-

Posts

10,231 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by NOBLNG

-

It’s a model…you can do anything you like to it.🙂

-

- 1 reply

-

- 3

-

-

Is the “Tamiya” lacquer thinner weak enough that it won’t melt the styrene like generic LT will?

-

It is looking great Urs!👍 I would not have the patience for all that decal work.😬

-

I think they’ve been running amok all over this forum!😬

-

My wife thinks I have more models than I will ever build, and she might be right? That said, she has never complained about me buying more…she just rolls her eyes and shakes her head. She has three guitars and two amps and….so we each have our hobbies. We have no kids to bequeath anything to, so our motto is: we can’t take it with us and the cheque to the undertaker should bounce.😜 I only have around a hundred kits and plan to build them all except for the ones I bought as possible parts donors, so I better get busy.😳

-

Nice! That maroon looks great on anything.👍

-

I love these kits. They aren’t great so I don’t mind trying heavy modifications!🤪 If you go with the V12, I am for sure following!😈

-

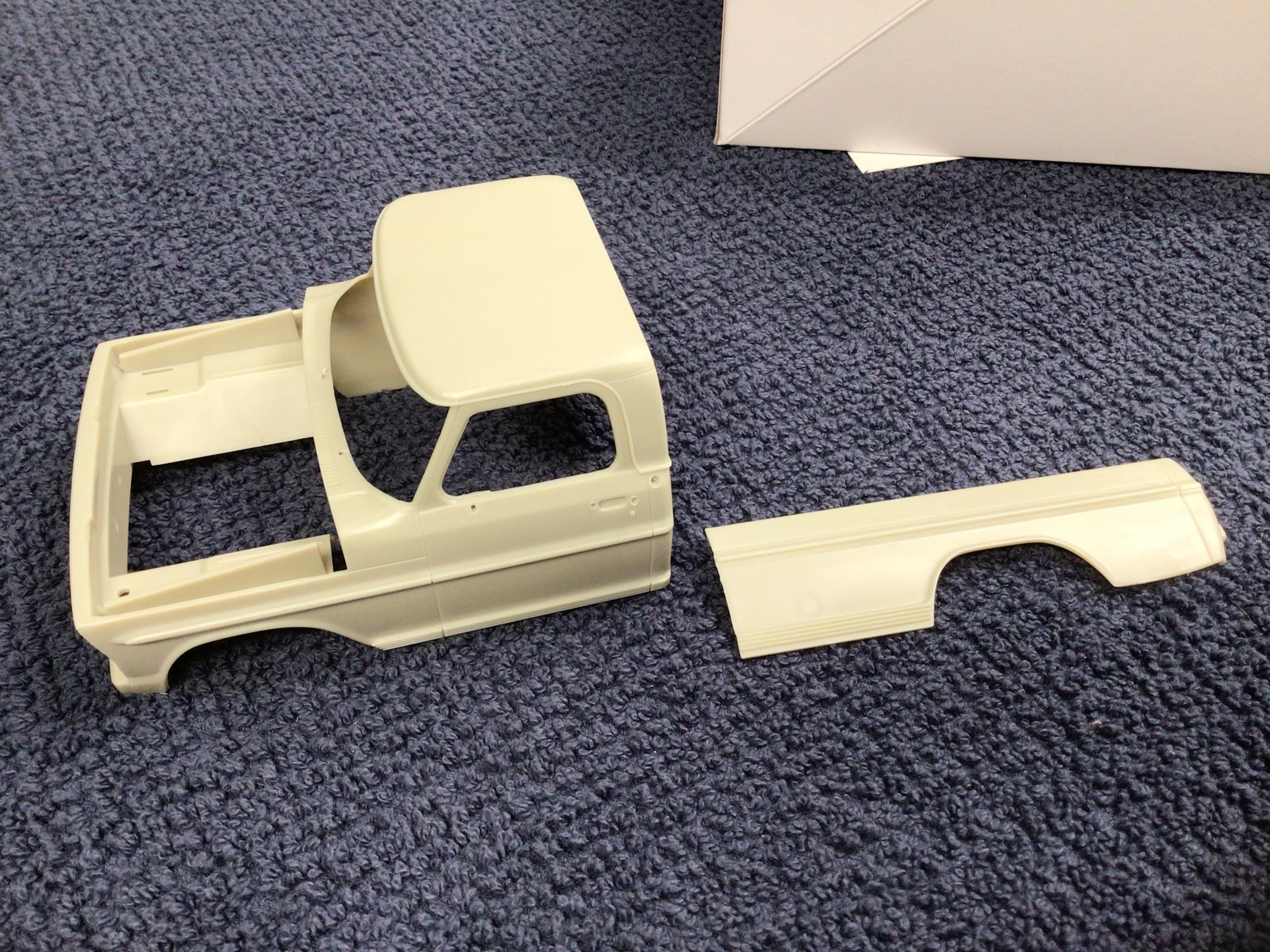

1972 Ford F100 replica build possible

NOBLNG replied to gtx6970's topic in Model Building Questions and Answers

Vallejo 71.317 light blue is pretty darn close to your buddys color in case you need another option. -

1972 Ford F100 replica build possible

NOBLNG replied to gtx6970's topic in Model Building Questions and Answers

Heres a link to a YouTube build of it. https://www.youtube.com/watch?v=aiz0BJnEqDw -

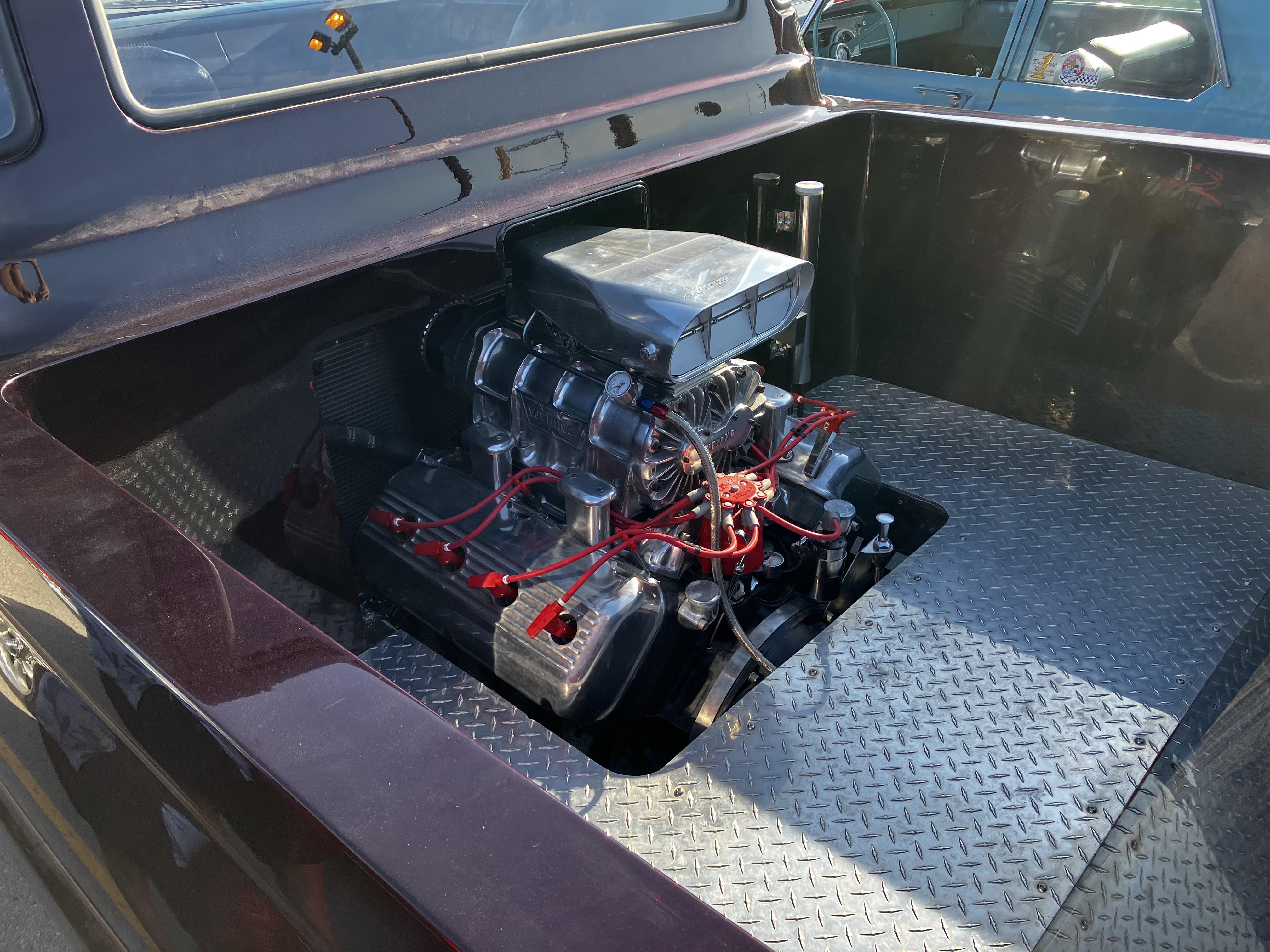

Nice start David. Engine looks fabulous!😎

-

Hubley '30 Packard Roadster Advice

NOBLNG replied to Andria H's topic in Model Building Questions and Answers

Do you have a dremel or similar rotary tool? Files will work, but a good quality set of burrs will make short work of that flash. -

RMCM #P-118 parts identification [help needed]

NOBLNG replied to sidcharles's topic in Model Building Questions and Answers

They are hydraulic. https://lainefamily.com/ModelABrakeUpgrade.htm -

1972 Ford F100 replica build possible

NOBLNG replied to gtx6970's topic in Model Building Questions and Answers

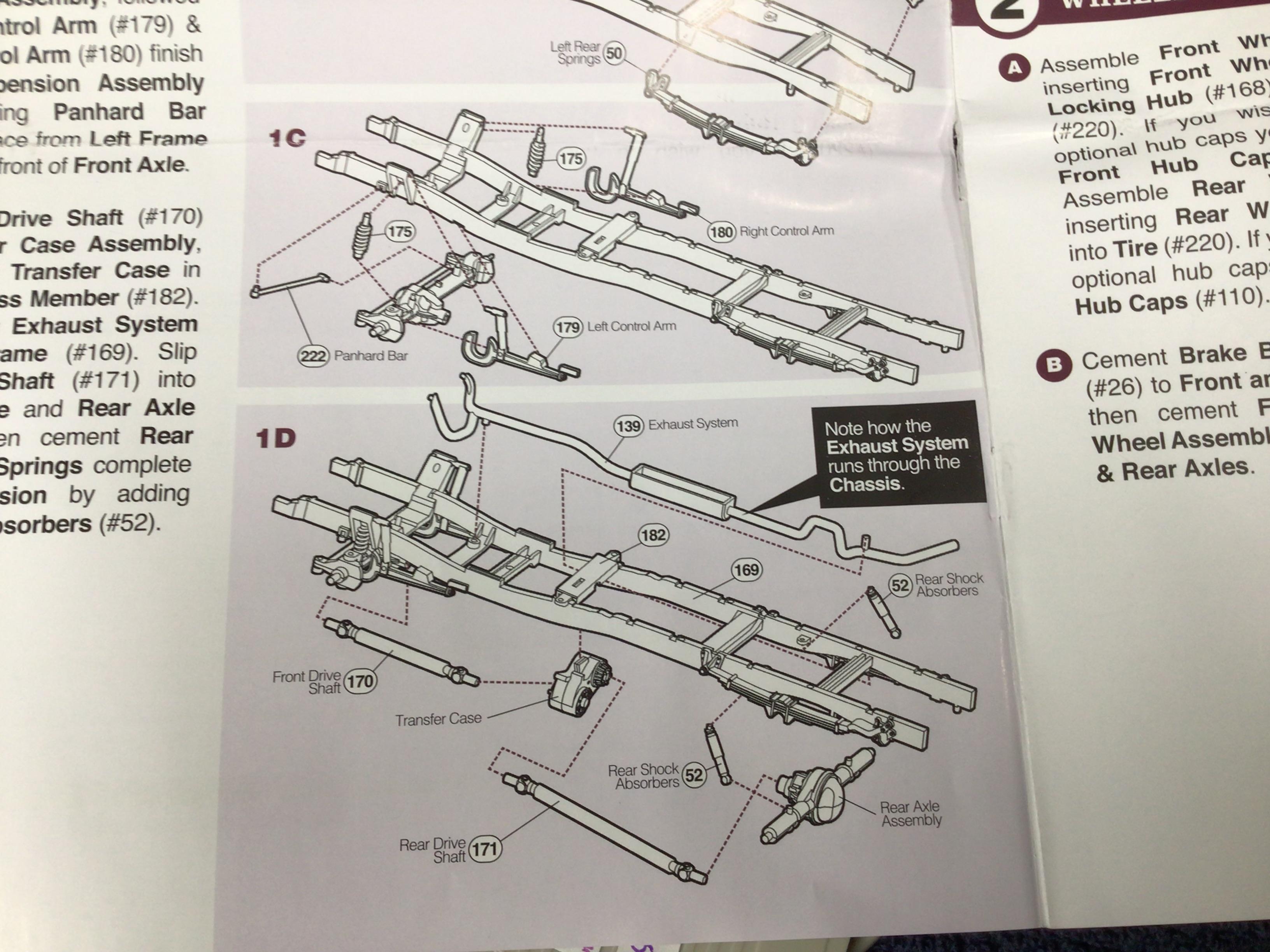

You’re welcome. Apparently the box art was corrected at some point. I don’t know if it ever contained F250 parts? My kit has the proper 1/2 ton front suspension. As in coil springs instead of leafs. -

Cool project!👍 Are you planning on shortening it up any?😈 Chevy did build 2 door Chevelle wagons. https://www.curbsideclassic.com/curbside-classics-american/1964-chevelle-300-2-door-station-wagon-it-should-have-been-called-nomad-why-did-they-build-these-anyway/

-

1972 Ford F100 replica build possible

NOBLNG replied to gtx6970's topic in Model Building Questions and Answers

The kit I have has 5 lug rims and the box art shows five lugs also. Kit #1230. Edit: It also has the upper and lower trim molded in, if that is what you’re looking for. It should be relatively easy to shorten the box and frame. -

Thoughts and ideas that hold forever true..........

NOBLNG replied to JollySipper's topic in The Off-Topic Lounge

I’ve wasted more masking tape and Bare Metal Foil by trying to be frugal than if I had just cut an obviously oversized piece in the first place. -

Anyway you want to build your model is all right by me, but It’s not a credo that has universal consensus.

-

Was the front bumper done with that stuff? If so, it looks pretty good!👍

-

Due to my exhaustive research and diligent planning 🙄…. the 1/32 interior fits with very little modification. I had to do some grinding and I re-oriented the dash slightly. Much easier than starting from scratch.🙂

-

- 39,258 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Does this resemble anyone's work area?

NOBLNG replied to 64SS350's topic in General Automotive Talk (Trucks and Cars)

I wish I had that many kits…but I still wouldn’t sit on them.😳 -

Breakfast consists of a cup of coffee and my meds.