-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

Your plumbing's looking great, Ian. I've been meaning to ask--which scale do you prefer working in? I can see advantages and disadvantages to both larger scales, and 1/25th. I don't think I'd ever complete a 1/12th model, because I would never feel like I could stop adding stuff!? This is going to be an incredible piece, my friend.

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

1969 Nova F/SA NHRA Stock Eliminator

Straightliner59 replied to R. Thorne's topic in WIP: Drag Racing Models

I'll be watching this. I've developed a greater love for door cars, over the past few years. -

'27 Turtledeck T dry lakes racer

Straightliner59 replied to Rocking Rodney Rat's topic in WIP: Drag Racing Models

Love it! Great work! I've often wondered why dry lakes and salt racers aren't in this forum. It makes sense, to me--they're all straightline racers. -

The fit of the floor is excellent. Some fine scratchbuilding, Ian.

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

Looking great, Marcos. It's really coming along!

-

Revell 29/30 Ford A kits. Extra Tires?

Straightliner59 replied to stavanzer's topic in Model Building Questions and Answers

No, no. They've showed us how they want us to do it, and we must conform! ? -

Washes and Weathering

Straightliner59 replied to bluestringer's topic in Model Building Questions and Answers

That's nice! I've always loved the 35Bs. I have the Monogram kit that I plan to "doctor up", one of these days. Beautiful work, sir! -

1/25 scale 10" 1960's slicks

Straightliner59 replied to ColonelKrypton's topic in Model Building Questions and Answers

I thought AMT had done a couple in their parts packs, but the Goodyears are 9" and the M&Hs are 10.5. -

Scratchbuilding-Where to begin?

Straightliner59 replied to olschoolkid's topic in Model Building Questions and Answers

I concur with Ace. I will say, however, that it's impossible to know what materials you'll need, until you've a specific project, in mind. For starters, I'd recommend getting an assortment package of Evergreen sheet (if they still sell those). With sheet, you can easily cut strips, rather than try to anticipate what stock you'll need. It's also handy to keep in mind that, in 1/25 scale, .040" is equal to 1". Extrapolating from there, it's a breeze to determine what size(s) you'll need for a specific project. An assortment of rod, tubing and strip will also be useful. I've attached a very simple scratchbuilding project I put together for an old website. It can help you get a feel for it, without grinding your teeth, to nubs. I scratchbuild a ton of stuff--that's the most enjoyable aspect of the hobby, for me. I'd rather build something, than scrape a bunch of mold lines! But, that's just me! I'm happy to help, in any way I can. -

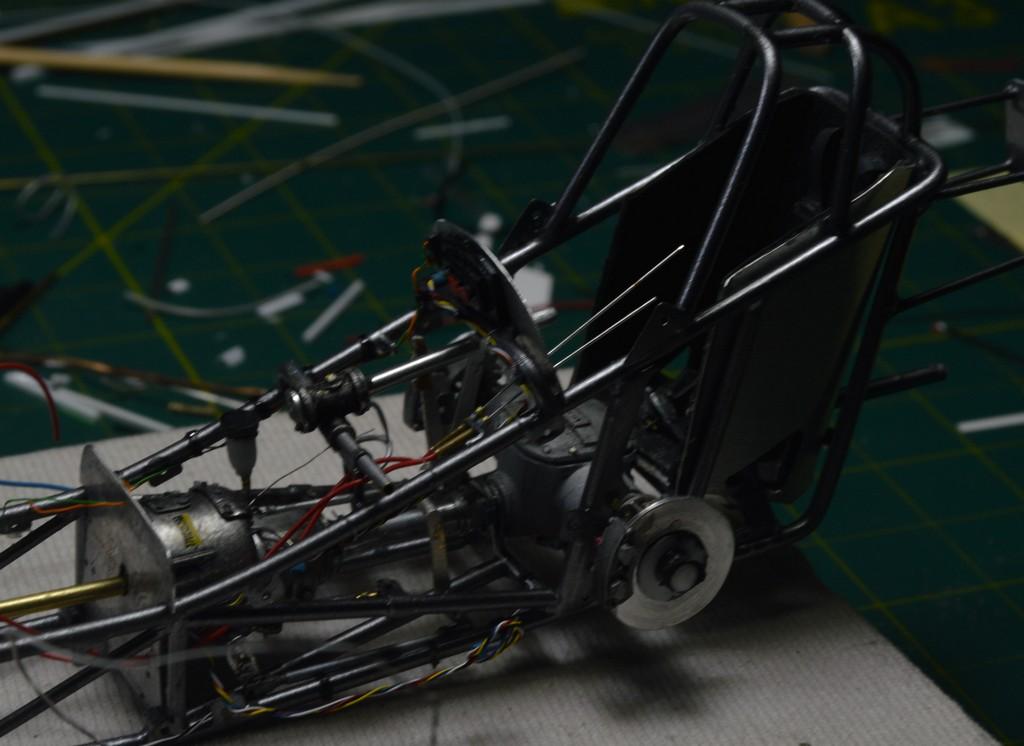

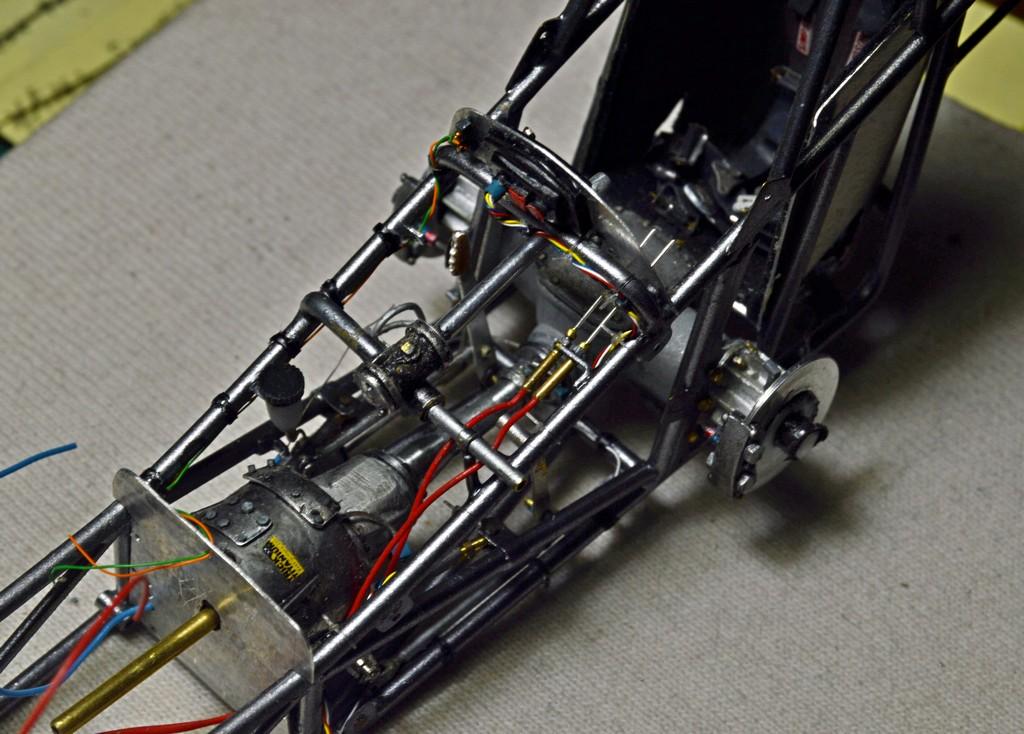

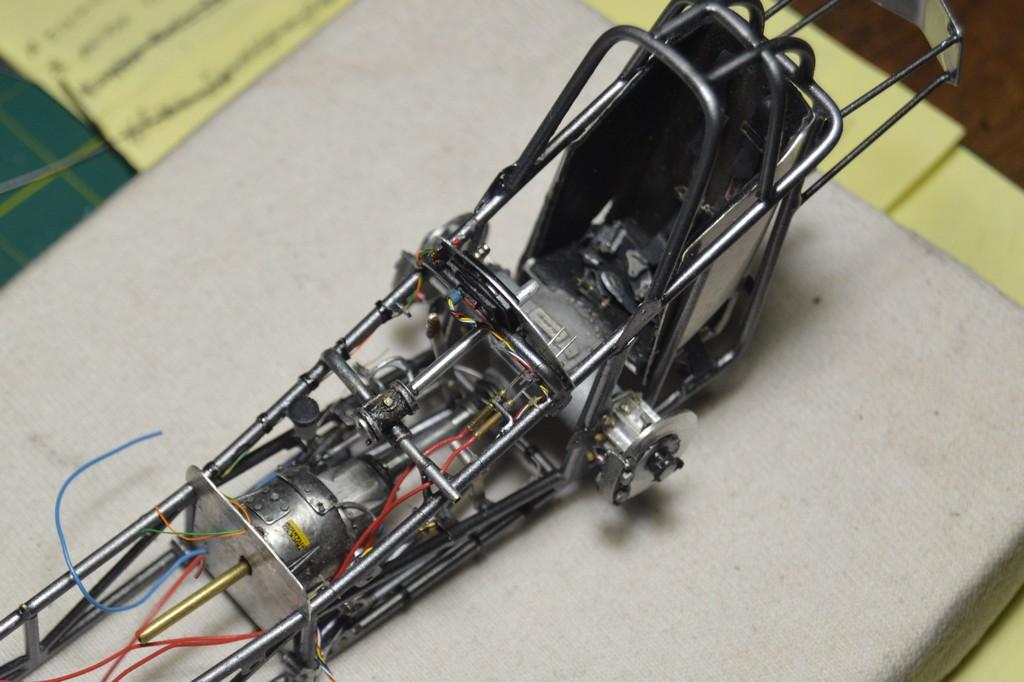

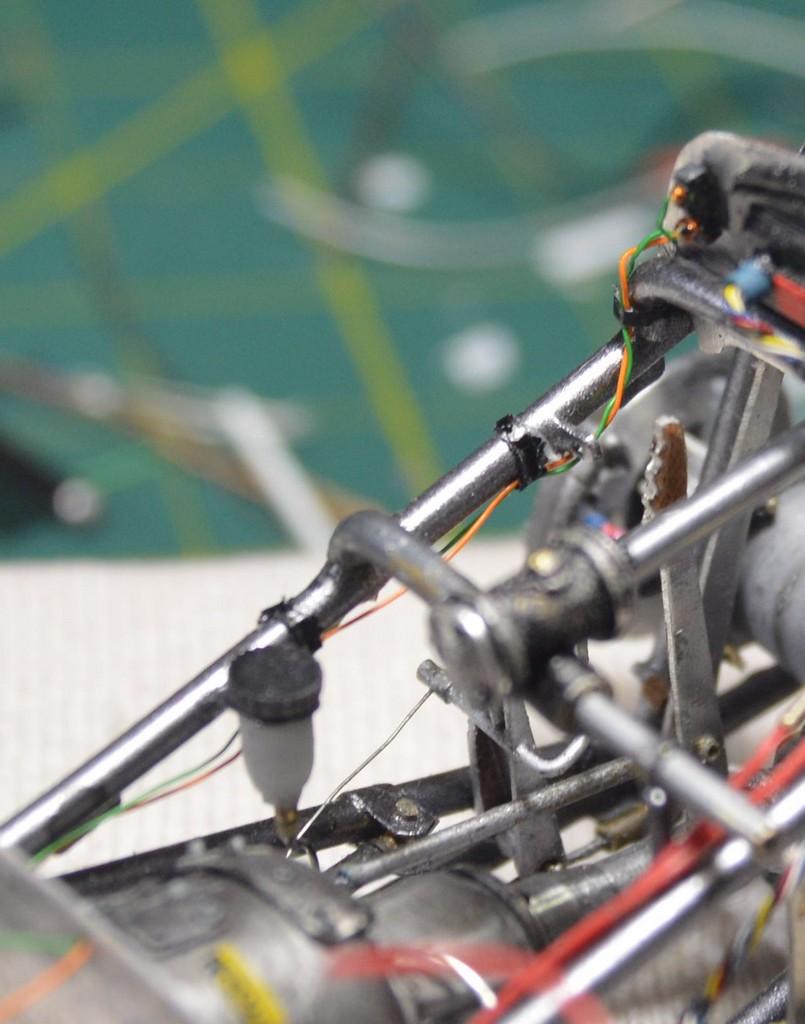

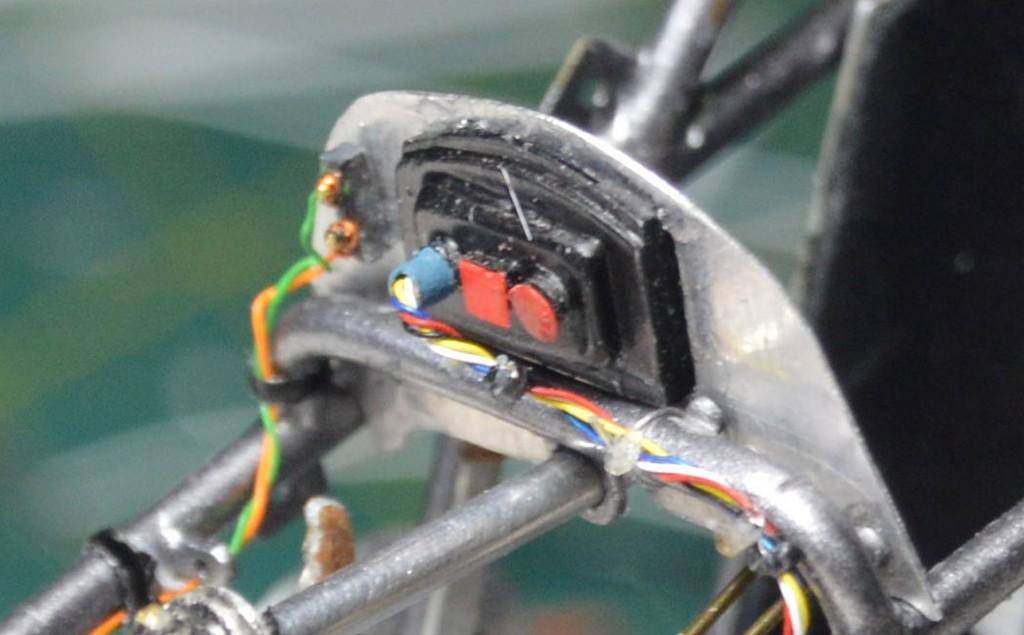

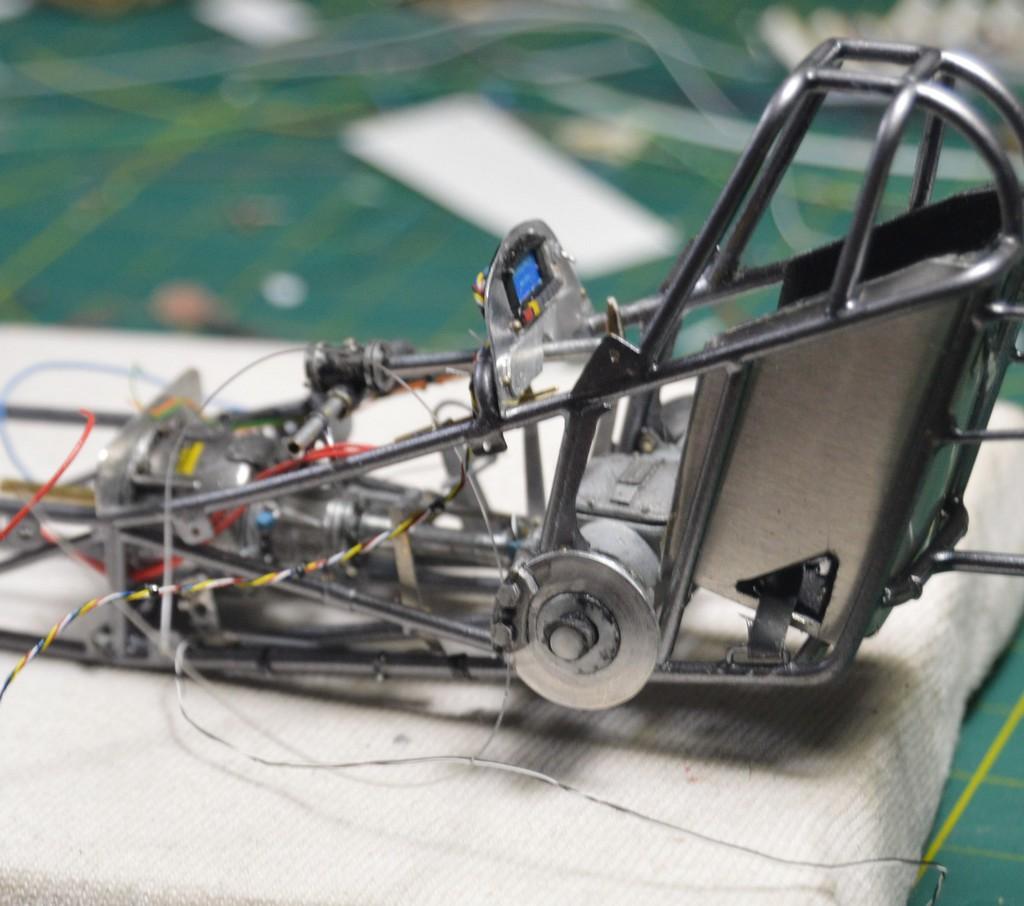

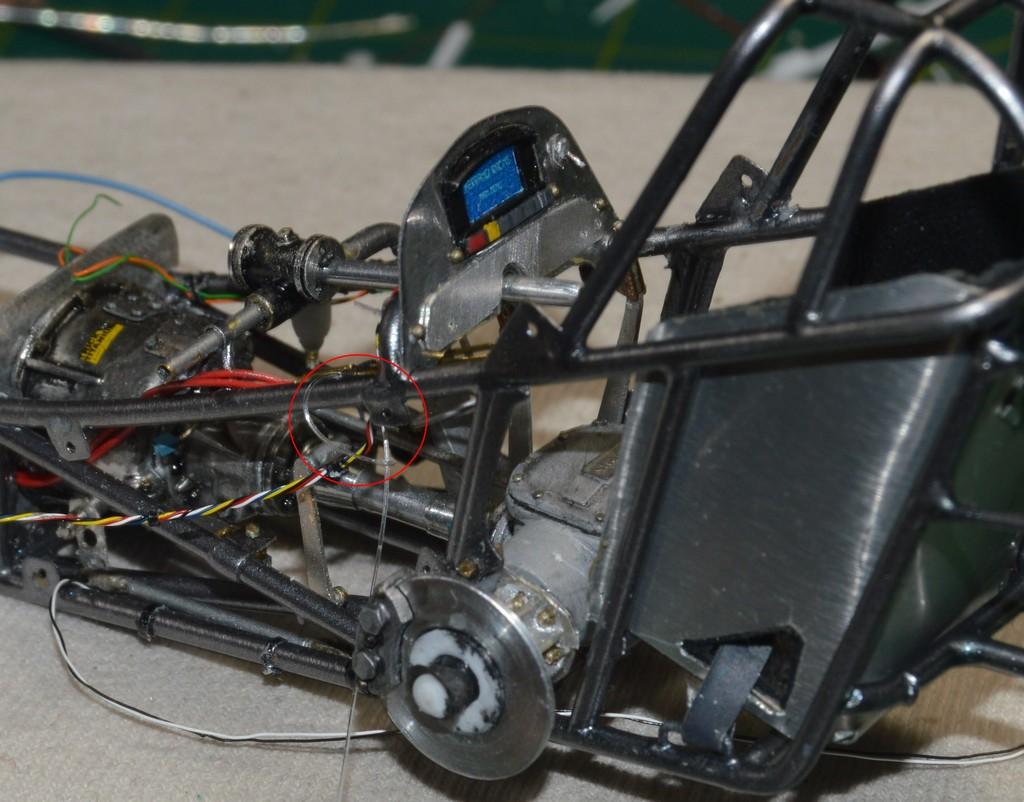

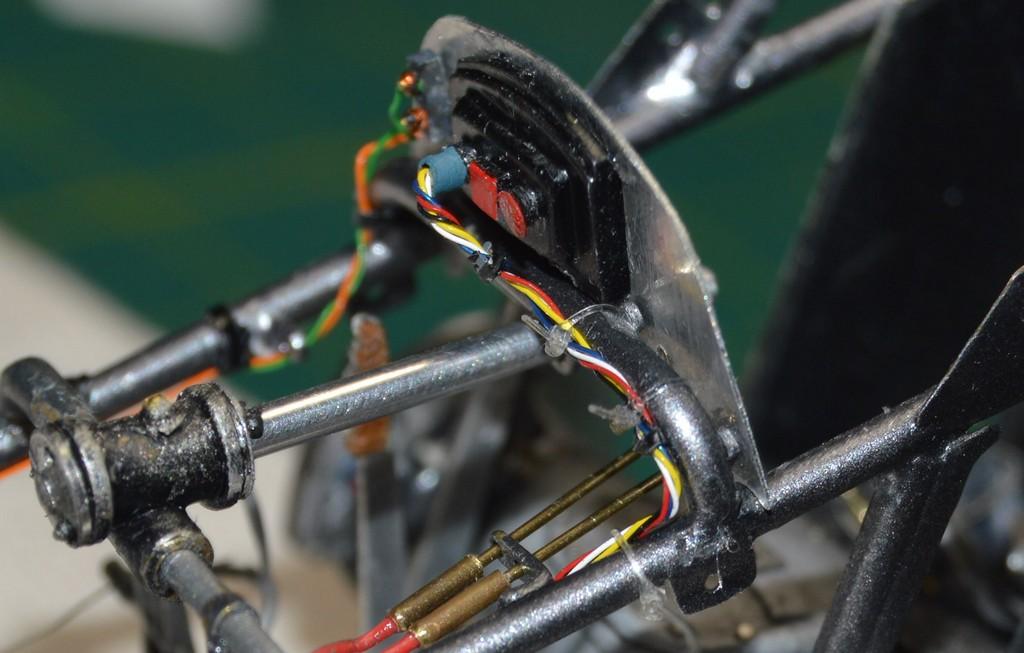

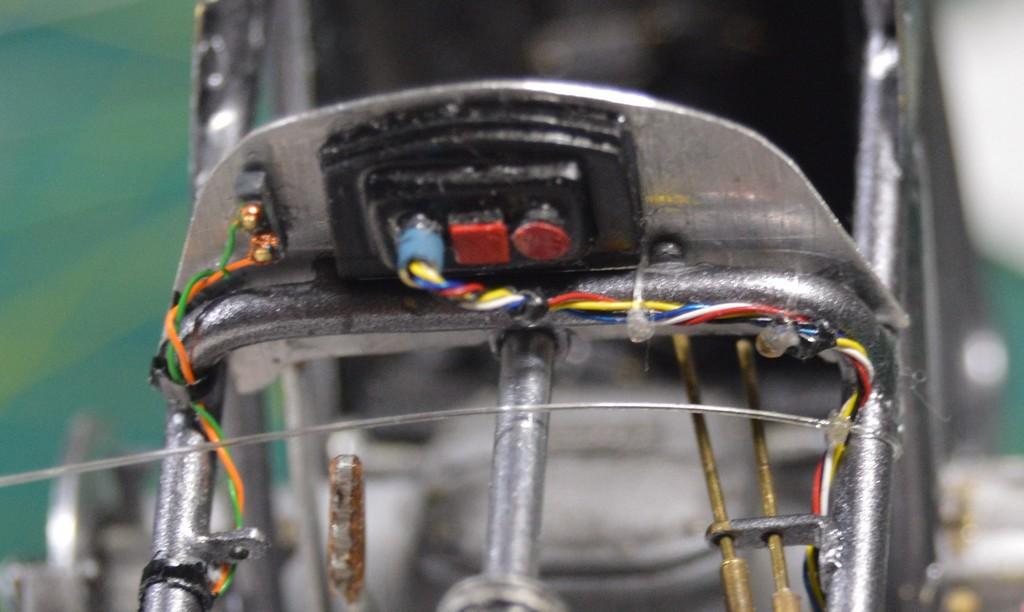

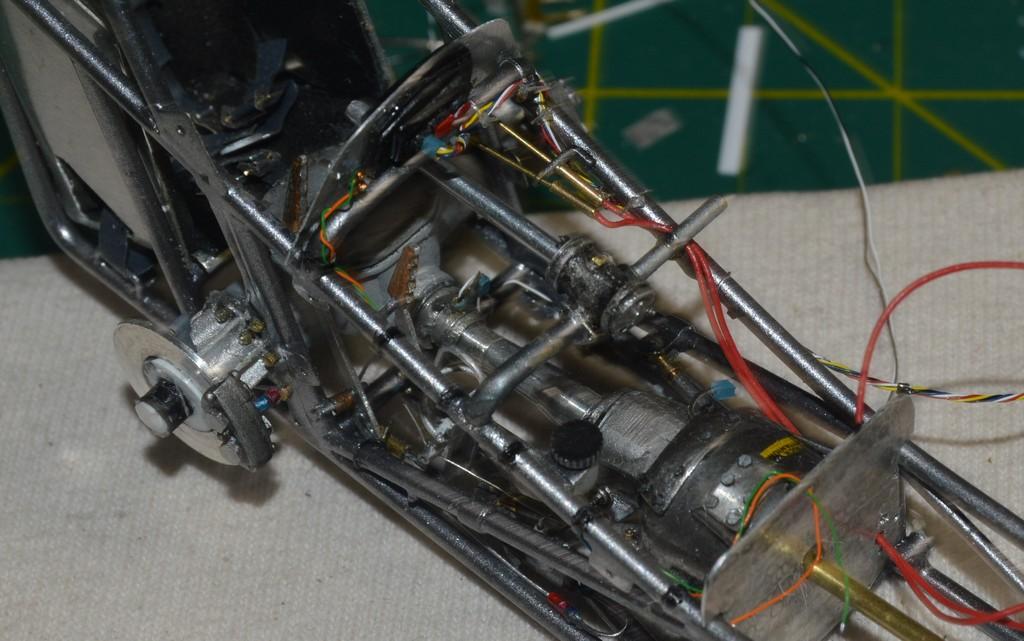

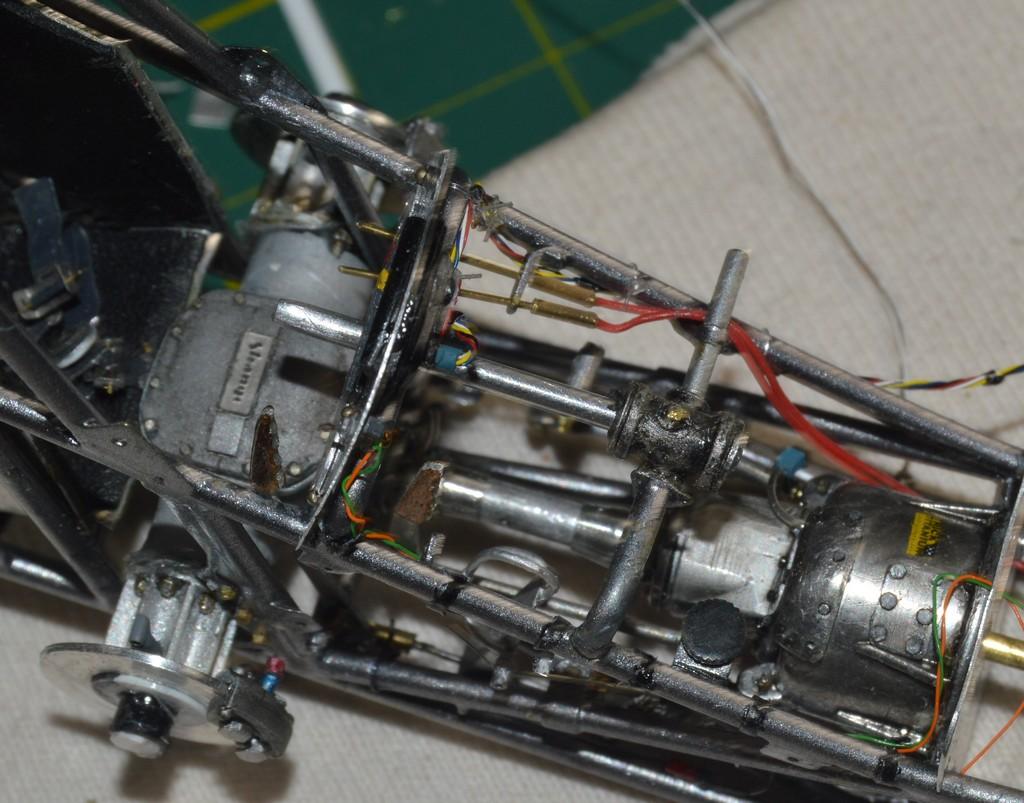

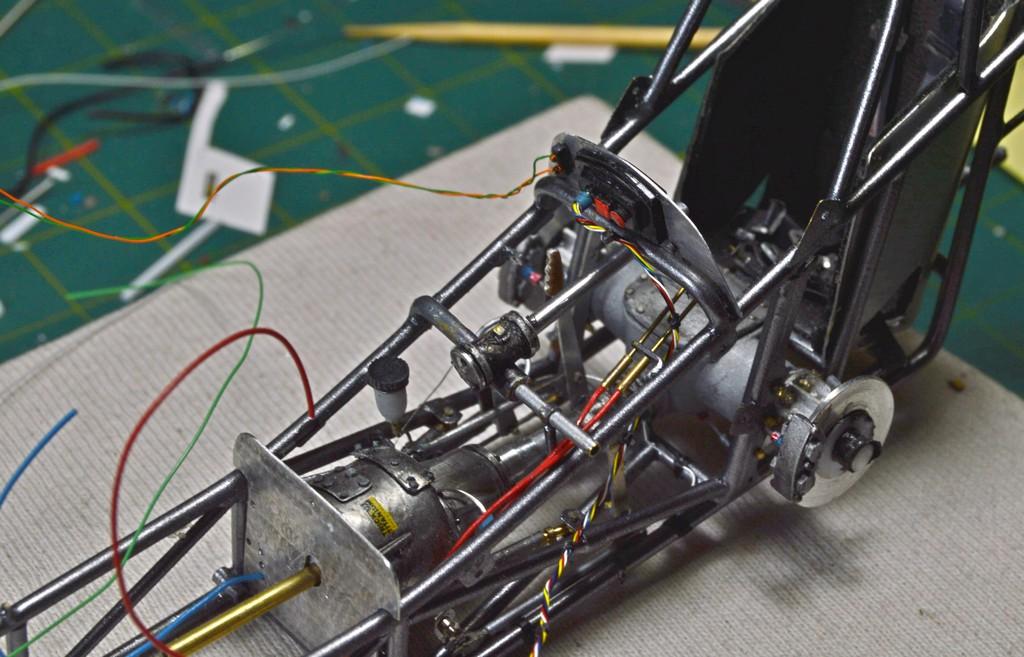

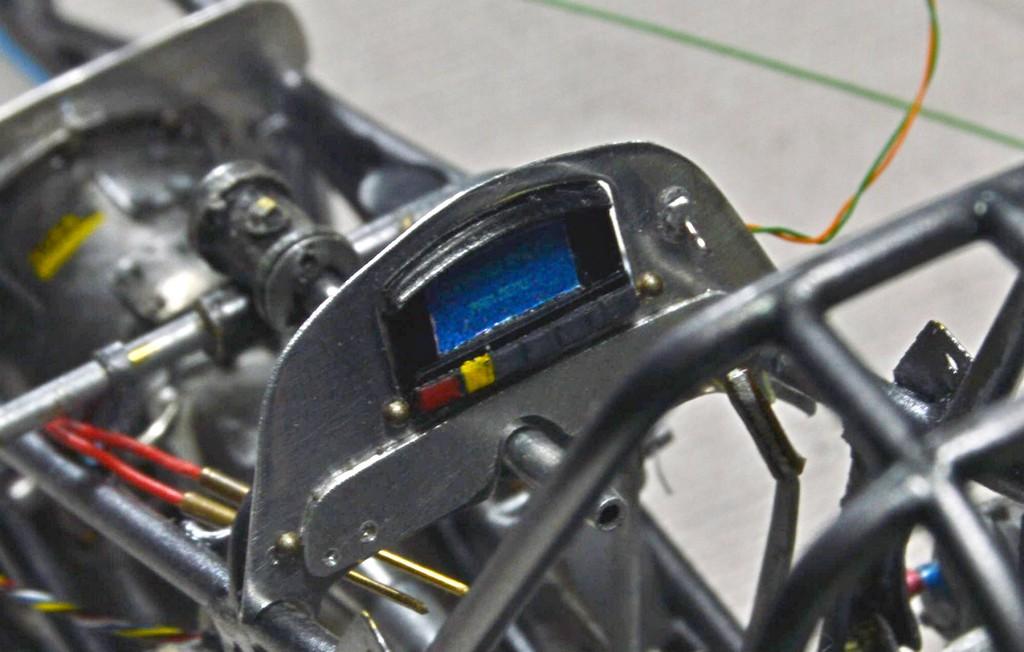

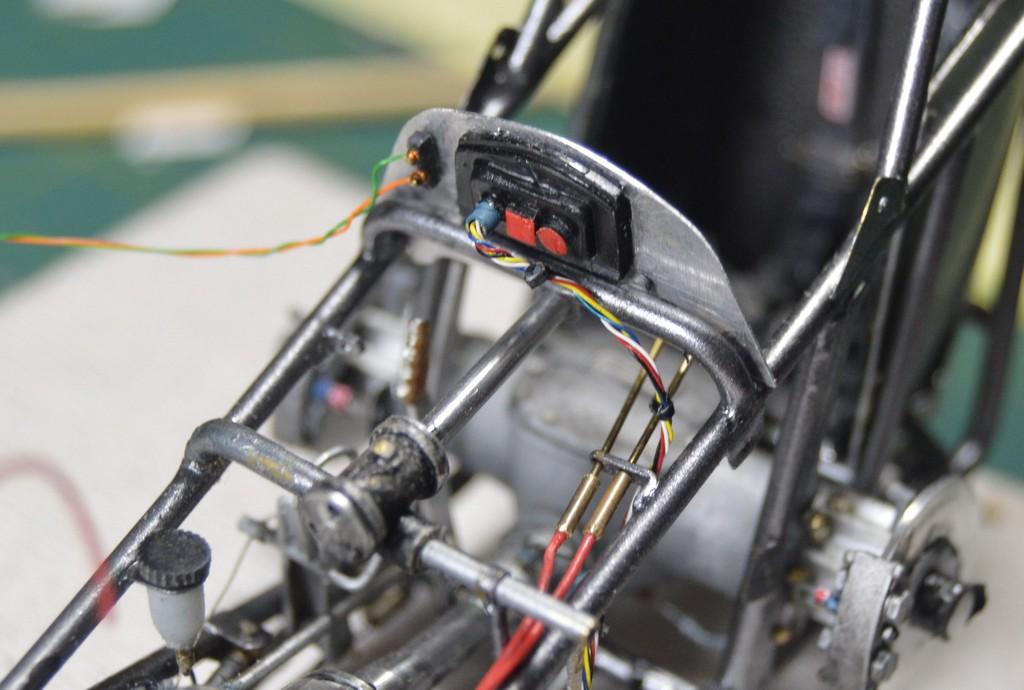

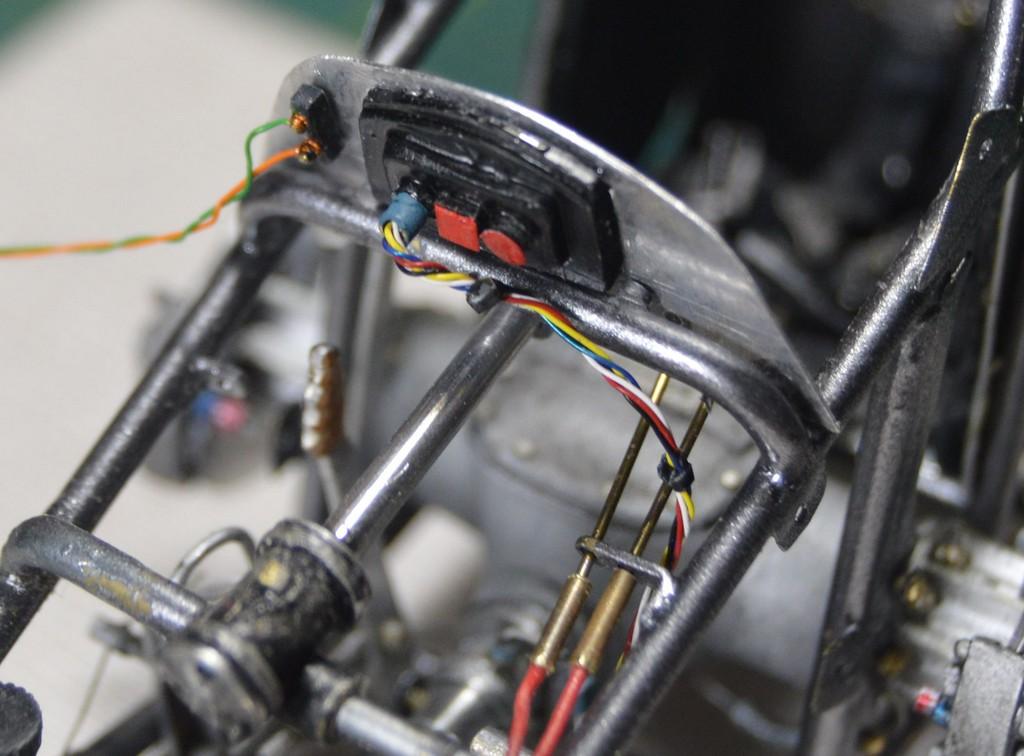

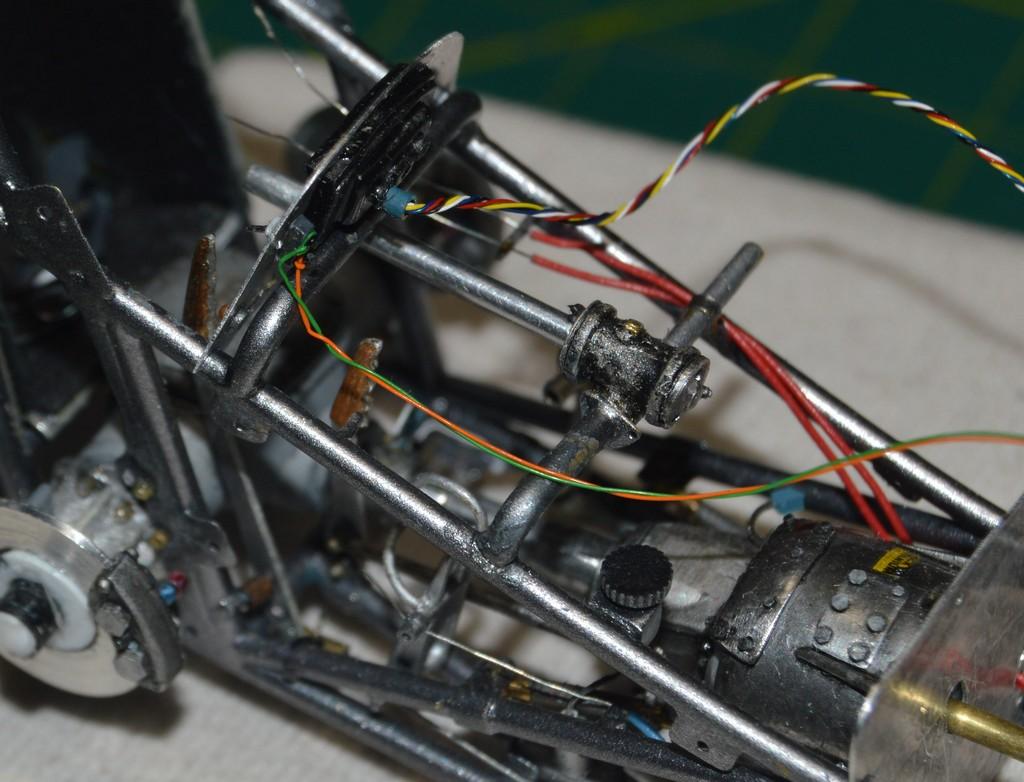

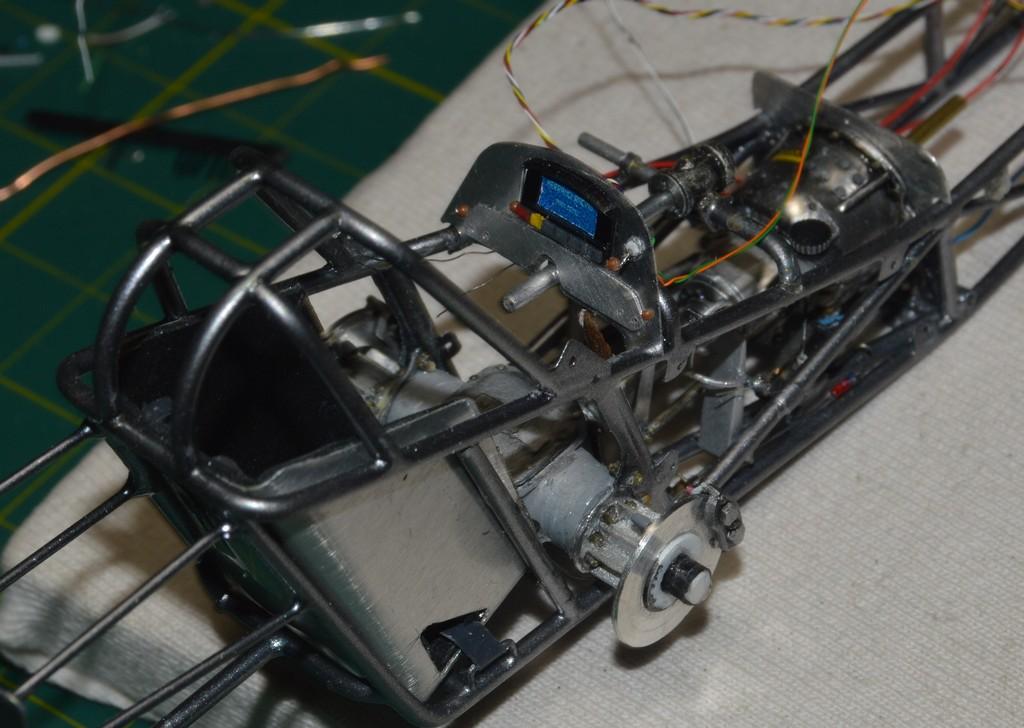

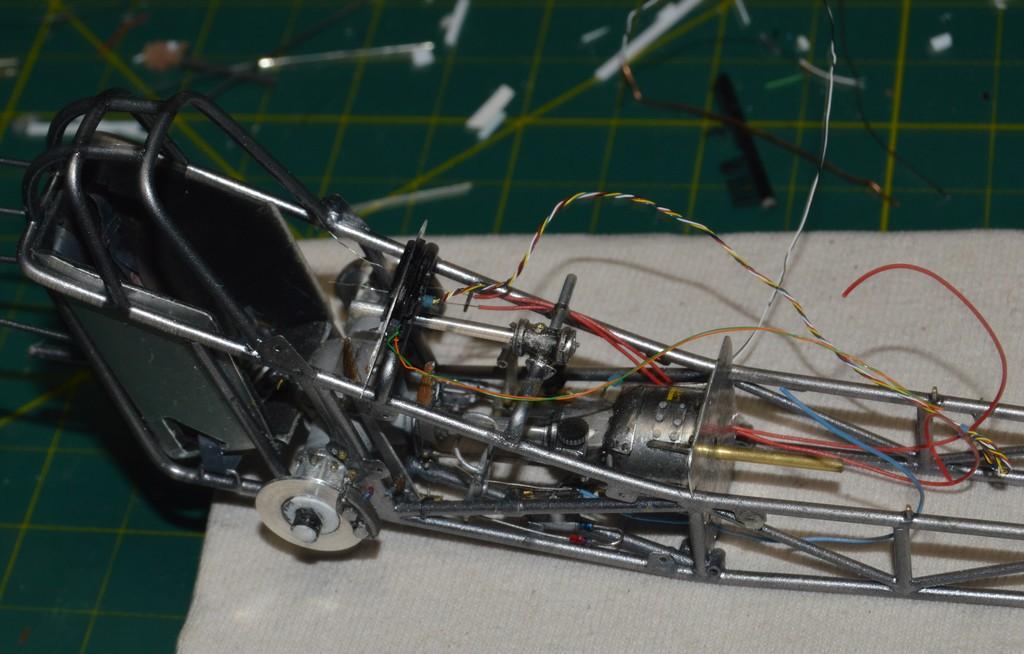

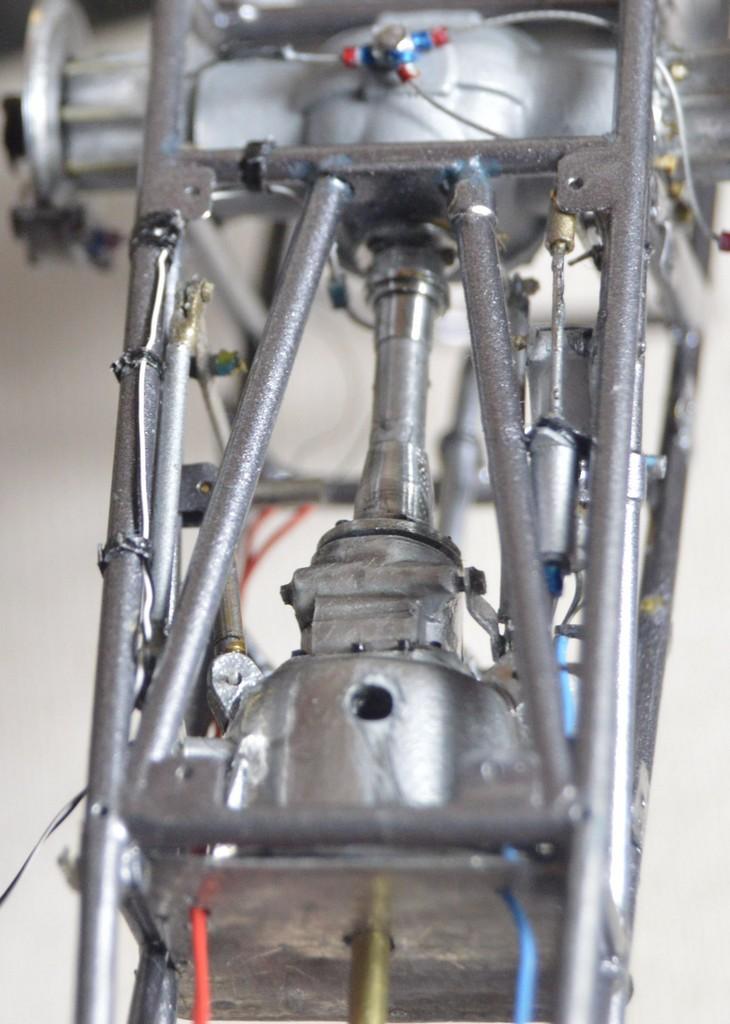

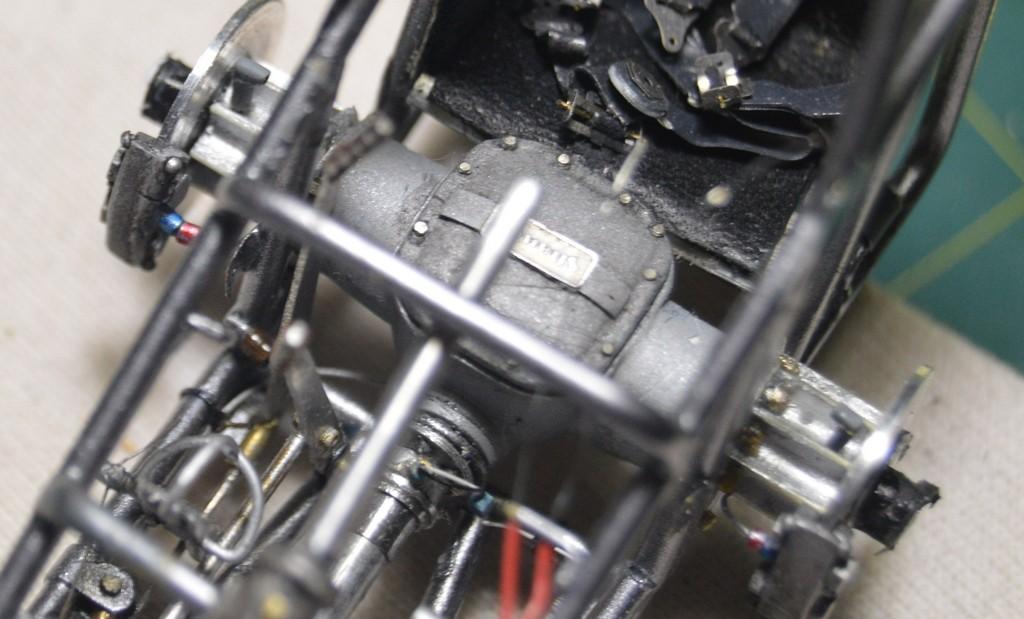

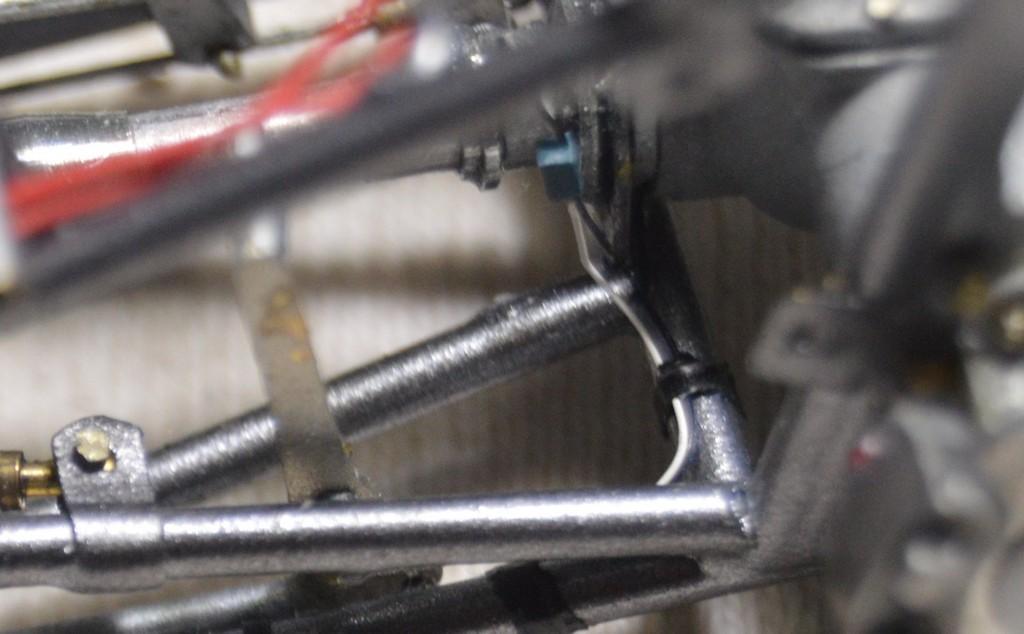

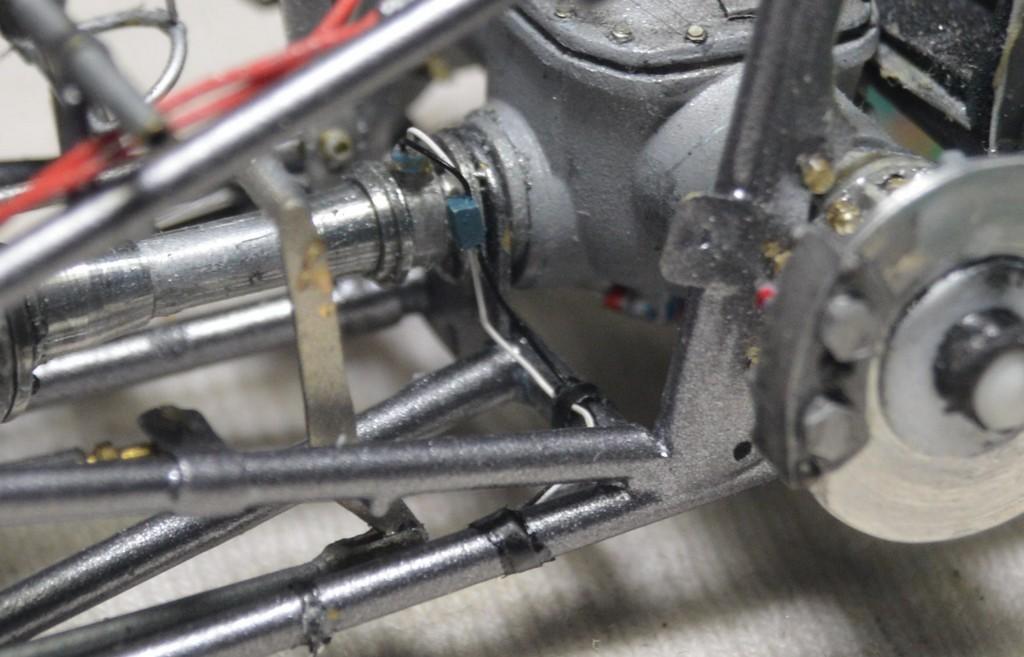

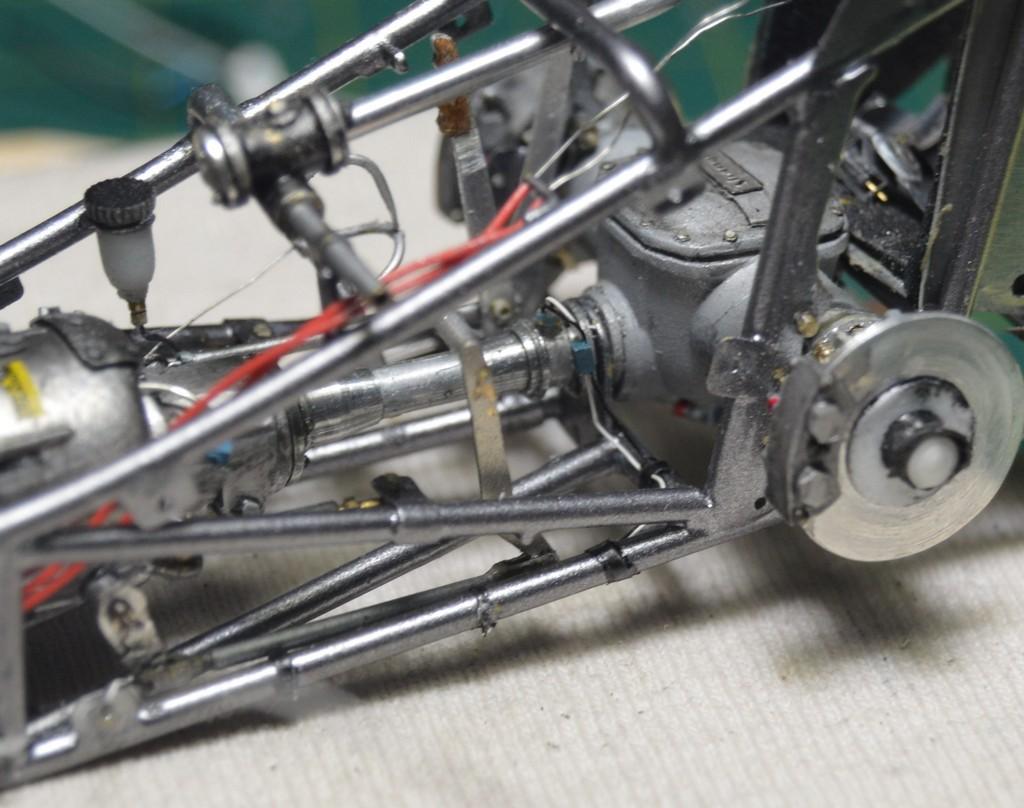

I did a whole bunch of housecleaning! "Tie-died" up the wiring. I used a combination of tape and zip-ties. I am very happy with the way it's turning out! I also got the control rods installed for the Manual hi-speed, and the hi-lo idle control valves. I still need to set up the one for the fuel shutoff. The kill switch it run through the motor plate, where it will meet up with the rest of the circuitry. Still work to do, but the crew really made some progress, today! I'll try to post the stuff about how I did the zip-ties, but, I want to see if I can get a bit more done, before bed. Photos are at various stages of completion. The first three are the latest. The red objects on the back of the gauge panel are dust caps for unused data ports. Thanks for looking!

-

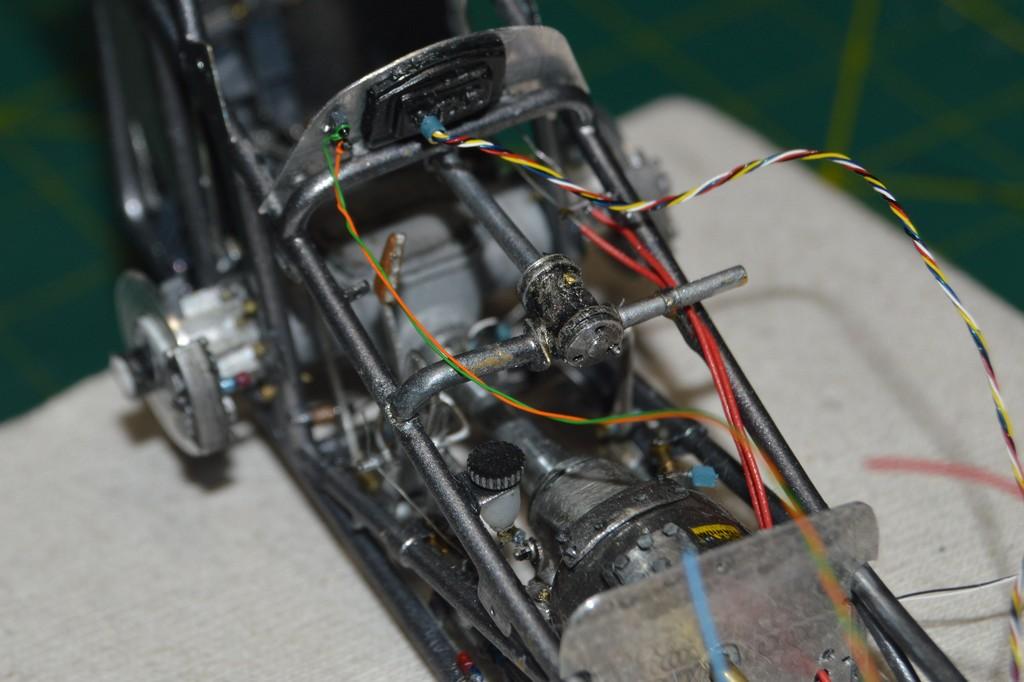

The dash is installed. I bundled the main harness with "electrical tape". I'll bind it to the chassis with zip-ties. The mag kill wires will be taped to the right side of the chassis, up to the motor plate. I am figuring out how to make the "T"-handles for the cables. I could easily do knobs, but I want the former. Questions, comments and critiques are, as always, welcome. Thanks for looking!

-

1/25 Revell Peterbilt 359

Straightliner59 replied to cifenet's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

It's funny, as many times as I've crawled under trucks to engage a PTO with a broken cable, or any number of other reasons, and seeing hundreds of those plastic plugs, I didn't even notice that. I was marveling at the colors he achieved. You're absolutely right. -

1/25 Revell Peterbilt 359

Straightliner59 replied to cifenet's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

What a wonderful piece of work. Your metallic finishes are simply fantastic. Enjoying this project, very much! -

1/25 Revell Peterbilt 359

Straightliner59 replied to cifenet's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Your brake cylinders are freaking gorgeous! Well, so is everything else, but, these really caught my eye. Excellent work! -

Good job, on both counts! Man, does that thing sit nice!

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

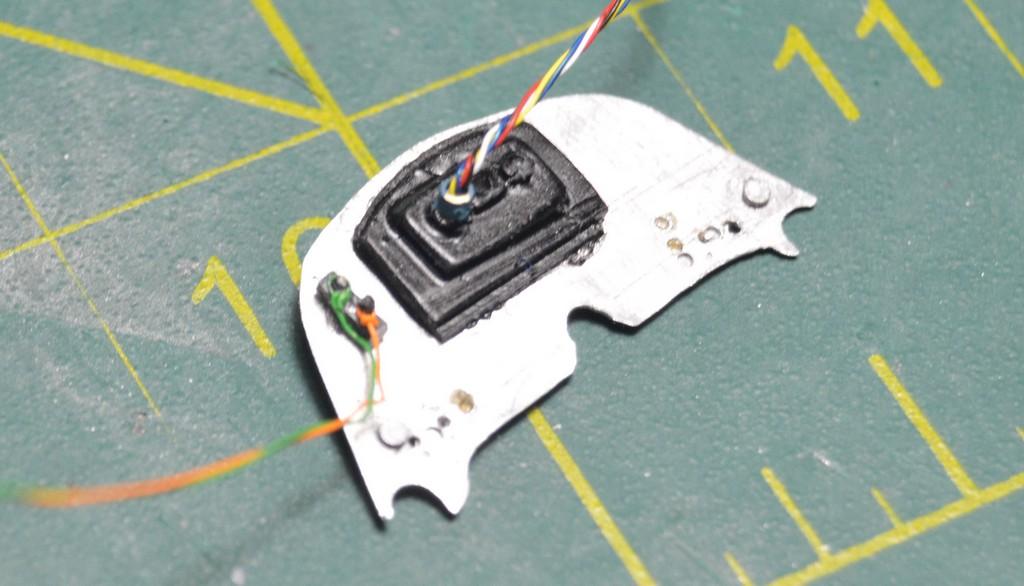

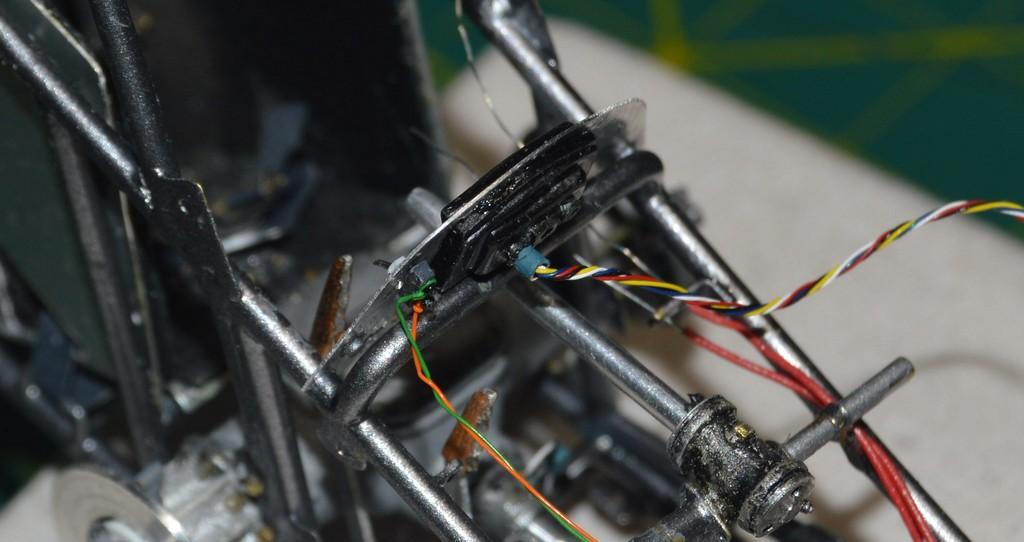

Got started with the wire-tying-down process. So far I have only done the shaft speed sensor. I used "electrical tape" to secure those two wires. I made axle speed sensors from .032" brass tubing, and got them installed. I am rethinking my approach--I may install the dash panel, prior to the E-box. Still not 100% sure which way I'll proceed, there. In the meantime, here are some photos of things I've been working on, the past couple of days. Thanks for looking!

-

Shirley Shahan’s Hornet Pro Stock

Straightliner59 replied to dragcarz's topic in WIP: Drag Racing Models

Honestly, I wouldn't. -

Shirley Shahan’s Hornet Pro Stock

Straightliner59 replied to dragcarz's topic in WIP: Drag Racing Models

Oh, yeah! Looks great! -

The art of scratchbuilding

Straightliner59 replied to ColonelKrypton's topic in Tips, Tricks, and Tutorials

That is really cool!