-

Posts

9,209 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by peteski

-

If these paints are new now old stock and unopened, I would just try to wrap an elastic few times around the cap (or use a wide elastic, or even one of those rubber disks for opening stuck food jar lids) and see if that'll give you good enough grip to unscrew the cap. Like you, I don't think there is any paint hardened in the treads but the small caps are not easy to get a grip on.

-

Bill, PM me with your email address and I'll sent you a ready to print PDF with bunch of plates in 1:25 and 1:24 scale with plate outline and cropping marks. I can't attach PDF to the post. When printing it out select "no scaling" or "1:1" or "actual size" (whatever option your PDF reader has for printing that document in original size).

-

Eliminating 3d print lines on small parts

peteski replied to Codi's topic in Tips, Tricks, and Tutorials

You have to make your own booth. It can be made from a large translucent storage container, rubber gloves, and an air filter. Here is one example: https://www.therailwire.net/forum/index.php?topic=50417.msg821918#msg821918 Nowadays It might also be possible that someone makes and sells such item. -

Coming Soon from Atomic City's JoHan line of new kits

peteski replied to thatz4u's topic in Car Kit News & Reviews

. . . also in the context of opening a hobby shop, or model train manufacturing company, or many other assorted businesses. Kind of like those ethnic jokes which we used to be able to tell before political correctness arrived: you could use the same joke for any ethnic group - just replace a Pole with an Italian or any other ethnicity. -

Keith, I just want to mention that there is a thread with plethora of recommendations about getting your first airbrush and compressor. It is a but overwhelming, but that is what happens every time this type of question is asked in a forum with thousands of members. I had an older (and loud) compressor with a 4 gal., tank for some years but last year, on @Ace-Garageguy recommendation I bought at Harbor Freight a very quiet Fortress compressor with a 2 gal. tank. Now that's the one I use. https://www.harborfreight.com/2-gallon-135-psi-ultra-quiet-oil-free-hand-carry-jobsite-air-compressor-64596.html I bought it around last Christmas and it was on sale.

-

I'm for the lacquer thinner trick (which has been mentioned on the forum multiple times). Just be patient as the thinner has to soak into the decades-old enamel paint. I would let it work for at least half a day, periodically checking if it loosened up yet and reapplying the thinner if it evaporated. You can do this to bunch of the bottles at the same time. When trying to unscrew the lid first wrap an elastic around the lid. Best are small wide ones sometimes used to bunch some fresh veggies or ones to preventing live lobster's claws from opening. Regular elastic will work too, but wrap it around the lid few times. The rubber gives your fingers extra gripping power. Pliers or similar metal gripping tools should be used only as a last result (as they will likely damage/distort the lid which might make is no longer tight).

-

Dave, in the photo the driver's side interior door panel looks like new. Did you replace it, or is it cleaned up original?

-

OK, so for you it's basically like starting fresh. It will take some practice to get comfortable using a (decent quality) airbrush, regardless if it's gravity or siphon-feed. or you might find out (like you did in your teens) that you just prefer spray cans.

-

I have that model, and also a 1993 Chrysler Concorde. These were 1:24 diecast models made by Brookfield Collectors Guild. I don't think they were promos, just collectible models.

-

What Paint To Use on ABS?

peteski replied to oldcarfan's topic in Model Building Questions and Answers

Yes, ABS is a type of what we call "styrene" and some model companies use ABS for their model kits too. IIRC some Tamiya kits are made using ABS. There would be the ABS symbol molded somewhere on the sprue (parts tree). ABS is a less brittle and sturdier overall than polystyrene (that is sometimes called "high impact"). So it can be painted using the same paints you would use on a typical automotive model kit, but some solvent-type liquid cement for polystyrene might not work as well on ABS. -

Those easily-changed nozzle "cartridges" seem like a handy feature, but since they can't be disassembled, they can't really be completely cleaned. This is not good, especially with the water-based acrylics. My friend (who had been using a dual-action Badger airbrush for years bought one of those Azteks because it seemed like handy airbrush with a sexy body design. But he ended up ditching it and going back to his Badger.

-

Sure, we all find or of fabricate tools which give us best results. As I also mentioned, the needle ones work really well for me. I have multiple size needles for when I need different amounts of CA dispensed. I agree that mounting your applicator in a permanent handle does seem like an excellent idea.

- 20 replies

-

- thin superglue

- ca

-

(and 1 more)

Tagged with:

-

Alex, we seem to be going in circles here with your dissing of siphon feed brushes. My siphon-feed Badger 200 is all-metal precision-machined airbrush, which as mentioned I owned for few decades. Not some cheap plastic toy. It works well. I believe all Badger airbrushed are metal. I'll say again that the airbrush you had bad experience seems to have been some crappy airbrush, and now you are hung up on badmouthing *ALL* siphon-feed airbrushes. That's not cool. YOU STILL HAVE NOT ANSWERED MY QUESTION ABOUT YOUR EXPERIENCE WITH USING AIRBRUSHES. Was the crappy airbrush your first one?

-

Moebius F250 steel wheel widening

peteski replied to Radretireddad's topic in Tips, Tricks, and Tutorials

Yes, good tip for getting even and repeatable cut. Does this mean you have to sacrifice a set of wheels from another kit? -

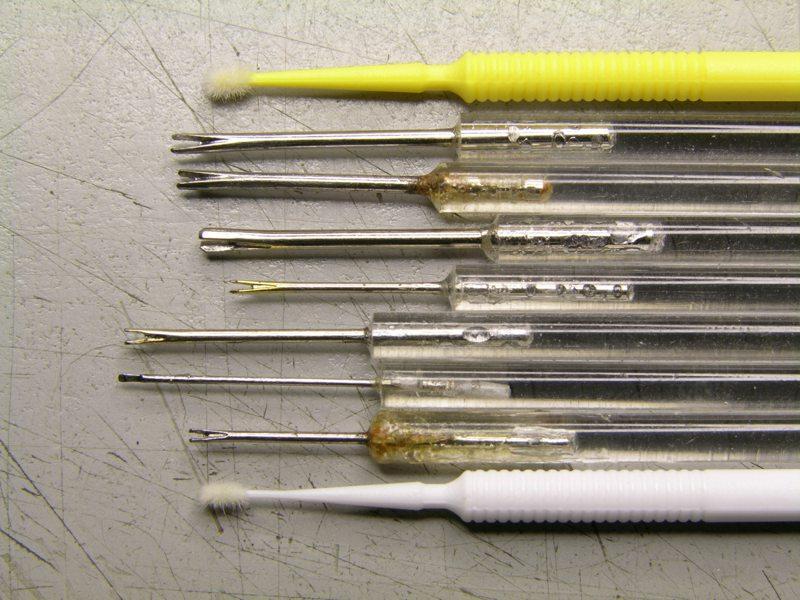

If you have a some good size sewing needles, Dremel with a cutoff wheel and something to make a handle (I use 1/8" acrylic rod, but a dowel will work too), you can make your own applicator which will last for years. I mentioned this in a post here, back in 2021 I have made these many years ago. Needles are made from hard steel and will not break like the photoetched applicators. Yes, they will eventually clog up, but I just scrape the glue out with an old hobby knife blade (not burning it off) after each modeling sessions, and as you see in the photo, they all look clean and ready for use. As you can see I have several sizes for dispensing different amounts of glue (although I mostly use about 3 sizes). The double wire design looks useful for dispensing larger amounts of CA than what I usually need.

- 20 replies

-

- 1

-

-

- thin superglue

- ca

-

(and 1 more)

Tagged with:

-

Alex, there is nothing inherently wrong with siphon-feed airbrushes. You had a bad experience and destroyed it before even trying to figure out what caused the issue, then you started to badmouth them. Many modelers (and as shown, even 1:1 body shops) successfully use siphon-feed airbrushes and spray guns. Looking at the posts in this thread you seem to have gone from describing the problem, to "taking a bat" to your misbehaving airbrush in about 2 hours. Why bother asking for assistance in troubleshooting since you can solve your problem so quickly in a very drastic way? Let me ask you again: is this the first time you tried to use an airbrush, and if you used them in the past, how much experience you had and what brand/model airbrushes have you used? The bottom line is: buy and use whatever type of airbrush you prefer. There is no need to put down some a well established design just because you had a bad experience with a single example of some off-brand airbrush.

-

Lets think this through logically. First of all, anybody (non-members) can access Fotki (not login, but they can view photos) and the other way is that registered users login into their account and they can view and upload photos into their account and also view other photos like non-users. If I understood him correctly Brad mentioned earlier that he cannot even access any other user's public photos on Fotki, while accessing the site as a non-Fotki-member. If that's really the case then the problem likely is not on Fotki site and contacting them will likely not help much. For example, can you see photos on https://public.fotki.com/drasticplasticsmcc/mkiba-build-under-c/academy-instructions/academy-ac-289-cobra/ If not, what is the error you are seeing? Brad, any chance you can try accessing Fotki from a real computer (not a smart phone)?

-

The term is "break up the wall". You were close Luc. I agree that tires with even generic sidewall details breaking up the smooth surface would be large visual improvement over the "bald" sidewalls. They could still leave enough blank sidewall for possible future branding. Not sure why manufacturers opt for smooth sidewalls. And the 1:1 automotive manufacturers requiring model companies to get a license to use their logos is also silly. Using the logos on models is like free advertising for them (and advertising is normally very expensive).

-

I've been using my Badger 200 siphon-feed internal-mix single-action airbrush for over 20 years and painted lots of models with it. Never had a problem like you described. I never heard of Vevor. Might in fact be a crappy airbrush. Have you used it in the past, or was it the first time you tried it?