on my models. I received a reply (all by snail mail back then) stating that they had no intention of discontinuing the regular Chrome foil. El (the BMF proprietor) also asked me if he could use the photos of my models in BMF ads and packaging. Of course I agreed and the rest is history. As a "payment" I received several sheets of BMF foils, but the best payment is seeing my model on every BMF envelope! I am still using those decades-old sheets (I'm a slow builder) and til recently I didn't even know that BMF introduced "new and improved" foil. But from what I see, the new foil is just as good as the original Chrome.

-

Nevermind - just figured it out. Click on the black dot in front of the Subject line.

-

In the past, before I logged out of the forum I would mark the site as read. When I returned and logged in again, The forums containing new posts show green "UNREAD" labels. Then within each forum the threads which contained added contents since I logged out would also have similar green tags. If I clicked on the green tag it would get me to the oldest "new" contents posted in that thread. It was very handy to catch up on the new posts. Sometime last week the "UNREAD" tags have disappeared from the individual posts. They are still there for each forum which has new contents, but not the threads themselves. So there is no good way I know to get to the oldest New contents of the individual threads. Nothign has changed on my end (same browser, no updates, etc.) I have the same problem on 2 different computer using different browsers. I suspect the change was done on the forum website. Anybody else noticed this? Any viable alternative for viewing new messages in a thread?

-

AMT '77 Pacer Wagon - a new loser out of box!

peteski replied to Faust's topic in Car Kit News & Reviews

I believe that these are the factory-stock wheels (and wheel covers) for that year Pacer. -

Oh my! Someone making something out of nothing. My goodness. I'm a Pollack and d-a-m-n proud of it. I also enjoy good Polish jokes. Self-deprecating? Maybe. Not a bigot. If you can't take my joke (and see it as racist or bigoted, then you are seeing something that isn't there). If we all have to turn into humorless touchy-feely drones then I might as well hide in my workshop and stay of the Interwebs. I do agree with you on one thing - more Photoshops lease. PS. You probably won't find http://www.engrish.com/ amusing either - I do. I even submitted some entries from when I visited Japan. None of it was racially motivated or bigoted.

-

AMT '77 Pacer Wagon - a new loser out of box!

peteski replied to Faust's topic in Car Kit News & Reviews

What size tires were used on Paces? What other kit tires could be used to replace the crappy hard-plastic 2-piece kit tires? There might be a chance that the wheels in this photo could be resin-cast. Maybe even tires too. Would there be any interest in these items? -

Speaking of Japanese car names, I've heard that the Mitsubishi Starion was actually supposed to be Stallion, but the Japanese had have a problem pronouncing el's and ahr's.

-

Could you expand on your question? I never used UV lamp for photoetching. Just for developing the photo-resist.

-

Using Calligraphy Pen Tips to Apply CA Glue

peteski replied to Miatatom's topic in Model Building Questions and Answers

I enjoy scraping - seriously. Besides, burning CA glue does create a nasty odor. -

testors paint question

peteski replied to Jim in Falls's topic in Model Building Questions and Answers

We all learned something new here. -

I use both - hobby knife with #11 blade about 90% of the time (sometimes with other blades) and a scalpel the other 10%. At some point hobby mail order companies (like Hobby Expo and Micro Mark) used to carry scalpel handles and blades. I'm not sure if they still do. Yes scalpel handles are smaller and thinner (they don't have a cylindrical-shape handle). The shape of the handle makes it easier to judge the angle of the blade. Their #11 blades are a bit smaller than hobby version and have finely honed blade. I also took a disposable scalpel (a #11 blade permanently attached to a plastic handle), trimmed the handle to about 1/2 length, and made it into a replaceable blade scalpel. That is my BMF tool: the short and very light handle gives me much finer control while trimming BMF. I use stainless blades and paint the tip with black Sharpie to make it easier to see.

-

Using Calligraphy Pen Tips to Apply CA Glue

peteski replied to Miatatom's topic in Model Building Questions and Answers

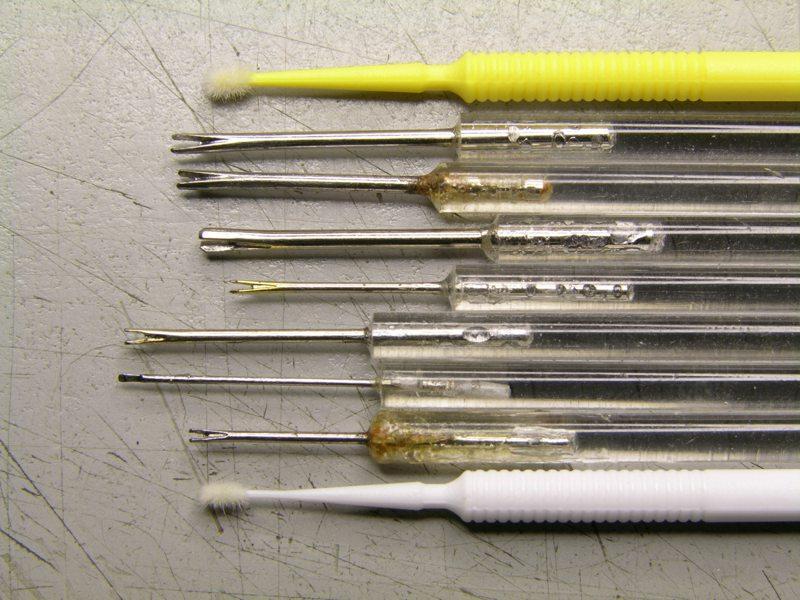

Here's my arsenal of CA aplicators. They are made from sawing needles and acrylic rod. It was not my original idea - I read about these decades ago in a magazine (probably FineScale Modeler). Also disposable Micro-Brushes as applicators for CA accelerator. When the needles get crusted up with hardened CA I use a hobby knife (with an older blade) to scrape the glue off. It doesn't take long and I like the ability to precisely apply just a tiny bit of glue where needed. I'm not sure how well a calligraphy pen will work. Thicker CA might not flow easily out of it and the thin stuff will probably start crusting up in it (especially if the ambient air is humid). -

testors paint question

peteski replied to Jim in Falls's topic in Model Building Questions and Answers

Yes, that is true - "#" has been used long before computers and "hash" is one of its names. It was (and still is) even used on the TouchTone telephone keypad along with the "splat" or asterisk. But like I mentioned, when I see it, the first thing that comes to my mind is that it indicates that the following number is some sort of part number. Or from my Unix background a hash symbol indicates that the rest of the line in a script is a comment (ignored). The "tag"meaning for me is far, far behind those. But I don't use Twitter or Instagram, so that's my excuse. I do know what hash tags are - they're just no something that first pops into my mind. -

testors paint question

peteski replied to Jim in Falls's topic in Model Building Questions and Answers

#1117 is a hash tag?! That made me smile - thanks. I guess the world is changing - a character we used in the past as a prefix for a part number has become a hash tag. -

1001 uses for Bondic on Fotki 7/30/17

peteski replied to Foxer's topic in Tips, Tricks, and Tutorials

Place a small puddle (about 1/4" diameter) on a piece of white paper (ink jet or laser printer paper). Don't make it too thin ( around 1/16" or a bit less). When in its liquid state it is perfectly colorless. Set it with the UV light. After it is set you can see that it picked up very slight amber tint. Very slight, but noticeable sitting on the white paper. At least that has been my experience. -

1001 uses for Bondic on Fotki 7/30/17

peteski replied to Foxer's topic in Tips, Tricks, and Tutorials

Has anybody noticed the name of the Bondic website: Not a Glue! They have a nifty chart of what tasks Bondic can handle at Bondic-vs-glue . They also have an extensive FAQ page. I recommend reading it. Here are few examples: If applied to smooth surfaces it seems to come off in one piece or chipped off easily but what if the surface is rough? The rougher the surface the better! Bondic® isn’t a glue, it has some adhesive properties but it sticks to smooth areas using a lot of surface tension rather than stickiness. If you can let the liquid Bondic® get into cracks and crevices then it will hold incredibly well. Can Bondic® bond dissimilar materials. Specifically high impact polystyrene and sand paper? It will work great in and on sandpaper and if you create some rough areas on the polystyrene that will allow the Bondic® to grip and you can get the LED UV light onto both, your good to go. How well does Bondic® work PVC tubing, Kevlar, or polypropylene? Bondic® works very well PVC tubing, Kevlar, and polypropylene, you just need to follow our principles. The principle of sealing or attaching things with Bondic® is based on how the surface is prepared and generally you want to make a ring around the item to create strength. Sometimes you even drill holes in both surfaces to create extra strength